Automatic hot-cutting side gate injection mold, and gate cutter and injection molding process thereof

A technology of side gate and injection mold, which is applied in the field of automatic hot-cut side gate injection mold, gate cutter and injection molding process, can solve the problems of low lifespan and residual gate cutting surface, so as to save mold cost, The effect of reducing maintenance cost and optimizing processing progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical means and effects that the present invention takes to achieve the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the automatic hot-cut side gate injection mold proposed according to the present invention, the used gate cutter and injection molding Process, its specific implementation, steps, structure, features and effects thereof are as follows in detail.

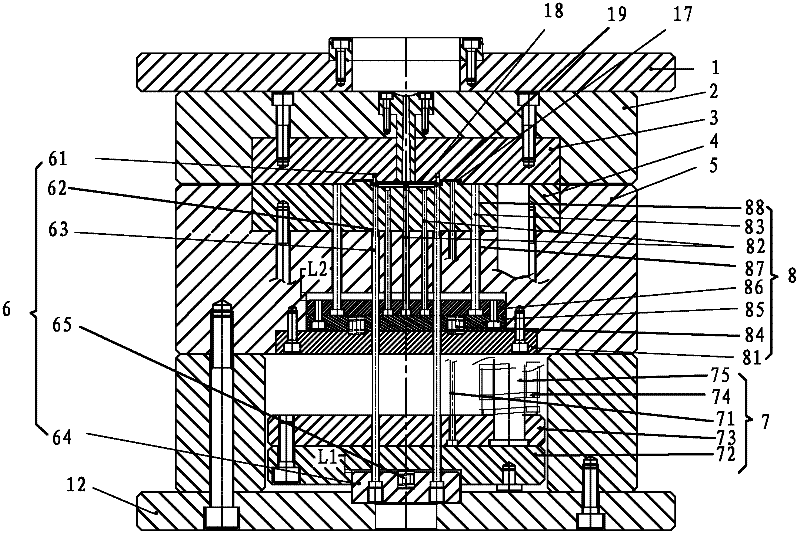

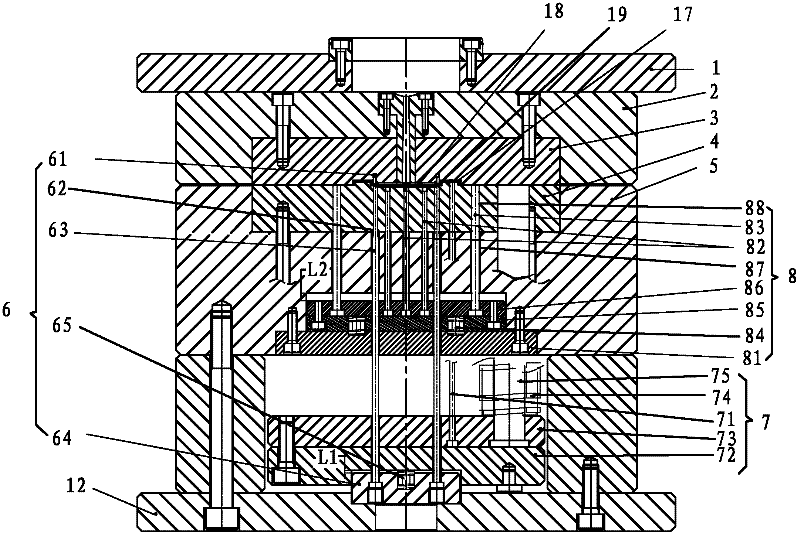

[0038] see figure 1 , as shown, a kind of automatic hot-cutting side gate injection mold of the preferred embodiment of the present invention, comprises the front mold fixing plate 1 that is arranged in sequence, the front mold core 3, the front template 2 that fixes described front mold core 3, rear The mold core 4, the back template 5 for fixing the rear mold core 4, the rear mold fixing plate 12 with a push hole, the part cavity 17 and the sprue are formed between the front mold core 3 and the rear mold core 4 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com