Dry-method natural gas desulphurization reactor

A reactor and natural gas technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of not paying attention to the gas flow characteristics inside the reactor, low desulfurization efficiency, unfavorable promotion and application, etc., to achieve industrial utilization value, improve The overall benefit and the effect of improving desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation and structure of a dry natural gas desulfurization reactor proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments , features and their effects are described in detail below.

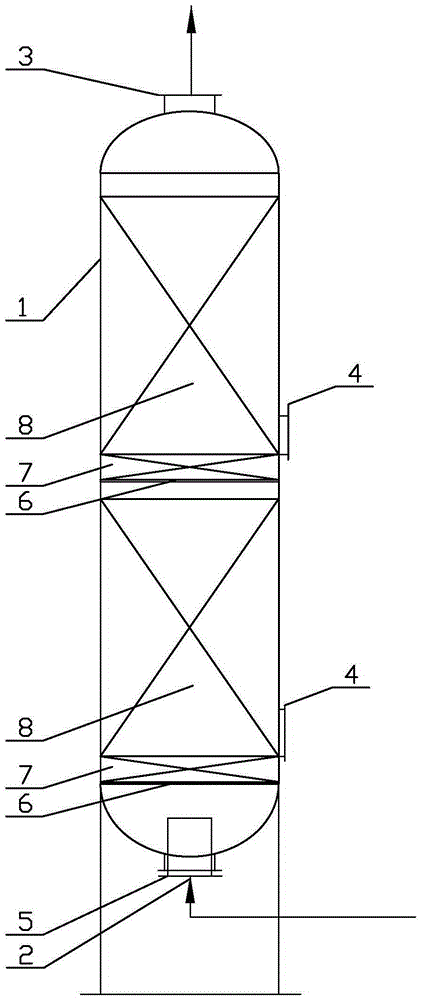

[0032] The structure of a dry natural gas desulfurization reactor of the present invention is as follows figure 1 As shown, it is mainly composed of a shell 1, a gas inlet 2, a gas outlet 3, a catalyst discharge port 4 and an inlet diffuser 5. The reactor shell 1 has a porous plate 6, a ceramic ball transition layer 7 and a catalyst layer 8 inside.

[0033] The shell 1 is a cylindrical main body, and the upper and lower ends are elliptical head structures, which are fully welded structures. The upper head is welded with a gas outlet 3, and the lower head...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com