Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Less organizational defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

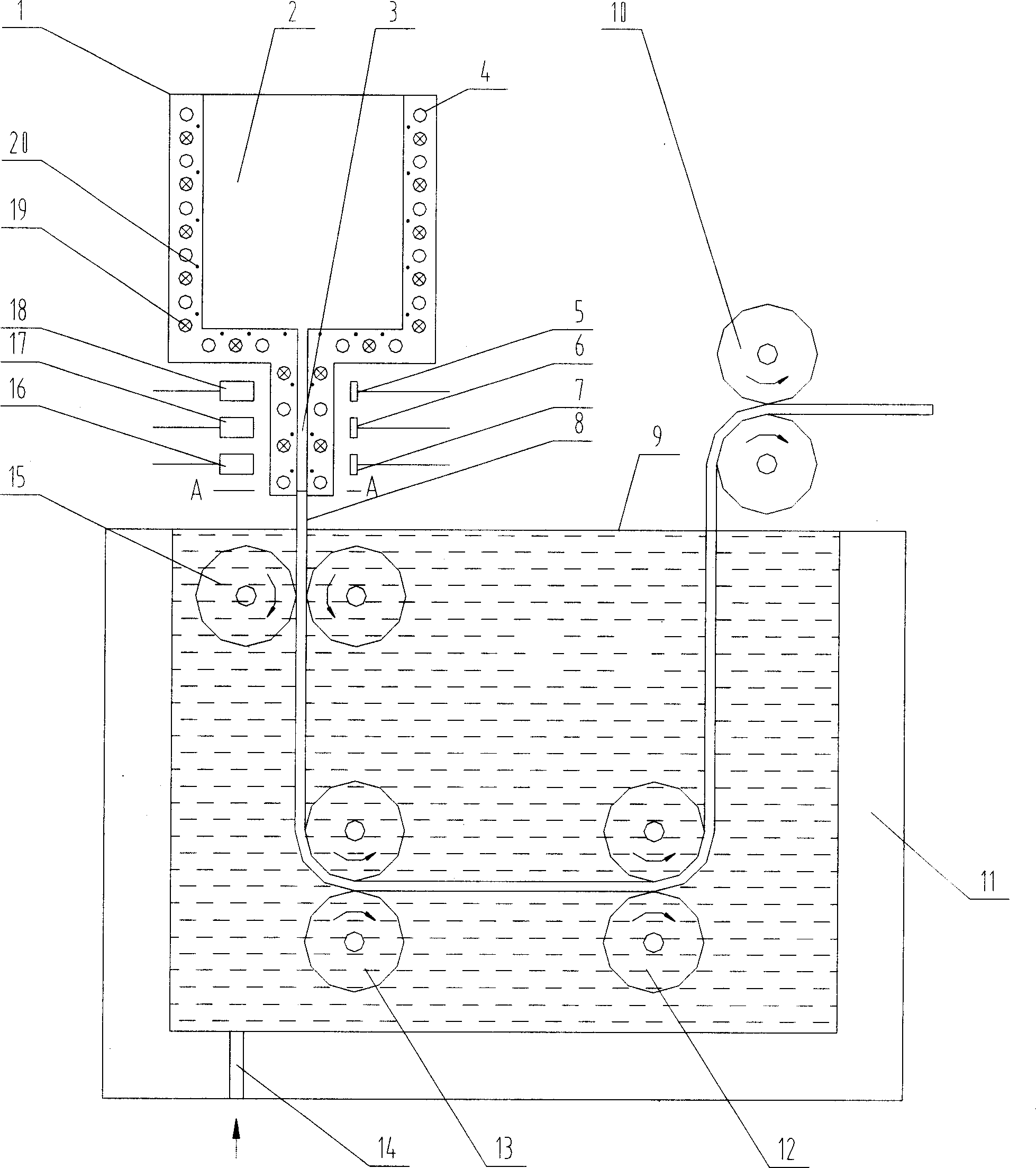

Quick manufacture method and device for metal part under action of magnetic field.

InactiveCN102950285AImprove mechanical propertiesImprove performanceIncreasing energy efficiencyMelting tankMetal powder

The invention relates to a quick manufacture method and device for a metal part by a high-energy beam under the action of magnetic field. In the process that the high-energy beam and metal powder act, the metal powder is molten; the electromagnetic force action is applied to the outer part of a molten pool to change the stressed situation of the molten pool; the solidification behavior of the metal molten pool is subjected to directional control; the inner tissue of a metal manufacture part is refined; and the performance of the metal manufacture part is improved. The device comprises a first electrode, a second electrode and a solenoid coil, wherein the first electrode and the second electrode are installed on a workbench; and when the solenoid coil works, the electromagnetic force can be still kept to be enough to act on the molten pool generated by high-energy beam radiation metal powder. According to the invention, the solenoid coil is electrified by the electrodes to generate a magnetic field; and when the high-energy beam acts on the metal powder, the stressed situation of the metal molten pool generated by the metal powder is affected by the electromagnetic force, the magnitude and the direction of the electromagnetic acting force are controlled via the change of the current and the voltage so as to control the stressed behavior of the metal molten pool.

Owner:HUAZHONG UNIV OF SCI & TECH

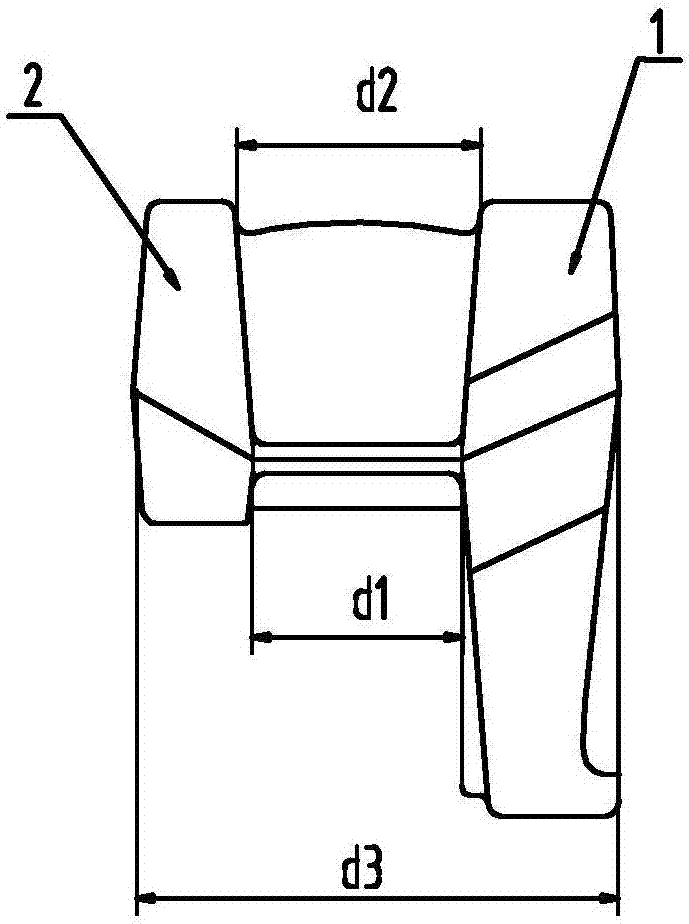

Electrified railway chromium-zirconium-copper contact line and machining process thereof

ActiveCN104342575AMaximum total rolling deformationLow costSingle bars/rods/wires/strips conductorsMetal/alloy conductorsCopperSolid solution

The invention discloses a preparation method of an electrified railway chromium-zirconium-copper contact line. Copper is taken as a substrate, 0.30-0.70% of Cr and 0.10-0.35% of Zr in percentage by weight are added into the substrate, and the total sum of impurities is no greater than 0.05%. The preparation method comprises the following steps: performing vacuum melting and vacuum horizontal continuous casting, thereby obtaining a long-length large cross section chromium-zirconium-copper continuous cast blank; performing full hot continuous rolling and on-line solid solution, thereby obtaining a long-length chromium-zirconium-copper line rod disc; drawing and peeling the disc, and performing cold continuous rolling, thereby reducing the diameter; further performing aging treatment to reinforce the disc; further performing cold continuous rolling by using a Y-type rolling machine, thereby pre-forming the line; and finally performing fine drawing formation once. The chromium-zirconium-copper contact line produced by using the preparation process is fine and uniform in grain, free of defect, high in strength, high in conductivity and high in softening temperature, and applicable to industrialized production.

Owner:YANTAI WANLONG VACUUM METALLURGY

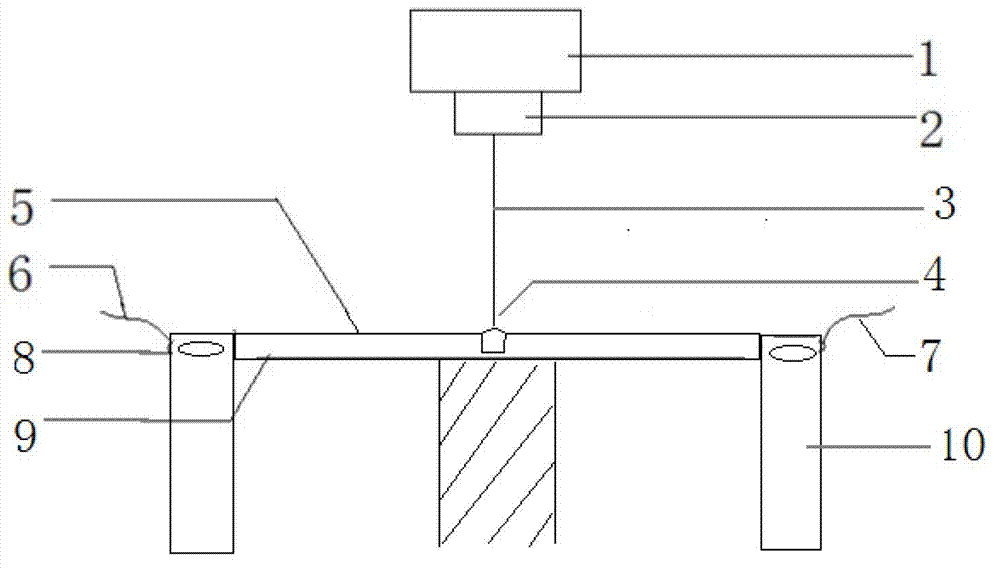

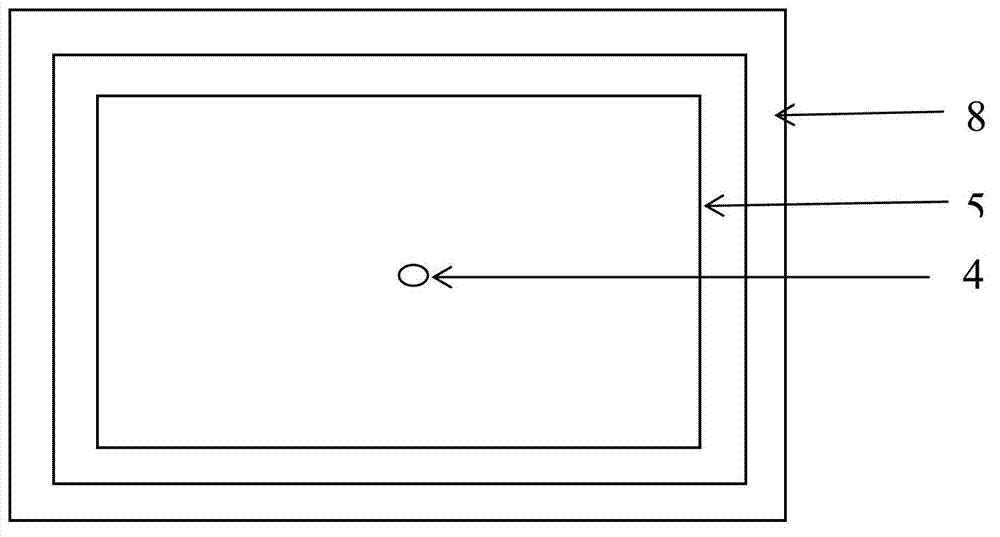

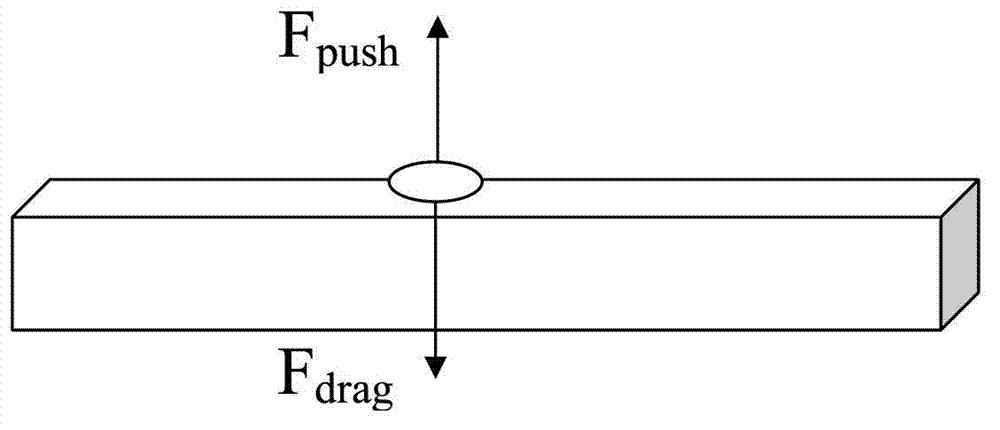

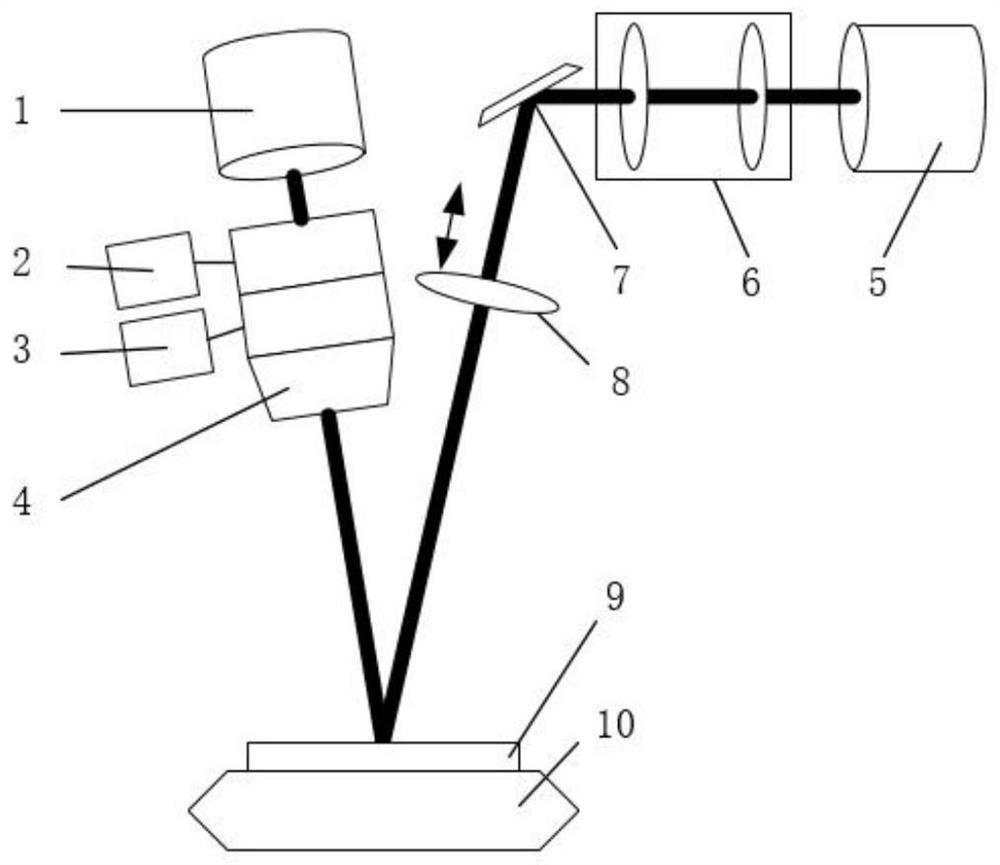

3D printing forming method and device for metal parts under action of magnetic field

The invention relates to a 3D printing forming method and device for metal parts under the action of a magnetic field. Under the action of a high-energy beam and metal powder, the metal powder can be melted, electromagnetic force is applied to the outside of a molten pool, the stress state of the molten pool is changed, directional control over the solidification behavior of the metal molten pool is achieved, the internal organization of metal workpieces can be refined, and thus the performance of the metal workpieces is improved. The device comprises a first electrode, a second electrode and an electromagnetic coil which are mounted on a workbench. When the electromagnetic coil works, the electromagnetic force can be kept to act on the high-energy beam to radiate the molten pool generated by the metal powder all the time. According to the 3D printing forming method and device for the metal parts under the action of the magnetic field, the electromagnetic coil is powered up by the electrodes to generate the magnetic field, when the high-energy beam acts on the metal powder, the stress state of the metal molten pool generated by the metal powder can be affected by the electromagnetic force, the size and the direction of the electromagnetic force can be controlled by changing currents and voltages, and therefore the stress behavior of the metal molten pool can be controlled.

Owner:丹阳惠达模具材料科技有限公司

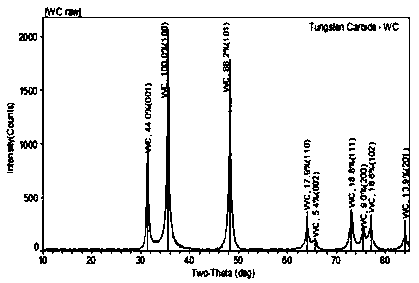

Preparation method of hard alloy bar for PCB (Printed Circuit Board) micro drill

The invention discloses a preparation method of a hard alloy bar for a PCB micro drill. The preparation method comprises the following steps: in terms of total weight percent, selecting 4-8% of Co powder, 0.1-0.5% of VC powder, 0.1-1.2% of Cr3C2 powder, 0.005-0.01% of TiN powder and 0.01-0.06% of Y2O3 powder with Fisher particle size of 0.6-1.0 micrometers, and the balance of WC powder with Fisher particle size of 0.3-0.8 micrometer, adding the selected powder into a ball mill, further adding 0.01-0.03% of oleic acid and 1-3% of polyethylene glycol, sufficiently stirring and mixing; adding alcohol according to the proportion of 400ml / kg, further adding mill balls for milling, filtering and drying pulp stock, and then, molding by virtue of mould pressing or extrusion or injection molding, and molding a hard alloy blank by sintering. A PCB micro drill made of the bar prepared by the preparation method is particularly suitable for tools for processing PCB through holes or blind holes with diameter of less than 0.3mm, has less structure defects, high strength, high hardness and good abrasive resistance.

Owner:河南大地合金有限公司

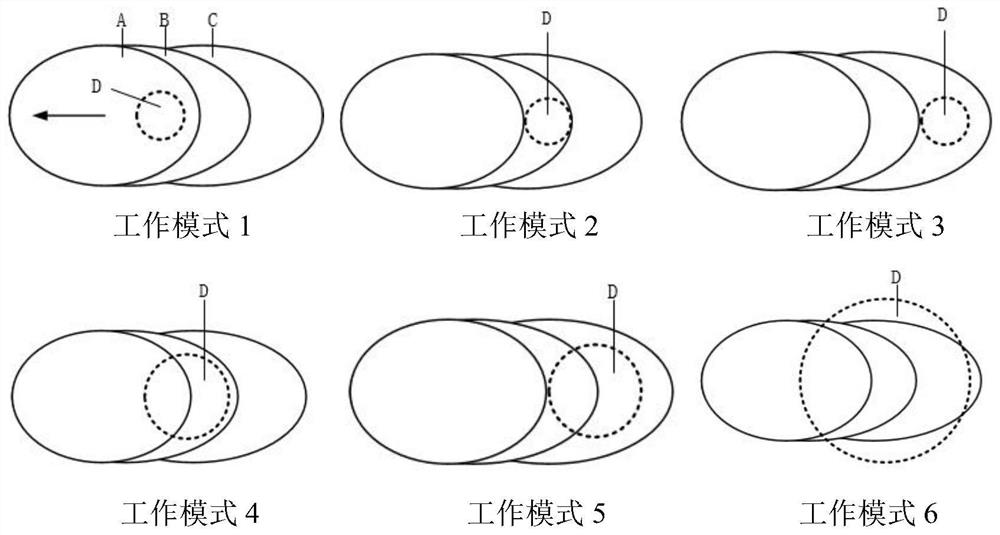

Laser additive and laser shock synchronous composite manufacturing method and system

InactiveCN112496339AReduce anisotropyInhibition formationAdditive manufacturing apparatusCrazingLaser additive manufacturing

The invention discloses a laser additive and laser shock synchronous composite manufacturing method and system. The system comprises a laser additive manufacturing module and a laser shock module; inthe laser additive manufacturing process, a beam of focused laser generated by the laser shock module acts on the surface of a molten pool, a pasty area of the rear edge of the molten pool and the surface of a high-temperature solidification area in real time; and shock waves generated by plasma induction are used for stirring the molten pool, destroying thick dendrites in the paste area and inducing residual stress in the high-temperature solidification area, so that convection of the molten pool is intensified, the temperature gradient is improved, the nucleation rate of the paste area is increased, and defects such as cracks in the high-temperature solidification area are relieved. Therefore, efficient laser additive manufacturing of high-performance metal parts can be achieved throughthe force-heat coupling effect of laser additive and laser shock synchronous compounding.

Owner:CHINA UNIV OF MINING & TECH

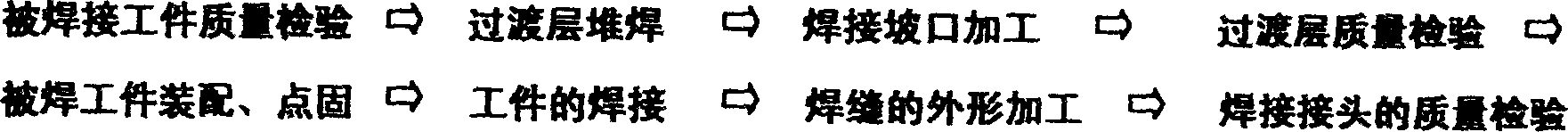

High carbon steel rail and high manganese steel frog welding technology

InactiveCN1442265AEasy to trainLess investmentWelding/cutting auxillary devicesAuxillary welding devicesShielded metal arc weldingHigh carbon

A technology for welding high-C steel rail and high-Mn steel switch fork of railway includes such steps as build-up welding of Cr-Ni-Mo alloy transition layer on the steel rail, build-up welding of Mn-Cr-Ni alloy transition layer on the switch fork and solid dissolving, matching their U-shaped bevel joint surfaces, and manual arc welding. Its advantages are high welding quality and stability and low cost.

Owner:唐山铁路道岔厂 +1

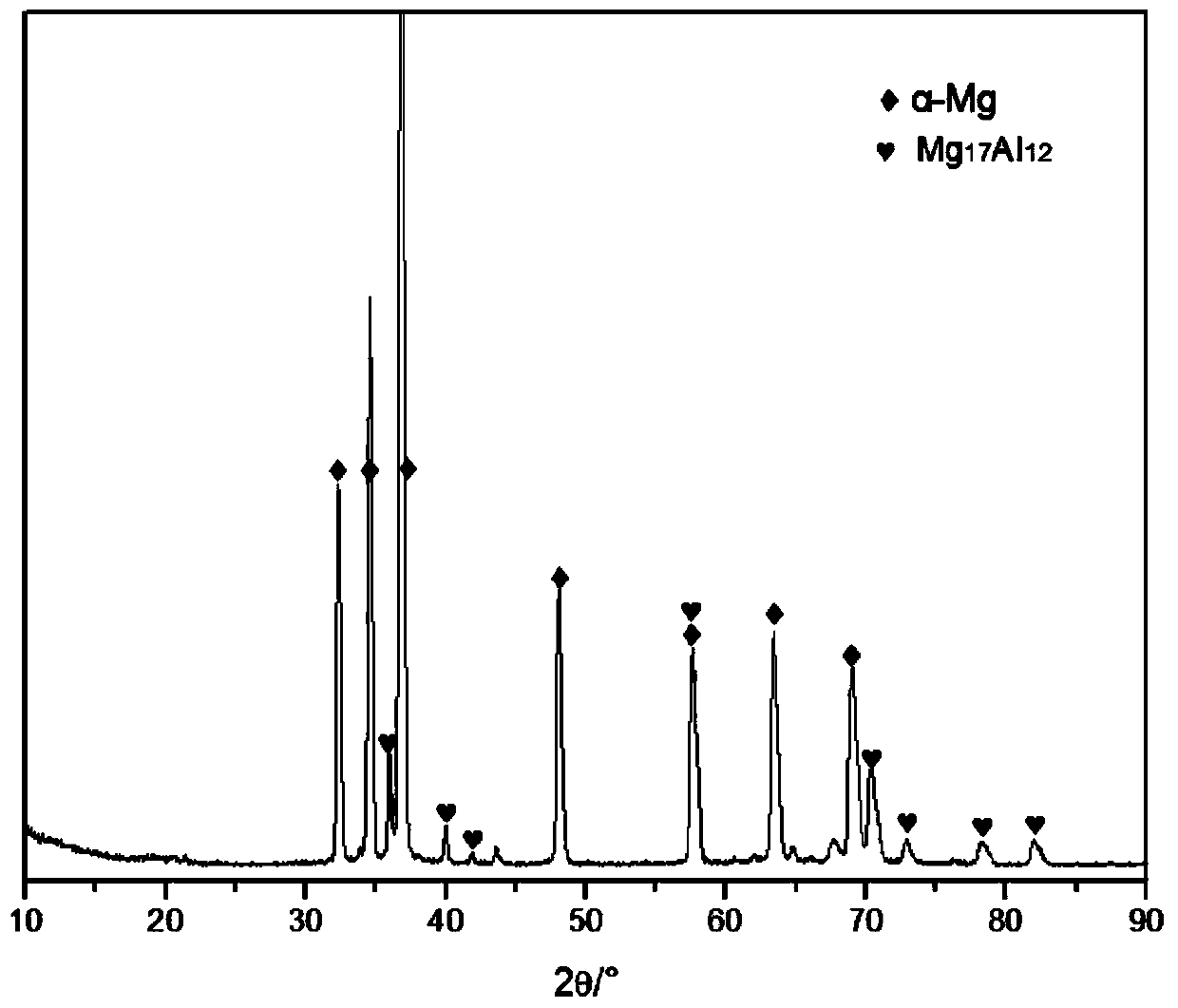

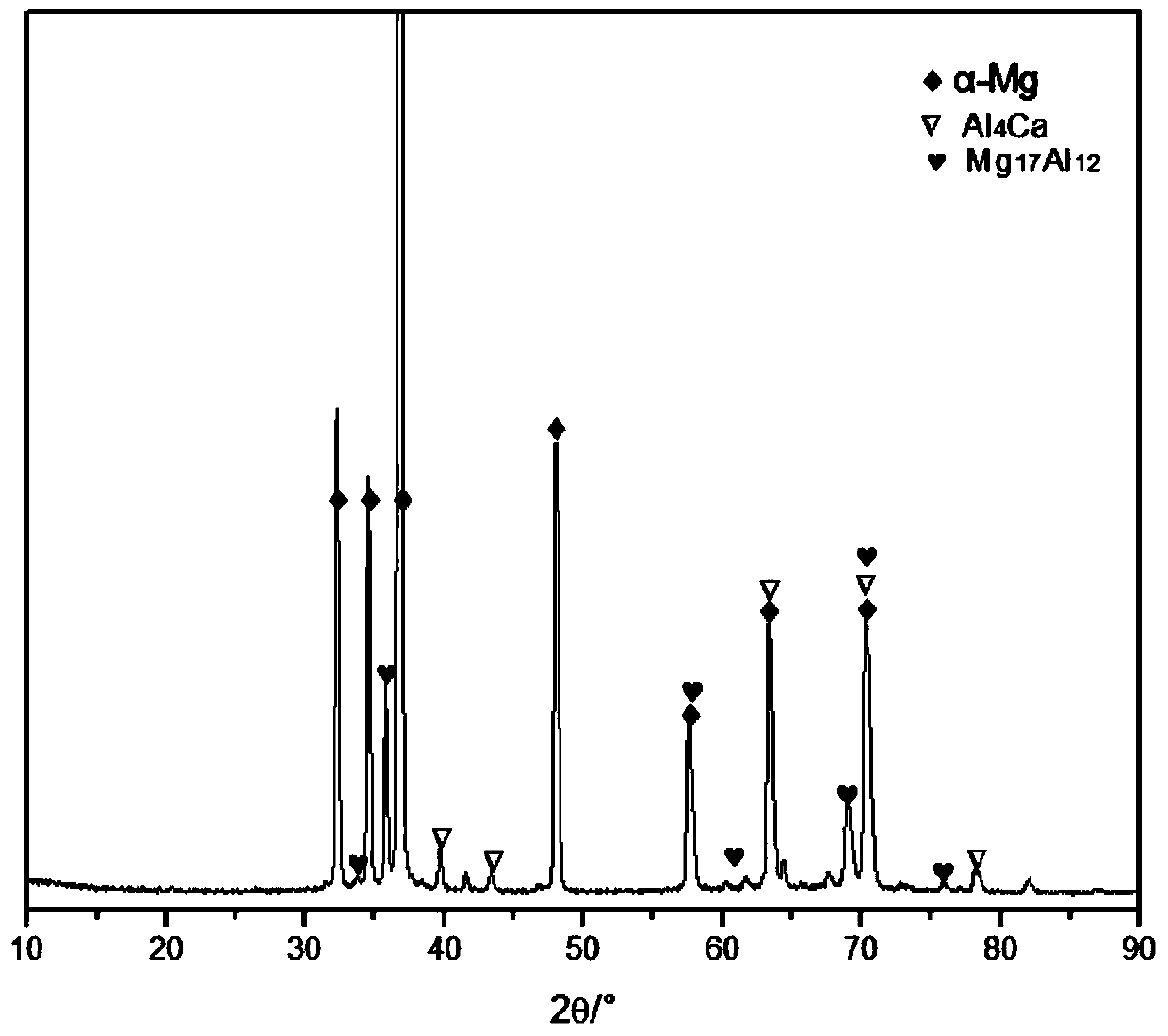

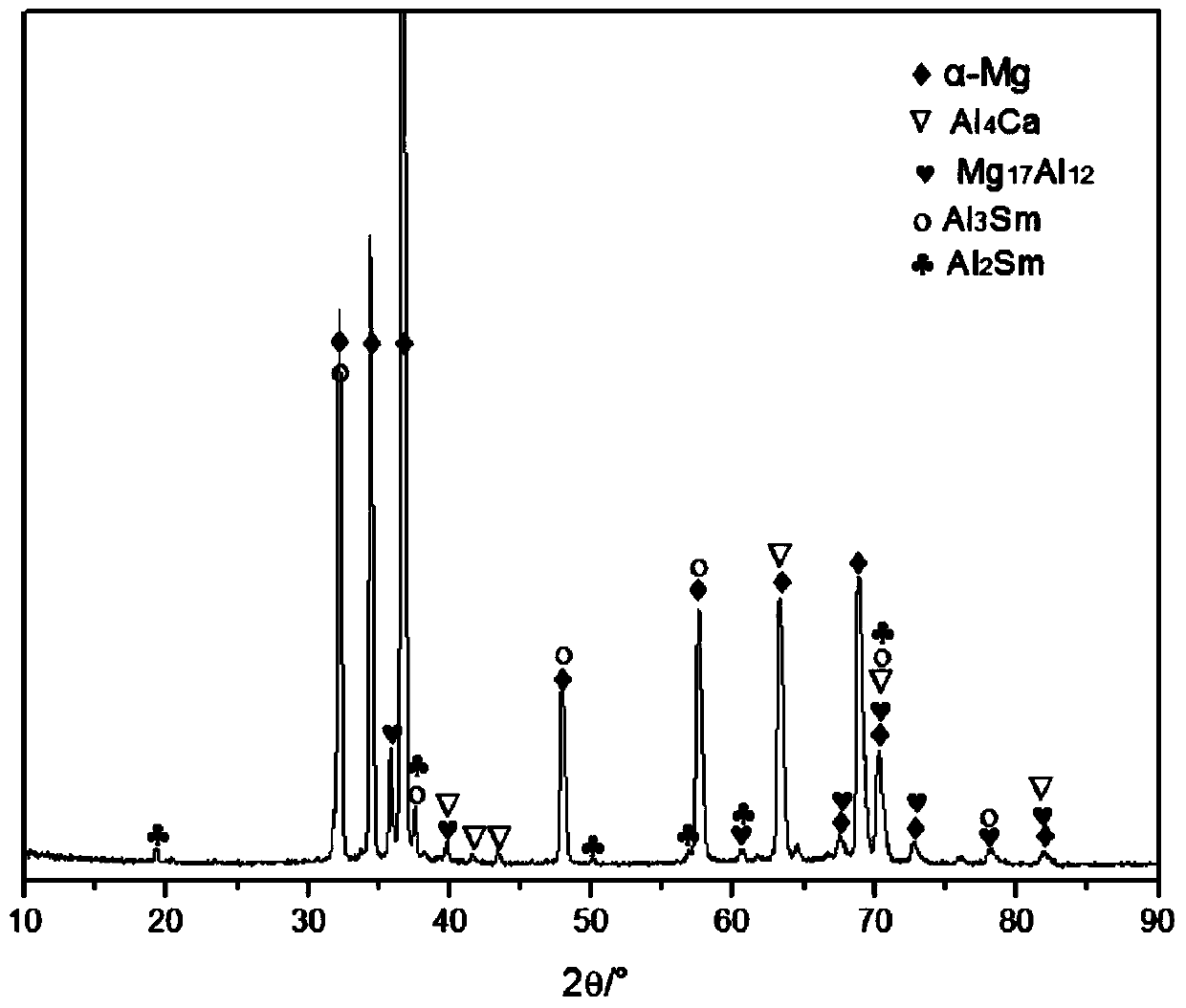

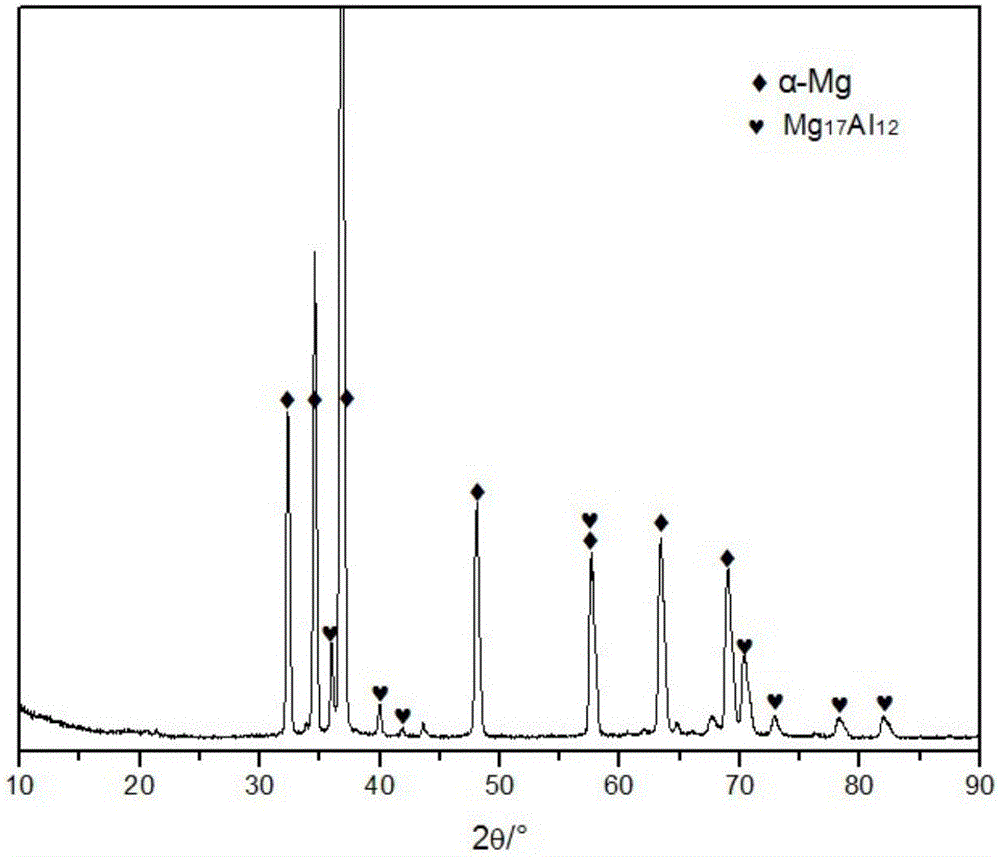

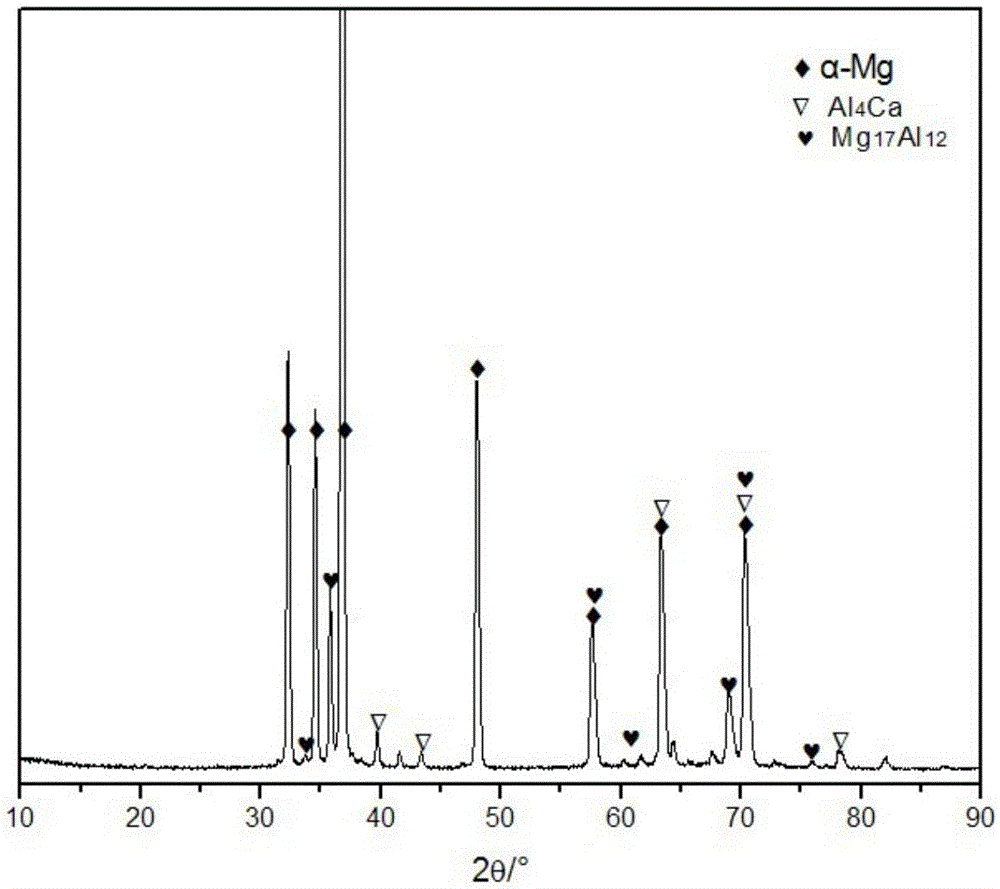

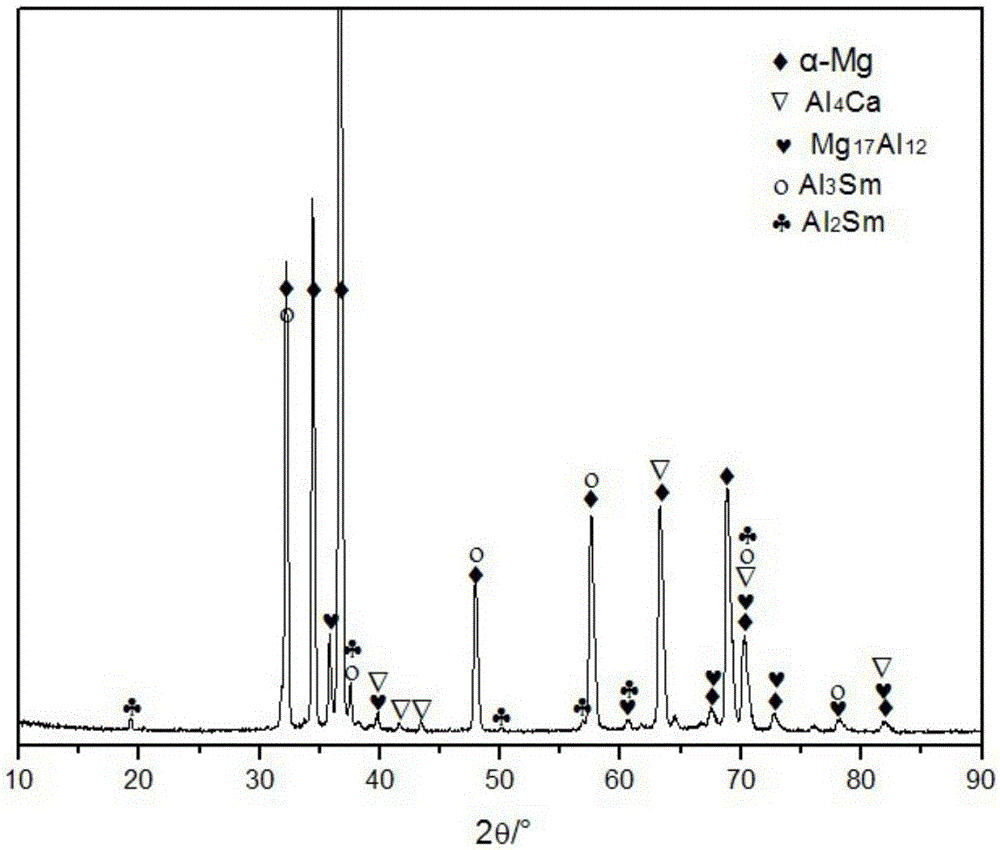

Magnesium-aluminum-zinc wrought magnesium alloy containing calcium and rare-earth samarium

InactiveCN103469039AGood casting performanceImprove antioxidant capacityRare earthThermal deformation

The invention relates to a magnesium-aluminum-zinc wrought magnesium alloy containing calcium and rare-earth samarium. The wrought magnesium alloy comprises the following components by mass percent: 5.3% to 6.0% of Al (aluminum), 0.7% to 1.0% of Zn (zinc), 0.4% to 0.5% of Ca (calcium), 0.2% to 1.5% of Sm (samarium), less than or equal to 0.15% of inevitable impurities and the balance of Mg (magnesium), wherein all the components taken as raw materials in proportion are fused and rapidly cooled in a salt bath; an obtained alloy spindle is annealed in a homogenization manner at 400 DEG C and air-cooled to reach a room temperature; then the hot extrusion is carried out on the alloy spindle at 360 DEG C according to the extrusion ratio being 25:1, so that the magnesium-aluminum-zinc wrought magnesium alloy containing the calcium and the rare-earth samarium is obtained. After the thermal deformation is carried out on the magnesium alloy, the tensile strength and the yield strength of the magnesium alloy are improved. Thus, the foundation for actual production applications of the wrought magnesium alloy is laid.

Owner:CHONGQING UNIV

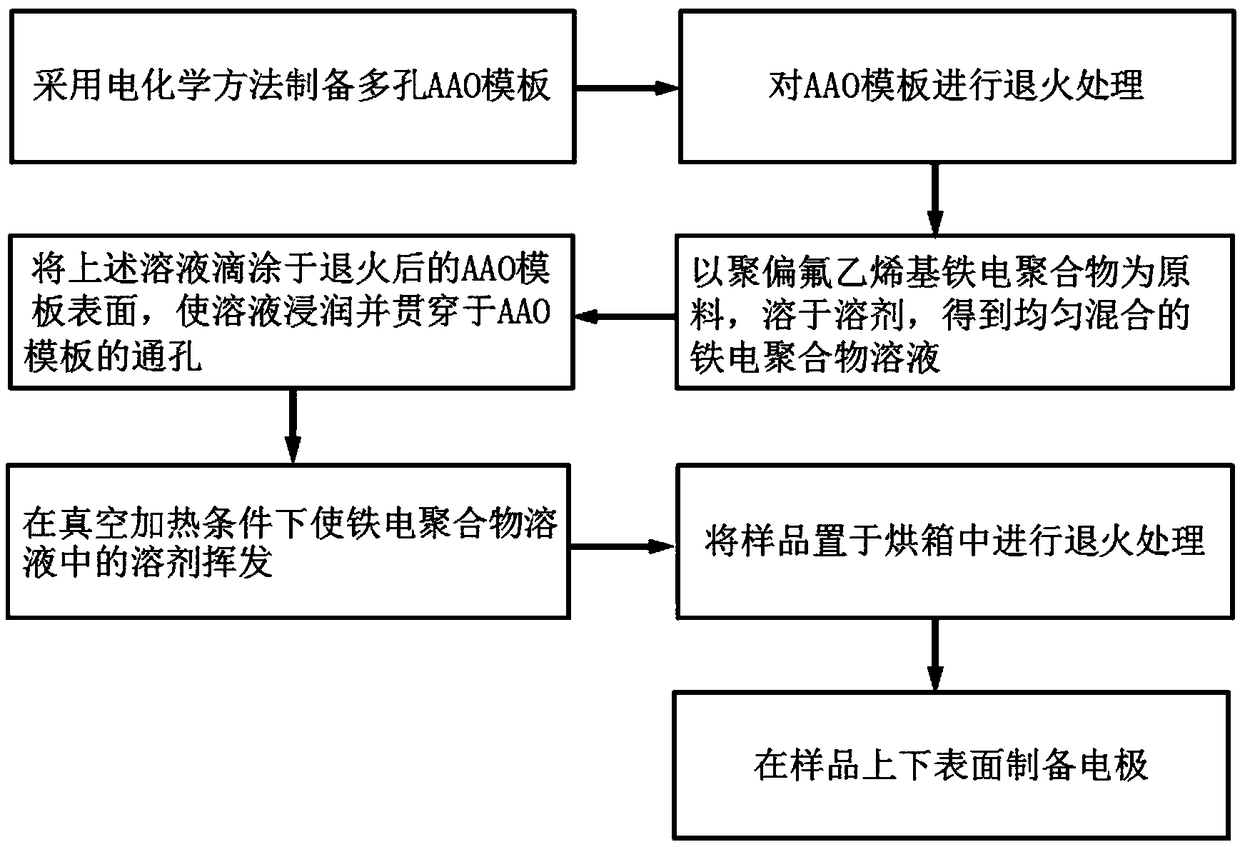

Ferroelectric polymer electric card material and preparation method thereof

InactiveCN108192247ASolve the problem of difficult heat conductionImprove the strength of the electric cardSurface reaction electrolytic coatingNanotechnologyFerroelectric polymersPolyvinylidene difluoride

The invention discloses a ferroelectric polymer electric card material and a preparation method thereof, wherein the ferroelectric polymer electric card material is a polyvinylidene fluoride (PVDF) based ferroelectric polymer electric card nanowire array; the PVDF based ferroelectric polymer electric card nanowire array is also embedded into a porous anodic aluminum oxide (AAO) template. Accordingto the preparation method, a PVDF based ferroelectric polymer electric card material is controlled to form the nanowire array; the nanowire array is also embedded into the porous anodic aluminum oxide AAO template; the ferroelectric polymer nanowire array is prepared in the porous anodic aluminum oxide AAO template through a solution infiltration method, and through improving the morphology, structure, internal microscopic joint construction and the like of a key ferroelectric polymer, in comparison with the prior art, the problems that the strength of a ferroelectric polymer electric card islow, the heat conduction in the electric card material is difficult and the refrigeration power density of an electric card device is low and the like are effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

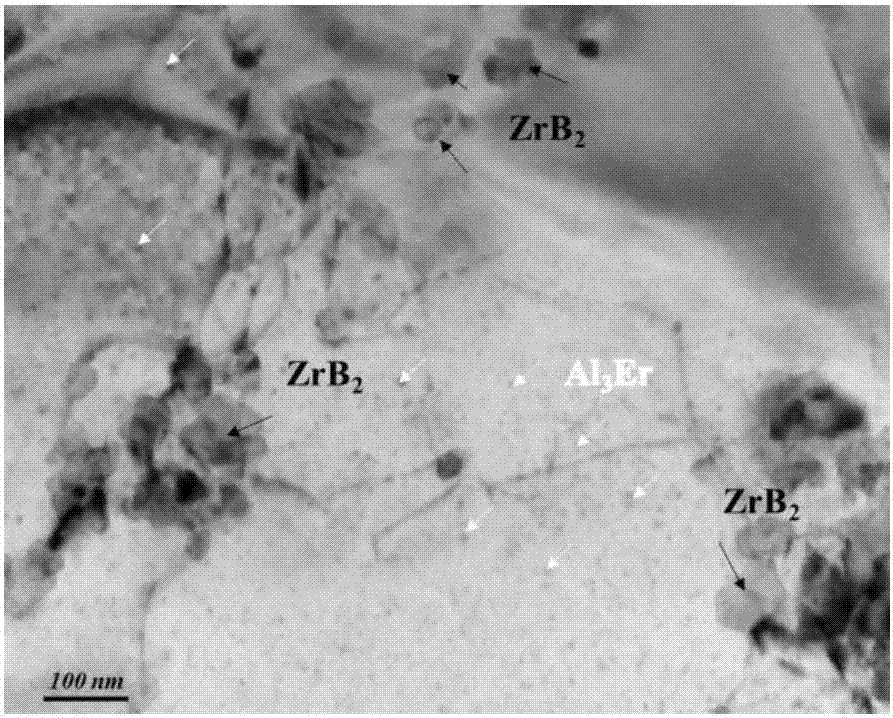

High-strength anti-fatigue in-situ nano strengthening aluminum alloy and die casting method thereof

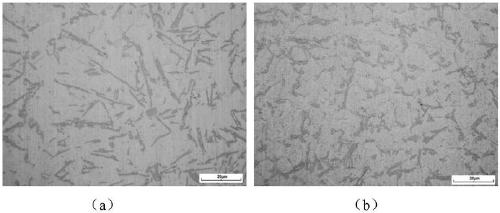

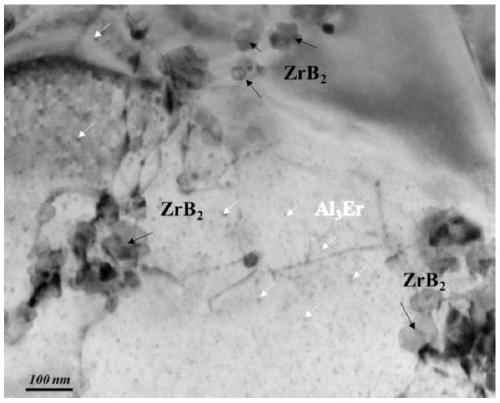

ActiveCN107267817AHigh strength anti-fatigueStrong anti-fatigueTransportation and packagingMetal-working apparatusDie castingHigh intensity

The invention relates to an aluminum matrix composite, in particular to high-strength anti-fatigue in-situ nano strengthening aluminum alloy and a die casting method thereof. In-situ nano strengthening and alloy component control are conducted, and an optimized nonlinear high-pressure die casting process is combined, so that the die casting is obtained. With the help of the scale effect, the interface effect and the heterogeneous nucleation effect of an in-situ nano ZrB2 reinforcement and a nano Al3Er precipitated phase, the strength, the anti-fatigue performance and the damping performance of the alloy are significantly improved; at the same time, the content of the elements Mg, Zn and Fe is increased, the elements Mn and Ni are introduced, the strengthening phase content is increased, the high strength is obtained, meanwhile, Al-Fe and other harmful coarse precipitated phases are effectively refined and rounded, and the good die casting performance of the alloy is ensured; and thus, a component produced through the high-strength anti-fatigue in-situ nano strengthening aluminum alloy and the die casting method thereof has the characteristics of being high in strength, plasticity, anti-fatigue performance and damping performance, and good in die casting performance.

Owner:JIANGSU UNIV +1

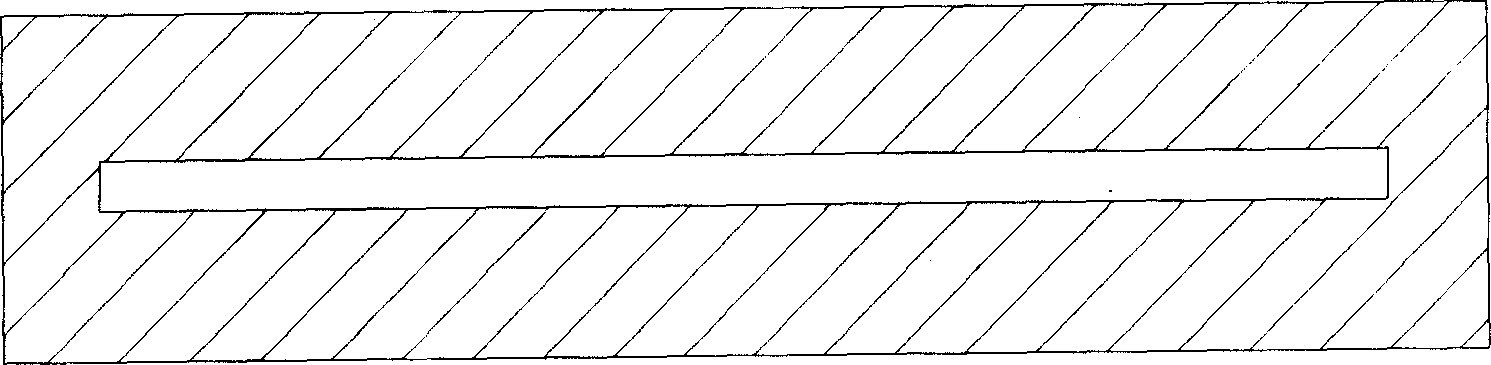

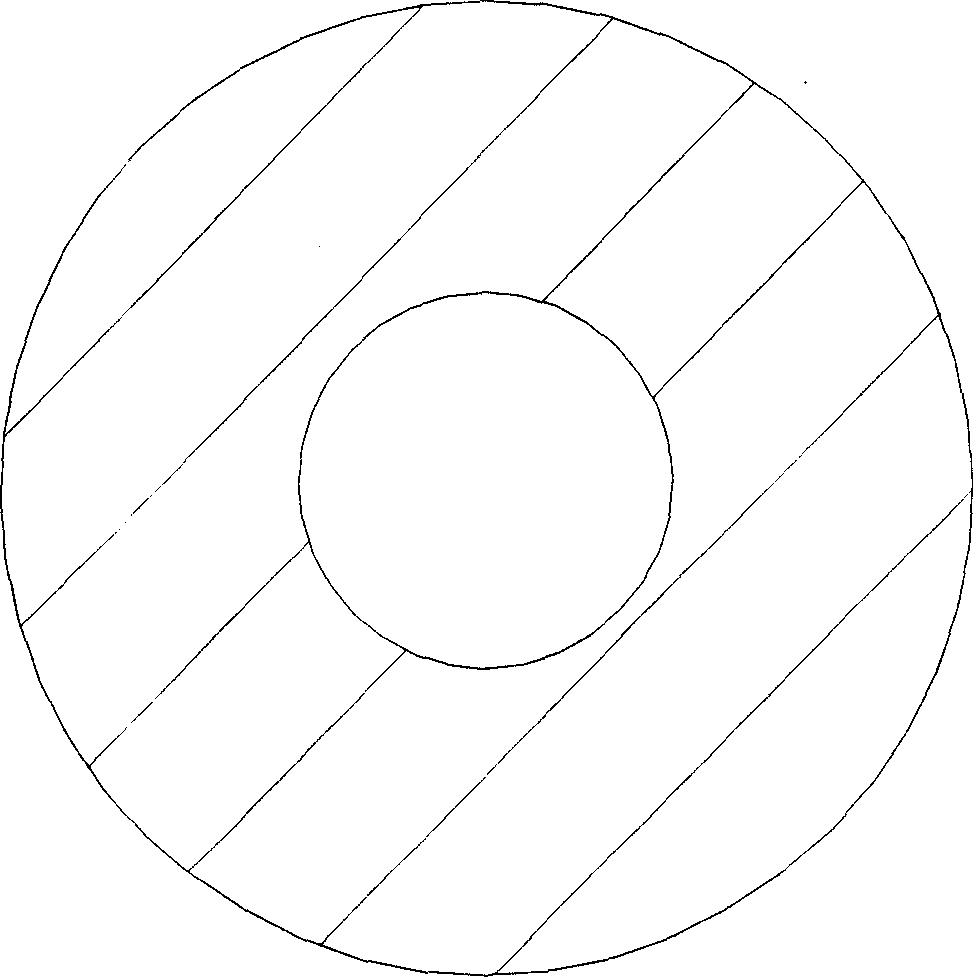

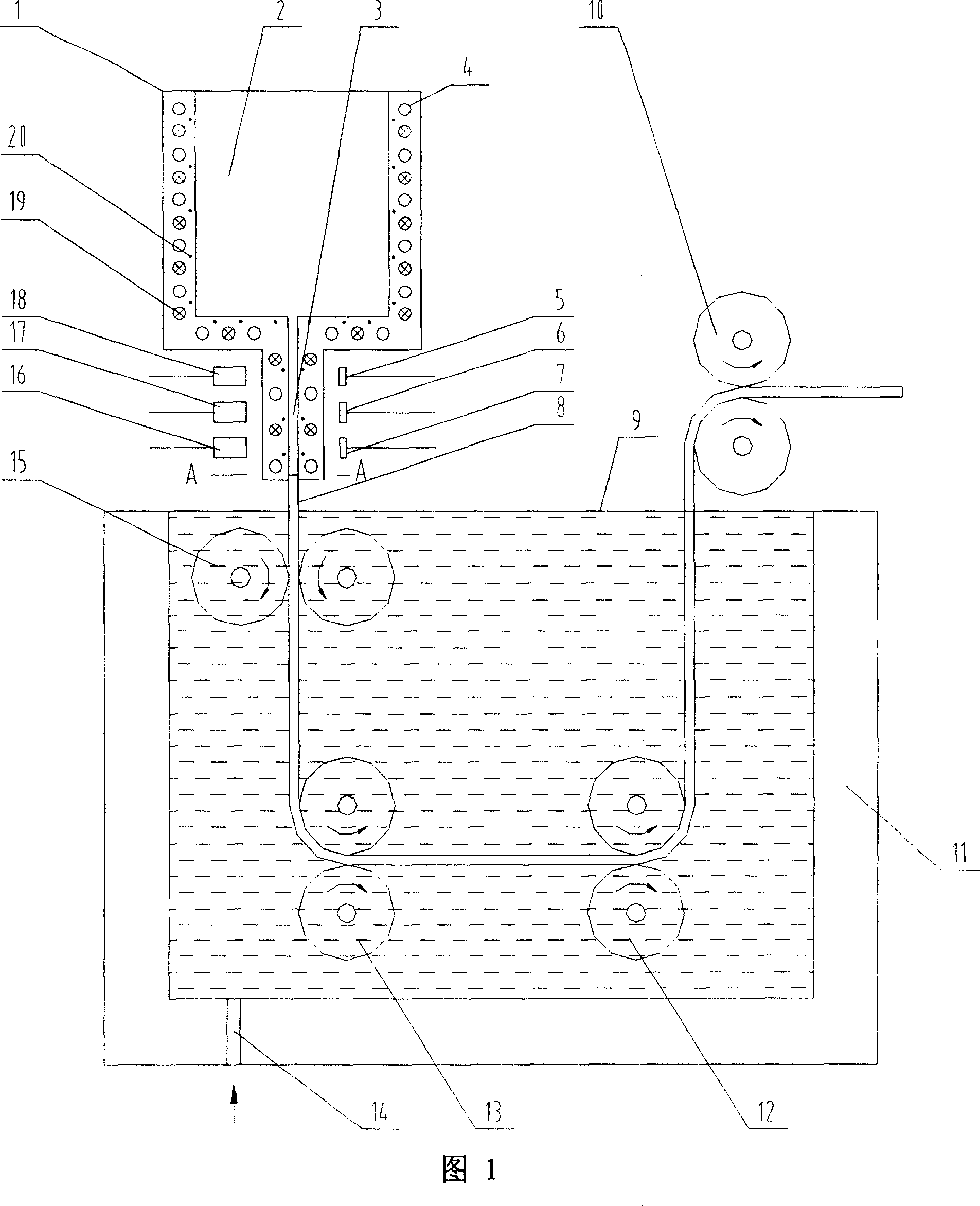

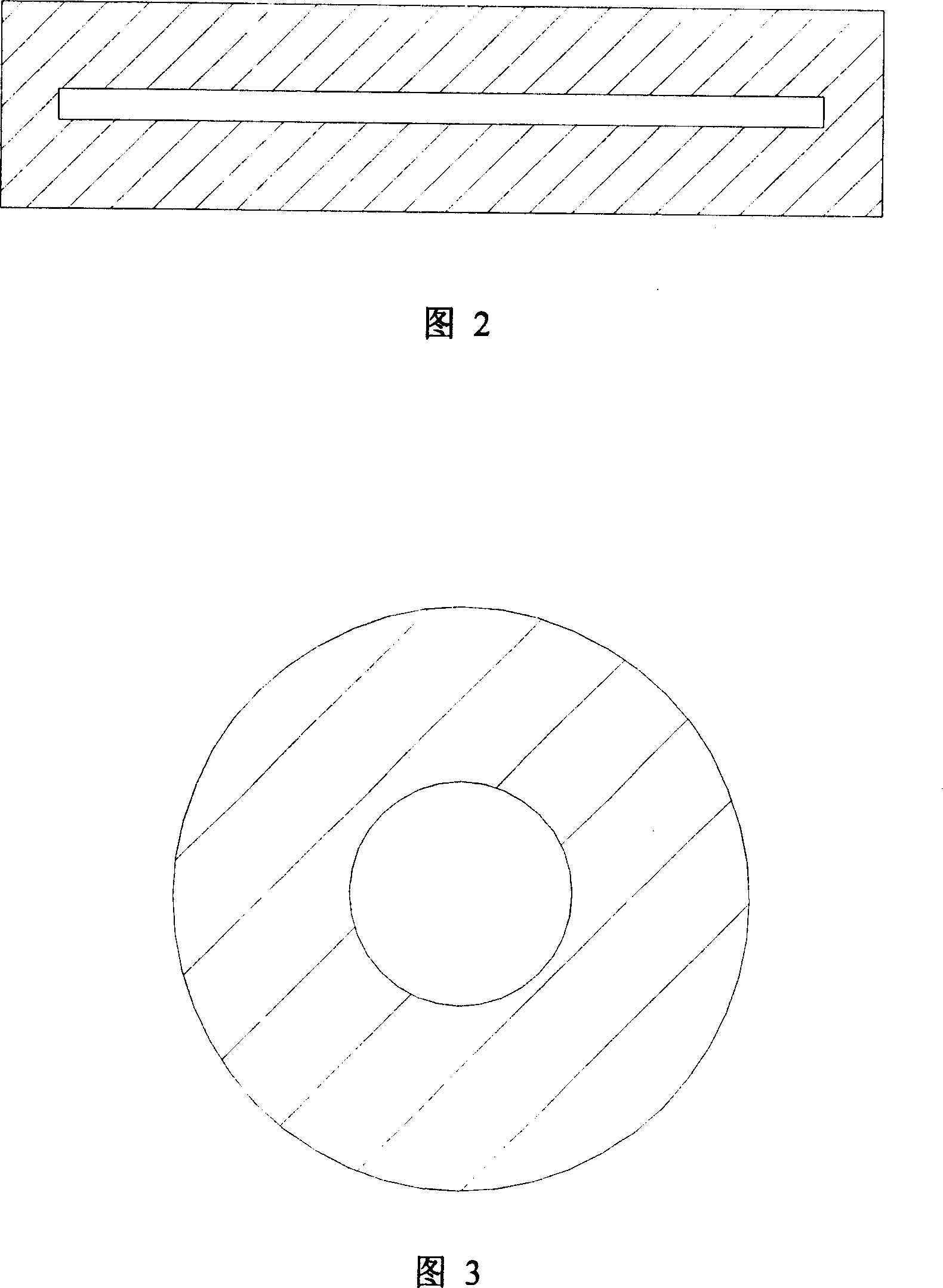

Method and equipment for successive co-orientation solidification casting and manufactured wire rod or plate and belt material

A casting method by continuous directional solidifying includes extending one end of drawing line or plate in crystallizing mouth, extending its another end is cooling liquid, preheating the crystallizer, pouring fluid material in the crystallizer, insulating for directional solidifying, and drawing said drawing line or plate to draw the solidified material in cooling liquid. Its apparatus is composed of crystallizer, drawing line or plate, cooling unit, drawing unit and check unit. Its product (wire or plate) features high quality and uniformity, and excellent performance.

Owner:周照耀

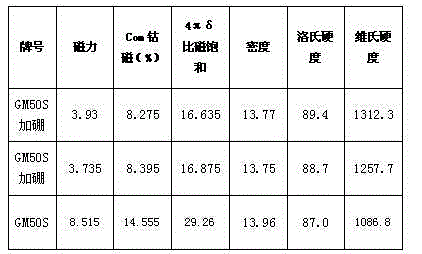

Preparation method for high-abrasion-resistance hard alloy

The invention discloses a method for preparing high wear-resistant cemented carbide. The parts by weight of each component in the raw material are: 83-90 parts of WC powder with a Fisher particle size of 1.2-2.0 μm, and a Fisher particle size of 0.6-1.0 μm Co powder 10-17 parts, B powder 0.7-1.0 parts, C powder 0.2-1.0 parts; the process steps of the high wear-resistant cemented carbide are: (1) select each material component; First add B powder, C powder and Co powder for stirring and grinding; (3) Then add tungsten carbide for grinding; (4) Filtration and drying; (5) Molding or extrusion or injection molding; (6) Sintering molding The sintering temperature is 1400-1425° C., the Ar pressure is 8-10 MPa, and the sintering time is 30-100 min. Practice has proved that the service life of the high wear-resistant cemented carbide of the present invention is 2 to 3 times that of ordinary cemented carbide.

Owner:河南大地合金有限公司

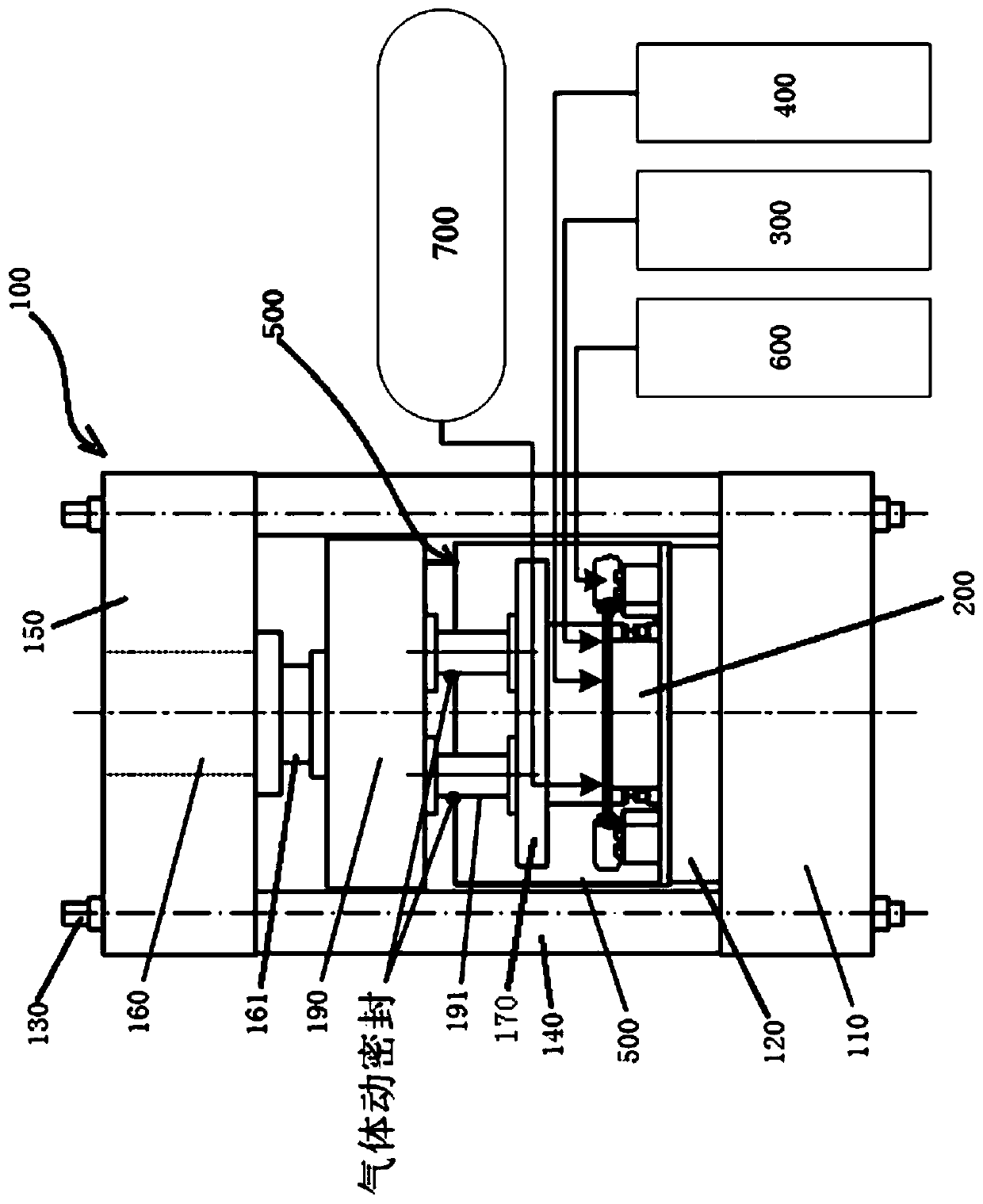

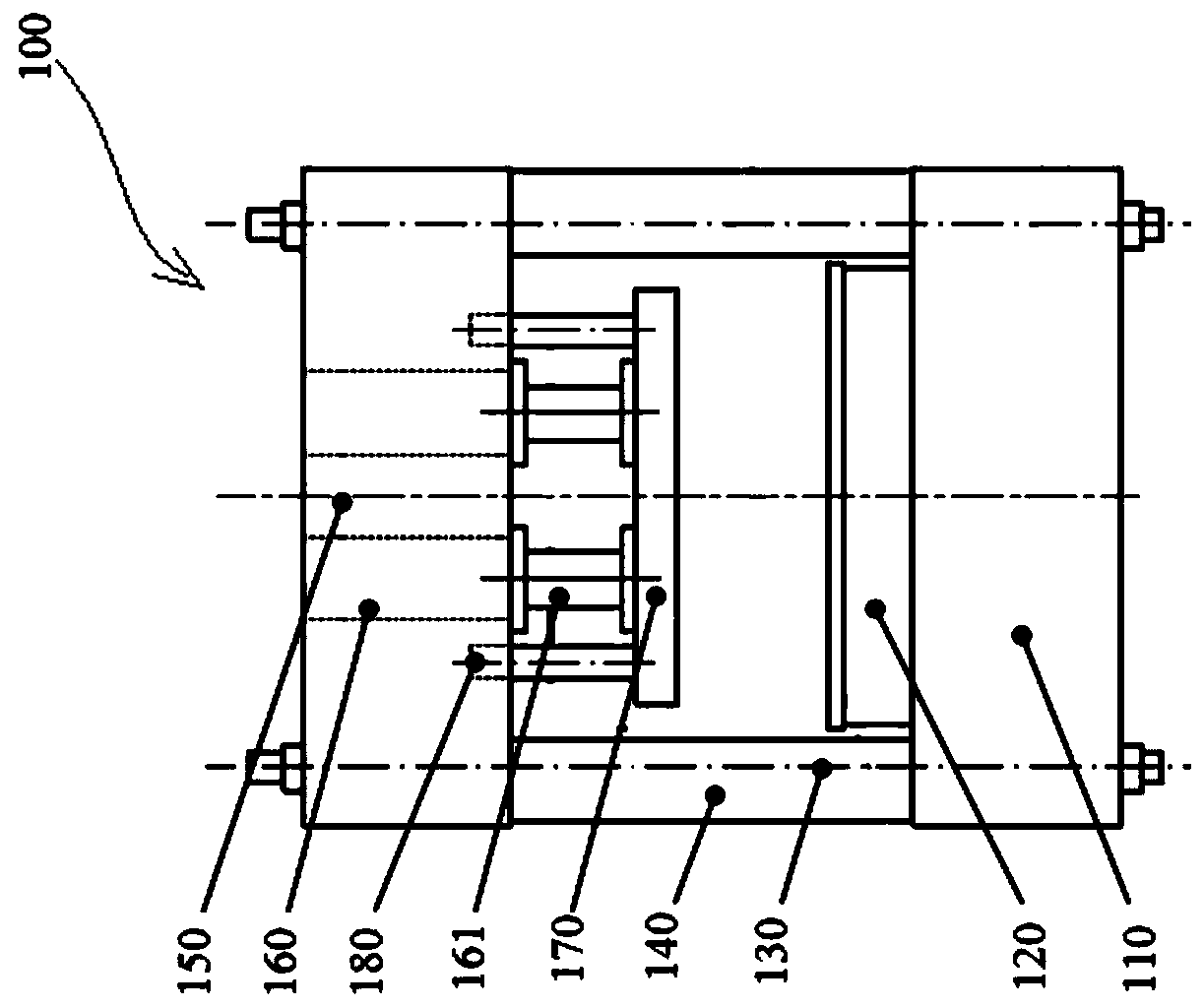

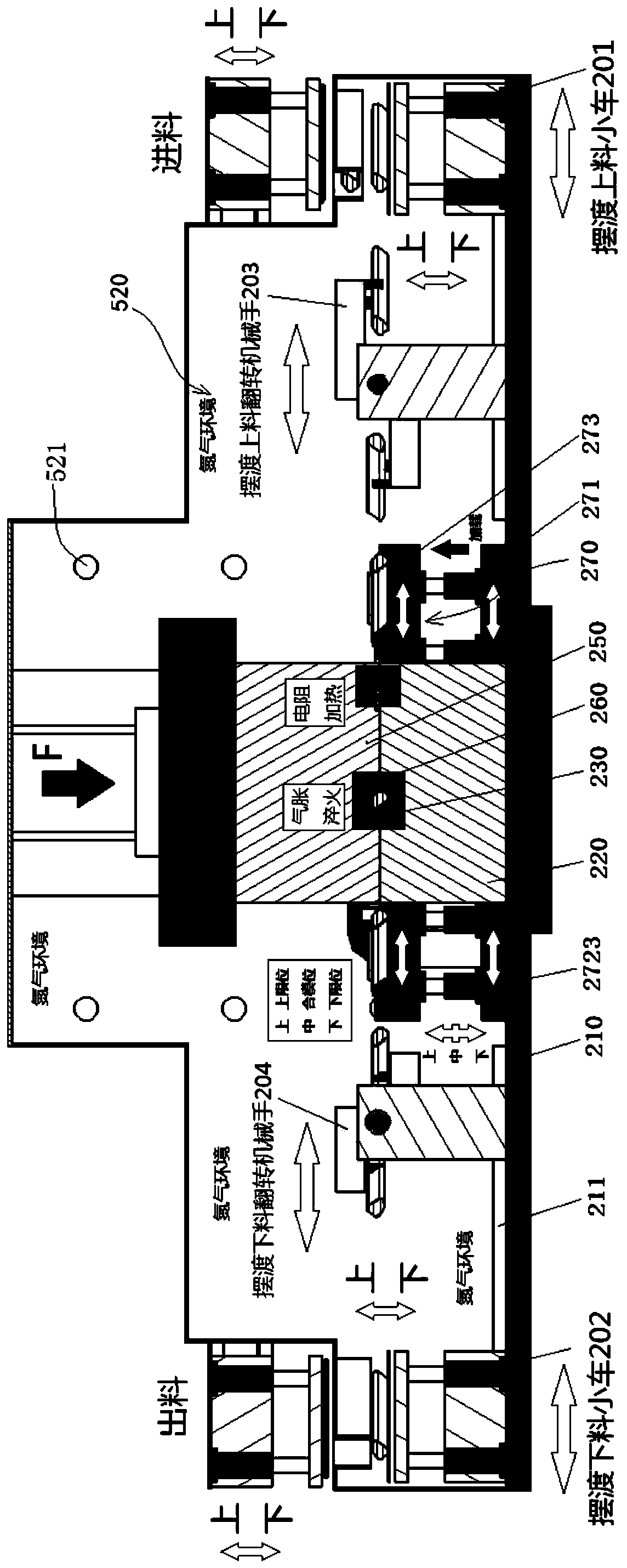

Hot metal gas forming and quenching system and process

ActiveCN111203467ALow costLess organizational defectsShaping toolsMetal-working feeding devicesQuenchingHydraulic press

The invention relates to a hot metal gas forming and quenching system. The system involves a hydraulic machine, a die assembly, a rapid heating module and a rapid cooling module, wherein the die assembly comprises a progressive die, and hot gas forming and rapid cooling of a workpiece can be achieved. The invention further provides a hot metal gas forming and quenching process. The hot metal gas forming and quenching system has the following advantages that 1, a pipe is manufactured by adopting an uncoated plate, so that the cost is lower, and the structure defects and the process risk are less than those of a pipe made of a coated and plated metal plate; 2, the progressive die is adopted, a resistance heating procedure and a hot gas forming and quenching procedure are achieved at the sametime in parallel, and progressive feeding is adopted, so that the takt is fast, and the efficiency is greatly improved; 3, the heating state of a part is protected in the whole process, oxidation isprevented, a coating is not needed, and the workpiece can be directly welded to a vehicle body without shot blasting after being formed, so that the cost is greatly saved; and 4, safety protection measures with directional damage are adopted, so that the safety is improved.

Owner:INTELLIGENT AEROSPACE MFG TECH BEIJING CO LTD

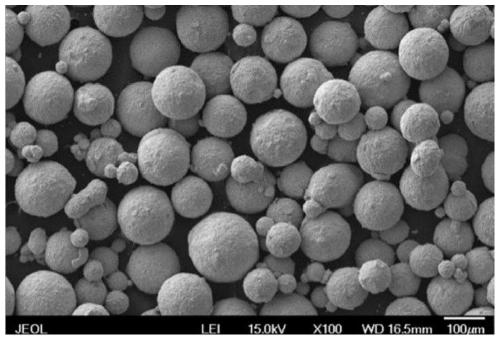

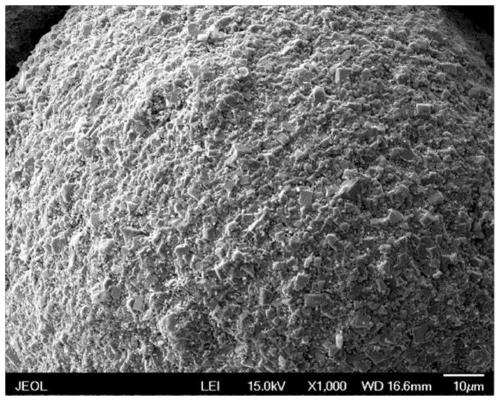

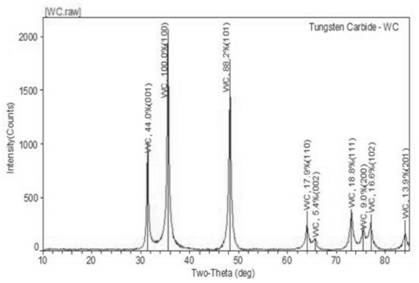

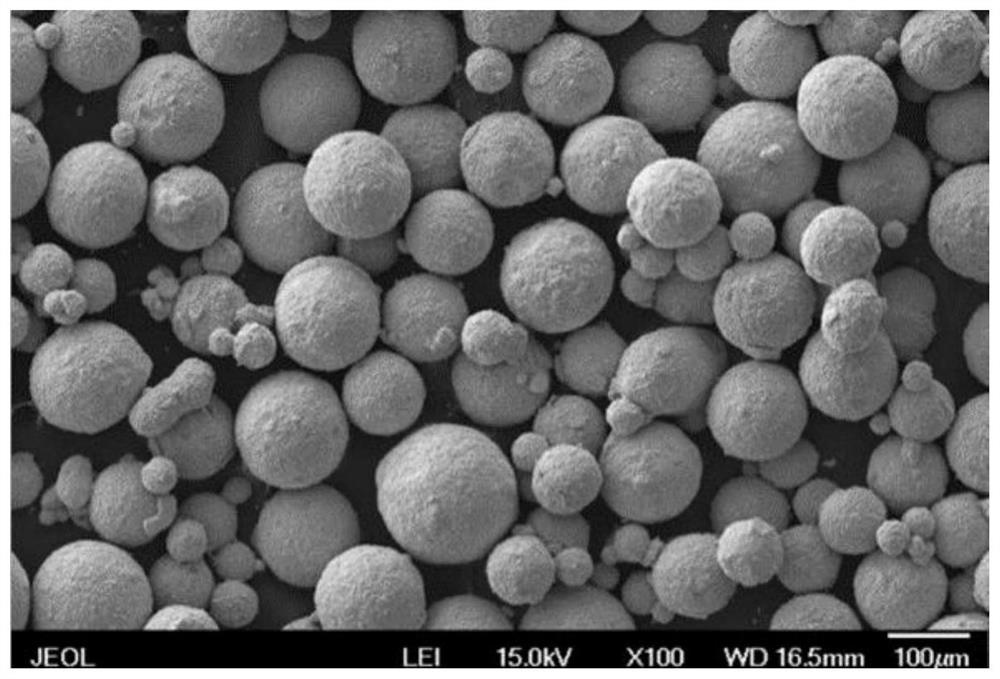

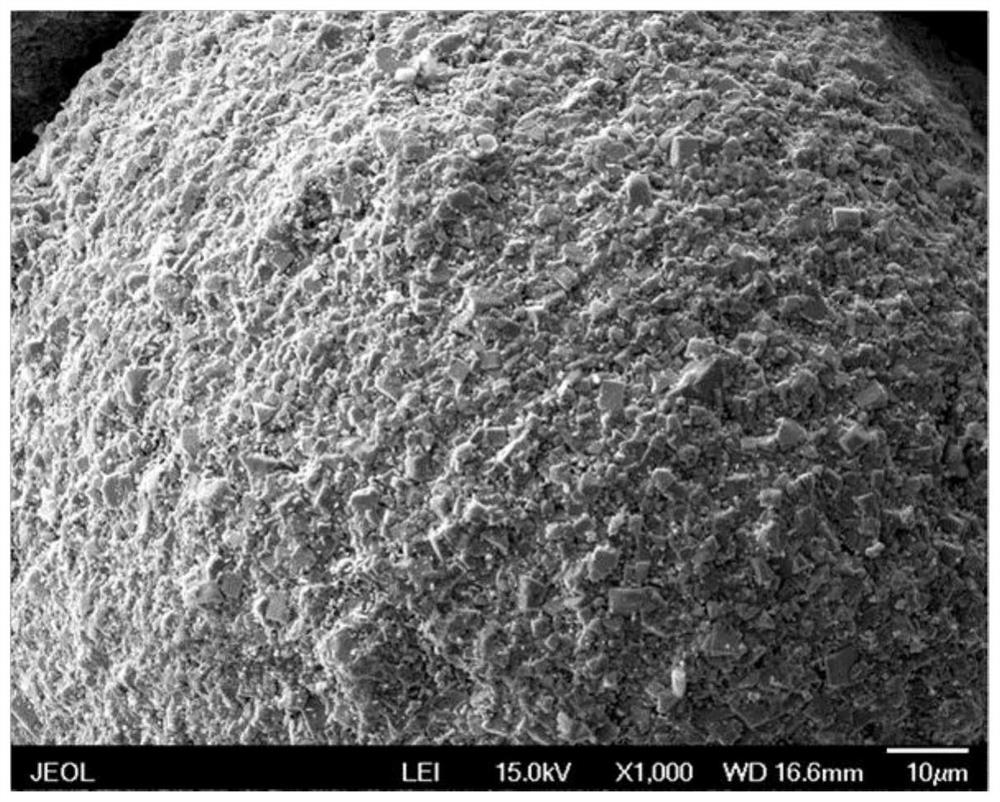

Powder material for 3D printing

ActiveCN110385430AHigh hardnessHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyWear resistantAlloy

The invention provides a powder material for 3D printing. The powder comprises a wear-resistant phase and a binding phase, wherein a mixture of sintered WC-Co hard alloy spherical particles and tungsten carbide particles serves as the wear-resistant phase, and Co-based alloy serves as the bonding phase. The weight percentage of the wear-resisting phase is 20-60%, the weight percentage of the bonding phase is 40-80%, the weight percentage of the sintered WC-Co hard alloy spherical particles is 5-15%, and the weight percentage of the coarse-grained or monocrystalline tungsten carbide particles is 15-45%. The failure period can be effectively avoided or delayed, and the wear resistance and working efficiency of the material are improved.

Owner:SEED TECH CORP LTD

Seawater erosion abrasion and biologic defiling resistant composite ceramic powder for hot spraying and preparation therefor

The invention discloses a hot spraying composite ceramic power of sea water corrosive wear resistant and biological defilement resistant and the preparing method. The composite ceramic power comprises 95%-98% material power and 2%-5% binder; the material power comprises 80%-95% reference-phase structure which comprises oxide ceramic principal phase component and close structure accessory component and 5-20% biological defilement resistant component; the oxide ceramic reference-phase structure comprises 80%-90% Cr2O3 and 10%-20% TiO2 or TiO2+Al2O3. The composite ceramic power comprises the following steps: proportioning; drying with atomise; high-sintering; screening. The invention is provided with the simple process, safety and the low cost.

Owner:WUHAN UNIV OF TECH

A chrome-zirconium-copper contact wire for electrified railways and its processing technology

ActiveCN104342575BMaximum total rolling deformationLow costSingle bars/rods/wires/strips conductorsMetal/alloy conductorsContact lineSolid solution

The invention discloses a preparation method of an electrified railway chromium-zirconium-copper contact line. Copper is taken as a substrate, 0.30-0.70% of Cr and 0.10-0.35% of Zr in percentage by weight are added into the substrate, and the total sum of impurities is no greater than 0.05%. The preparation method comprises the following steps: performing vacuum melting and vacuum horizontal continuous casting, thereby obtaining a long-length large cross section chromium-zirconium-copper continuous cast blank; performing full hot continuous rolling and on-line solid solution, thereby obtaining a long-length chromium-zirconium-copper line rod disc; drawing and peeling the disc, and performing cold continuous rolling, thereby reducing the diameter; further performing aging treatment to reinforce the disc; further performing cold continuous rolling by using a Y-type rolling machine, thereby pre-forming the line; and finally performing fine drawing formation once. The chromium-zirconium-copper contact line produced by using the preparation process is fine and uniform in grain, free of defect, high in strength, high in conductivity and high in softening temperature, and applicable to industrialized production.

Owner:YANTAI WANLONG VACUUM METALLURGY

Electric railway contact line and machining process thereof

InactiveCN105063410AReduce transmission lossConducive to energy saving and emission reductionMetal/alloy conductorsCable/conductor manufactureCeriumContact line

The invention discloses an electric railway contact line and a machining process thereof. The raw materials include 0.08-0.40% of zirconium, 0.05-0.10% of cerium, 0.05% of total impurities or less and the balance copper. According to the machining process of the contact line, a large-length and large-section continuous casting billet is obtained through vacuum melting and vacuum horizontal continuous casting; a large-length wire rod is obtained through full hot continuous rolling and on-line solid solution; the wire rod is subjected to drawing and stripping and then subjected to thermo-mechanical treatment for reducing; aging treatment reinforcement is carried afterwards; cold continuous rolling pre-formation is carried out at room temperature through a Y-type rolling mill; finally, finish drawing formation is carried out. The electric railway contact line produced through the process is fine and uniform in grain, free of defects, high in strength, electric conductivity and softening temperature and suitable for large-scale industrial production.

Owner:YANTAI WANLONG VACUUM METALLURGY

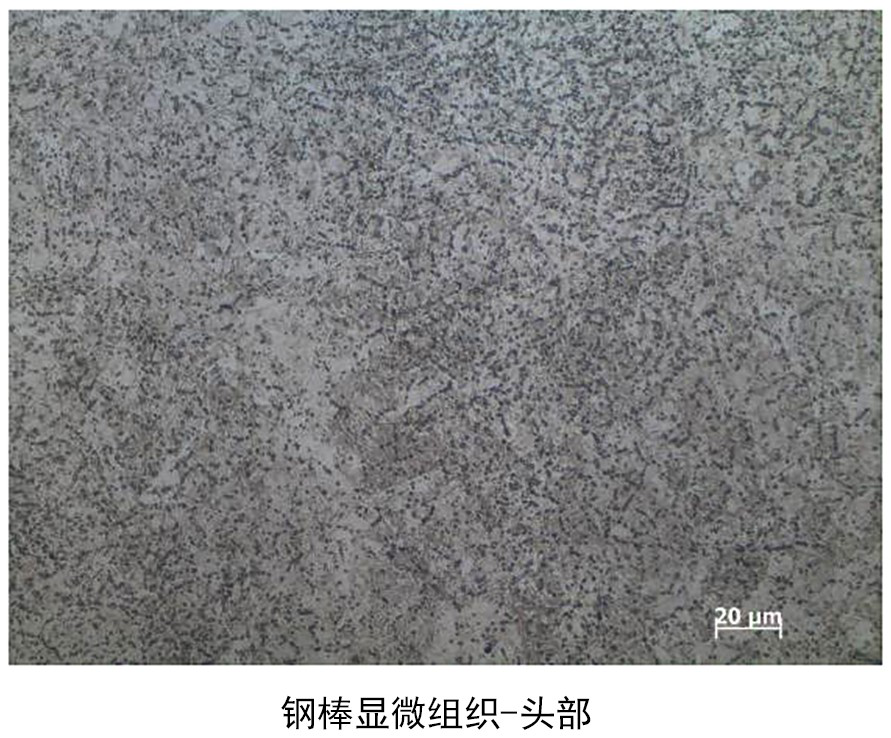

A method for preparing a low-defect high-performance high-speed steel wire

InactiveCN108220583APrevent precipitationImprove organizational qualityFurnace typesHeat treatment furnacesHigh-speed steelCooling speed

The invention relates to a method for preparing a low-defect high-performance high-speed steel wire. The method can eliminate structure defects of the high-speed steel wire and can improve wire structure quality and performance. The method is mainly characterized in that after high-speed steel is heated to 840-900 DEG C and fully austenitized, the steel is rapidly cooled to 730-780 DEG C at a cooling speed of not less than 2 DEG C / min, is maintained at the temperature for 30 min to 6 h, and then is cooled in a furnace to about 500 DEG C, and then a product is discharged from the furnace. The high-speed steel wire produced by the method has advantages of few structure defects, high structure quality, and the like and has good comprehensive mechanical performance.

Owner:SOUTHEAST UNIV

Method for carbonitriding on stainless steel surface

InactiveCN111500971AUniform steel structureFully release the stressSolid state diffusion coatingRare-earth elementTempering

The invention discloses a method for carbonitriding on a stainless steel surface. By quenching and tempering and ion implanting of rare earth elements on the stainless steel surface, the temperature,carbon potential and ammonia flow rate in a carbonitriding process can be fully controlled. A thickness and a microstructure of a carbonitriding layer on the stainless steel surface can be effectivelycontrolled, and stainless steel products with high strength, high hardness, good wear resistance and excellent fatigue resistance can be obtained. The method for carbonitriding on the stainless steelsurface has the good advantages of short production cycle, simple method and high production efficiency and can be applied to industrial production.

Owner:广州珈鹏科技有限公司

High abrasion-resistant hard alloy

The invention relates to a high abrasion-resistant hard alloy. The high abrasion-resistant hard alloy is prepared by mixing, granulating and sintering of raw materials of, by weight, 83-90 parts of WCpowder with the fisher particle size being 1.2-2.0 [mu]m, 10-17 parts of Co powder with the fisher particle size being 0.6-1.0 [mu]m, 0.7-1.0 part of B powder and 0.2-1.0 part of C powder. Accordingto the prepared high abrasion-resistant hard alloy, B and C are added in the raw materials and se rve as crystal material inhibitors, crystal material refining of the alloy structure is guaranteed, and abrasion resistance of prepared bar materials is enhanced effectively.

Owner:天津明源机械设备有限公司

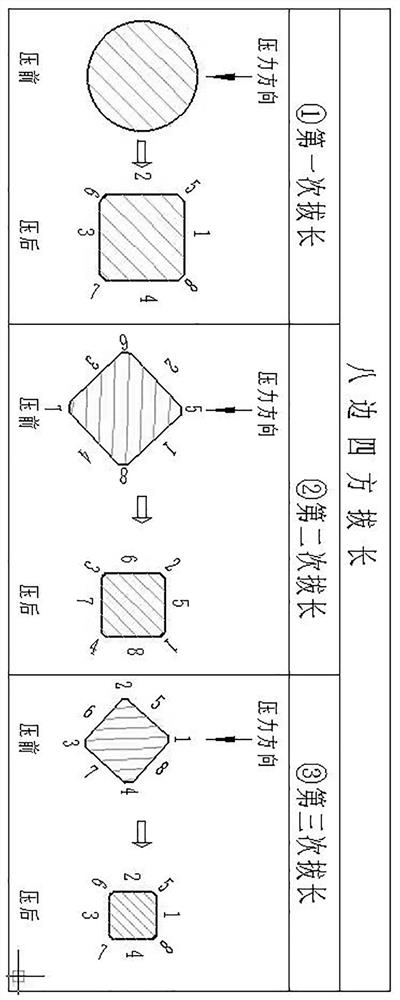

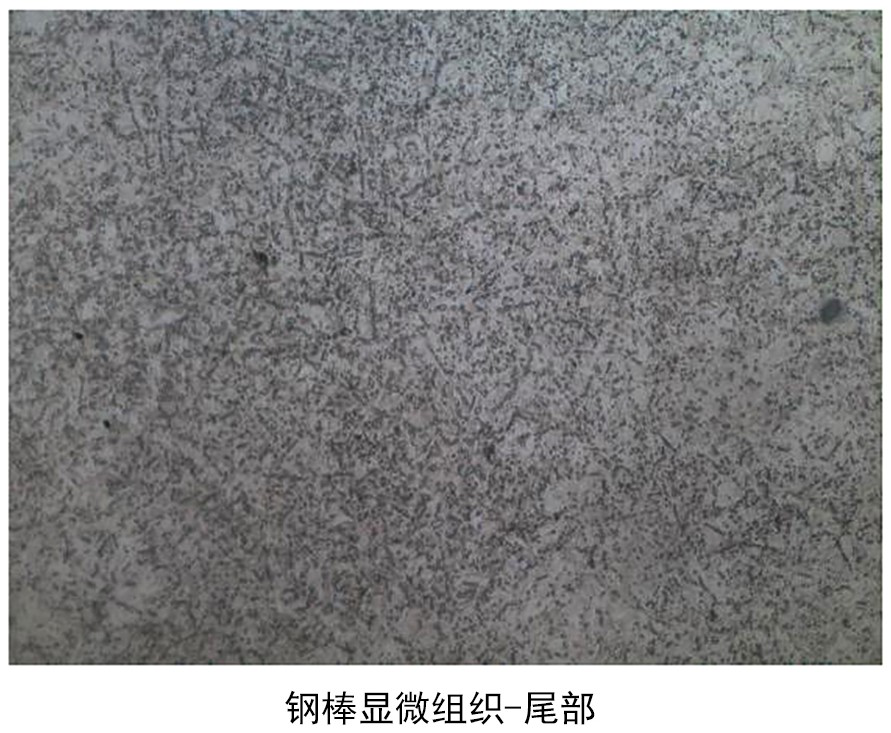

Forging production process of 30Cr15MoN high-nitrogen martensitic stainless steel bar

ActiveCN112496216AAvoid plastic dropUniform tissueMetal-working apparatusTemperature controlMartensitic stainless steel

The invention belongs to the technical field of metal pressure machining processes, and particularly discloses a forging production process of a 30Cr15MoN high-nitrogen martensitic stainless steel bar, which comprises the steps of electroslag remelting, heating, forging preparation, forging and red annealing. According to the method, the problems that 30Cr15MoN steel in an existing forging processis prone to cracking and uneven in structure are effectively solved by combining the optimized forging mode that drawing is directly conducted without upsetting and an eight-edge four-method is adopted for drawing with strict temperature control, meanwhile, the forging heating number is reduced, and the production efficiency is improved; The steel bar forged through the method is excellent in performance in all aspects and can meet the material requirements of high-precision sharp-end projects.

Owner:DEQING TIANMA BEARING CO LTD

A 3D printed powder material

ActiveCN110385430BImprove cutting performanceImprove bending strengthAdditive manufacturing apparatusTransportation and packagingSingle crystalCemented carbide

Owner:SEED TECH CORP LTD

Production method of high-performance cladding coating on surface of aluminum alloy

PendingCN113529073AIncrease productivityTightly boundMetallic material coating processesAlloy surfaceAluminium alloy

The invention relates to an aluminum alloy surface modification technology, in particular to a production method of a high-performance cladding coating on the surface of an aluminum alloy. The production method of the high-performance cladding coating on the surface of the aluminum alloy comprises the following steps: conducting ball milling on Ni60, SiC and La2O3 with certain mass fractions to produce cladding powder; and blending the mixed powder obtained after ball milling into paste, coating the surface of the aluminum alloy with the paste, conducting drying, conducting cold pressing on a coating layer to form a prefabricated block, conducting induction cladding on the prefabricated block, subjecting a test piece obtained after cladding to heat-preservation aging standing treatment, and then making the test piece stand in air in a room temperature state. According to the production method of the high-performance cladding coating on the surface of the aluminum alloy, the problem of interface bonding of an aluminum alloy matrix and a cladding layer is solved, so that a polymorphic microstructure is generated in a transition area; and the service life of an aluminum alloy component is prolonged, and the aluminum alloy component adapts to severe environments.

Owner:ZHONGBEI UNIV

A high-strength anti-fatigue in-situ nano-reinforced aluminum alloy and its die-casting method

ActiveCN107267817BEasy dischargePromote infiltrationTransportation and packagingMetal-working apparatusHigh resistanceDie casting

The invention relates to an aluminum-based composite material, in particular to a high-strength anti-fatigue in-situ nano-strengthened aluminum alloy and a die-casting method thereof. Die castings are obtained through in-situ nano-strengthening and alloy composition regulation, combined with an optimized nonlinear high-pressure die-casting process. In situ nano-ZrB 2 Reinforcement and Nano-Al 3 The scale effect, interface effect and heterogeneous nucleation effect of Er precipitates significantly improve the strength, fatigue resistance and damping performance of the alloy; at the same time, the content of Mg, Zn and Fe elements is increased, and Mn and Ni elements are introduced, While increasing the content of the strengthening phase and obtaining high strength, the harmful coarse precipitation phases such as Al-Fe are effectively refined and rounded, and the good die casting performance of the alloy is guaranteed; thus, the alloy and the die casting method of the present invention are used to produce the alloy. The components show high strength plasticity, high fatigue resistance, high damping performance and good die casting performance.

Owner:JIANGSU UNIV +1

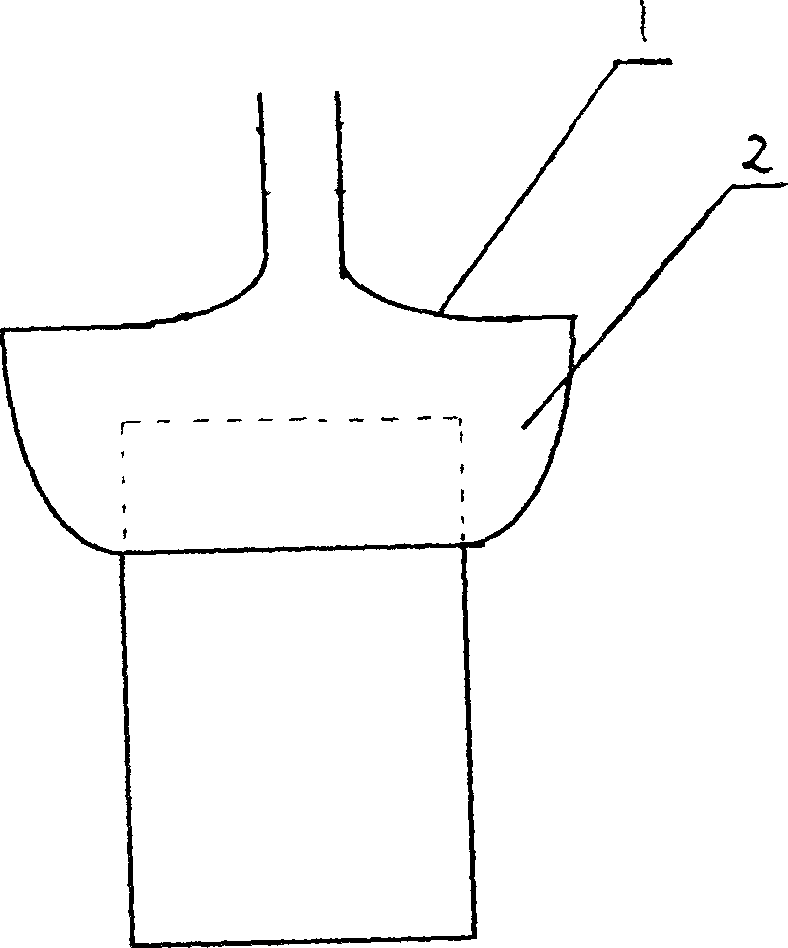

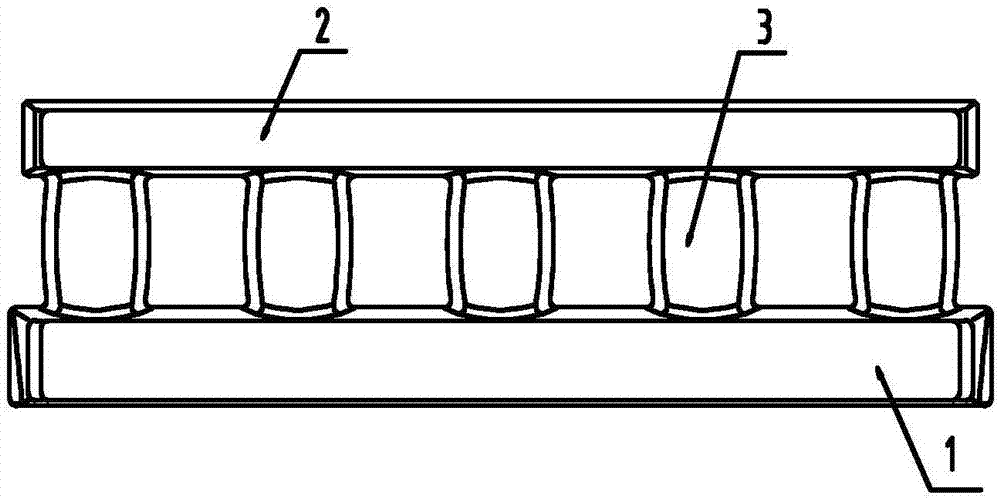

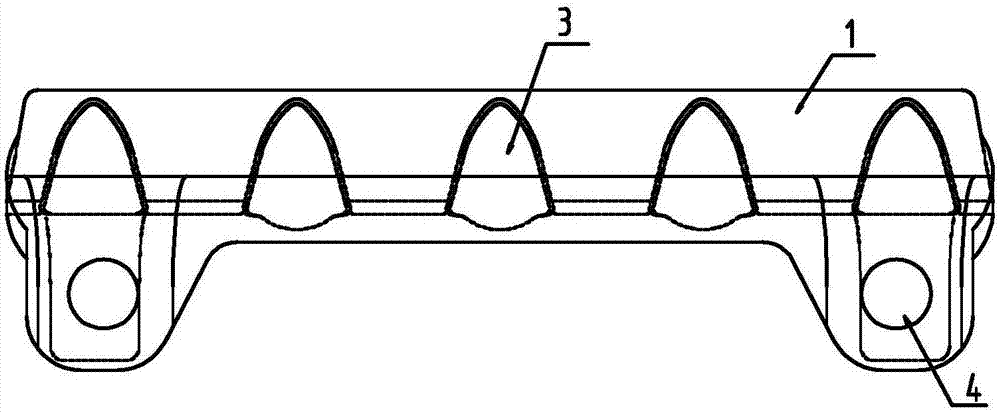

Integral die forged 151mm pitch pin track and scraper conveyer

InactiveCN106869926AHigh strengthLess organizational defectsUnderground transportPropulsionEngineeringUltimate tensile strength

The invention relates to an integral die forged 151mm pitch pin track and a scraper conveyer and belongs to the technical field of mining scraper conveyers. The integral die forged 151mm pitch pin track comprises a main track plate, an auxiliary track plate and a plurality of pin teeth, the main track plate and the auxiliary track plate are arranged in parallel, the multiple pin teeth are arranged between the main track plate and the auxiliary track plate at equal intervals, and the distance between every two adjacent pin teeth is 151 mm. The main track plate, the auxiliary track plate and the pin teeth are formed at a time though an integral die forging process, and the structure defects of materials are reduced; the pin teeth are distributed at the equal intervals of 151 mm, the bearing capacity, strength and use stability of the pin track are improved by increasing the pitch of the pin track, and thus the overall service life of the pin track is prolonged, the traction force of a coal cutter reaches 1350 kN, the strength of a pin row of the scraper conveyer reaches 150 kN, and the requirement of the medium-thickness coal seam coal cutter for two-way coal cutting on an inclined working face with a large inclination angle is met.

Owner:SHANDONG ENERGY HEAVY EQUIPMENT GROUP HENGTU TECH CO LTD

Method and equipment for successive oriented solidification casting and wire rod or plate and belt material thereby

InactiveCN1307013CEasy to operateEasy to controlPolycrystalline material growthFrom frozen solutionsWire rodDirectional solidification

A casting method by continuous directional solidifying includes extending one end of drawing line or plate in crystallizing mouth, extending its another end is cooling liquid, preheating the crystallizer, pouring fluid material in the crystallizer, insulating for directional solidifying, and drawing said drawing line or plate to draw the solidified material in cooling liquid. Its apparatus is composed of crystallizer, drawing line or plate, cooling unit, drawing unit and check unit. Its product (wire or plate) features high quality and uniformity, and excellent performance.

Owner:周照耀

High-temperature alloy turbine disc coating and manufacturing method thereof

InactiveCN113166917AEvenly distributedLow impurity contentMolten spray coatingMetallurgySolid solution strengthening

The invention discloses a high-temperature alloy turbine disc coating which comprises the following components in percentage by mass: 10-13 percent of Cr, 2-4 percent of Al, 1.5-4 percent of Si, 5-8 percent of Fe, 1-1.5 percent of Ti, 0.5-1 percent of C, 4-6 percent of B, 1.2-2 percent of Zn, 1-2 percent of Mo, 0.2-0.4 percent of Sb, 0.5-0.8 percent of Co, 3-5 percent of Cu and the balance of Ni. The invention further discloses a manufacturing method of the high-temperature alloy turbine disc coating. The coating is uniform in structure, refined in grain, low in oxygen content, few in structure defects in the casting process, few in composition segregation in the structure, free of dendritic segregation, high in solid solubility, uniform in solid solution strengthening phase distribution and low in impurity content. And nano-scale multi-element ceramic reinforced phases are uniformly distributed in the coating to form a wear-resistant framework, so that the coating is prevented from being peeled off.

Owner:NANJING JIANGDONG IND & TRADE CO LTD

A new type of valve-air lead-acid battery for electric vehicles

ActiveCN106207278BImprove mechanical propertiesImprove electrical performanceFinal product manufactureElectrode carriers/collectorsAlloyElectric vehicle

The invention relates to a novel valve-regulated lead-acid battery for electric vehicles, a novel valve-regulated lead-acid battery for electric vehicles in the battery, which is characterized in that the negative grid in the lead-acid battery uses a quaternary alloy, Ca 0.06‑ 0.09%, Sn 1.0‑1.2%, Al 0.015‑0.035%, Pb complement; the positive grid uses a quaternary alloy, Ca 0.06‑0.09%, Sn 0.5‑0.7%, Al 0.015‑0.035%, Pb complement. The invention also includes the limitation on the composition and content of the lead paste of the positive and negative plates, and the preparation of the lead-acid storage battery. The invention fundamentally solves the problems of the consistency of batteries used in groups and the service life of deep cycles.

Owner:山东久力新能源集团有限公司

A magnesium-aluminum-zinc deformed magnesium alloy containing calcium and rare earth samarium

The invention relates to a magnesium-aluminum-zinc wrought magnesium alloy containing calcium and rare-earth samarium. The wrought magnesium alloy comprises the following components by mass percent: 5.3% to 6.0% of Al (aluminum), 0.7% to 1.0% of Zn (zinc), 0.4% to 0.5% of Ca (calcium), 0.2% to 1.5% of Sm (samarium), less than or equal to 0.15% of inevitable impurities and the balance of Mg (magnesium), wherein all the components taken as raw materials in proportion are fused and rapidly cooled in a salt bath; an obtained alloy spindle is annealed in a homogenization manner at 400 DEG C and air-cooled to reach a room temperature; then the hot extrusion is carried out on the alloy spindle at 360 DEG C according to the extrusion ratio being 25:1, so that the magnesium-aluminum-zinc wrought magnesium alloy containing the calcium and the rare-earth samarium is obtained. After the thermal deformation is carried out on the magnesium alloy, the tensile strength and the yield strength of the magnesium alloy are improved. Thus, the foundation for actual production applications of the wrought magnesium alloy is laid.

Owner:CHONGQING UNIV

Crystal orientation template for BaTiO3-based lead-free piezoelectric ceramics and method for fabricating the same

The invention discloses a crystal orientation template for BaTiO3-based lead-free piezoelectric ceramics represented by formula 1: Ba(Ti1-xAx)O3 (wherein, A is Zr or Sn, 0<x<1). According to the crystal orientation template for BaTiO3-based lead-free piezoelectric ceramics, zirconium or tin is melted, so that the composition ratio is similar to base material for preparing the BaTiO3-based lead-free piezoelectric ceramics, and the structural defects can be reduced. The BaTiO3-based lead-free piezoelectric ceramics with high displacement properties can be manufactured through crystal orientation.

Owner:KOREA INST OF MASCH & MATERIALS

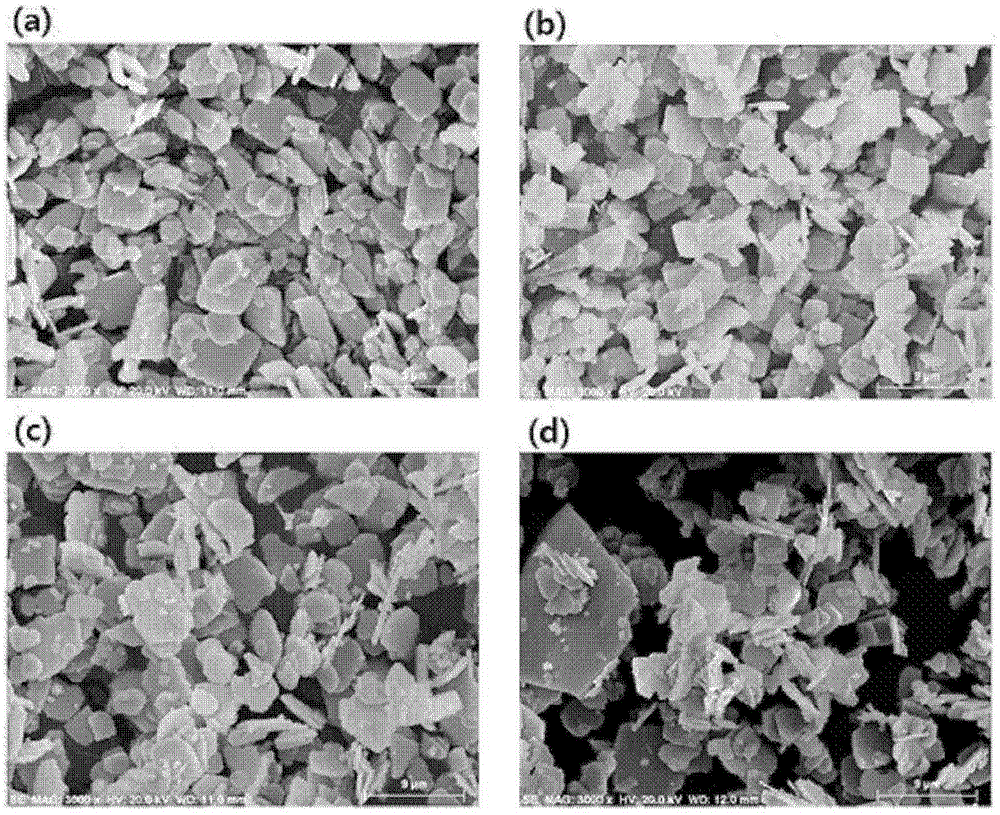

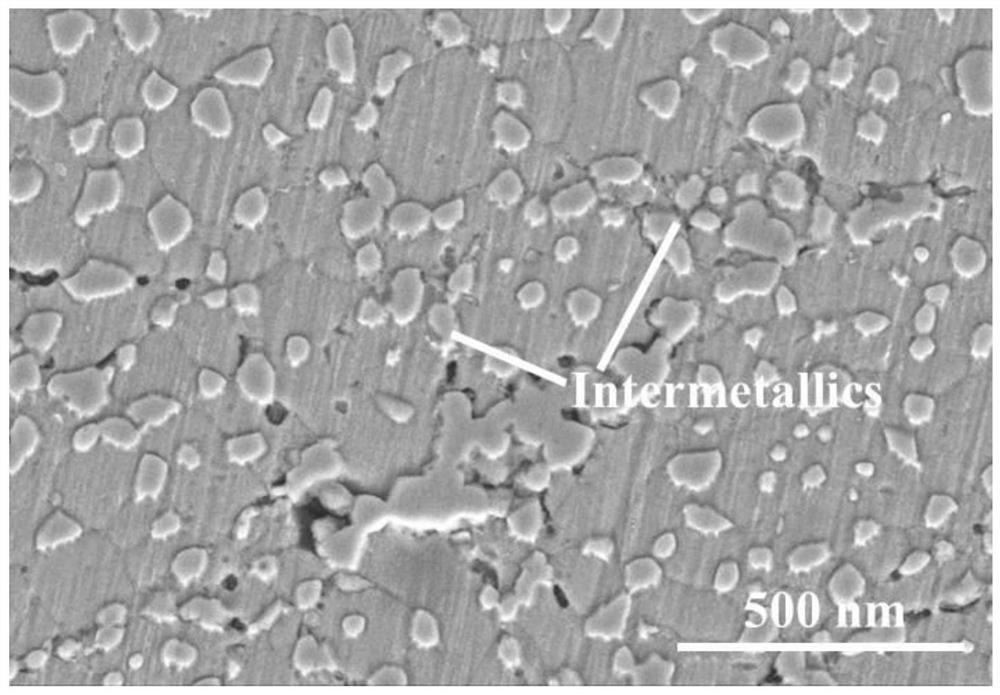

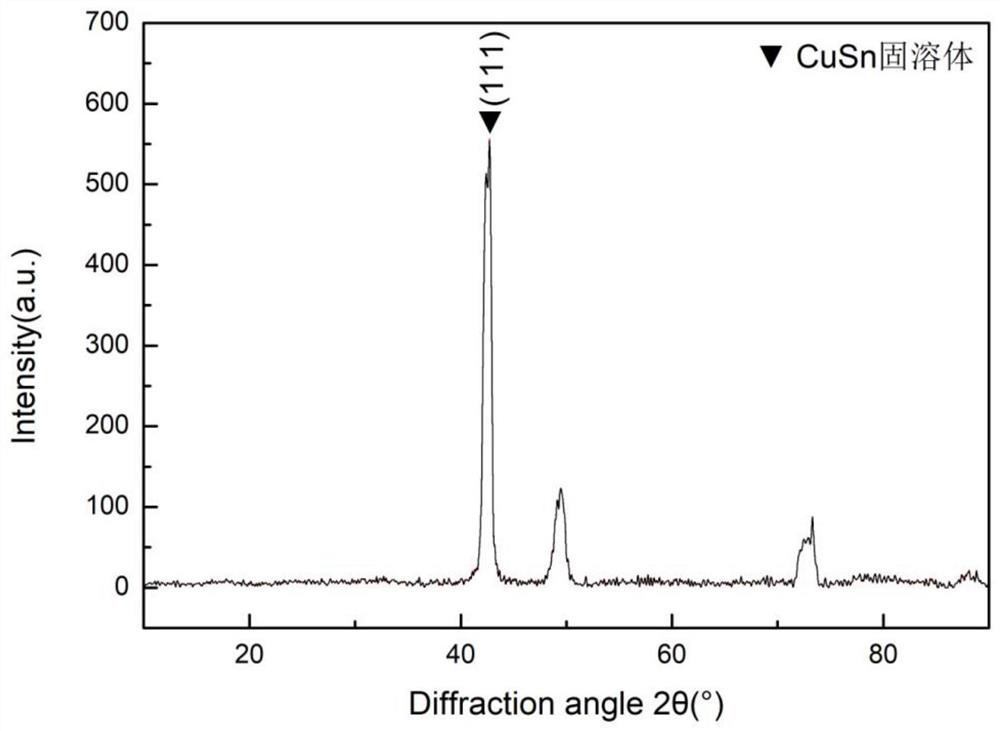

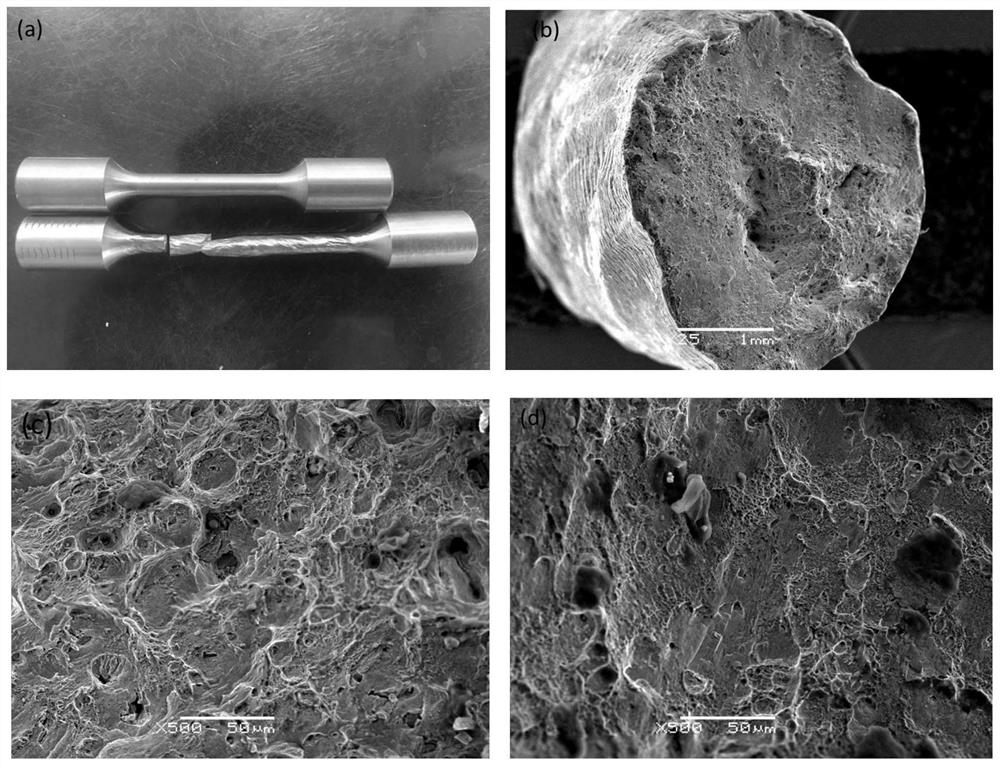

Manufacturing method and application of nano intermetallic compound dispersion strengthened copper alloy

ActiveCN111471888BImprove wear resistanceImprove conductivityFriction liningRare-earth elementElectric machine

The invention discloses a manufacturing method and application of nano-intermetallic compound dispersion strengthened copper alloy. The composition and mass percentage of the copper alloy are as follows: Sn: 4-8%, Ni: 1.5-4%, Ag: 0.05-0.6%, rare earth elements : 0.07~0.2%, Zn: 1.48~2.43%, X: 3.52~7.57%; wherein, X is any one or more of Al, Mn, Sc, B; rare earth elements include at least Ce, La and Y; The mass percentage of rare earth elements and Sn is 1:(40~55); the mass percentage of Ce, La and Y is (0.2~0.5):1:(0.1~0.35), and the balance is Cu. The copper alloy can be used in friction discs of high-speed train motor rotors. The copper alloy of the invention has good wear resistance and electrical conductivity.

Owner:NANJING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com