Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Low preparation equipment requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste alphalt regenerating agent and its preparing method

InactiveCN1580130ARaw materials are easy to getLow preparation equipment requirementsBuilding insulationsBituminous materialsEngineering

A kind of regenerant of wasted asphaltum belongs to the manufacturing field of asphaltum-processing accessory material, includes light oil, rosin, anti-aging agent, anti ultraviolet radiation auxiliary agent and so on and is featured by the following composition, in the amounts of weight: between 75% and 90% of light oil, between 10% and 25% of rosin, between 0.1% and 1% of anti-aging agent and between 0.1% and 1% of anti ultraviolet radiation. Aiming to the character of aged wasted asphaltum, the invention adds rosin, anti-aging agent and anti ultraviolet radiation auxiliary agent to light oil, selects and allocates the components reasonably. The invention have the advantage of finding the material easily, low requirement to the producing equipments, easy producing techniques, low cost, convenient use, obvious regeneration, taking action rapidly and long lasting active force. After practical use, the regenerant of wasted asphaltum in the invention can make the aged wasted asphaltum reach the technical indexes of the original asphaltum and the roads paved with it have almost the same life length as those paved with new asphaltum.

Owner:浙江兰亭高科控股有限公司

Self-decomposition temporary plugging agent for workover fluid and using method of temporary plugging agent

InactiveCN105086973AWith self-blocking functionImprove protectionDrilling compositionFiberWater based

The invention discloses a self-decomposition temporary plugging agent for a workover fluid and a using method of the temporary plugging agent. The self-decomposition temporary plugging agent comprises 10-40 parts of particles I with the particle size ranging from 1 mm to 10 mm by mass, 20-60 parts of particles II with the particle size ranging from 20 meshes to 40 meshes by mass, 0.2-1 part of staple fibers with the length ranging from 3 mm to 10 mm by mass and 18-40 parts of superfine powder with the particle size ranging from 100 meshes to 300 meshes by mass; the particles I, the particles II, the staple fibers and the superfine powder are any one of or a mixture of several of polylactic acid, poly lactic-glycolic acid and polycaprolactone in any ratio. The using method of the agent comprises steps as follows: the staple fibers are evenly mixed in the water-based workover fluid, other components of the self-decomposition temporary plugging agent are added, and the mixture is evenly mixed. The self-decomposition temporary plugging agent for the workover fluid can be completely degraded into carbon dioxide and water in an aqueous solution and causes no damage to stratums, and the using method of the agent is suitable for on-site preparation.

Owner:CNPC BOHAI DRILLING ENG

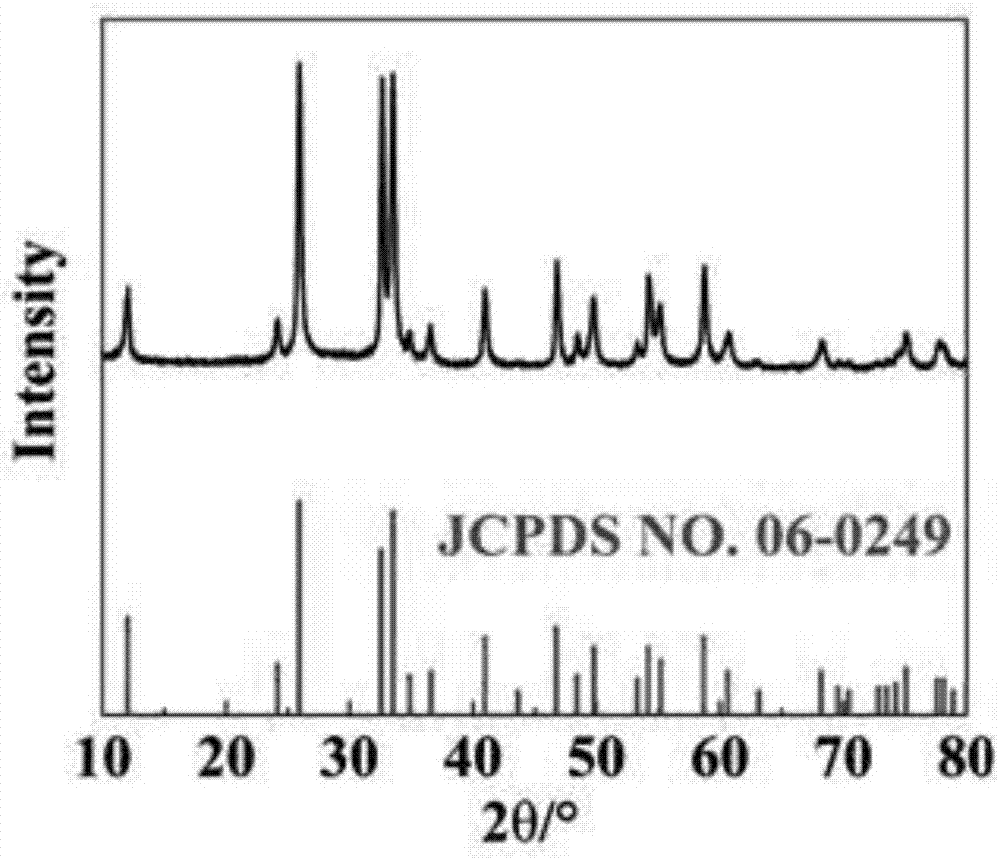

Preparation method of BiOCl nanometer photocatalyst, prepared photocatalyst, and application of prepared photocatalyst

InactiveCN107159273AImprove performanceExcellent degradation performance of organic dyesPhysical/chemical process catalystsWater/sewage treatment by irradiationChlorideViscosity

The invention provides a preparation method of a BiOCl nanometer photocatalyst, the prepared photocatalyst, and application of the prepared photocatalyst. The method comprises the following steps: (1) dissolving bismuth nitrate and sodium carboxymethylcellulose into water, stirring evenly to obtain a bismuth containing mixed solution, wherein the mass ratio of the bismuth nitrate to the sodium carboxymethylcellulose is (0.3-5):1, the viscosity of the sodium carboxymethylcellulose is 200-500 mPas; (2) dropwise adding a chloride solution into the mixed solution obtained in the step (1), stirring evenly to obtain a bismuth containing precursor solution; (3) regulating the pH value of the bismuth containing precursor solution obtained in the step (2) to 5.0-6.5, stirring evenly to form a reactant; (4) enabling the reactant to react for 24-30 hours at the temperature of 150-160 DEG C to obtain a precipitate; (5) washing and drying the precipitate obtained in the step (4) to obtain a BiOCl powder. The provided preparation method is simple, green and pollution-free, the preparation cycle is short, the cost is low, and the property and the stability of the prepared photocatalyst are excellent.

Owner:WUHAN TEXTILE UNIV

Polyvinylidene fluoride anti-pollution membrane and preparation method thereof

ActiveCN107149882AEasy to makeLow preparation equipment requirementsMembranesSemi-permeable membranesPhase conversionUltraviolet

The invention discloses a polyvinylidene fluoride anti-pollution membrane and a preparation method thereof, and belongs to the field of environmental functional membrane materials. The preparation method comprises: (1) self-polymerizing dopamine on the surface of polyvinylidene fluoride powder, and adhering the generated poly dopamine functional layer onto the surface of the polyvinylidene fluoride powder; (2) preparing a poly dopamine modified polyvinylidene fluoride membrane by using a phase conversion method; and (3) depositing a nano-TiO2 functional layer on the membrane prepared in the step (2) through a liquid phase deposition method to prepare the polyvinylidene fluoride anti-pollution membrane. According to the present invention, by combining the strong adhesion and the polyfunctional group of poly dopamine, the ultraviolet resistance and stable chemical performance of polyvinylidene fluoride, and the advantages of hydrophilicity, high photocatalytic activity and the like of nano-TiO2, the polyvinylidene fluoride anti-pollution membrane is developed; and the prepared polyvinylidene fluoride anti-pollution membrane has excellent pollution resistance, and can be used in various membrane separation fields.

Owner:天津鼎芯膜科技有限公司

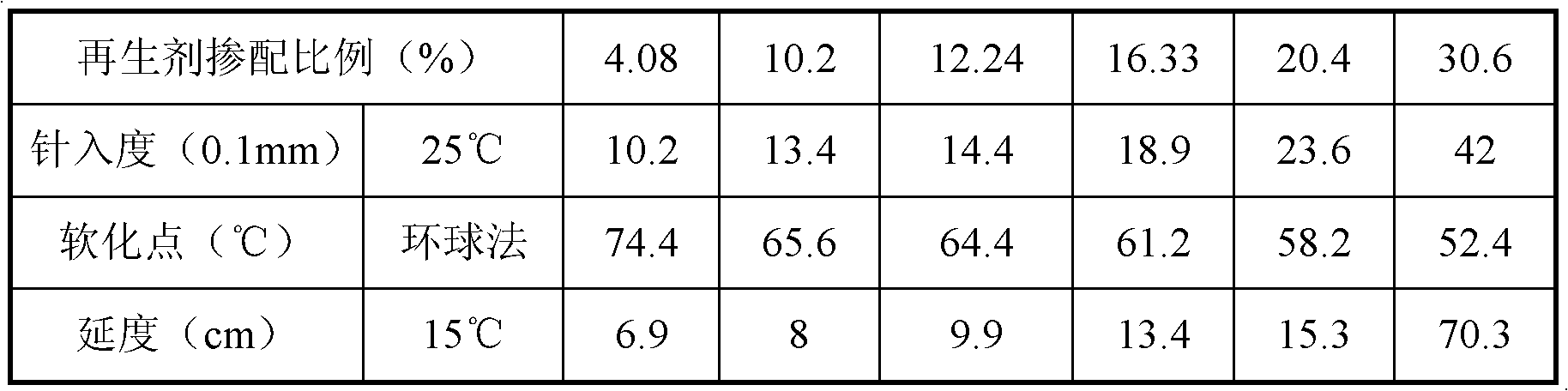

Plain asphalt reclaiming agent and preparation method and application thereof

InactiveCN101845227ARaw materials are easy to getLow preparation equipment requirementsBuilding insulationsPlasticizerBituminous materials

The invention belongs to the field of a composite containing an asphalt material and a preparation method and application thereof, in particular to a plain asphalt reclaiming agent and preparation and application thereof. The plain asphalt reclaiming agent is prepared from the following components: 23-35 parts of matrix asphalt, 60-75 parts of reclaimed oil, 3-5 parts of plasticizer and 0-5 parts of high temperature stabilizer, and is obtained by heating, mixing and stirring the materials. The preparation method comprises the following steps: heating the matrix asphalt at 115-135DEG C; heating and evenly stirring the reclaimed oil, plasticizer and high temperature stabilizer at 115-135 DEG C to obtain a mixture; and finally, stirring the matrix asphalt and the mixture at 115-135 DEG C and cooling to obtain the plain asphalt reclaiming agent. The application is as follows: taking aging asphalt and heating at 110-135 DEG C, adding the plain asphalt reclaiming agent, wherein the additive amount thereof is more than 30% of that of the aging asphalt; and stirring the mixture at 100-110 DEG C to obtain the reclaimed asphalt. The invention has the advantages of low cost and good reclaiming effect.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

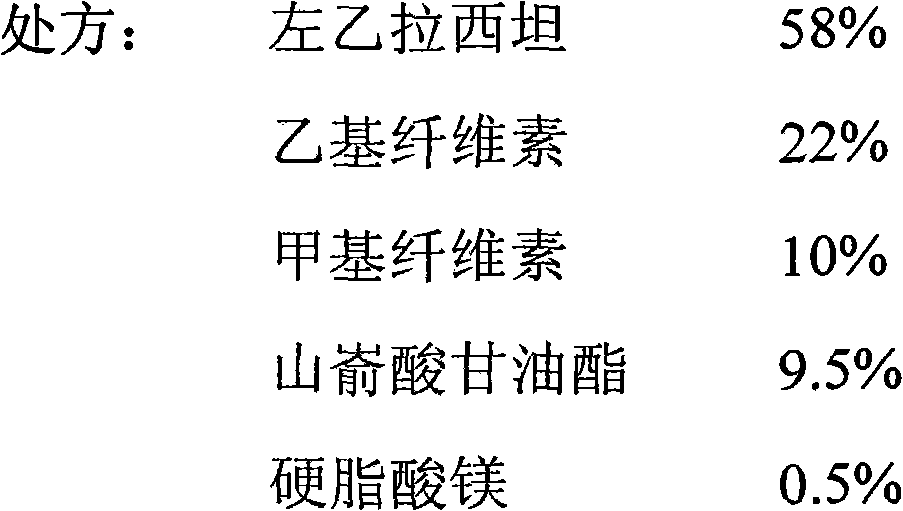

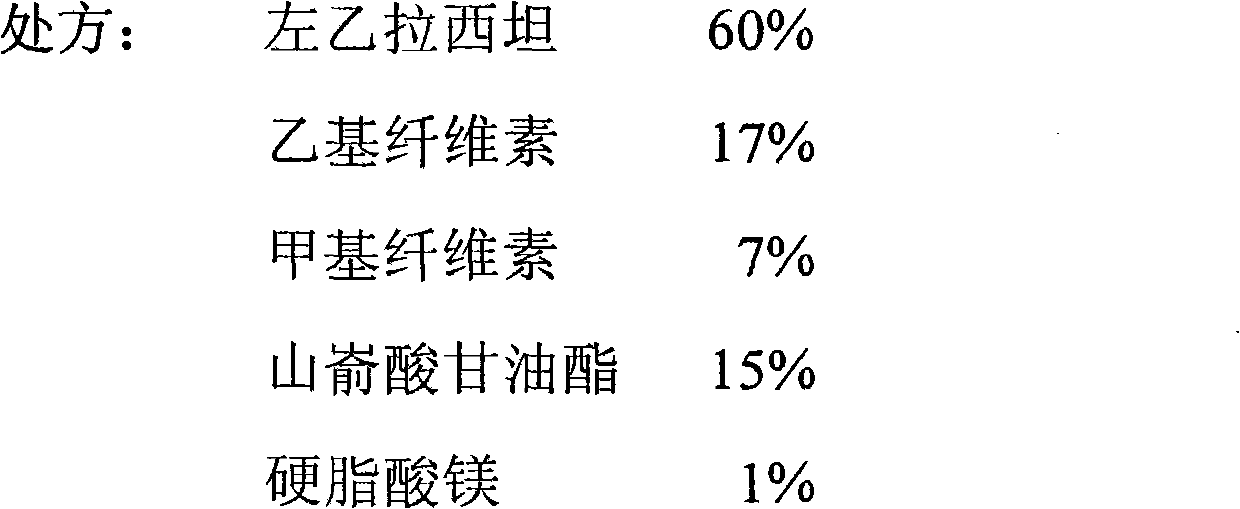

Levetiracetam slow release medicinal composite and preparation method thereof

ActiveCN102379857ASimple preparation processPromote reproductionOrganic active ingredientsNervous disorderControl releaseBiocompatibility Testing

The invention relates to a levetiracetam slow release medicinal composite and a preparation method thereof. The tablet core of the medicinal composite is mainly composed by 55-65% of levetiracetam in weight percentage and 35-45% of non hydrophilia auxiliary material with the slow release function in weight percentage, the non hydrophilia auxiliary material with the slow release function is mixed by one, two or three of ethyl cellulose, methyl cellulose or behenic acid glyceride, and the slow release medicinal composite does not need a functional controlled release coating to adjust the drug release. The levetiracetam medicinal composite has stable drug release performance, good biocompatibility and dissolution performance; and the preparation technology is simple, is easy to reproduce, and is applicable to industrialization production.

Owner:SHENZHEN SALUBRIS PHARMA CO LTD

FeS2 film and preparation method thereof

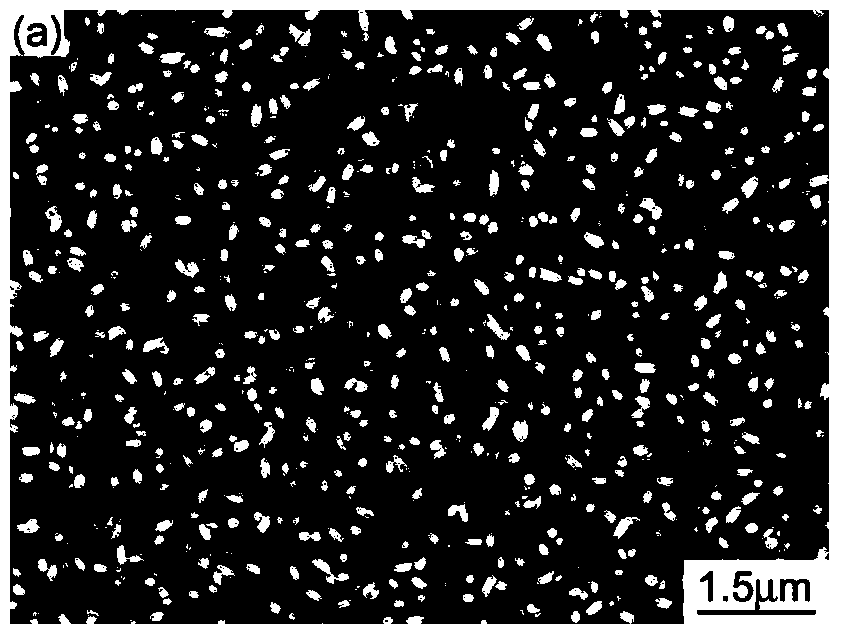

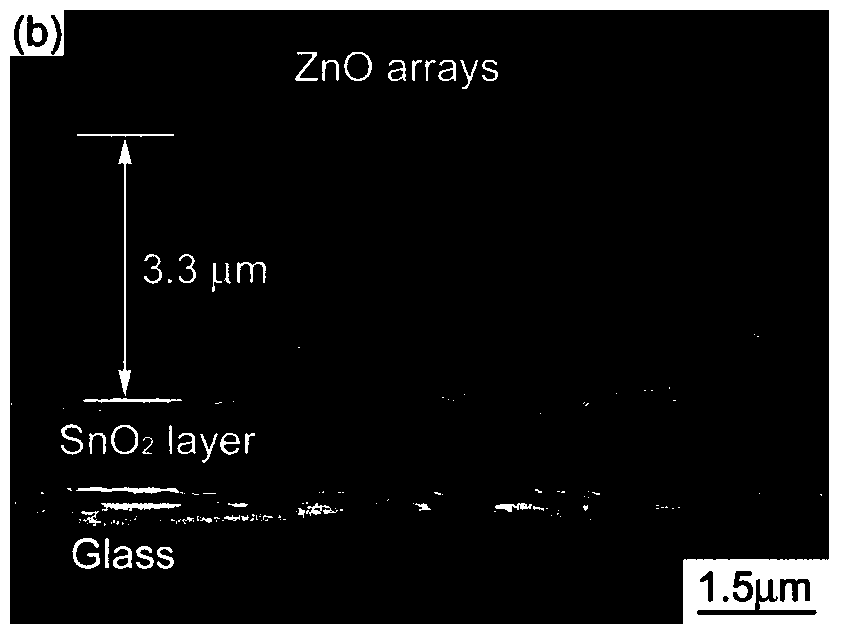

InactiveCN103824902AIncrease the effective light absorption areaEnhanced light absorptionFinal product manufacturePhotovoltaic energy generationRoom temperatureNanorod

The invention discloses a preparation method of a FeS2 film. The method comprises the following steps: using FTO conductive glass as a base; configuring a seed layer solution; soaking the base into the seed layer solution to coat in a pulling manner at room temperature; forming a layer of even ZnO nanocrystalline seed on the surface of the base; preparing a precursor solution; forming an even and compact ZnO nano rod array film on the surface of the base; covering the surface of the base with a Fe(OH)3 nano rod array by the ZnO nano rod array film at room temperature; carrying out vulcanizing treatment, and converting the Fe(OH)3 nano rod array into an FeS2 nano rod array. The FeS2 film comprises the base made of the FTO conductive glass; the base is covered with the FeS2 nano rod array; each FeS2 nano rod is formed by stacking FeS2 nano particles. The FeS2 film has the advantages that the optical absorption properties and the photoelectric conversion efficiency are improved by increasing the effective optical absorption area of a ferrous disulfide film.

Owner:ZHEJIANG UNIV

Method for preparing grapheme/cobalt-nickel bimetallic hydroxide

InactiveCN107393730AWide variety of sourcesLow priceHybrid capacitor electrodesHybrid/EDL manufactureNickel saltHigh pressure

The invention discloses a method for preparing grapheme / cobalt-nickel bimetallic hydroxide. The method comprises the following steps: selecting graphite powder with certain granularity, performing oxidation treatment, filtering and cleaning to obtain graphite powder, then performing microwave expansion on the graphite powder to obtain expanded worm graphite powder, placing the expanded worm graphite powder in an N-methyl pyrrolidone solvent, performing ultrasonic concussion and centrifugal separation, extracting suspension liquid on the upper layer, placing a cobalt salt and a nickel salt with a certain molar ratio therein to obtain a precursor with certain concentration, placing the precursor in a high pressure reactor for heating, filtering, cleaning and drying the product after cooling the same to obtain the grapheme / cobalt-nickel bimetallic hydroxide. The composite material has the advantages of cheap raw materials, low cost, good electrode storage effect and so on, and can be applied to the electrode materials and electrochemical catalysis of supercapacitors.

Owner:浙江美都墨烯科技有限公司

Preparation method of composite nanostructure double-effect sulfur fixation type lithium-sulfur battery anode material

InactiveCN108172806AImprove cycle lifeInhibition of dissolutionMaterial nanotechnologyPositive electrodesNew energyNanostructure

The invention provides a preparation method of a composite nanostructure double-effect sulfur fixation type lithium-sulfur battery anode material. A nanotube structure is used as a support, nanosheetsare grown in a nanotube via a hydrothermal reaction to form a physical barrier, an organic ligand is added to perform chemical coordination so as to realize a physical-chemical double-effect sulfur fixation structure, and sulfur is injected into the nanotube via carbon disulfide sulfur injection to obtain the lithium-sulfur battery anode material. The composite nanostructure achieves the purposeof high-efficiency sulfur fixation via physical sulfur fixation and chemical sulfur fixation, the preparation method provided by the invention has the advantages of easy acquisition of raw materials,simple process, convenient operation, low cost, environmental friendliness and the like, the requirements for the preparation equipment in the entire reaction process are low, thereby being conduciveto the industrial production, and the prepared material can effectively inhibit the shuttle effect of polysulfide, prolong the cycle life of the lithium-sulfur battery, relieve the volume expansion, and improve the electrochemical performance of the lithium-sulfur battery, so that the prepared material is further applied to the field of new energy resources.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

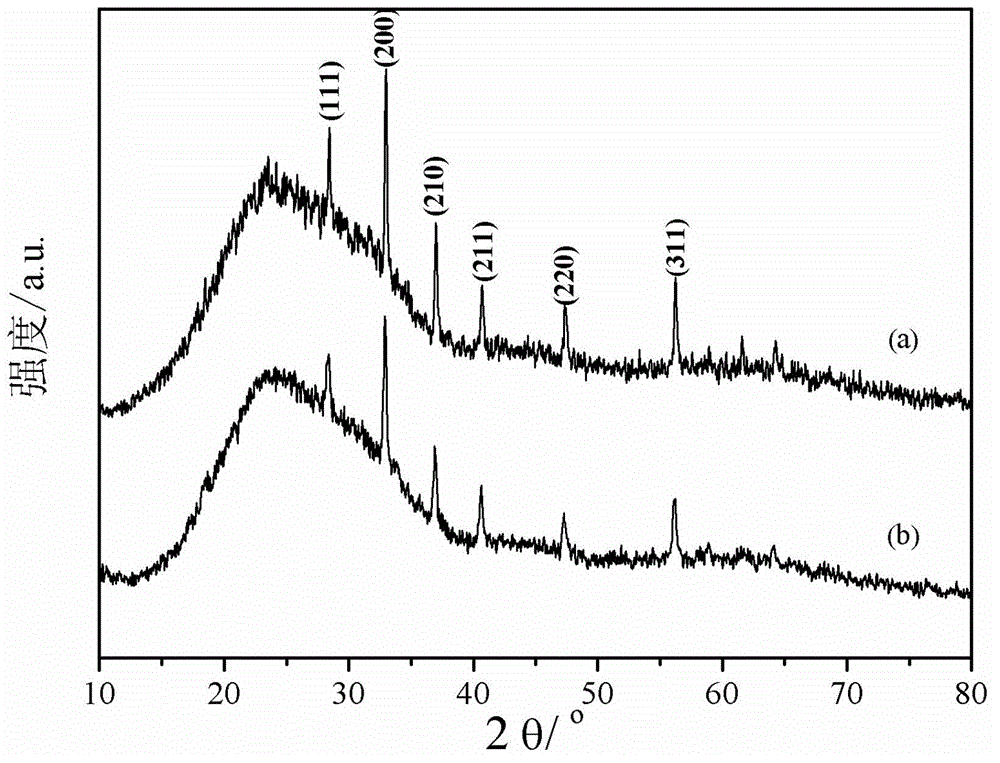

Method for preparing ferrous disulfide film by chemical bath deposition and vulcanization

InactiveCN102912322ALow preparation equipment requirementsSynthesis conditions are simpleLiquid/solution decomposition chemical coatingIonMalonic acid

The invention relates to a method for preparing a ferrous disulfide film by chemical bath deposition and vulcanization. The method comprises the following steps: adopting citric acid or malonic acid as a complex agent; obtaining uniform, compact and high-crystallized precursor films on modified general glass in a water bath environment of less than 100 DEG C; vulcanizing; and quickly cooling to obtain the FeS2 film with the purity of not less than 99%. The citric acid or the malonic acid is adopted as the complex agent for complexing metal ions, so that a large amount of ferrous ions and sulfur ions can be inhibited to be not subjected to homogeneous deposition in a solution during early reaction period, thereby enabling heterogeneous deposition to become a main body and being favorable for film formation. Through the adoption of a water bath heating way, a reaction solution is uniformly heated, and the film statically and slowly grows and is uniform and compact. Through the adoption of a quick cooing way, impurity phases are dynamically reduced to improve the purity of the film. The ferrous disulfide film has no selectivity for a substrate, is synthesized in a low-temperature solution, is good in crystallinity, simple in process and low in cost, and is suitable for large-scale production application.

Owner:TIANJIN UNIV

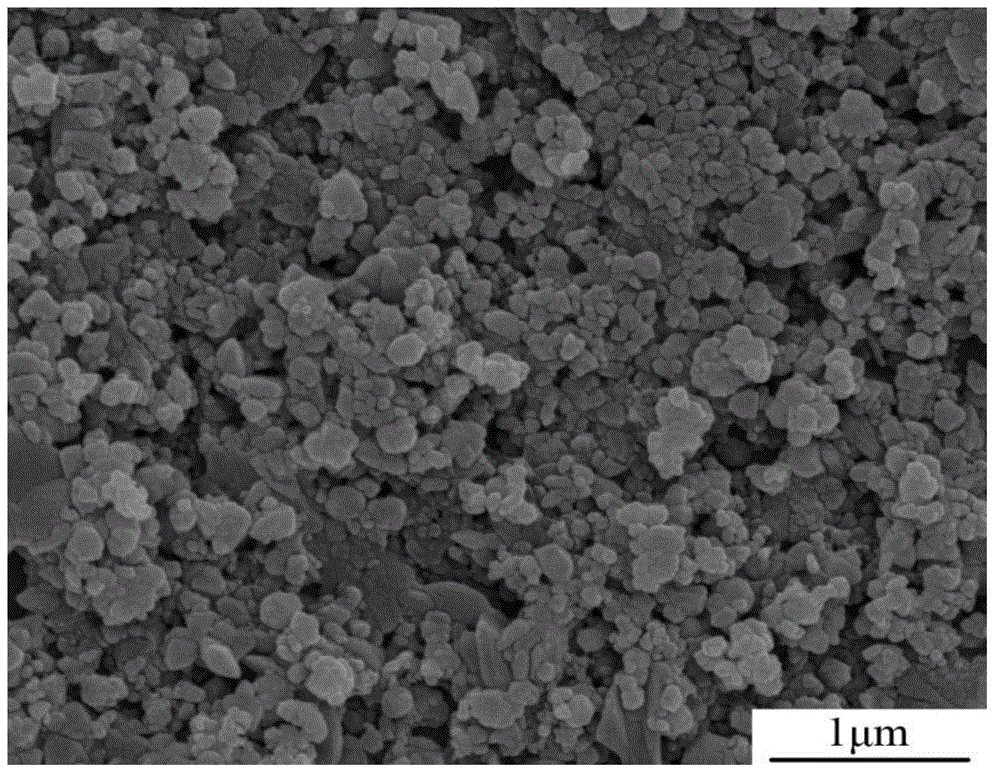

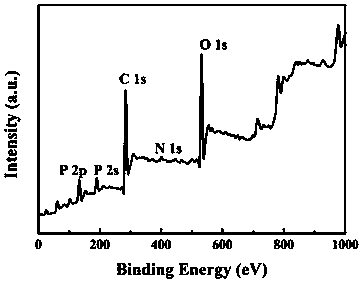

Preparation method of highly doped nitrogen, phosphorus and carbon nano-sheet for efficient hydrogen production

InactiveCN109455701AIncrease the doping concentrationNovel structureMaterial nanotechnologyGrapheneHigh concentrationElectricity

The invention discloses a preparation method of a highly doped nitrogen, phosphorus and carbon nano-sheet for efficient hydrogen production to improve the dosage concentration of heterogeneous atoms such as nitrogen and phosphorus in carbon materials, increase catalytic activity sites in the carbon materials and improve catalytic activity of the carbon materials. An appropriate proportion of nitrogen sources, carbon sources and phosphorus sources are dissolved, stirred, mixed, dried, pyrolyzed and the like to obtain the high-concentration nitrogen and phosphorus doped carbon nano-sheet. The preparation method has the advantages that raw materials are easily obtained, the technology is simple, operation is convenient, the preparation method is low in cost and environmentally friendly and the like. The whole reaction process is low in requirement for preparation equipment, industrial production is facilitated, the prepared materials have nitrogen and phosphorus with high dosage concentration, electro-catalysis hydrogen production performance is effectively improved, and the preparation method has practical industrial significance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

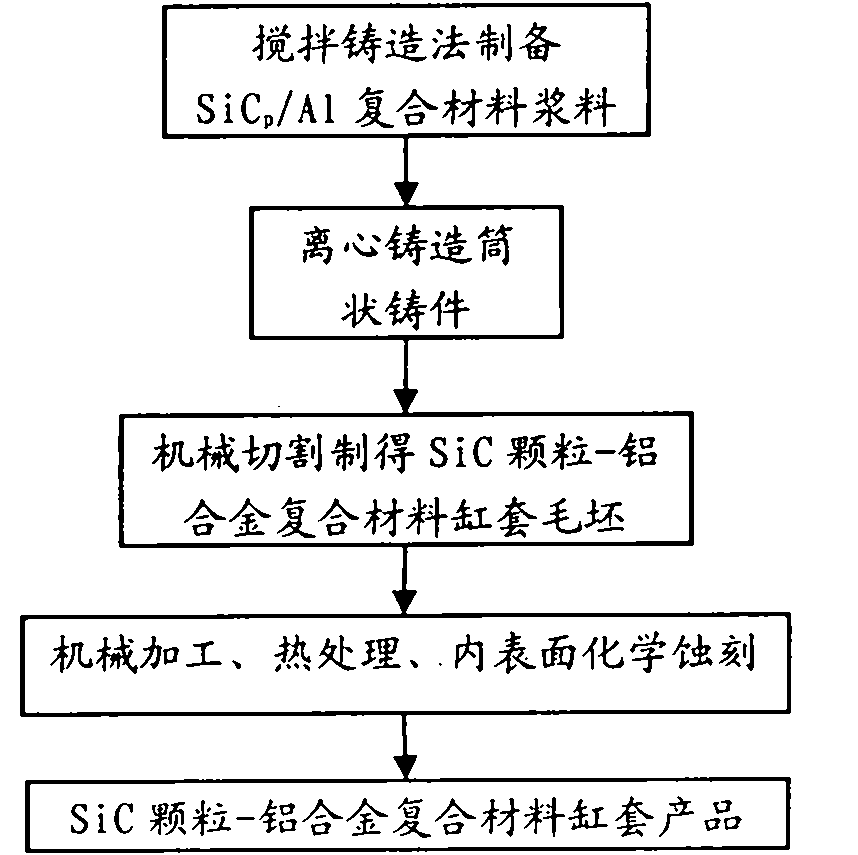

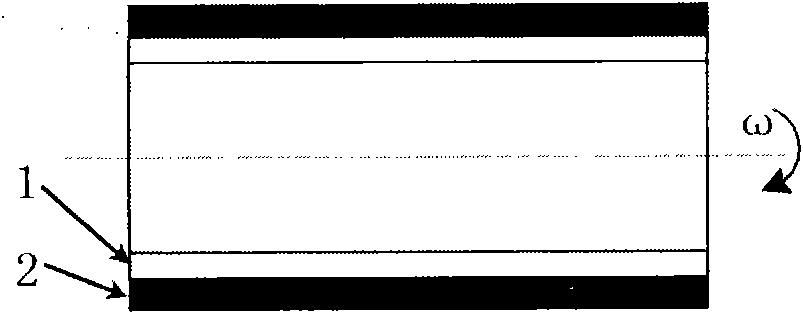

Method for preparing SiC particle-aluminum alloy composite material cylinder liner

InactiveCN102029369AMeet performance characteristicsSimple preparation processCylindersAlloy compositeSlurry

The invention relates to a method for preparing a SiC particle-aluminum alloy composite material cylinder liner, which can meet the requirement of light-weight manufacturing of engines. The method comprises the following steps of: preparing SiC particle-aluminum alloy composite material slurry with volume fraction of between 10 and 20 percent by a stirring casting method; heating to the temperature of between 700 and 750 DEG C for later use; forming the SiC particle-aluminum alloy composite material slurry which is heated to the temperature of between 700 and 750 DEG C and serves as a raw material in a cylindrical mould which is preheated to the temperature of between 350 and 500 DEG C by a centrifugal casting method under the condition that a G parameter is between 50 and 100g; cooling and solidifying to obtain a cylindrical cast, wherein the cast consists of a SiC particle-aluminum alloy composite material annular belt which is distributed close to the external diameter of the cylindrical cast and has an average volume fraction of between 35 and 55 percent and an aluminum alloy annular belt which is distributed close to the internal diameter of the cylindrical cast and does not have any SiC particles; removing the aluminum alloy annular belt part which is distributed close to the internal diameter of the cylindrical cast and does not have the SiC particles by a machining method to obtain a cylindrical member which is made of a high-size SiC particle-aluminum alloy composite material; and mechanically turning and thermally processing the high-size SiC particle-aluminum alloy composite material cylindrical member and chemically corroding the inner wall of the cylinder liner to prepare a cylinder liner part. The SiC particle-aluminum alloy composite material cylinder liner prepared by the method has the characteristics of low linear expansion coefficient, high wear resistance and high thermal performance.

Owner:CHONGQING UNIV

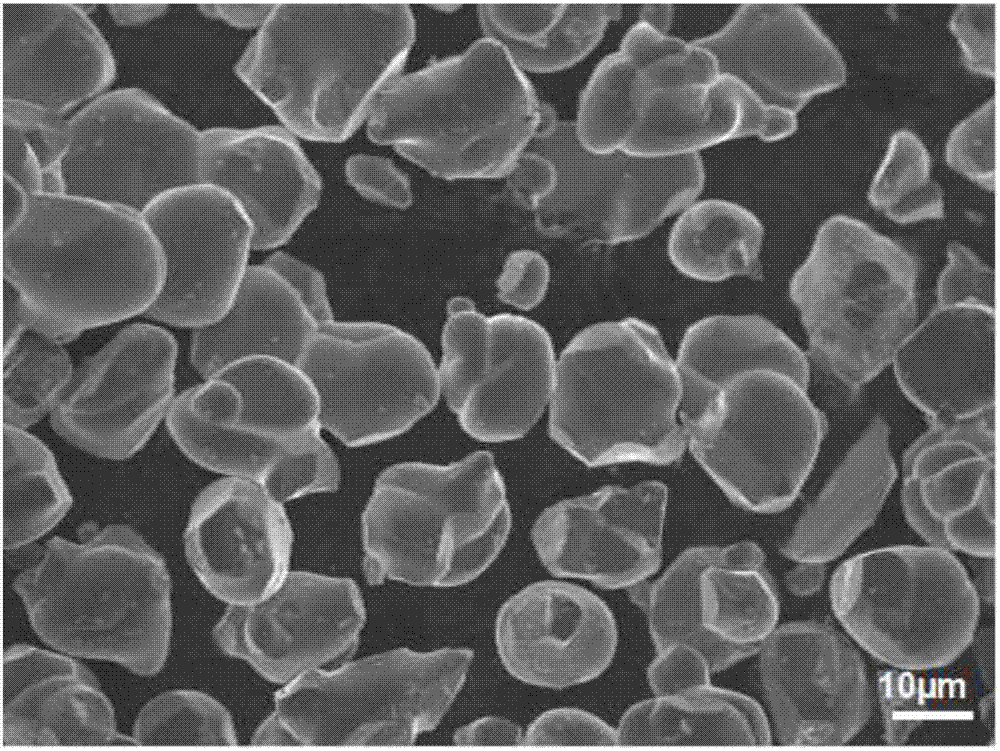

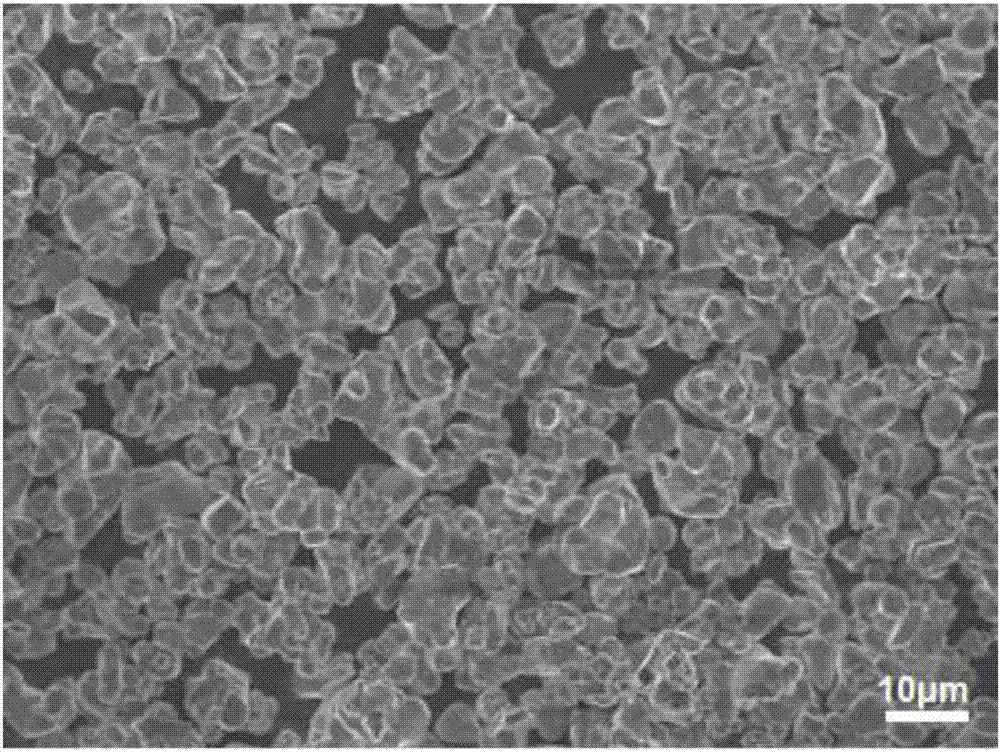

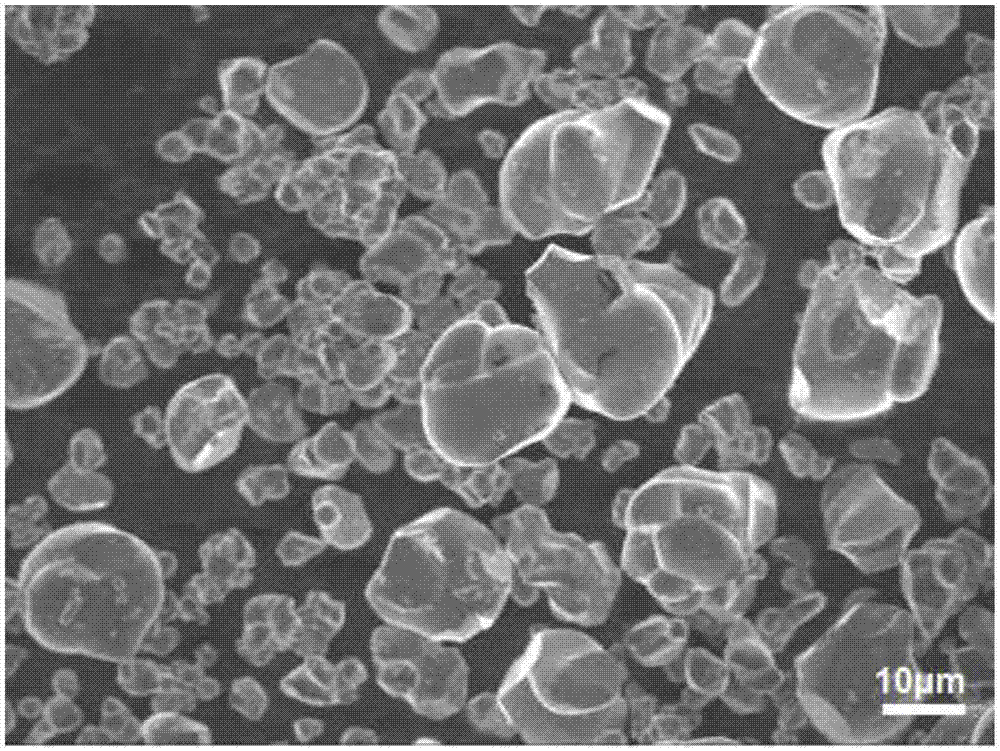

A mixed material of lithium cobalt oxide and three elements and a preparing method thereof

InactiveCN107482211AExcellent compaction densityExcellent securityCell electrodesSecondary cellsGranularityHigh voltage

A mixed material of lithium cobalt oxide and three elements and a preparing method thereof are disclosed. Solid-phase mixing and sintering synthesis are adopted to prepare the mixed material from the lithium cobalt oxide having a specific granularity and three elements having a specific granularity according to a proper ratio. The method has low requirements on preparing equipment, but the prepared mixed material has a high compaction density (4.40 g / cm<3> or above), and has better safety performance at 4.5 V or even a higher voltage.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

Polyvinylidene fluoride separation membrane and its preparation method

A polyvinylidene fluoride separation membrane comprises the following membrane preparation complex composition: by weight, 30-80% of a polyvinylidene fluoride resin or polyvinylidene fluoride copolymer; 20-70% of a water-soluble diluent; 0-50% of teflon powder particles; 0-30% of hydrophilic polymer; and 0-30% of inorganic particles. The invention also provides a preparation method of the polyvinylidene fluoride separation membrane. According to the preparation method, a sinter moulding technology is adopted, and a single screw extruder or double screw extruder (blending) are used for continuous extrusion, wherein the extrusion temperature is 140-180 DEG C. According to the invention, a solvent of the polyvinylidene fluoride resin is not required, cross-section structure of the separation membrane is uniform without large voids. Simultaneously, heating is not required to completely melt the polyvinylidene fluoride resin, the separation membrane requires low moulding temperature, and the requirement on separation membrane preparation equipment is low.

Owner:吕晓龙

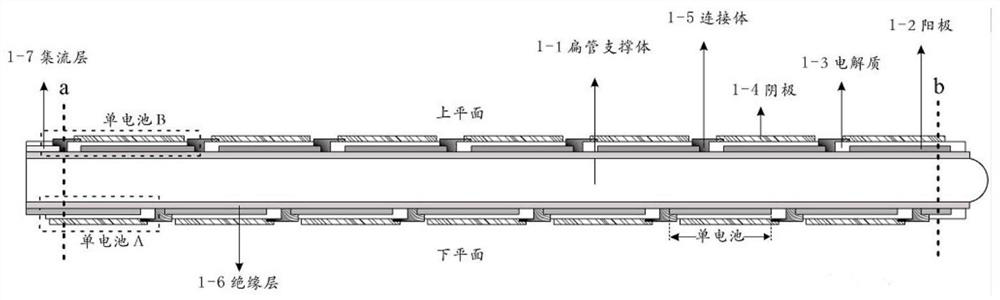

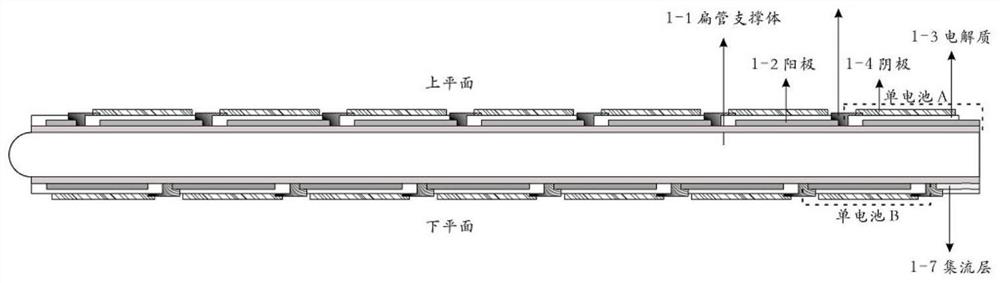

Self-sealing metal flat tube supported solid oxide fuel cell/electrolytic tank structure

PendingCN113948730AImprove efficiencyQuick start strategyFuel cell heat exchangeFinal product manufactureFuel cellsElectrical battery

The invention provides a self-sealing metal flat tube supported solid oxide fuel cell / electrolytic cell and a cell stack structure thereof. The structure comprises an insulating layer and a flat tube supporting body prepared from a metal material; the insulating layer covers the two planes of the flat tube supporting body; a battery pack is distributed on the insulating layer and is formed by connecting a plurality of single batteries in series through connectors to form a U shape; and the current collecting layer of the first single battery and the current collecting layer of the last single battery in the battery pack are both positioned at the opening end and are respectively used for leading in and leading out current. According to the design of the metal flat tube supporting body and the insulating layer provided by the invention, the flat tube supporting body is made of metal with high thermal conductivity, low cost and high strength, so that the starting rate of the cell can be remarkably improved, the cycle starting times can be increased, and a feasible scheme is provided for a high-efficiency, high-stability and quick-starting strategy of the fuel cell.

Owner:XI AN JIAOTONG UNIV

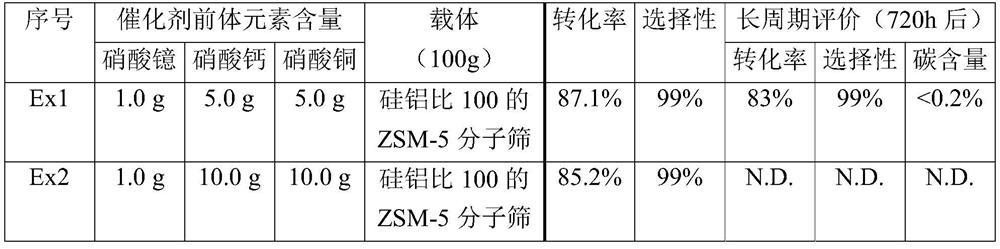

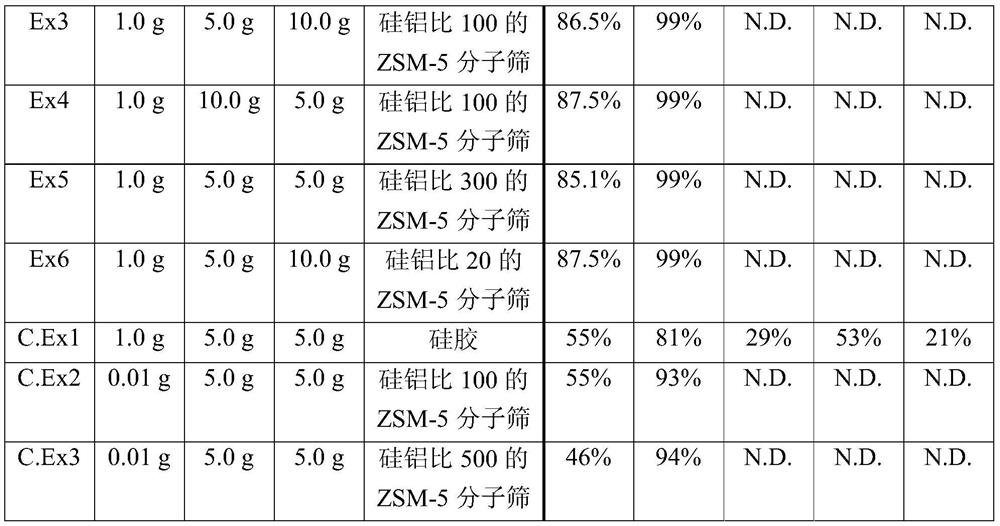

Catalyst for synthesizing 6-aminocapronitrile, preparation method thereof and method for synthesizing 6-aminocapronitrile by using catalyst

PendingCN113649062ASimple manufacturing methodImprove qualityMolecular sieve catalystsPreparation by carboxylic acid amide dehydrationMolecular sievePtru catalyst

The invention provides a preparation method of a catalyst for synthesizing 6-aminocapronitrile from caprolactam. The preparation method comprises the following steps: 1) preparing a mixed aqueous solution of ternary active components of ytterbium nitrate, calcium nitrate and copper nitrate for later use; (2) weighing a ZSM-5 silicon-aluminum molecular sieve, and adding the molecular sieve into the mixed aqueous solution of the ternary active components in the step (1); (3) dipping for 4-10 hours at the temperature of 25-80 DEG C; and 4) evaporating to dryness, drying, forming and roasting to obtain the catalyst. Wherein the mass ratio of the ytterbium nitrate to the calcium nitrate to the copper nitrate is 1: (1-20): (1-20), and the ratio of the total mass of the ytterbium nitrate, the calcium nitrate and the copper nitrate to the mass of the ZSM-5 silicon-aluminum molecular sieve is (0.01-0.4): 1. The catalyst disclosed by the invention is simple in preparation method, stable in quality, high in catalytic efficiency, high in product space-time yield, long in service life, low in requirements on catalyst preparation equipment and easy for industrial production.

Owner:BEIJING RISUN TECH CO LTD

Composite material dowel steel for cement concrete road and its preparing method

InactiveCN100451238CImprove corrosion resistanceIncreased durabilityPaving detailsGlass fiberRoad surface

This invention discloses a compound material dowel bar for concrete road paving, which contains bar core and glass fiber reinforced plastics pipe made of wound fiber and resin and covered on bar core, the fiber content is 60-75 % and the resin content is 25-40 %. The section of dowel bar is round or ellipse. Said compound material dowel bar has fine erosion resistance, durability and associativity with concrete, capable of saving 30 % of cost than that of steel dowel bar.

Owner:SOUTH CHINA UNIV OF TECH

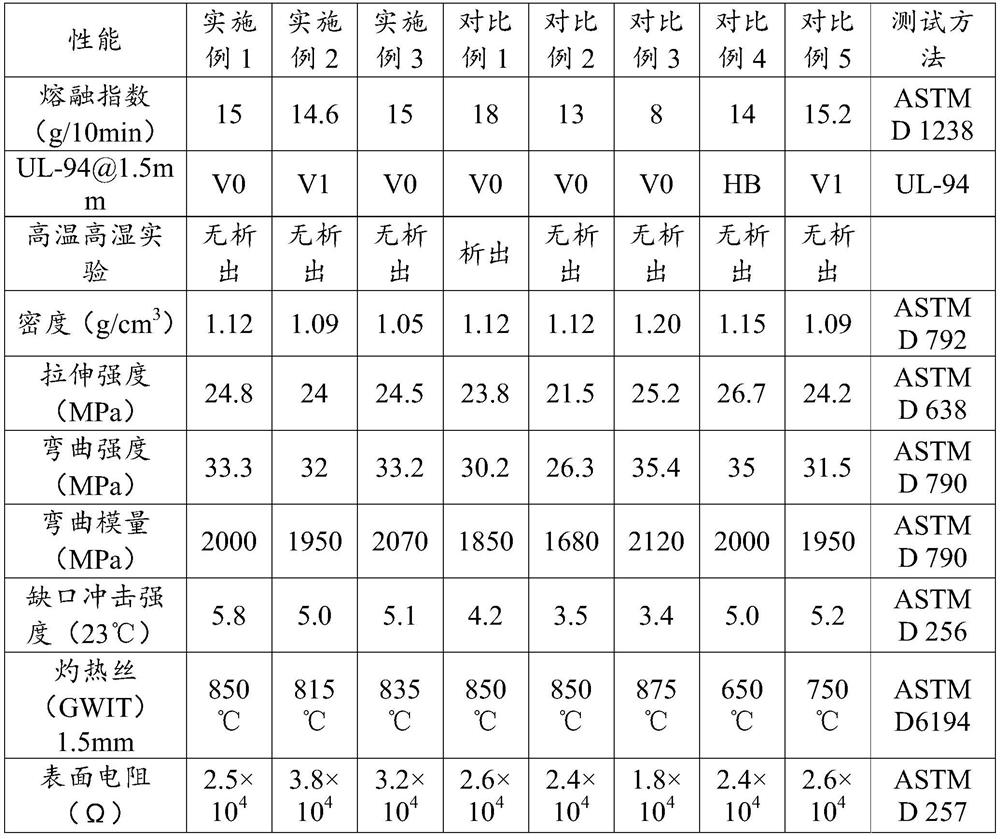

High-temperature-resistant high-humidity-resistant halogen-free flame-retardant antistatic polypropylene material

PendingCN112521681ARetain mechanical and mechanical propertiesHigh heat distortion temperatureHeat deflection temperaturePolymer science

The invention discloses a high-temperature-resistant high-humidity-resistant halogen-free flame-retardant antistatic polypropylene material, and belongs to the technical field of high polymer materials. According to the high-temperature-resistant high-humidity-resistant halogen-free flame-retardant antistatic polypropylene material disclosed by the invention, a halogen-free flame retardant, a coupling agent and expandable graphite with specific contents are added into polypropylene resin, and the expandable graphite is modified by utilizing the coupling agent and then the modified graphite ismatched with other components, so that the original mechanical properties of the polypropylene resin can be effectively retained, the thermal deformation temperature and the flame retardance of the material are remarkably improved, and meanwhile, the material can be prevented from being separated out in a high-temperature and high-humidity environment; the material also meets the GWIT standard ofglowing filaments at 850 DEG C, has excellent antistatic performance, and particularly meets the high use requirements of the glowing filaments in the field of electronic products. The invention further discloses a preparation method of the high-temperature-resistant high-humidity-resistant halogen-free flame-retardant antistatic polypropylene material. The preparation method is simple in operation steps and low in requirements for preparation equipment, and can achieve industrial large-scale production.

Owner:GUANGDONG JUHANG INST FOR ADVANCED MATERIALS CO LTD

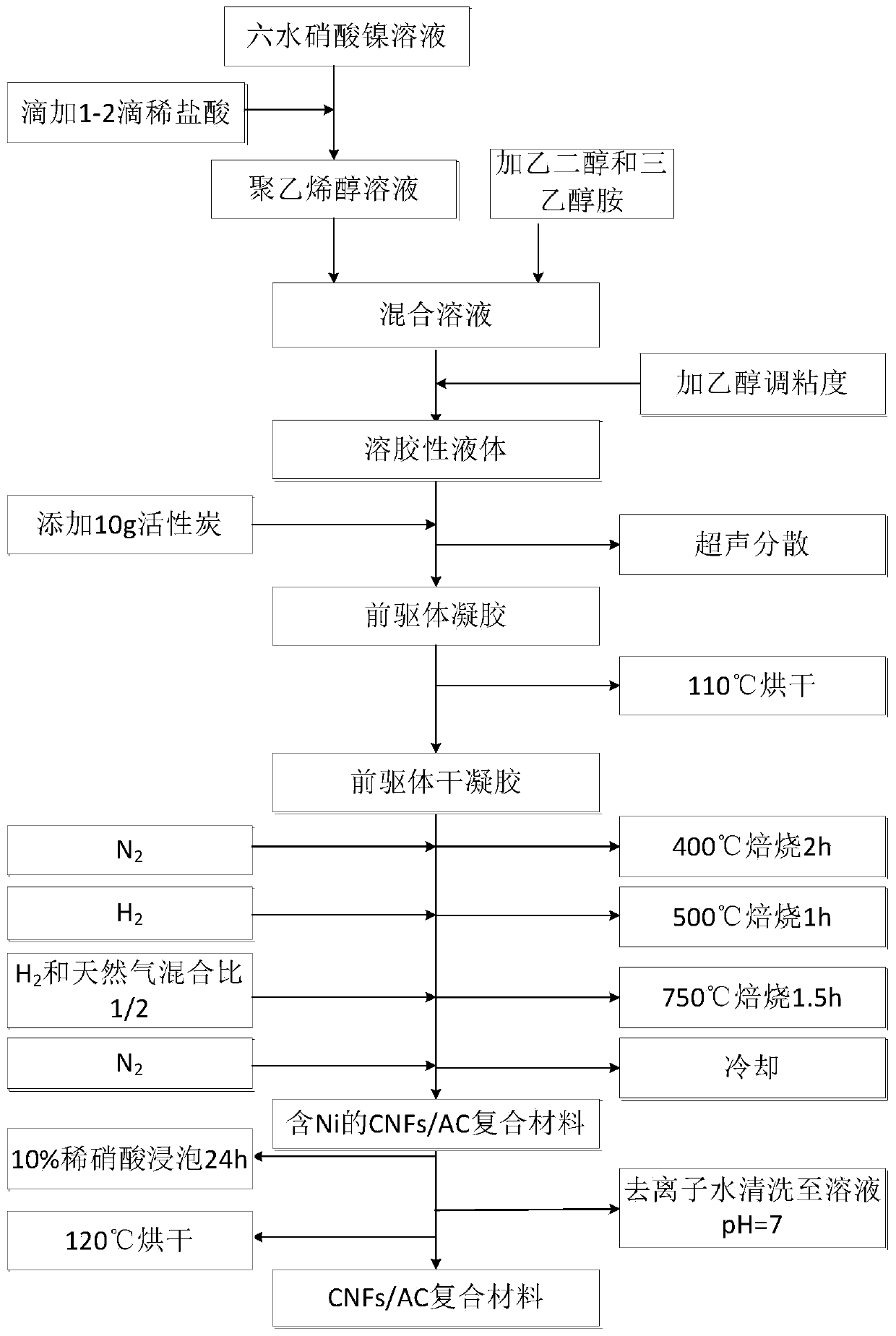

Carbon nanofiber and activated carbon composite material and preparation method thereof

ActiveCN109876772ALarge specific surface areaHigh adsorption-desorption efficiencyOther chemical processesDispersed particle separationCarbon fibersPolyvinyl alcohol

The invention discloses a carbon nanofiber and activated carbon composite material and a preparation method thereof. The preparation method comprises the following steps: A) respectively preparing a polyvinyl alcohol solution and a nickel nitrate hexahydrate solution; B) dropwise adding diluted hydrochloric acid into the polyvinyl alcohol solution, adding the nickel nitrate hexahydrate solution into the polyvinyl alcohol solution, and uniformly stirring; C) dropping glycol and triethanolamine into the mixed solution and uniformly stirring, thereby obtaining transparent sol liquid; D) adding activated carbon, then performing ultrasonic treatment, and standing, thereby obtaining precursor sol; E) drying the precursor sol into dry precursor gel; F) preparing the dry precursor gel into a nickel-containing carbon nanofiber and activated carbon composite material in a vertical roasting furnace of a CCVD reactor according to the conditions; G) soaking the nickel-containing composite materialin diluted hydrochloric acid or dilute nitric acid, removing metallic oxides on the surface, washing with deionized water, and drying, thereby obtaining the carbon nanofiber and activated carbon composite material. The method is capable of combining the advantages of activated carbon and carbon nanofibers and is capable of promoting efficient adsorptive property of the composite material to oil gas.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

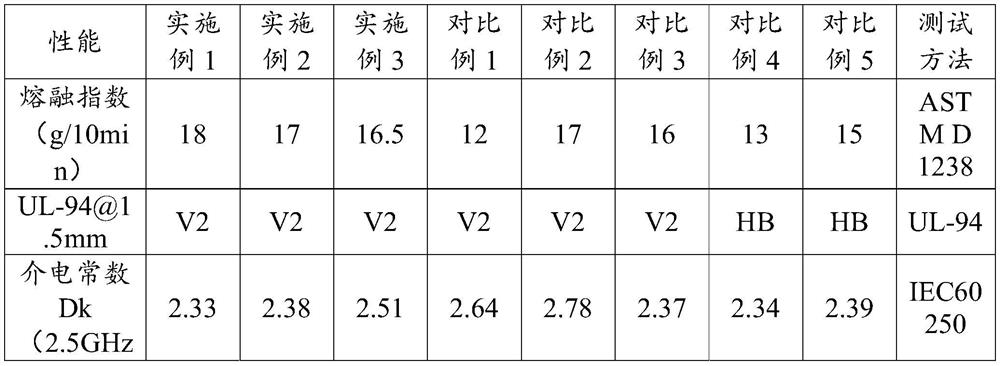

Halogen-free flame-retardant low-dielectric-loss glass fiber reinforced polypropylene material

ActiveCN112521688ALow preparation equipment requirementsEasy to operateGlass fiberHeat deflection temperature

The invention discloses a halogen-free flame-retardant low-dielectric-loss glass fiber reinforced polypropylene material, and belongs to the technical field of high polymer materials. The halogen-freeflame-retardant low-dielectric-loss glass fiber reinforced polypropylene material is prepared from the following components in parts by weight: 35 to 80 parts of polypropylene resin, 10 to 40 parts of low-dielectric-loss glass fiber and 1 to 4 parts of halogen-free flame retardant; and the dielectric loss of the low-dielectric-loss glass fiber at the frequency of 4-4.5 GHz is 4*10 <-2>-5*10 <-2>.According to the product, the halogen-free flame retardant with specific content and the glass fiber material with specific dielectric loss coefficient are added into the polypropylene resin, so thatthe original mechanical properties of the polypropylene resin can be effectively retained, the dielectric loss of the material is relatively low, and the thermal deformation temperature and flame retardancy of the material are also improved, and the material meets high use requirements in the field of electronic products. The invention further discloses a preparation method of the product. The preparation method is simple in operation steps and low in requirements for preparation equipment and achieves industrial large-scale production.

Owner:GUANGDONG JUHANG INST FOR ADVANCED MATERIALS CO LTD

Preparation method of ultrafine granular sodium antimonate

A preparation method of ultrafine granular sodium antimonate comprises the following steps: (1) stirring and mixing antimony trioxide and potassium hydroxide with water, dissolving, heating, then adding an aqueous solution of hydrogen peroxide, and oxidizing to obtain a potassium citrate solution; (2) slowly adding the potassium citrate solution obtained by the reaction in the step 1) into a high-concentration sodium hydroxide solution of 600-800 g / L, and stirring at a high speed at 80-95 DEG C and reacting to obtain sodium antimonate having a particle diameter of less than or equal to 3.0 microns, and cooling; (3) carrying out solid-liquid separation on the reaction liquid in the step (2), carrying out slurry washing on the sodium antimonate solid with water for 2 to 3 times, spin-dryingafter washing and drying through a dryer so as to obtain the finished product ultrafine granular sodium antimonate. The ultrafine granular sodium antimonate prepared by the above preparation method has uniform particle size which is less than or equal to 3 microns, and is mainly used as a flame retardant in fabrics such as fibers and a clarifying agent for glass shells of color kinescopes and high-grade glass. The preparation process is simple; requirements on preparation equipment are low; energy consumption is low; and the product purity is high.

Owner:CHANGSHA YEXING ANTIMONY IND

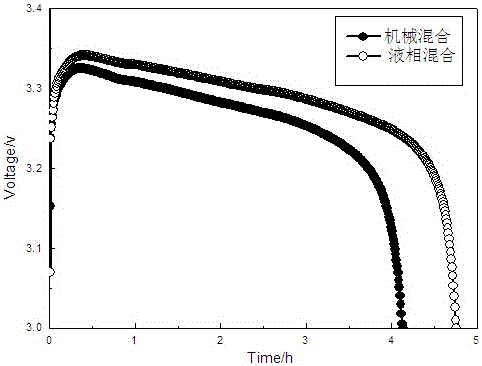

Lithium thionyl chloride battery positive electrode and preparation method thereof

InactiveCN106328883AOvercome hydrophobicityLarge amount of compoundNon-aqueous electrolyte accumulator electrodesElectricityLithium

The invention discloses a lithium thionyl chloride battery positive electrode and a preparation method thereof. The lithium thionyl chloride battery positive electrode contains a conductive material represented by acetylene black and carbon nano tube, wherein the weight parts of the acetylene black and the carbon nano tube are as follows: 70-90 of acetylene black and 25-5 of carbon nano tube. A carbon film of a composite positive electrode is prepared by mixing the acetylene black with the liquid phase of the carbon nano tube, and the prepared carbon positive electrode has good conductivity, while the polarization of a carbon electrode is reduced due to increase of conductivity, thus improving the electrical properties of the electrode; the voltage increasing amount of the battery reaches 20mV, and the capacity increase amount reaches 1.3Ah, and therefore, the battery positive electrode prepared according to a liquid phase mixing method promotes the working voltage and capacity of the battery.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

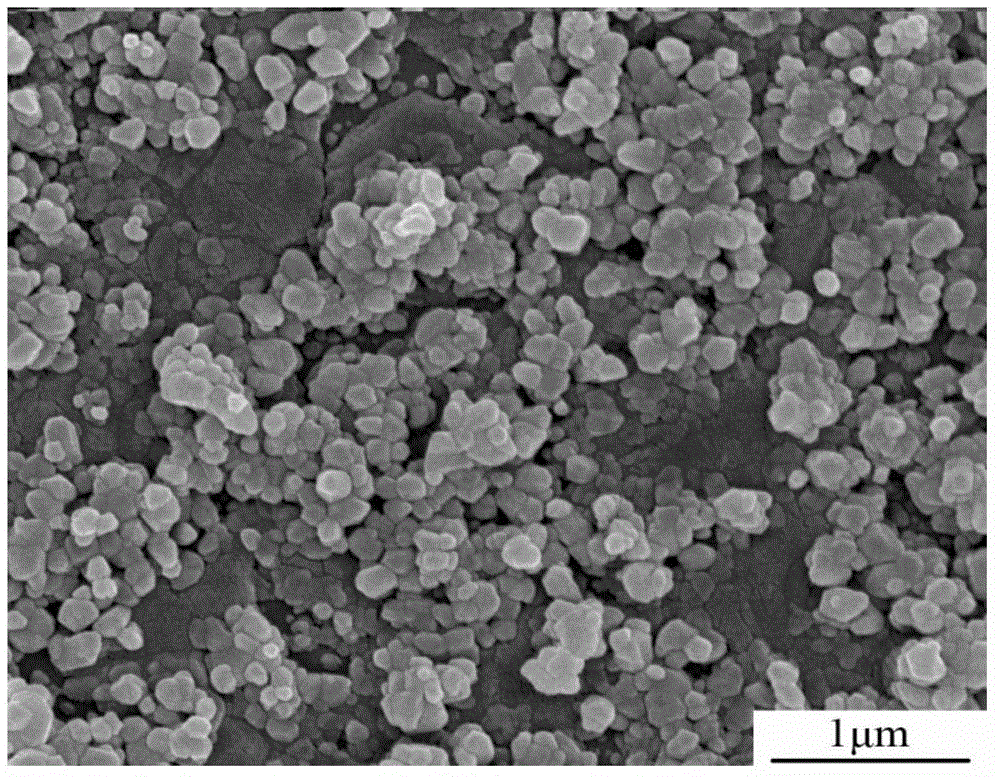

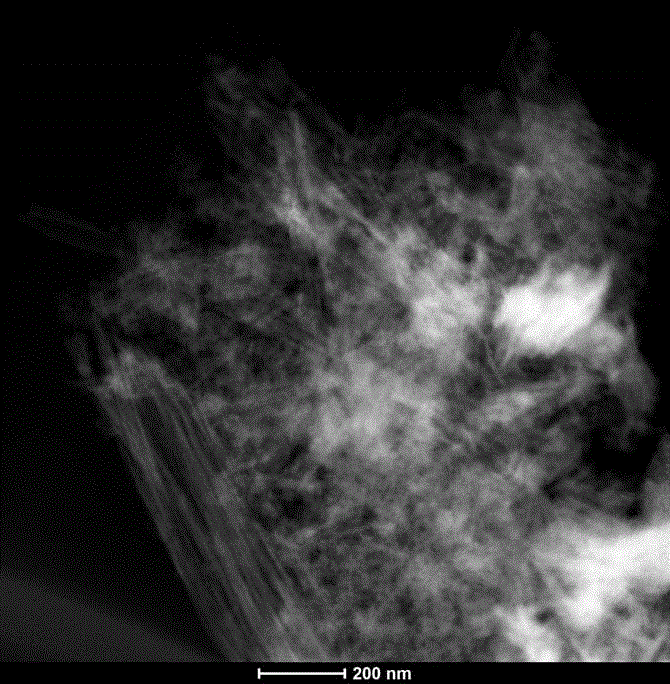

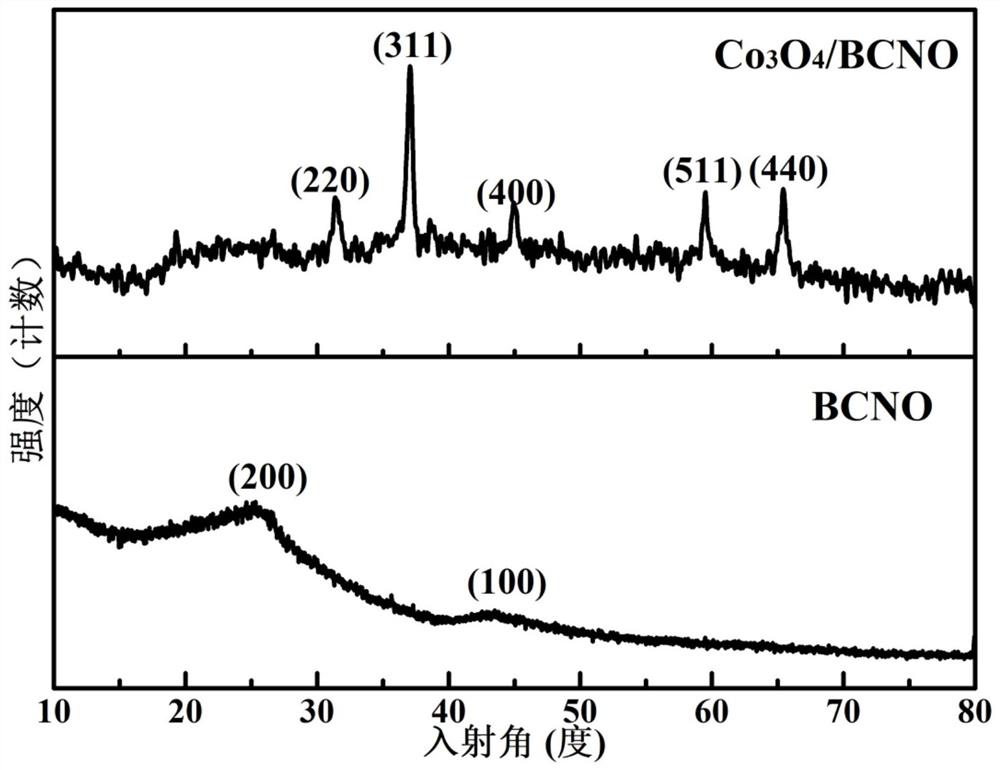

Preparation method of oxygen evolution reaction electrocatalyst with loading Co3O4 on BCNO nano-sheet

ActiveCN108855181AThe preparation method is simple and easyEasy to operatePhysical/chemical process catalystsElectrodesSolventClean energy

The invention discloses a preparation method of an oxygen evolution reaction electrocatalyst with loading Co3O4 on a BCNO nano-sheet. The preparation method comprises the following steps of by adopting ethylene glycol as a solvent and utilizing boric acid, melamine and cobalt acetate as raw material, performing condensation on boric acid and melamine in ethylene glycol to form a BCNO nano-sheet precursor, and performing one-time sintering in a muffle furnace without a protective atmosphere to synthesize a Co3O4 / BCNO nano-sheet composite catalyst. The Co3O4 / BCNO nano-sheet composite catalyst has relatively high electro-catalytic property and electrochemical stability and can be used in the field of development of zinc-air batteries and clean energy and the like as the oxygen evolution reaction electrocatalyst.

Owner:HEBEI UNIV OF TECH

Copper foil in-situ growth three-dimensional copper sulfide negative electrode material for sodium-ion battery, preparation method and application

PendingCN111453759AUniform growthLow preparation equipment requirementsFinal product manufactureCylindrical casing cells/batteryElectron transmissionCopper foil

The invention discloses a copper foil in-situ growth three-dimensional copper sulfide negative electrode material for a sodium-ion battery, a preparation method and application. A method for preparinga copper-foil-loaded copper sulfide negative electrode material for a sodium-ion battery comprises the following steps of: taking a certain current for constant output, taking a copper foil as an anode, taking a graphite flake as a cathode and taking a solution A as an electrolyte for reaction, repeatedly washing the reacted copper foil with deionized water, drying with nitrogen to obtain a product A, and finally annealing in argon to obtain a product B; and directly tabletting the product B as a negative plate of a button cell. By preparing the in-situ grown negative plate, the use of a binder is abandoned, and an electrode active substance directly grows on a current collector, so that the active substance of the current collector is in full contact. According to the method, the manufacturing cost of the battery is reduced, the battery assembling steps are simplified, the overall energy density and the electron transmission efficiency of the battery are effectively improved, and theelectrochemical performance of the battery is greatly improved.

Owner:SHAANXI UNIV OF SCI & TECH

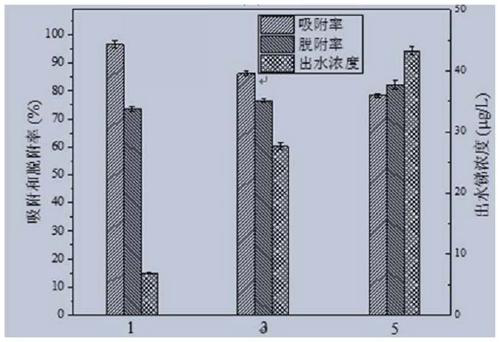

Preparation method of high-efficiency antimony removal adsorbent and its application in printing and dyeing wastewater treatment

InactiveCN110064357BEasy to prepareLow preparation equipment requirementsOther chemical processesWater contaminantsPhysical chemistrySilicon oxide

The invention belongs to the technical field of water pollution treatment and relates to a preparation method of an efficient antimony removal adsorbent and an application of the efficient antimony removal adsorbent in printing and dyeing wastewater treatment, in particular to a preparation method of a porous stable amorphous water iron ore-silicon dioxide composite material and a method for treating antimony-containing printing and dyeing wastewater by utilizing the efficient adsorption characteristic of the composite material to antimony. According to the invention, a sol-gel-microemulsion method is used, a template agent is added to achieve self-assembling to synthesize the porous stable amorphous water iron ore-silicon dioxide composite material in one step. The shape change of the amorphous iron-silicon composite material is achieved by changing the types and the addition amount of the template agent, the iron-silicon ratio, the sintering conditions and the like. The prepared iron-silicon composite material is used for removing the antimony in the practical comprehensive printing and dyeing wastewater, the maximum adsorption capacity of the iron-silicon composite material canreach more than 40mg / g, and the stable discharge of the antimony (below 50mu g / L) can be achieved only by adding about 0.1kg per ton of the printing and dyeing wastewater.

Owner:ZHEJIANG UNIV

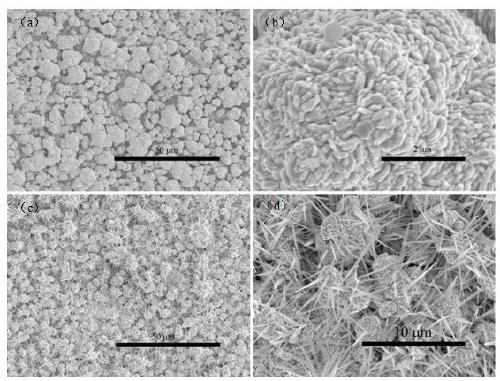

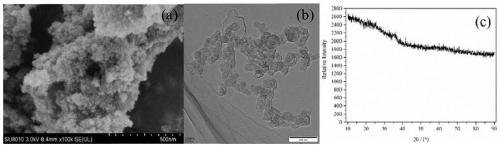

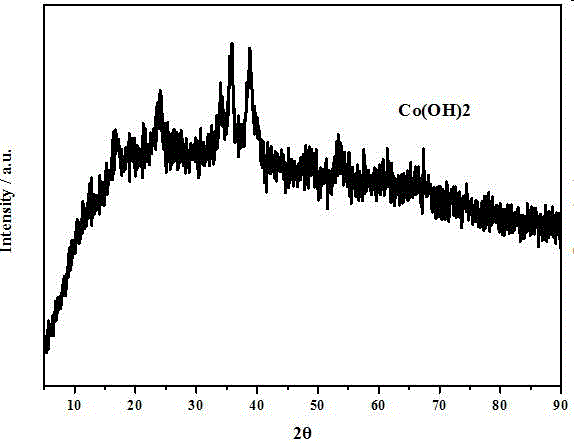

Co(OH)<2> with nano-tube structures, method for preparing Co(OH)<2> and application thereof

InactiveCN106809886ALow costEasy to prepareMetal/metal-oxides/metal-hydroxide catalystsCobalt oxides/hydroxidesAlcoholCobalt

The invention belongs to the field of catalyst synthesis, and particularly discloses Co(OH)<2> with nano-tube structures, a method for preparing the Co(OH)<2> and application thereof. The method includes mixing cobalt sources, cuprous oxide and SDS (sodium dodecyl sulphate) with one another to obtain mixtures and dissolving the mixtures in isovolumetric mixed solution of water and absolute ethyl alcohol; ultrasonically dispersing the mixtures and the isovolumetric mixed solution and then stirring the mixtures and the isovolumetric mixed solution to uniformly mix the mixtures and the isovolumetric mixed solution to obtain first solution; adding sodium thiosulfate solution into the first solution, and continuing to stir the sodium thiosulfate solution and the first solution until colors of solution are turned into light green; filtering and washing the solution and drying the solution under the vacuum conditions to obtain the Co(OH)<2>. The Co(OH)<2> can be used as a catalyst. The Co(OH)<2>, the method and the application have the advantages that the method is simple and convenient and has low requirements on preparation equipment, and potential safety hazards in experimental procedures can be reduced; as compared with commercial RuO<2> catalysts, the electrocatalytic water oxidation activity and stability of the Co(OH)<2> are obviously superior to the electrocatalytic water oxidation activity and stability of RuO<2>, good FTO attaching effects can be realized, the Co(OH)<2> is free of falling, and accordingly the Co(OH)<2> and the method have excellent application prospects.

Owner:ZHENGZHOU UNIV

A polyvinylidene fluoride anti-fouling film and its preparation method

ActiveCN107149882BEasy to makeLow preparation equipment requirementsSemi-permeable membranesMembranesPhase conversionUltraviolet

The invention discloses a polyvinylidene fluoride anti-pollution membrane and a preparation method thereof, and belongs to the field of environmental functional membrane materials. The preparation method comprises: (1) self-polymerizing dopamine on the surface of polyvinylidene fluoride powder, and adhering the generated poly dopamine functional layer onto the surface of the polyvinylidene fluoride powder; (2) preparing a poly dopamine modified polyvinylidene fluoride membrane by using a phase conversion method; and (3) depositing a nano-TiO2 functional layer on the membrane prepared in the step (2) through a liquid phase deposition method to prepare the polyvinylidene fluoride anti-pollution membrane. According to the present invention, by combining the strong adhesion and the polyfunctional group of poly dopamine, the ultraviolet resistance and stable chemical performance of polyvinylidene fluoride, and the advantages of hydrophilicity, high photocatalytic activity and the like of nano-TiO2, the polyvinylidene fluoride anti-pollution membrane is developed; and the prepared polyvinylidene fluoride anti-pollution membrane has excellent pollution resistance, and can be used in various membrane separation fields.

Owner:天津鼎芯膜科技有限公司

A BCNO nanosheet loaded with CO 3 o 4 Preparation method of electrocatalyst for oxygen evolution reaction

ActiveCN108855181BThe preparation method is simple and easyEasy to operatePhysical/chemical process catalystsElectrodesPtru catalystElectrical battery

The invention is a BCNO nanosheet loaded with Co 3 O 4 Preparation method of electrocatalyst for oxygen evolution reaction. This method uses ethylene glycol as the solvent and boric acid, melamine and cobalt acetate as raw materials. Boric acid and melamine are condensed in ethylene glycol to form a BCNO nanosheet precursor, which is sintered once in a muffle furnace without a protective atmosphere to form Co. 3 O 4 / BCNO nanosheet composite catalyst, the Co 3 O 4 / BCNO nanosheet composite catalyst has high electrocatalytic performance and electrochemical stability, and can be used as an electrocatalyst for oxygen evolution reaction in the development of zinc-air batteries and clean energy.

Owner:HEBEI UNIV OF TECH

Aqueous cellulose acetate (CA) dispersion and preparation method thereof

InactiveCN102108135AGood reproducibilityImprove stabilityPharmaceutical non-active ingredientsCellulose acetateMicroparticle

The invention relates to aqueous cellulose acetate (CA) dispersion and a preparation method thereof, and belongs to a preparation technology of a polymer micro-particle suspension. The preparation method is characterized in that CA is taken as a main raw material; an emulsifier, an organic solvent and water are taken as auxiliary materials; and the aqueous CA dispersion is prepared by utilizing an innovative method, namely an ethanol demulsification-centrifugal dispersion method. The invention aims at providing the brand-new aqueous CA dispersion and the preparation method thereof. The aqueous CA dispersion prepared by the method has the advantages of simplified processing technique, low requirements for preparation equipment, good repeatability and good stability, thus facilitating industrial production; meanwhile the aqueous CA dispersion also has the characteristics of higher solid content, low viscosity, less pollution, short coating time, good film forming property and good sustained and controlled release effect on medicaments; and the aqueous CA dispersion can be utilized as a taste masking material for masking unpleasant odor of the medicaments so as to increase the compliance of a patient.

Owner:COSCI MED TECH CO LTD

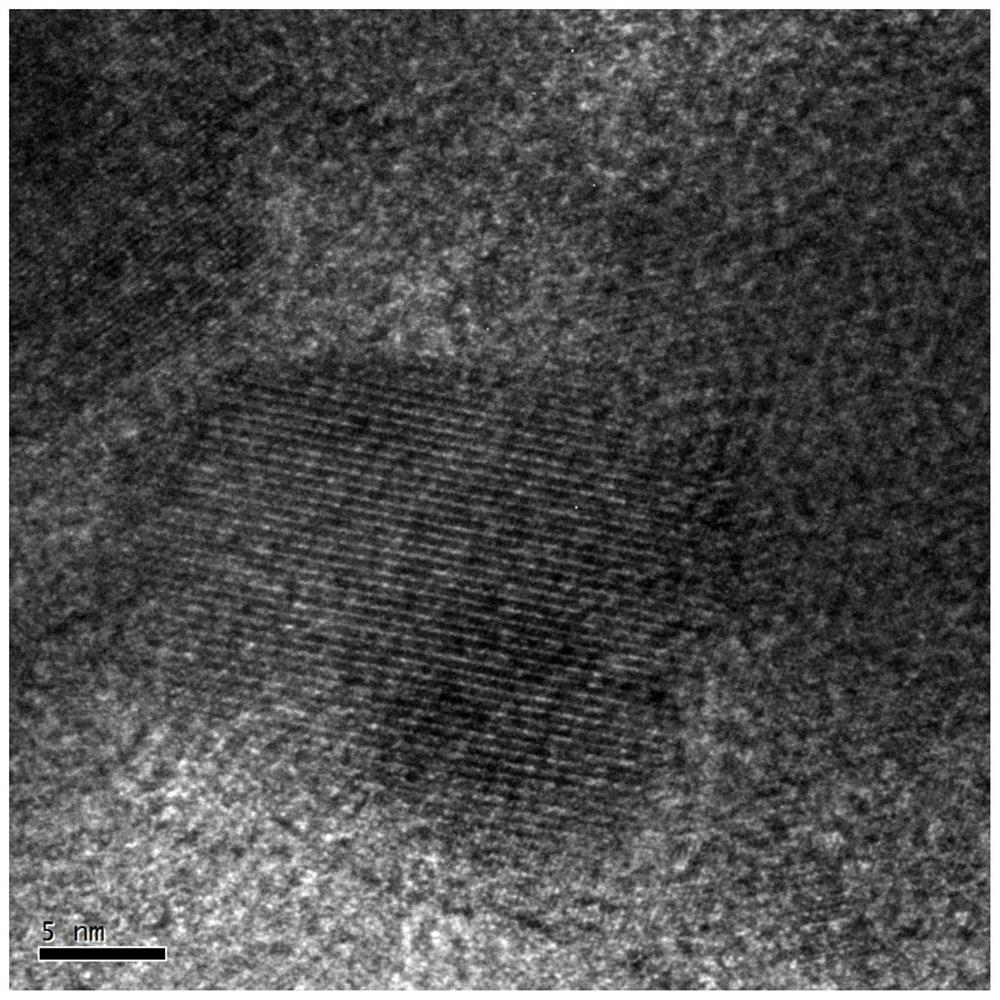

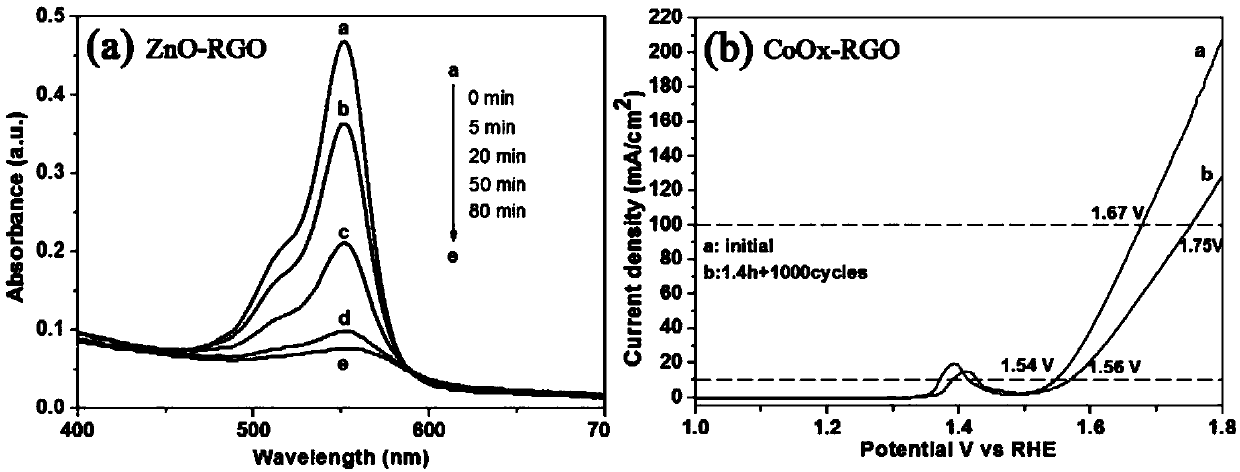

Method for in-situ preparation of small-size metal oxide on graphene

ActiveCN107619045AEasy to operateAvoid uneven and large particlesMaterial nanotechnologyCarbon compoundsChemical agentReducing agent

The invention discloses a method for in-situ preparation of small-size metal oxide on graphene. The method comprises the following step: radiating a graphene-metal ionic reaction liquid by using laserof which the wavelength is 200-600nm (the radiation times are different according to nucleation speeds of different oxides, generally 15 minutes to 2 hours), so as to obtain small-size metal oxides of which the granularity is less than 3nm on graphene through in-situ preparation, wherein the graphene-metal ionic reaction liquid is at least one of a flocculent mixed solution generated after metalions are adsorbed and complexed with graphene, a flocculent mixed solution generated after metal ions are adsorbed and complexed by graphene oxide, and a flocculent mixed solution generated after metal ions are adsorbed and complexed by reduced graphene oxide. The method is not only small in size of metal oxides (the granularity is less than 3nm), uniform in dispersion, free of chemical agents such as reducing agents and stabilizers, free of raw material amount requirement, simple to operate and green and efficient.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com