Associative waterborne polyurethane/polyacrylate copolymer emulsion anti-settling thickener

A technology of water-based polyurethane and polyacrylate, which is applied in the direction of coating, etc., to achieve the effect of simple production method, convenient use and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

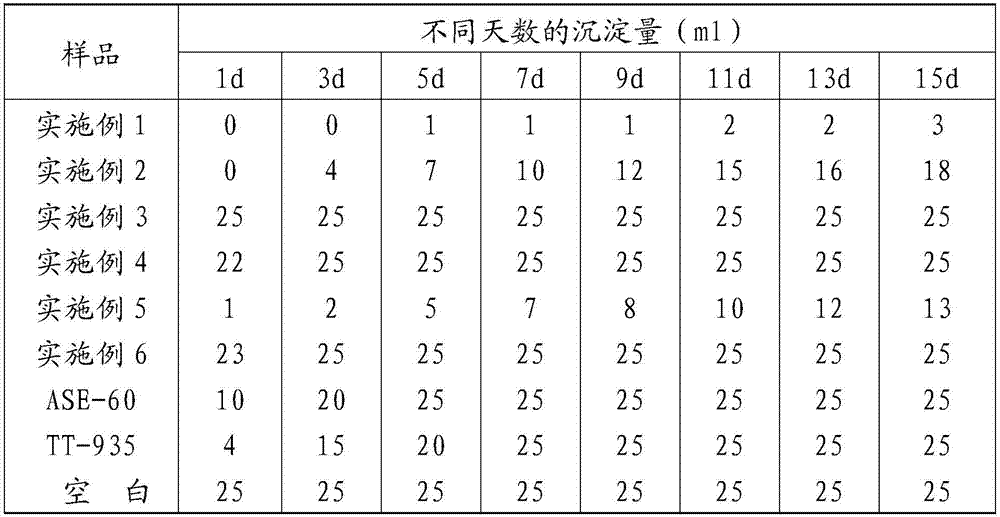

Examples

Embodiment 1

[0042] (1) Synthesis of waterborne polyurethane

[0043] Add 33.5 parts of Pol-2356 (hydroxyl value 54-56 mg KOH / g, produced by Qingdao Yutian Chemical Industry), 3 parts of non-ionic hydrophilic diol N-120 (hydroxyl value 100-120 mg KOH / g, German Gusa Company), 1 part of trimethylolpropane (Sweden Pastor Company), 4 parts of dimethylolpropionic acid (DMPA) hydrophilic agent (Sweden Pastor Company), heated to 70°C under full stirring , add 20 parts of isophorone diisocyanate, heat up to 75-85°C for 3-5 hours, add 5-30 parts of end-blocking agent hydroxyethyl acrylate for 2-3 hours, then cool down to 50°C, add 2 parts of salt forming agent, salt forming for 10 minutes, adding 120 parts of deionized water, stirring for 60 minutes and discharging to obtain the required water-based polyurethane;

[0044] Since the added hydrophilic glycol N-120 is nonionic, and the dimethylol propionic acid (DMPA) hydrophilic agent is anionic, the resulting waterborne polyurethane is waterborne a...

Embodiment 2

[0051] Repeat the step method of example 1, just in the synthetic of aqueous polyurethane, replace the nonionic hydrophilic glycol N-120 ( non-ionic), other are all the same as Example 1. Then the obtained water-based polyurethane does not contain non-ion.

Embodiment 3

[0053] Only synthesize water-based polyurethane according to the synthetic step method of water-based polyurethane in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com