ER50-G non-copperizing welding wire

An ER50-G, copper-free technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of easy evaporation, increase in the amount of spatter, uneven powder, etc., to avoid welding hot cracks , the effect of improving the working environment and making extensive use of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further illustrate the technical means and effects adopted by the embodiments of the present invention to achieve the intended purpose of the invention, through the following preferred embodiments, the characteristics and effects of the ER50-G copper-free welding wire proposed in the embodiments of the present invention are described in detail as follows: rear.

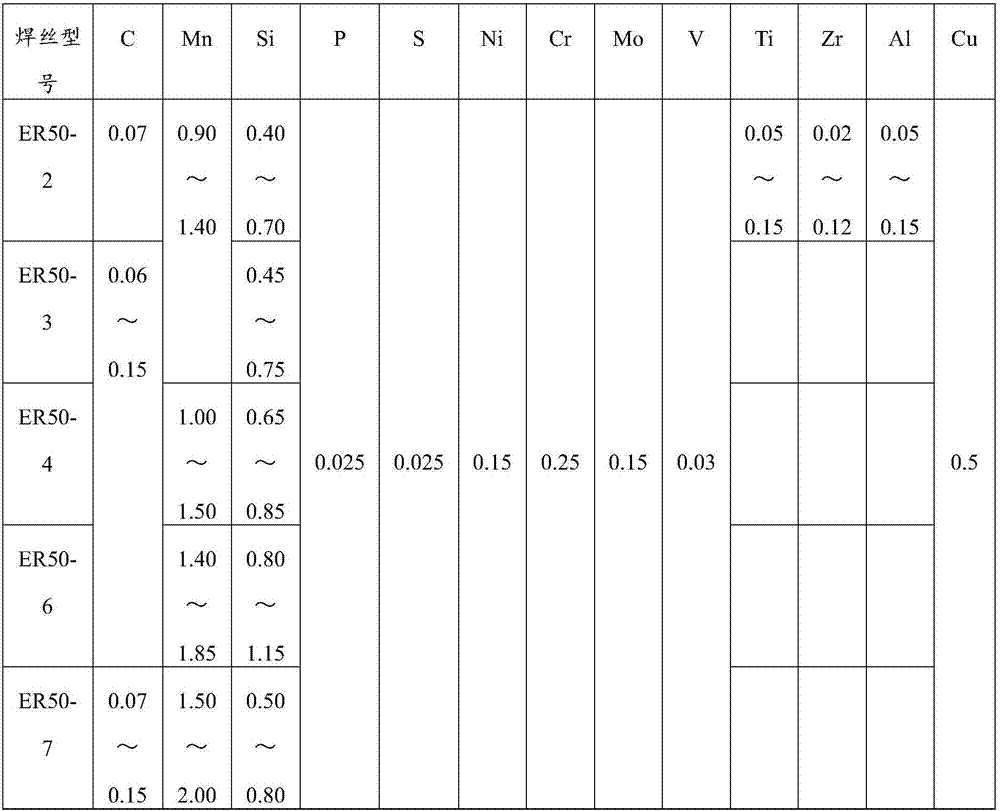

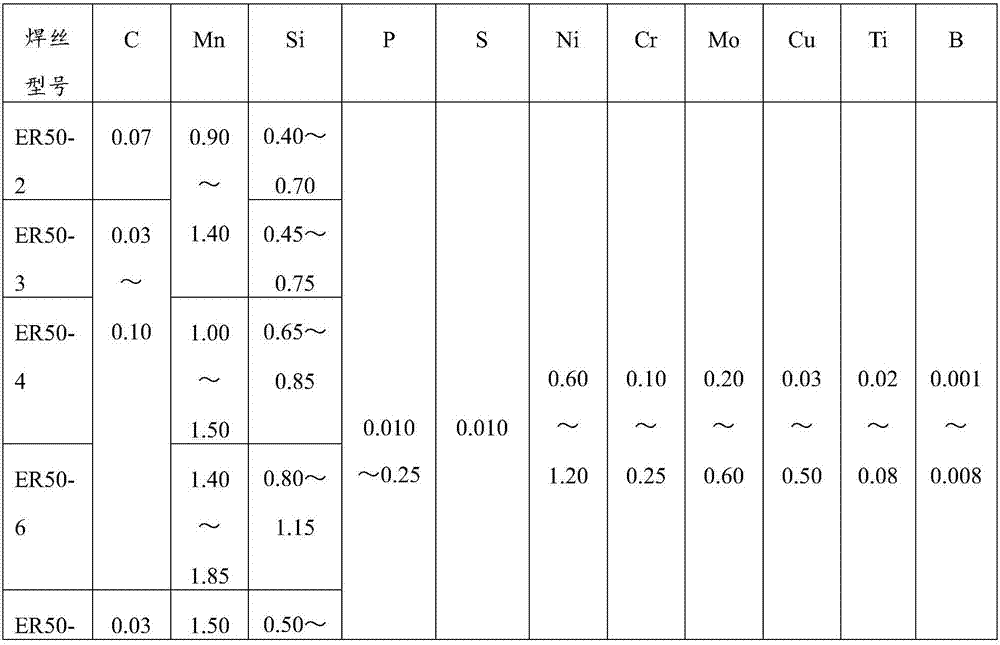

[0048] An ER50-G copper-free welding wire according to the embodiment of the present invention, its chemical composition is by mass percentage: C 0.03-0.10%, Mn 0.90-2.00%, Si 0.3-1.15%, S≤0.010%, P 0.010-0.30% , Cr 0.10-0.25%, Cu 0.30-0.50%, and the rest is Fe; it is characterized in that the ER50-G copper-free welding wire also contains Ni 0.60-1.20%, Mo 0.20-0.60%, Ti0.02-0.08% , B 0.001~0.008%;

[0049] Carbon (C) is unfavorable to the atmospheric corrosion resistance of steel, and at the same time C affects the welding performance, cold brittleness and stamping performance of steel, so the C c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com