PU white primer beneficial to low-temperature quick drying and free of prickly heat

A fast drying, white primer technology, applied in the field of coatings, can solve the problems of poor construction performance of the coating film, affecting the shipping efficiency, low coating efficiency, etc., to ensure smoothness and flatness, prolong surface drying time, improve sanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This example provides a kind of PU white primer that is good for low temperature and fast drying and does not suffer from prickly heat. The PU white primer is composed of component A and component B. During use, component A and component B are mixed After curing, the paint film D1 is formed.

[0033] Wherein, component A is made up of the raw material of following weight part:

[0034]

[0035]

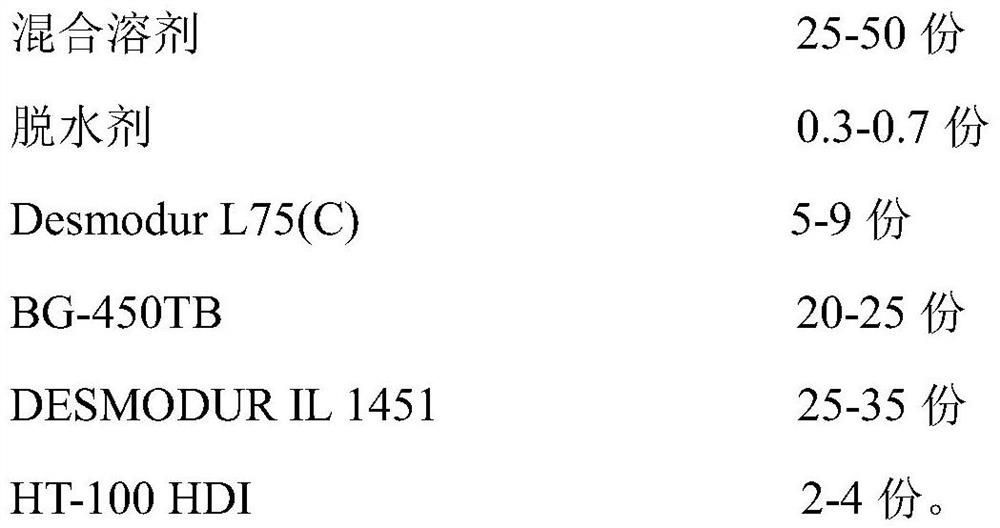

[0036] The component B is composed of the following raw materials in parts by weight:

[0037]

[0038] A kind of PU white primer that is beneficial to low-temperature rapid drying and does not suffer from prickly heat disclosed in this embodiment is prepared by the following method:

[0039] (a) Preparation of component A: first weigh 4 parts of coconut oil resin and 21 parts of fatty acid alkyd resin and put them into the reaction kettle, then disperse for 7 minutes at a stirring speed of 700 rpm, and then weigh 24 parts in turn Titanium dioxide and 33 parts of hea...

Embodiment 2

[0044] This embodiment provides a kind of PU white primer that is beneficial to low-temperature rapid drying and does not cause prickly heat. The PU white primer is also composed of component A and component B. During use, mix component A and component B After mixing, it cures to form the paint film D2.

[0045] Wherein, component A is made up of the raw material of following weight part:

[0046]

[0047]

[0048] The component B is composed of the following raw materials in parts by weight:

[0049]

[0050] A kind of PU white primer that is beneficial to low-temperature rapid drying and does not suffer from prickly heat disclosed in this embodiment is prepared by the following method:

[0051](a) Preparation of component A: first weigh 4 parts of coconut oil resin, 21 parts of fatty acid alkyd resin and 9 parts of castor oil resin and put them into the reaction kettle in turn, and then disperse for 7 minutes at a stirring speed of 700 rpm , and then successively ...

Embodiment 3

[0055] This example provides a kind of PU white primer that is good for low temperature and fast drying and does not suffer from prickly heat. The PU white primer is composed of component A and component B. During use, component A and component B are mixed Post-cure to form paint film D3.

[0056] Wherein, component A is made up of the raw material of following weight part:

[0057]

[0058] The component B is composed of the following raw materials in parts by weight:

[0059]

[0060] A kind of PU white primer that is beneficial to low-temperature rapid drying and does not suffer from prickly heat disclosed in this embodiment is prepared by the following method:

[0061] (a) Preparation of component A: first weigh 3 parts of coconut oil resin, 17 parts of fatty acid alkyd resin and 7 parts of castor oil resin into the reaction kettle in turn, and then disperse for 6 minutes at a stirring speed of 600 rpm , and then successively weighed 19 parts of titanium dioxide an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com