Brushing and arranging device for clothes production

A finishing device and a technology for sanding, applied in the field of garment production, can solve the problems of low sanding work efficiency, affecting product quality, uneven flatness, etc., achieving good sanding effect, improving product quality, increasing warmth retention and softness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

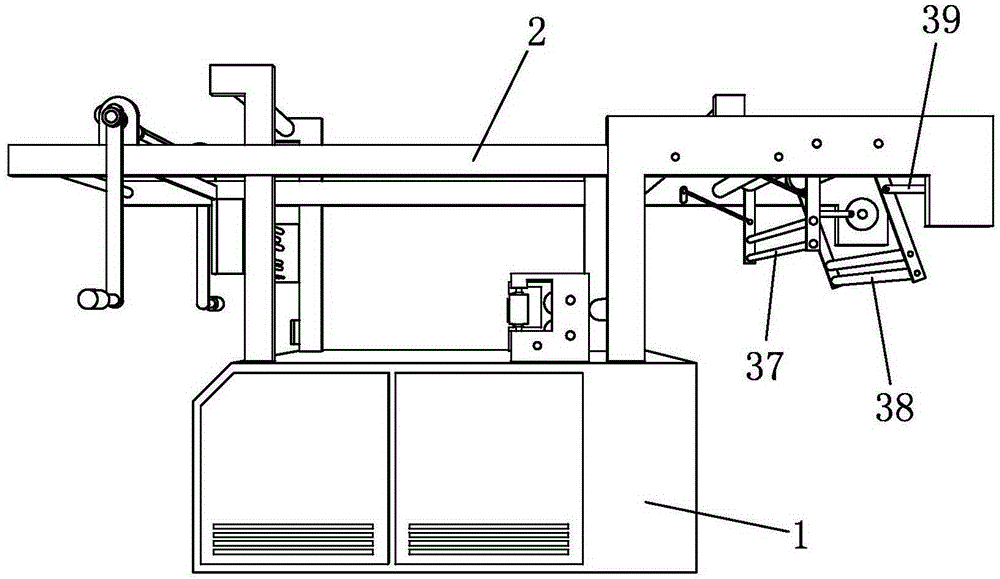

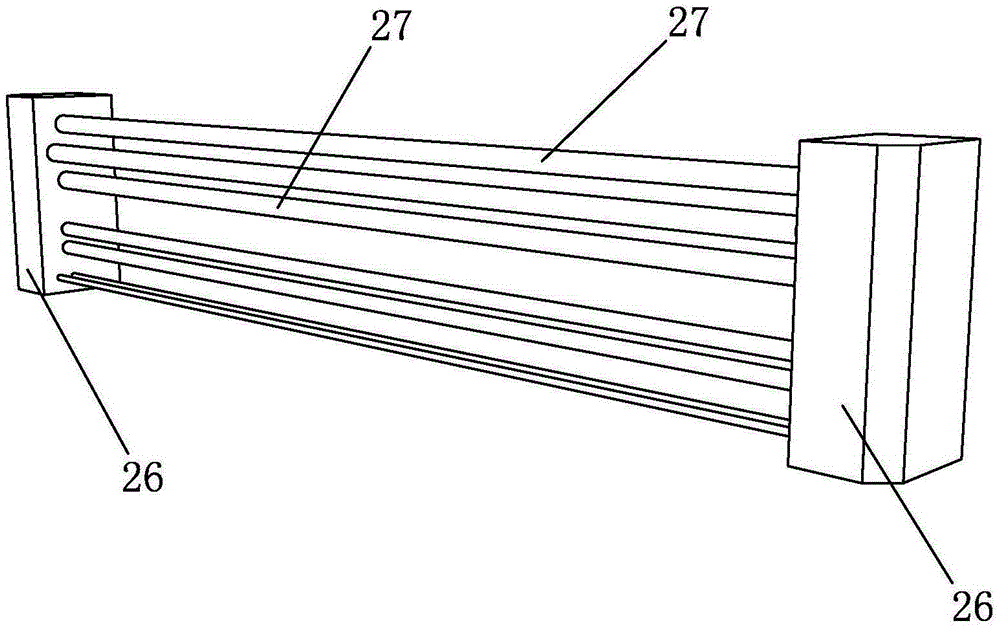

[0026] Such as Figure 1 to Figure 6As shown, it is a kind of sanding finishing device for garment production of the present invention, comprising a body 1, a support 2 is provided on the body 1, a cloth feed roller 3 and a cloth discharge roller 4 are provided on the support 2, and a cloth feed roller 4 is provided on the support 2. The cloth feeding roller 5 and the bracket 2 are provided with a tension control device 6, the tension control device 6 includes a handle 24 and two tension rods 25, and the tension of the fabric is adjusted through the conversion direction of the tension rod 25, mainly by the rotation of the handle 24. The direction of the tension rod 25 is converted. The tension control device 6 is arranged between the cloth feeding roller 3 and the cloth feeding roller 5 . The bracket 2 is provided with a spreader 7, which is arranged below the cloth feeding roller 5, and the spreader 7 includes a fixed base 26 and five spreader rollers 27, which are adjusted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com