Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "High deformation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

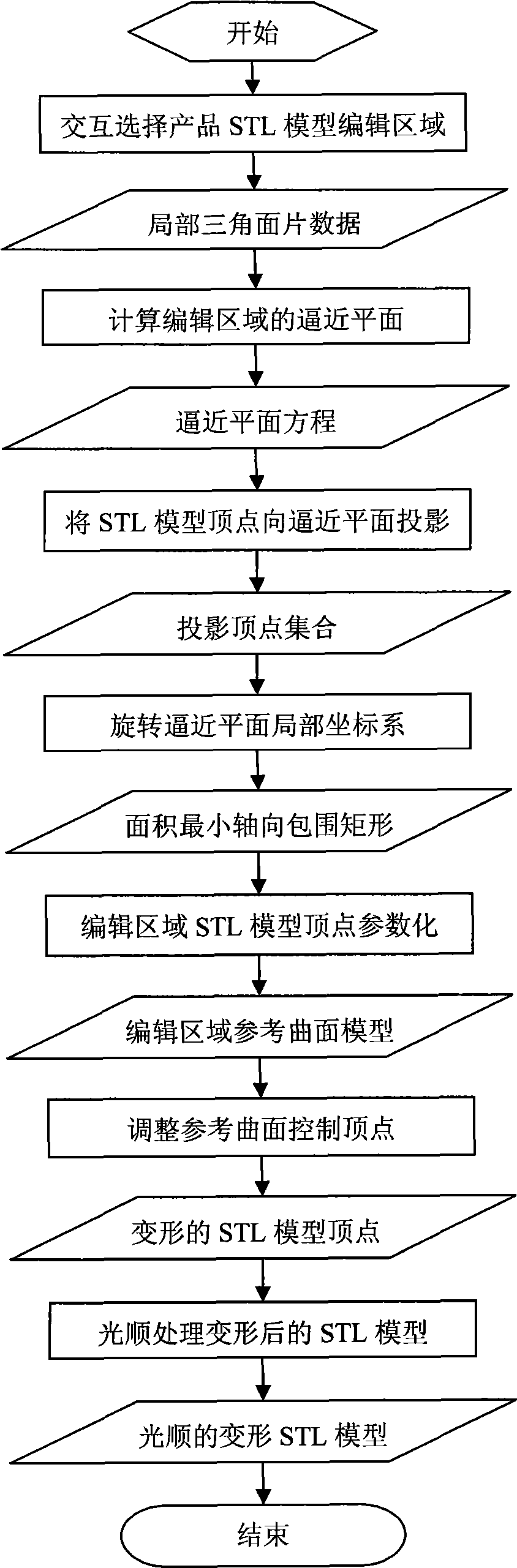

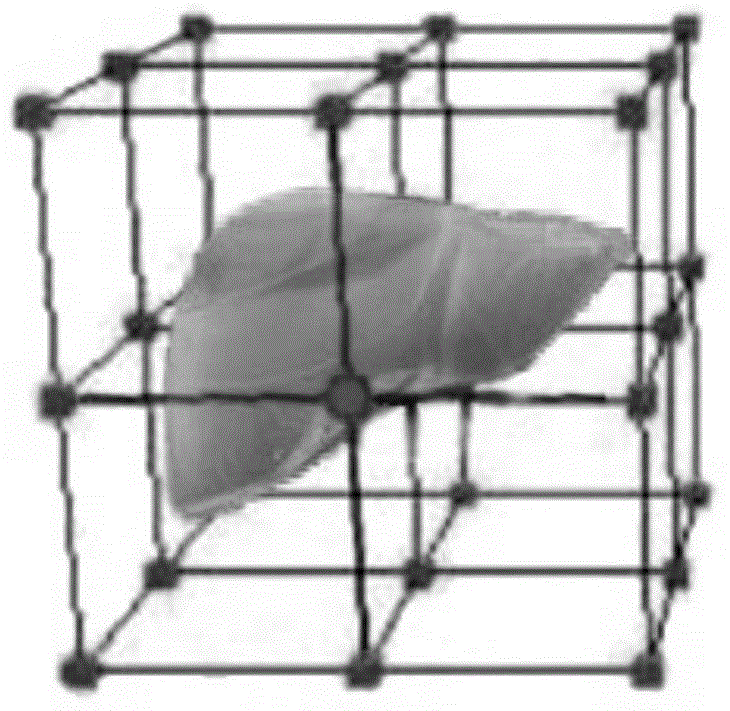

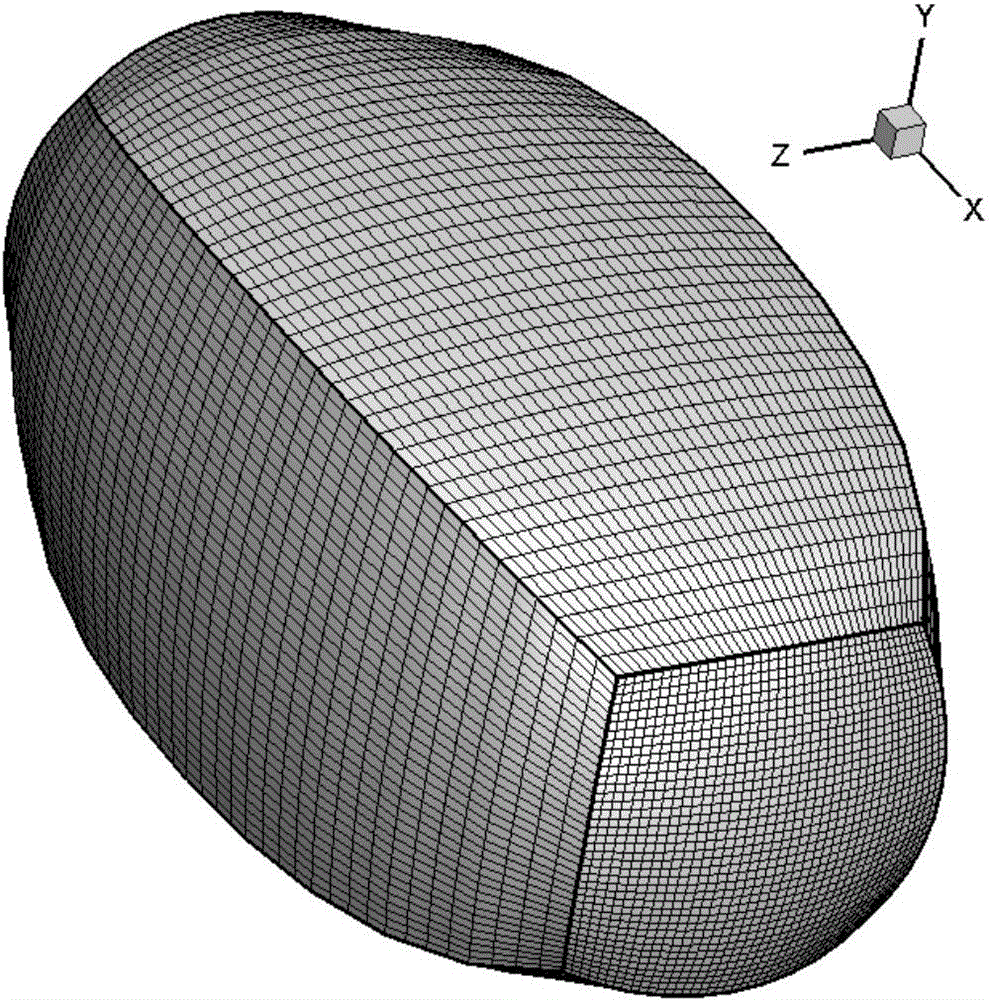

Deformation design method for product STL model

InactiveCN101510316ARealize detailed feature designSmall amount of calculationSpecial data processing applications3D modellingComputer graphics (images)Least squares

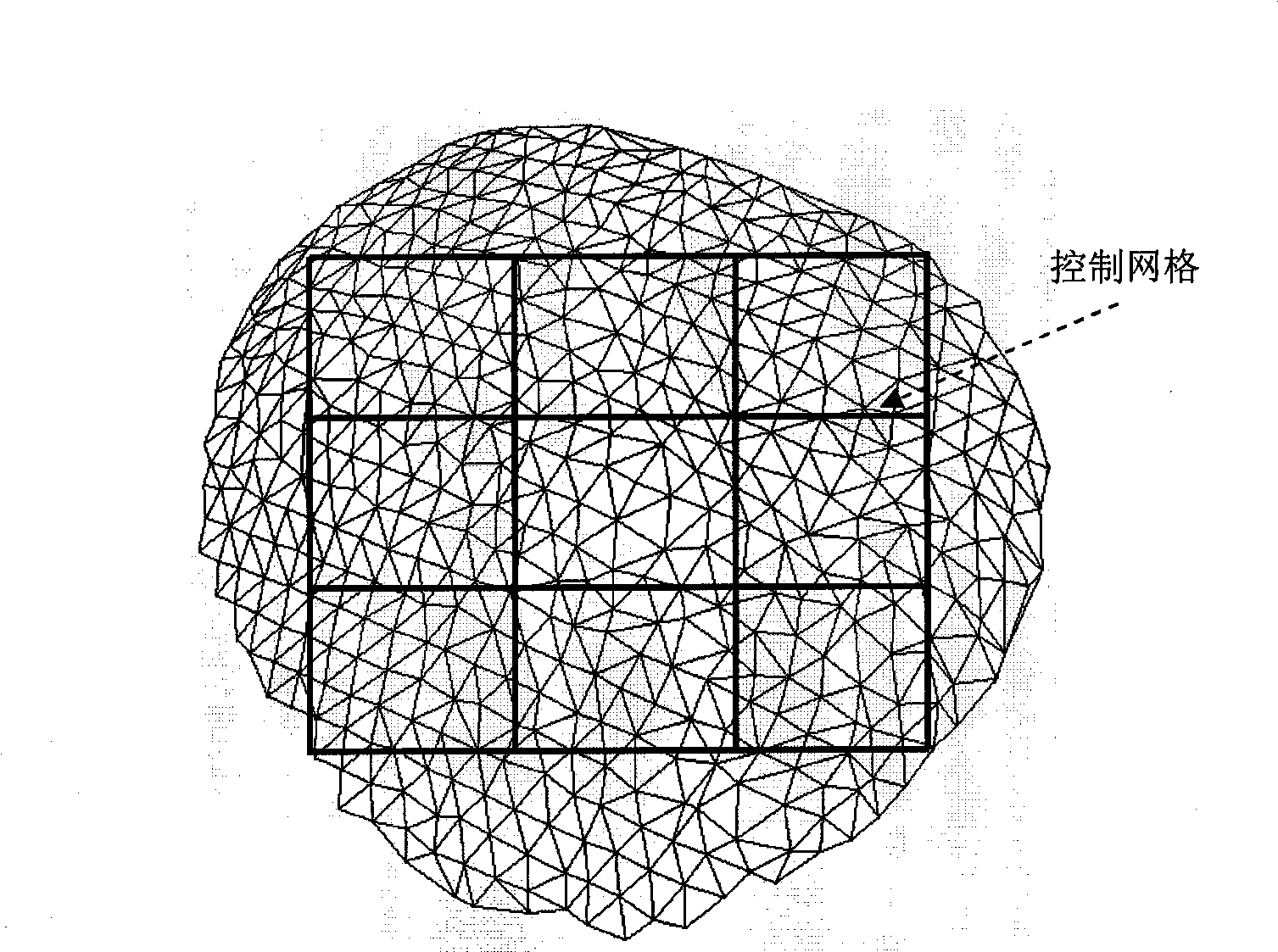

The invention provides a deformation design method of a product STL model, which is characterized in that the approaching plane of an editing area of the product STL model is solved by adopting the least square method, the vertex of the product STL model is projected to the approaching plane to set up a local plane coordinate system of a projection point set and obtain an axial bounding rectangle with minimum area of the projection point set, the vertex of the product STL model is parameterized, the reference curved surface of the editing area is solved, the mapping relation between the vertex of the product STL model and the projection point on the reference curved surface is set up, the control vertex of the reference curved surface is adjusted, the displacement of the projection point is calculated, the vertex coordinate of the product STL model is adjusted according to the displacement of the projection point to finish the deformation of the editing area of the product STL model, a first-order geometric continuous triangular B * zier curved surface is constructed for the deformed model to realize smoothing treatment of the model, and a smoothed product STL model is obtained by dispersing the triangular B * zier curved surface to finish the deformation innovative design of the product STL model. The method can accurately control the model shape and effectively improve the smoothness and deformation design efficiency of the product STL model.

Owner:SHANDONG UNIV OF TECH

Electrified railway chromium-zirconium-copper contact line and machining process thereof

ActiveCN104342575AMaximum total rolling deformationLow costSingle bars/rods/wires/strips conductorsMetal/alloy conductorsCopperSolid solution

The invention discloses a preparation method of an electrified railway chromium-zirconium-copper contact line. Copper is taken as a substrate, 0.30-0.70% of Cr and 0.10-0.35% of Zr in percentage by weight are added into the substrate, and the total sum of impurities is no greater than 0.05%. The preparation method comprises the following steps: performing vacuum melting and vacuum horizontal continuous casting, thereby obtaining a long-length large cross section chromium-zirconium-copper continuous cast blank; performing full hot continuous rolling and on-line solid solution, thereby obtaining a long-length chromium-zirconium-copper line rod disc; drawing and peeling the disc, and performing cold continuous rolling, thereby reducing the diameter; further performing aging treatment to reinforce the disc; further performing cold continuous rolling by using a Y-type rolling machine, thereby pre-forming the line; and finally performing fine drawing formation once. The chromium-zirconium-copper contact line produced by using the preparation process is fine and uniform in grain, free of defect, high in strength, high in conductivity and high in softening temperature, and applicable to industrialized production.

Owner:YANTAI WANLONG VACUUM METALLURGY

Method for preparing semisolid blank

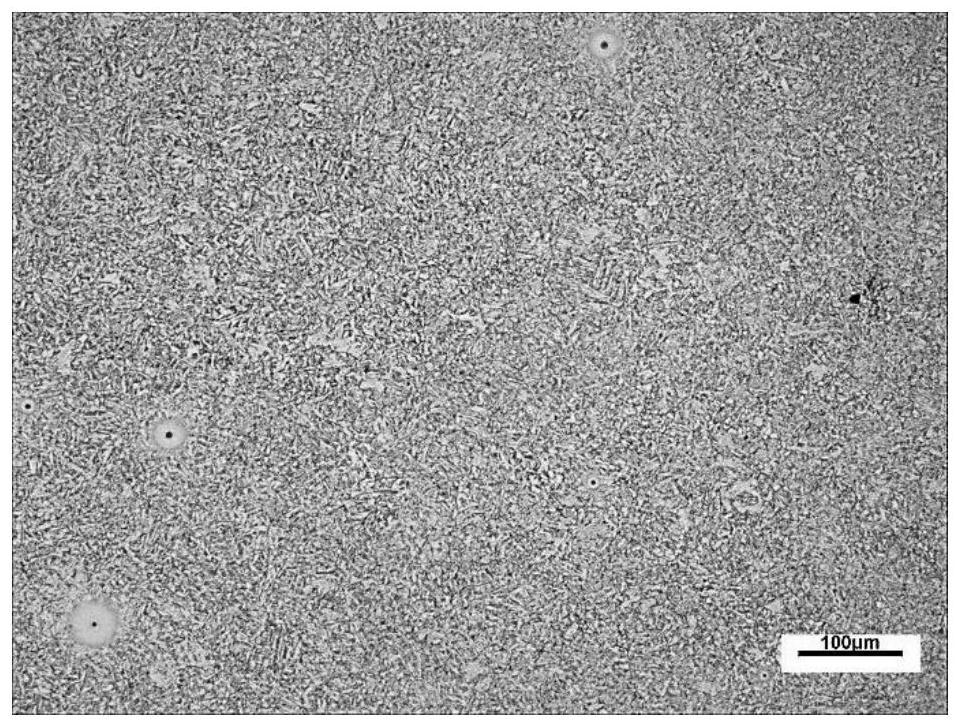

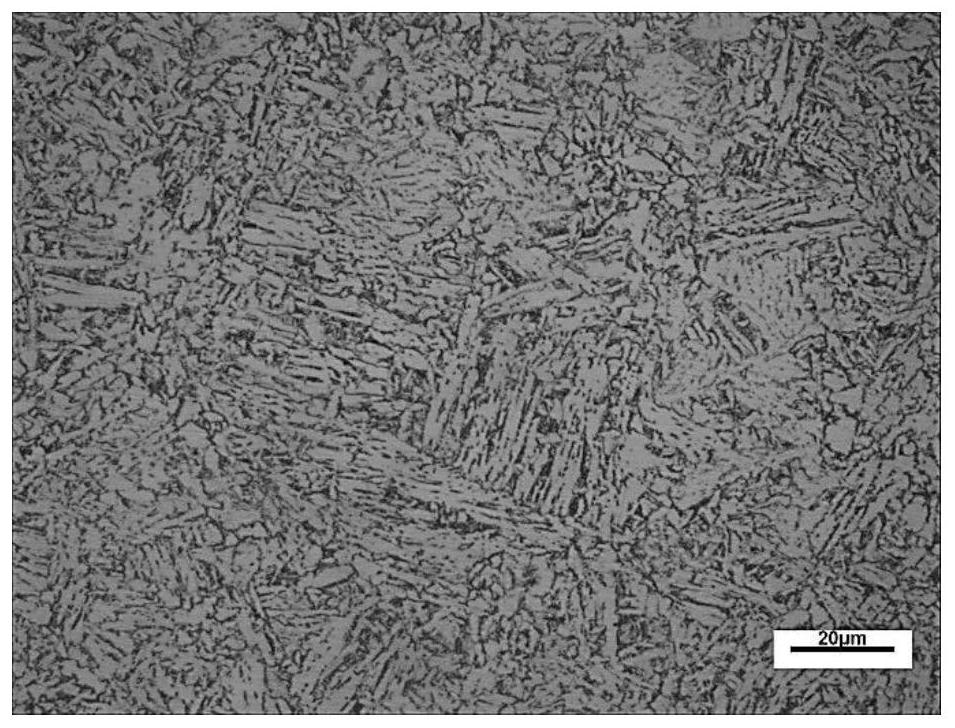

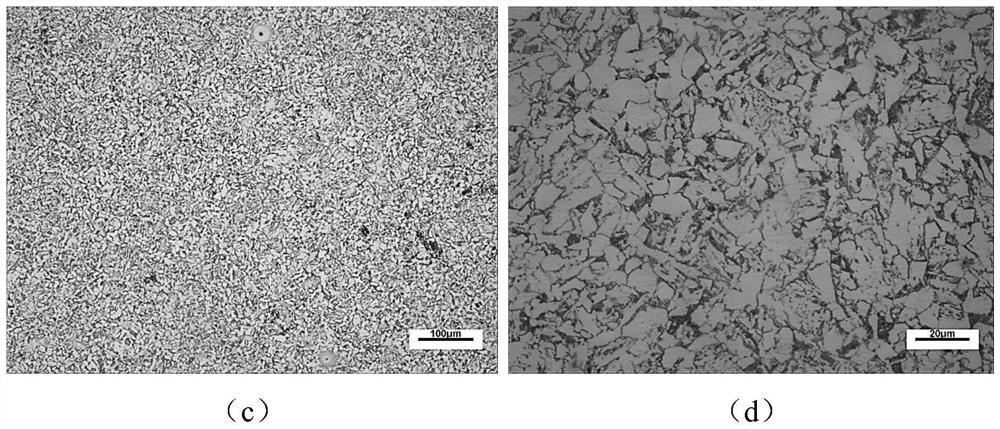

The invention relates to a method for preparing a semisolid blank, utilizes an improved SIMA (strain induced melt activation) method to prepare the semisolid blank, and belongs to the technical field of metal semisolid blank. The method comprises the following steps of: firstly, measuring a liquid solid phase line point of the semisolid alloy to be prepared, then, heating an alloy blank so as to carry out asynchronization multitrack rolling or pillar squeezing transformation, finally, remelting, and carrying out heat preservation for a long time so as to obtain the required semisolid blank. The asynchronization rolling or pillar squeezing transformation is capable of generating large deformation amount, group bough crystal formed in the blank is destroyed, the asynchronization rolling is utilized to replace pre-deformation processes such as the existing upset, compression, equal diameter angle compression, and the semisolid blank is prepared and has the advantages of uniform formation, high nodularity, and accurate control solid phase rate.

Owner:KUNMING UNIV OF SCI & TECH

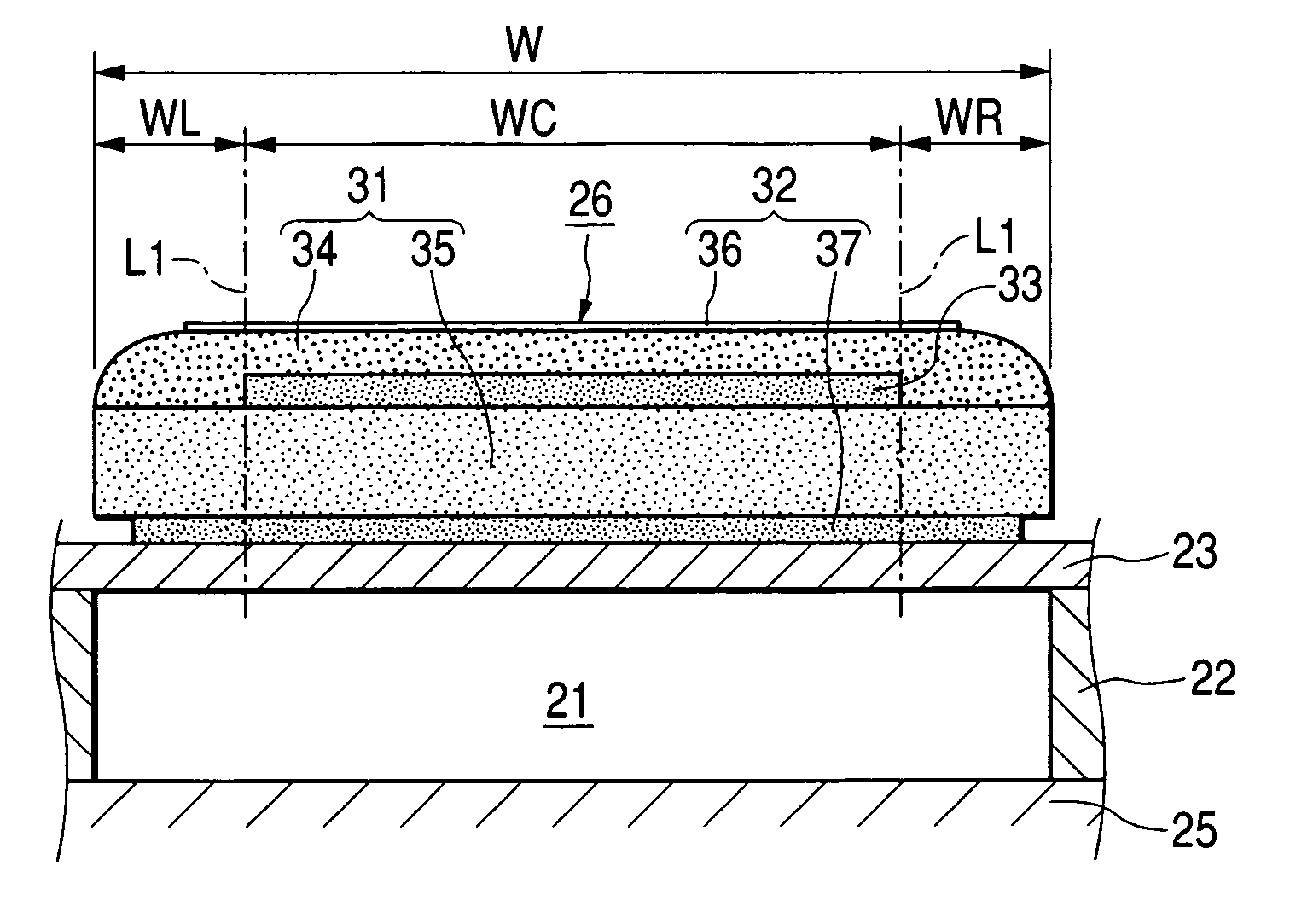

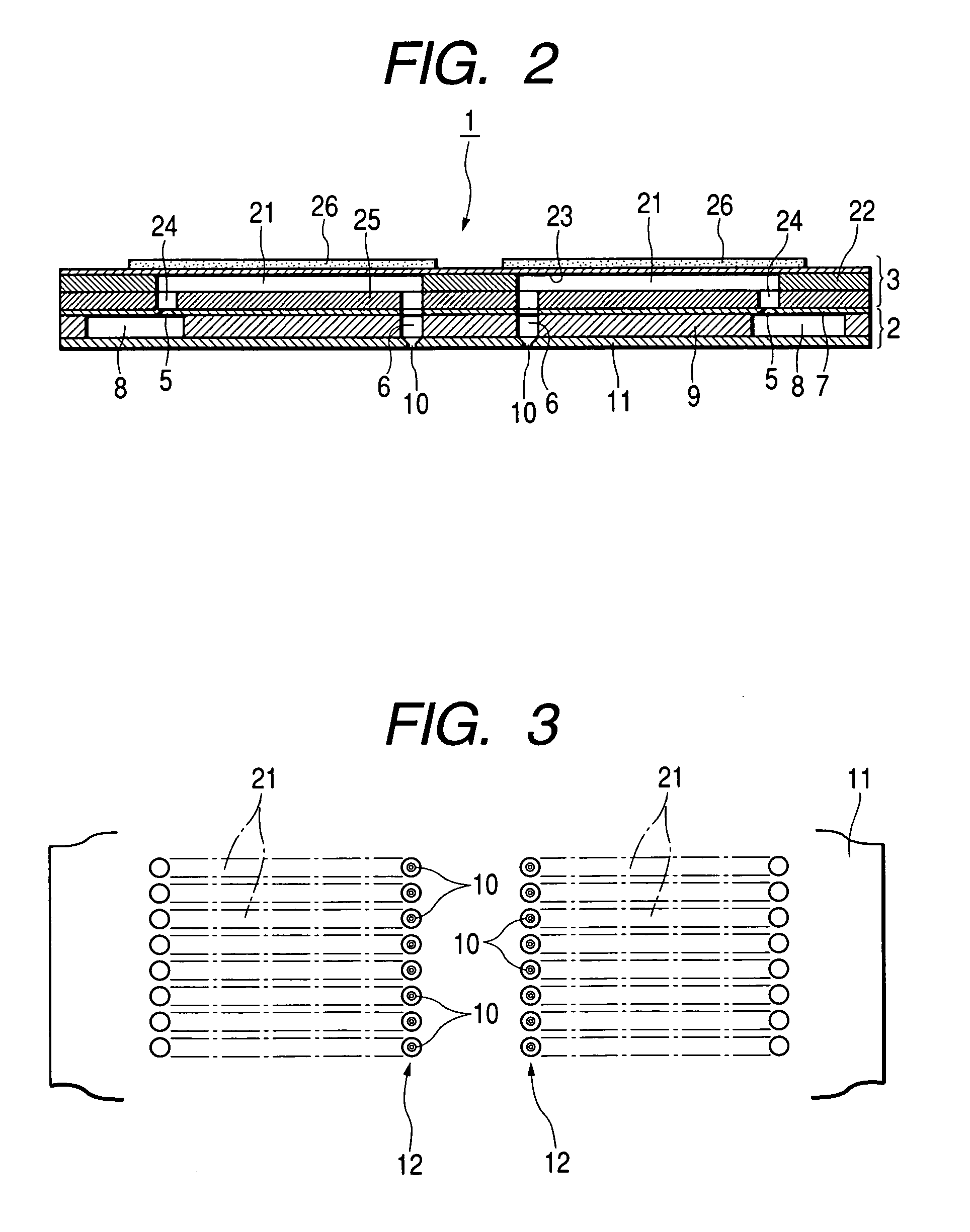

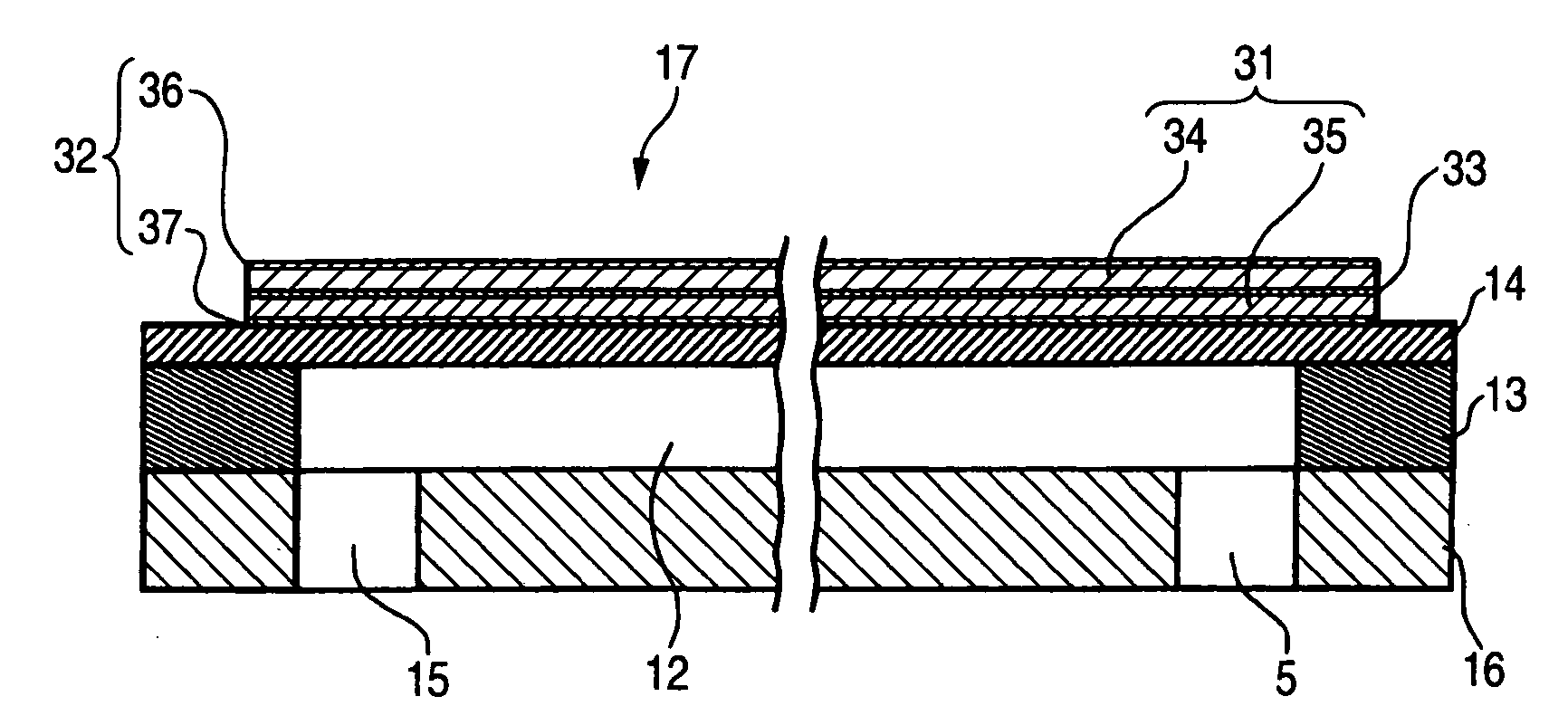

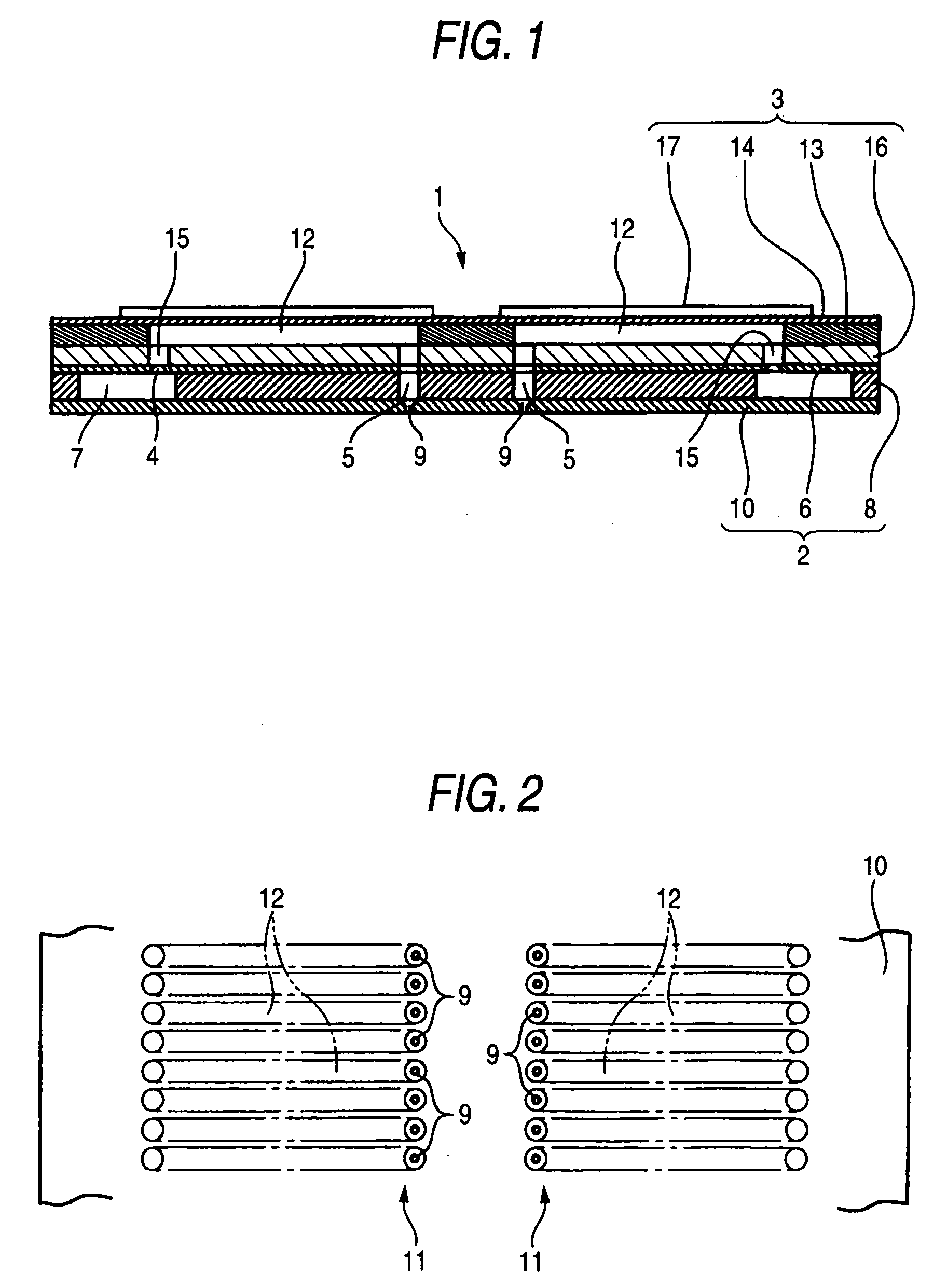

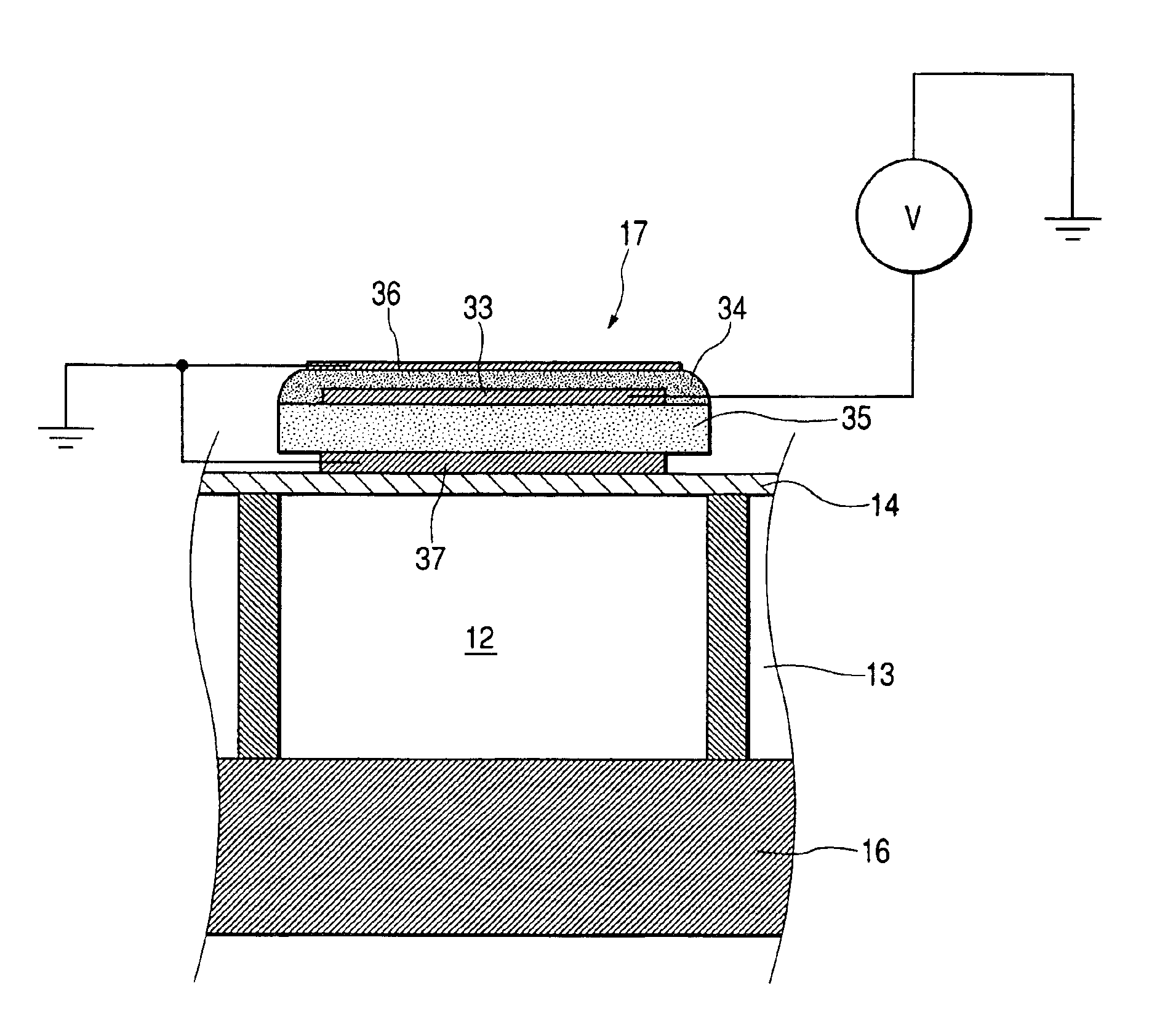

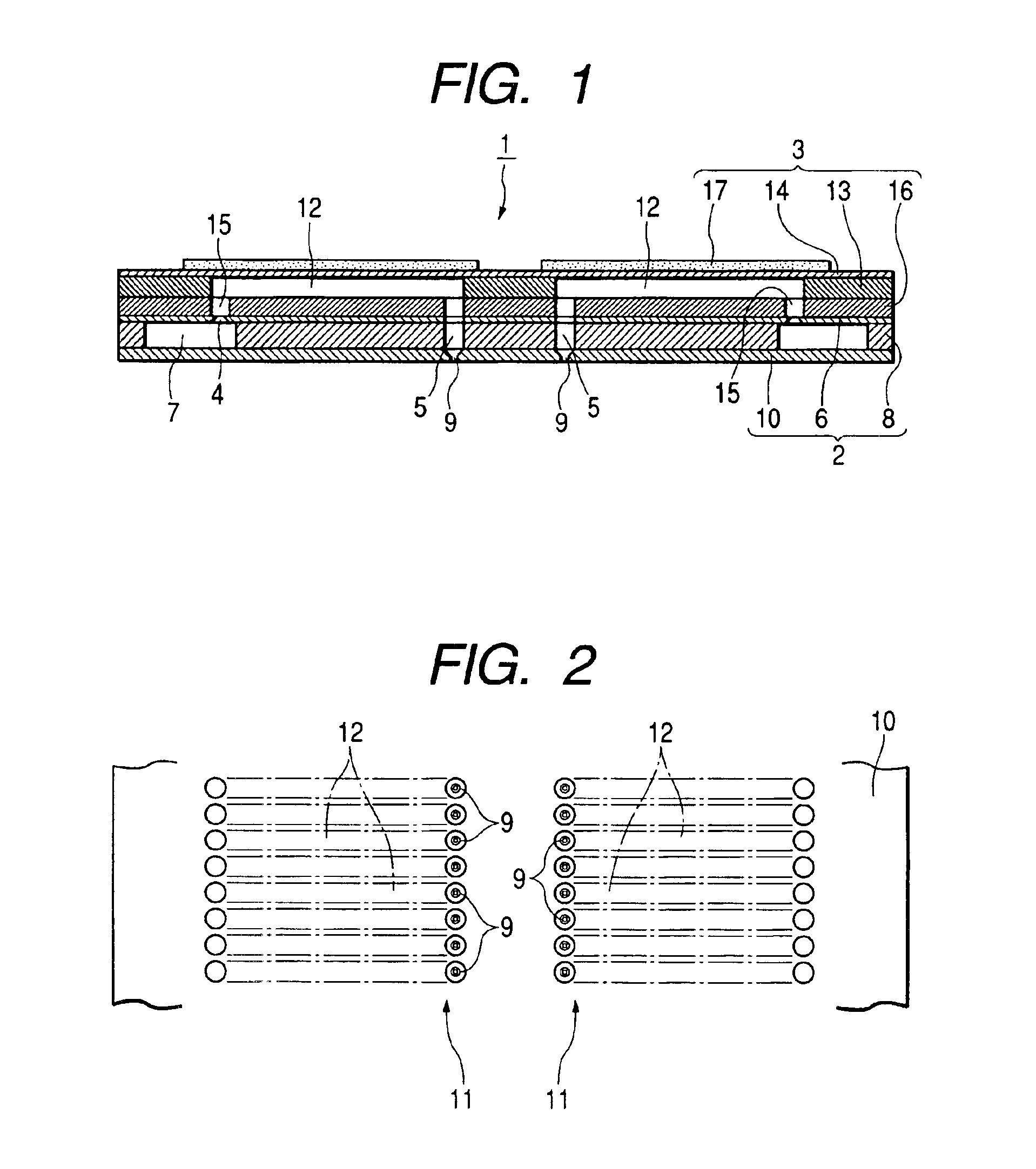

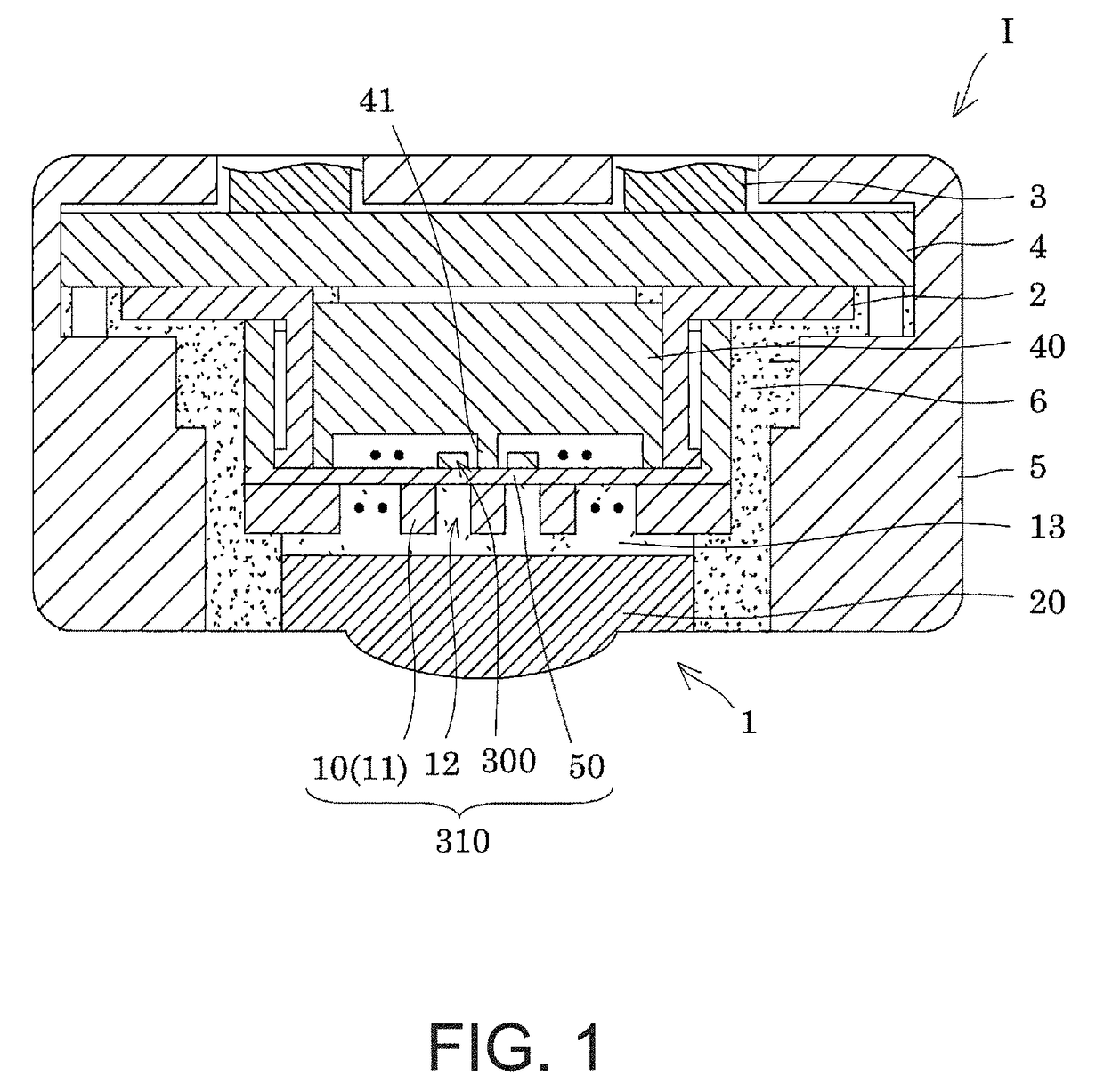

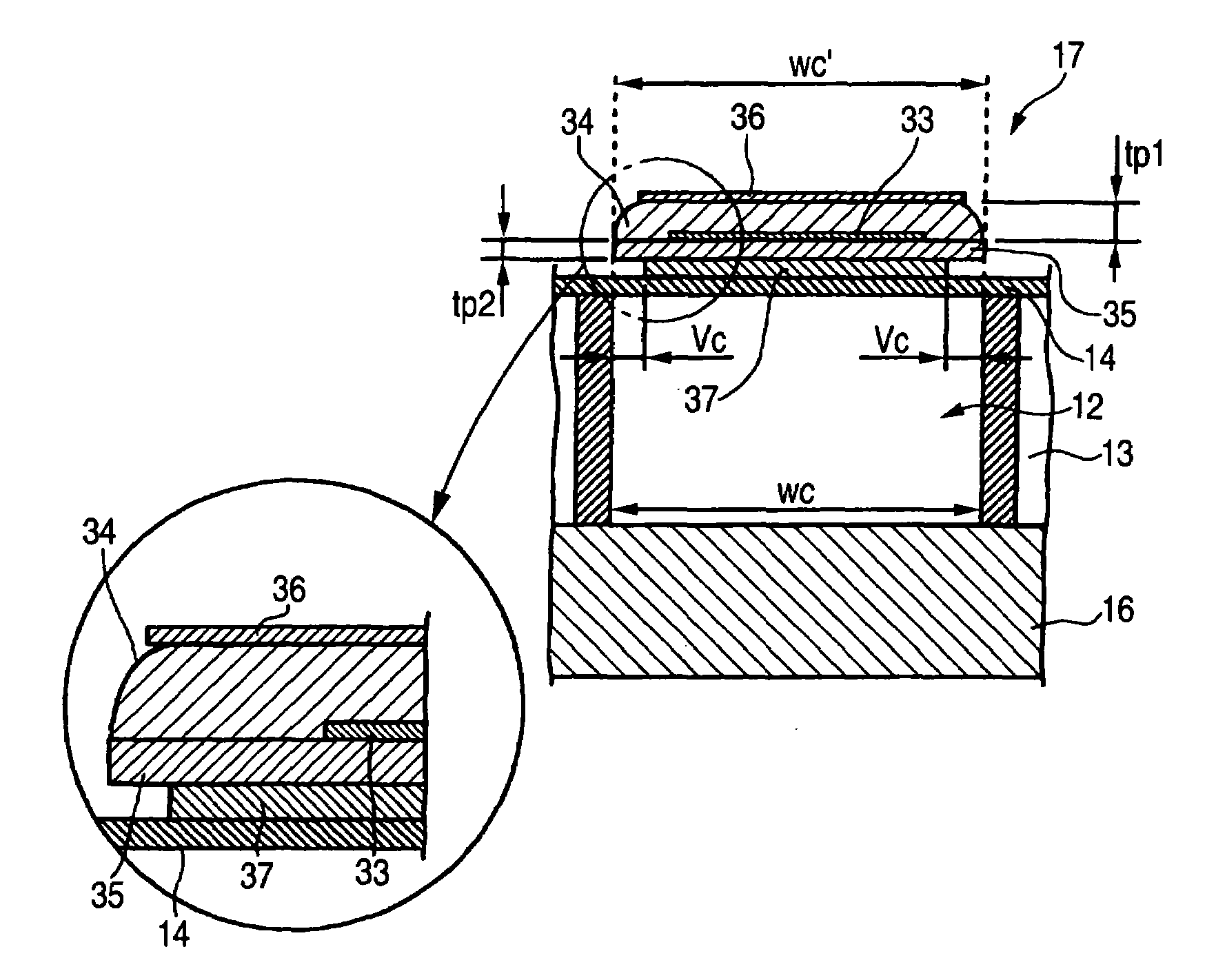

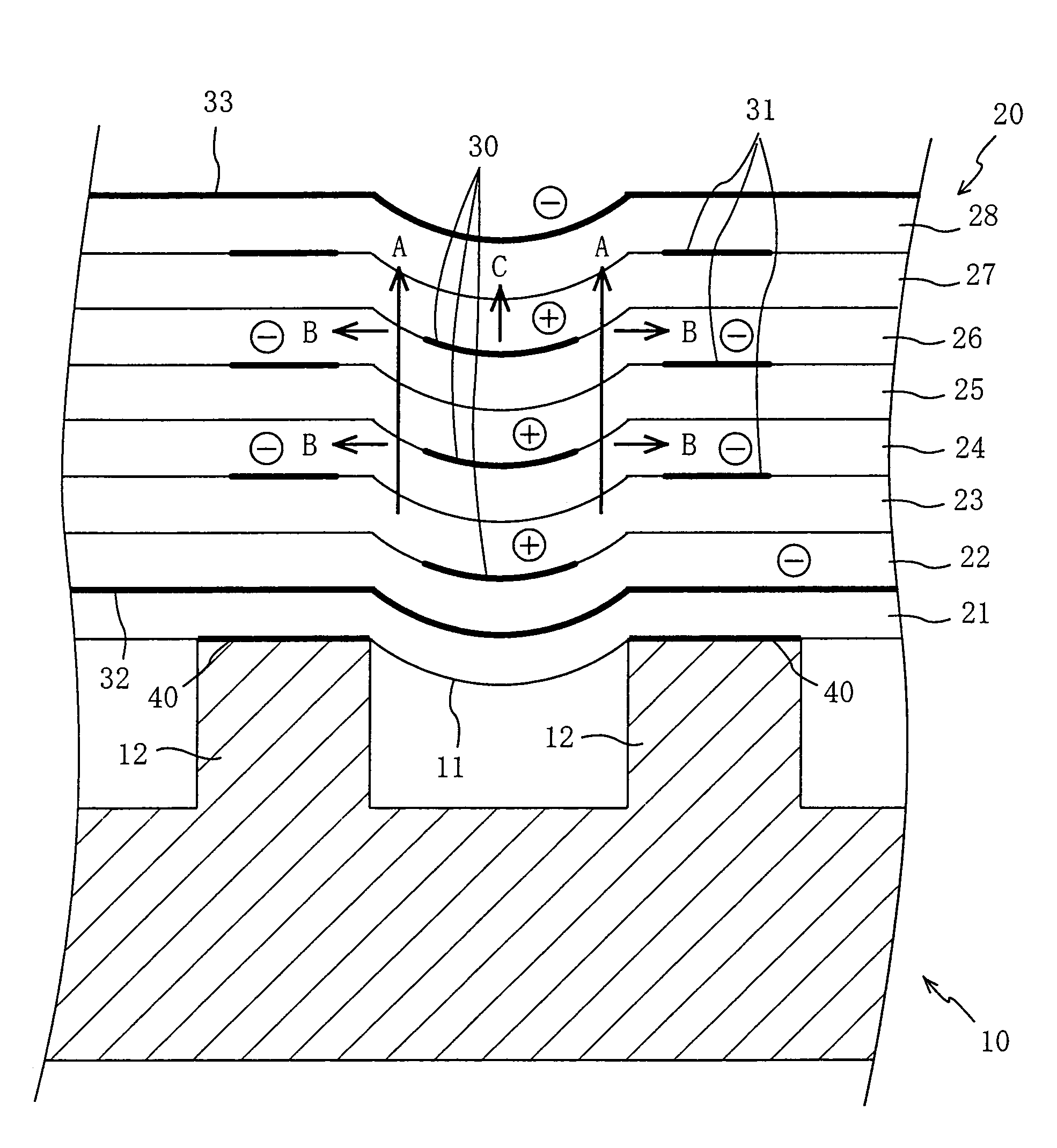

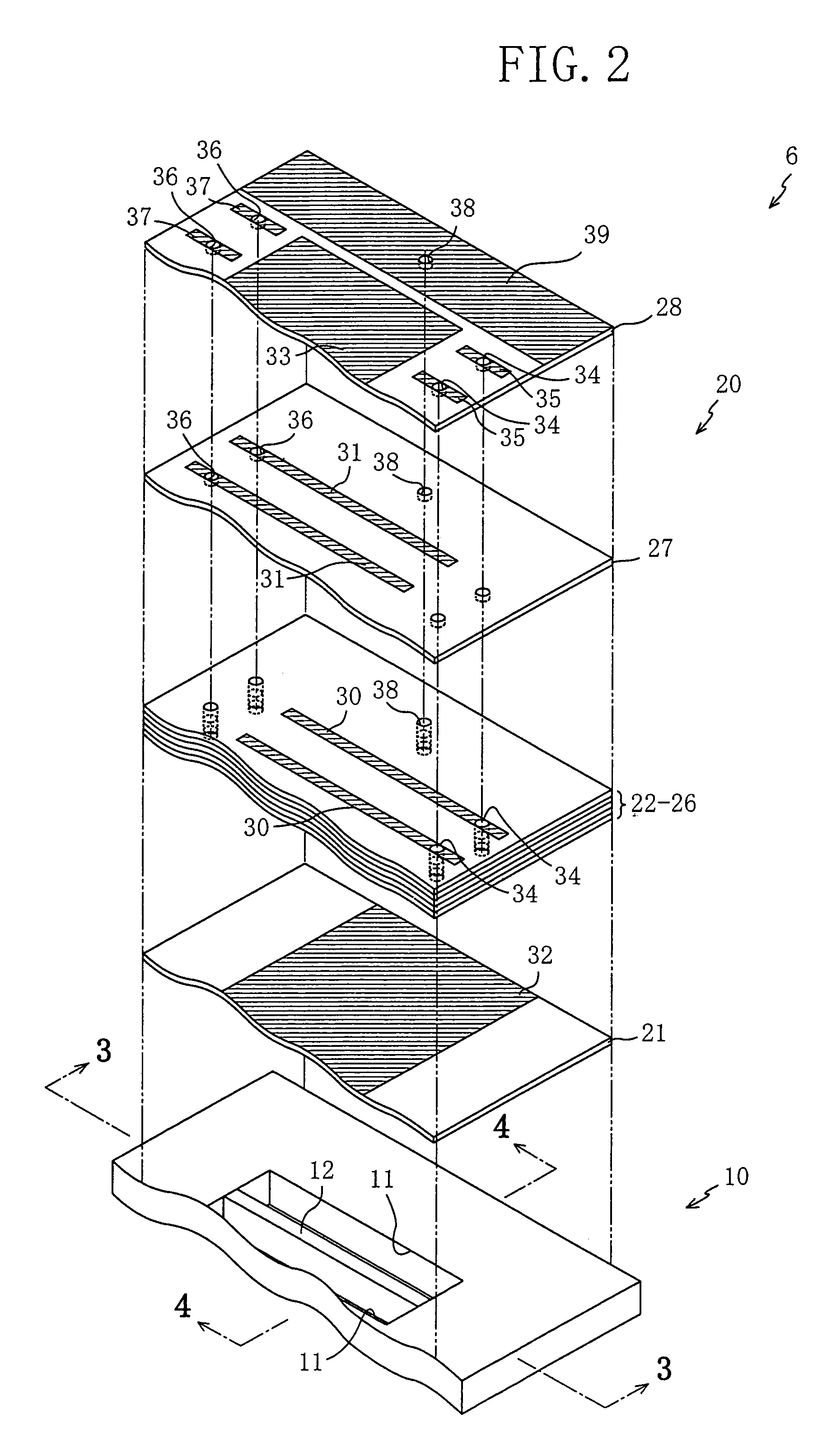

Piezoelectric element, piezoelectric actuator and liquid jetting head incorporating the same

InactiveUS6997547B2Degree of improvementEffective deformationPiezoelectric/electrostriction/magnetostriction machinesFlexible member pumpsPiezoelectric actuatorsEngineering

A first piezoelectric layer is laminated on a first common electrode and comprised of a first piezoelectric material having a first residual stress. A drive electrode is laminated on the first piezoelectric layer, to which a drive signal is supplied externally. A second piezoelectric layer is laminated on the drive electrode and comprised of a second piezoelectric material having a second residual stress lower than the first residual stress. A second common electrode is laminated on the second piezoelectric layer.

Owner:SEIKO EPSON CORP

Method for removing residual formic acid in epoxidized fatty acid methyl esters or epoxidized soybean oil by use of eutectic solvent

ActiveCN103272407ASimple process operationLow costLiquid solutions solvent extractionSolventFormic acid

The invention belongs to the field of chemical technology and specifically relates to a method for removing residual formic acid in epoxidized fatty acid methyl esters or epoxidized soybean oil by the use of a eutectic solvent. The method provided by the invention comprises the following specific steps: sending crude epoxidized fatty acid methyl esters or crude epoxidized soybean oil which contains 0.2-15wt% of formic acid and is obtained by a epoxidation process through a formic acid method into an extraction kettle, adding a certain amount of an extractant under the condition of stirring, stirring for a period of time, standing for layering, sending a material on the upper layer into a vacuum dehydration kettle for further dehydration and refining, pouring an extract on the lower layer into an extractant regeneration kettle; heating under the condition of pressure reduction to distill formic acid in the extract, recycling the formic acid steam after being condensed in a condenser, and sending residual extractant left in the extractant regeneration kettle into the extraction kettle for recycling. The method provided by the invention has advantages of no discharge of waste water, high formic acid removal rate, simple technological operation, environmental protection, safety and low cost, and is suitable for both small-scale device and large-scale device production.

Owner:石家庄搏澳增塑材料科技有限公司

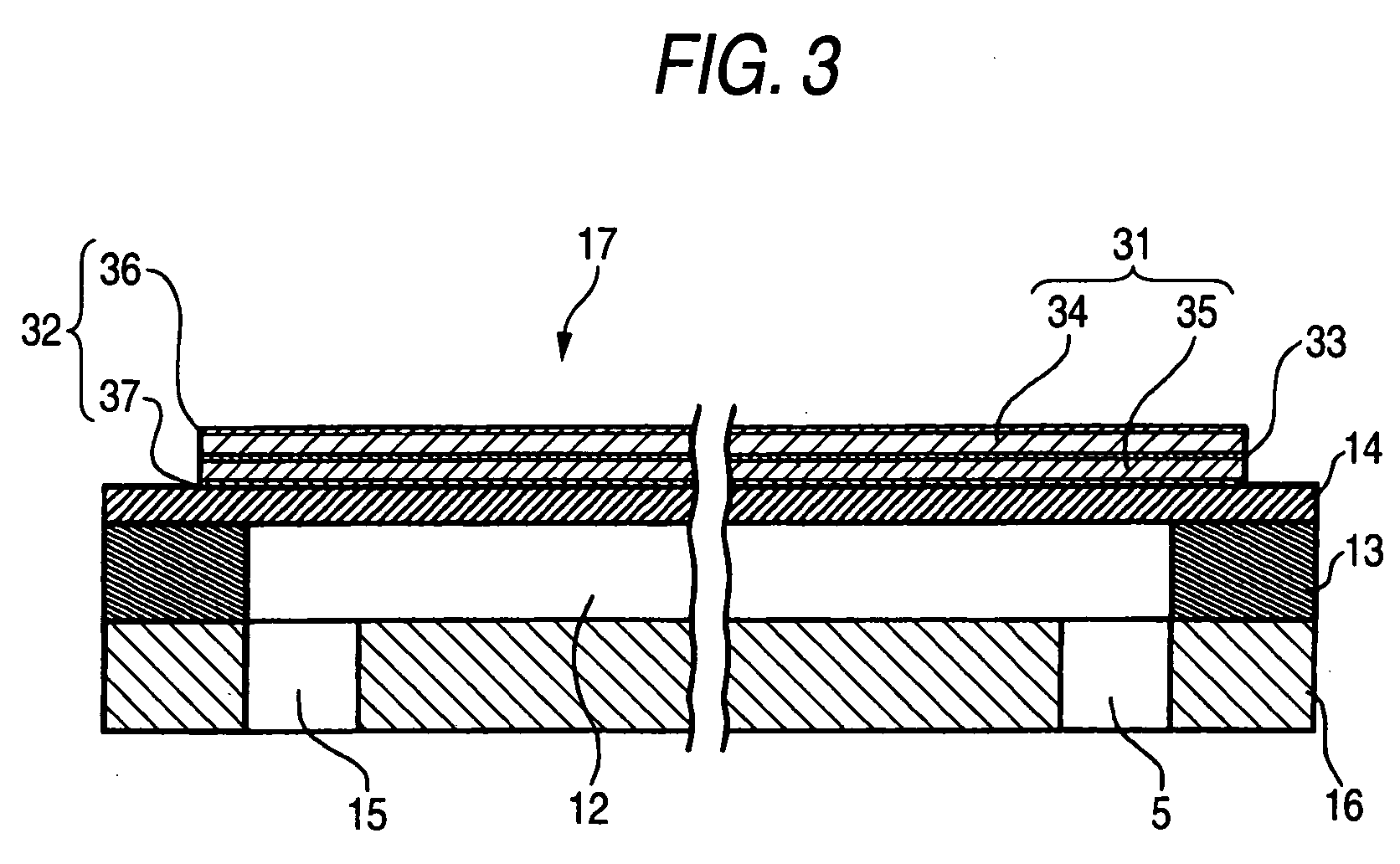

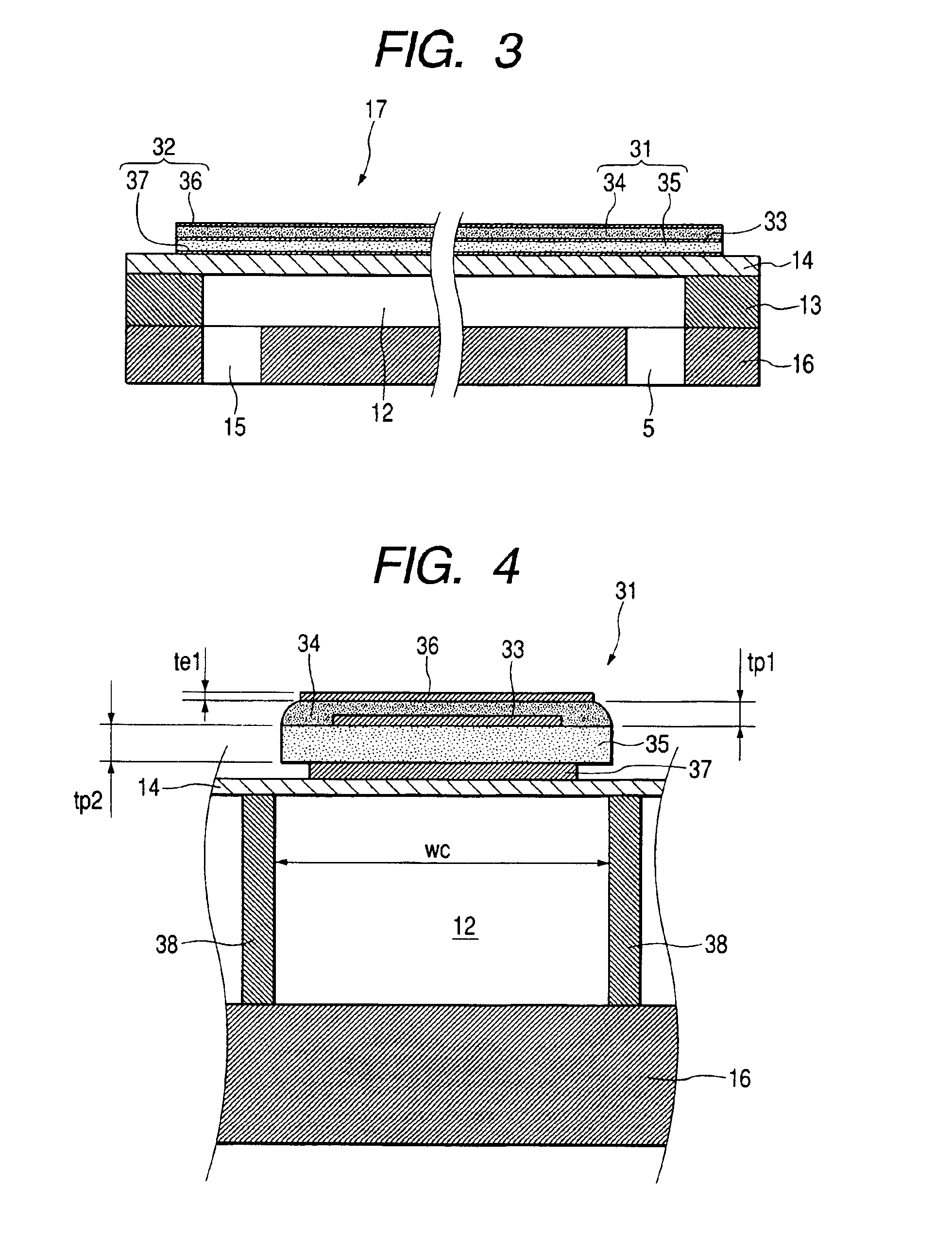

Piezoelectric actuator and fluid ejection head having the same

ActiveUS20050225205A1Improved deformation stabilityImprove production efficiencyInking apparatusPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsElectrical and Electronics engineering

A first common electrode is formed on a vibration plate and to be fixed at a predetermined potential. A first piezoelectric layer is laminated on the first common electrode and having a first thickness. A drive electrode is laminated on the first piezoelectric layer, to which a drive signal is supplied externally. A second piezoelectric layer is laminated on the drive electrode and having a second thickness thicker than the first thickness. A second common electrode is laminated on the second piezoelectric layer and to be fixed at the predetermined potential.

Owner:SEIKO EPSON CORP

Piezoelectric element, piezoelectric actuator and liquid ejection head incorporating the same

InactiveUS6918659B2Effective vibrationGreat degree of deformationPiezoelectric/electrostriction/magnetostriction machinesFlexible member pumpsPiezoelectric actuatorsVoltage

A first common electrode is fixed at a predetermined potential. A first piezoelectric layer is laminated on the first common electrode and has a first deformability with respect to a predetermined voltage. A drive electrode is laminated on the first piezoelectric layer, to which a drive signal is supplied externally. A second piezoelectric layer is laminated on the drive electrode and having a second deformability with respect to the predetermined voltage which is larger than the first deformability. A second common electrode is laminated on the second piezoelectric layer and to be fixed at the predetermined potential.

Owner:SEIKO EPSON CORP

Piezoelectric device for ultrasonic sensor

ActiveUS20170179365A1Avoid disconnectionAvoid separationMechanical vibrations separationPiezoelectric/electrostrictive/magnetostrictive devicesUltrasonic sensorPiezoelectric coefficient

A piezoelectric device includes a substrate with a cavity, a vibrating plate which is provided on the substrate so as to block an opening surface of the cavity, and a piezoelectric element which is provided on a surface of the vibrating plate opposite to the cavity, including a first electrode, a piezoelectric layer, and a second electrode, in which the second electrode has a laminated structure including a Pt layer (lower layer side electrode) and an Ir layer (upper layer side electrode), in which the Pt layer is in contact with the piezoelectric layer, and in which, if it is assumed that two directions which are parallel to a surface of the substrate and mutually perpendicular are defined as an X direction and a Y direction, the Ir layer is extended to an outside of the cavity at least in the X direction on an X-Y plane view.

Owner:SEIKO EPSON CORP

Piezoelectric actuator and fluid ejection head having the same

InactiveUS7265481B2Improved deformation stabilityImprove deformationInking apparatusPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsElectrical and Electronics engineering

Owner:SEIKO EPSON CORP

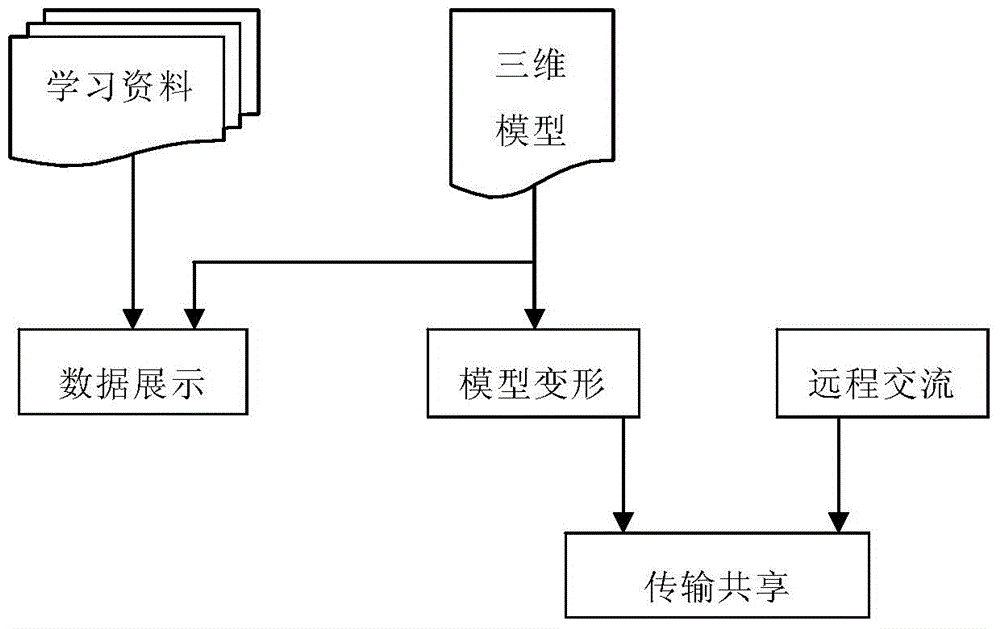

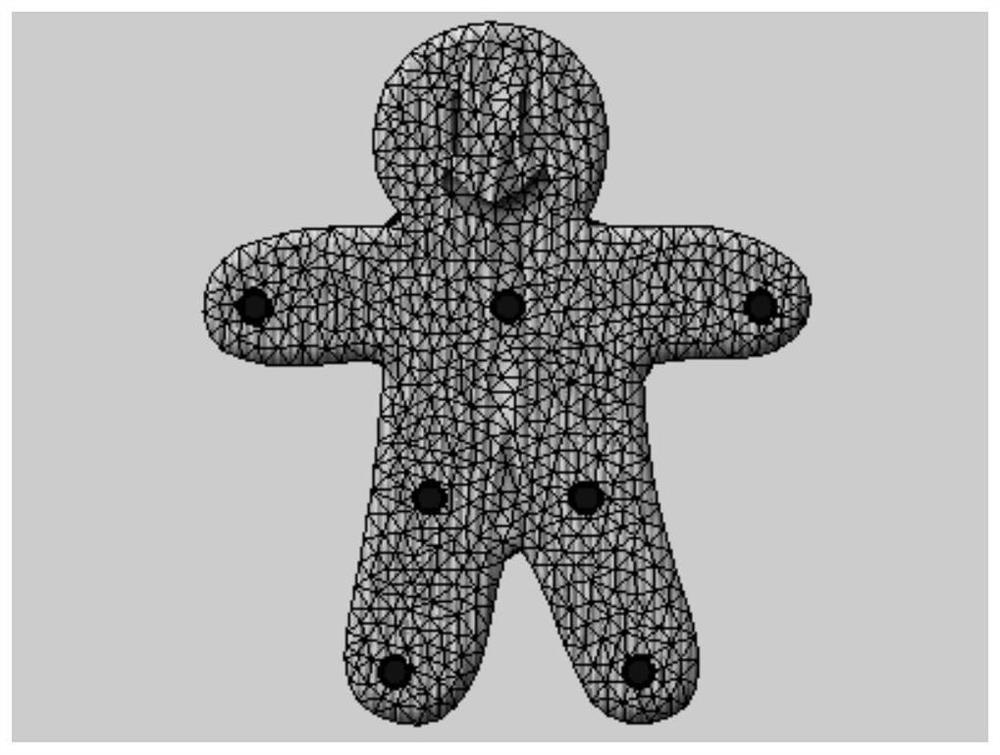

Three-dimensional mechanical data simulation remote sharing and interactive discussion method

ActiveCN103942405ARich learning contentHigh deformation efficiencySpecial data processing applicationsData simulationMedical communication

The invention discloses a three-dimensional mechanical data simulation remote sharing and interactive discussion method. A three-dimensional mechanical data model is used for deformation simulation to achieve simulation of various pathological changes, and various medical image data forms are used for remote sharing and remote interactive discussion, the richness and authenticity of various medical data are displayed to some extent, and medical treatment learners can analyze and discuss the pathology of a patient more accurately. According to an algorithm, the model can be converted to a frequency domain from a geometric space domain by using one transmission method, then a receiving end reversely converts the data from the frequency domain to the geometric space domain, the algorithm enables the quantity of transmitted data to be small, the compression ratio to be higher, transmission to be faster and the like, and therefore medical personnel in another place can carry out medical communication and mutual-assistance discussion more quickly.

Owner:北京百博团人工智能技术研究院

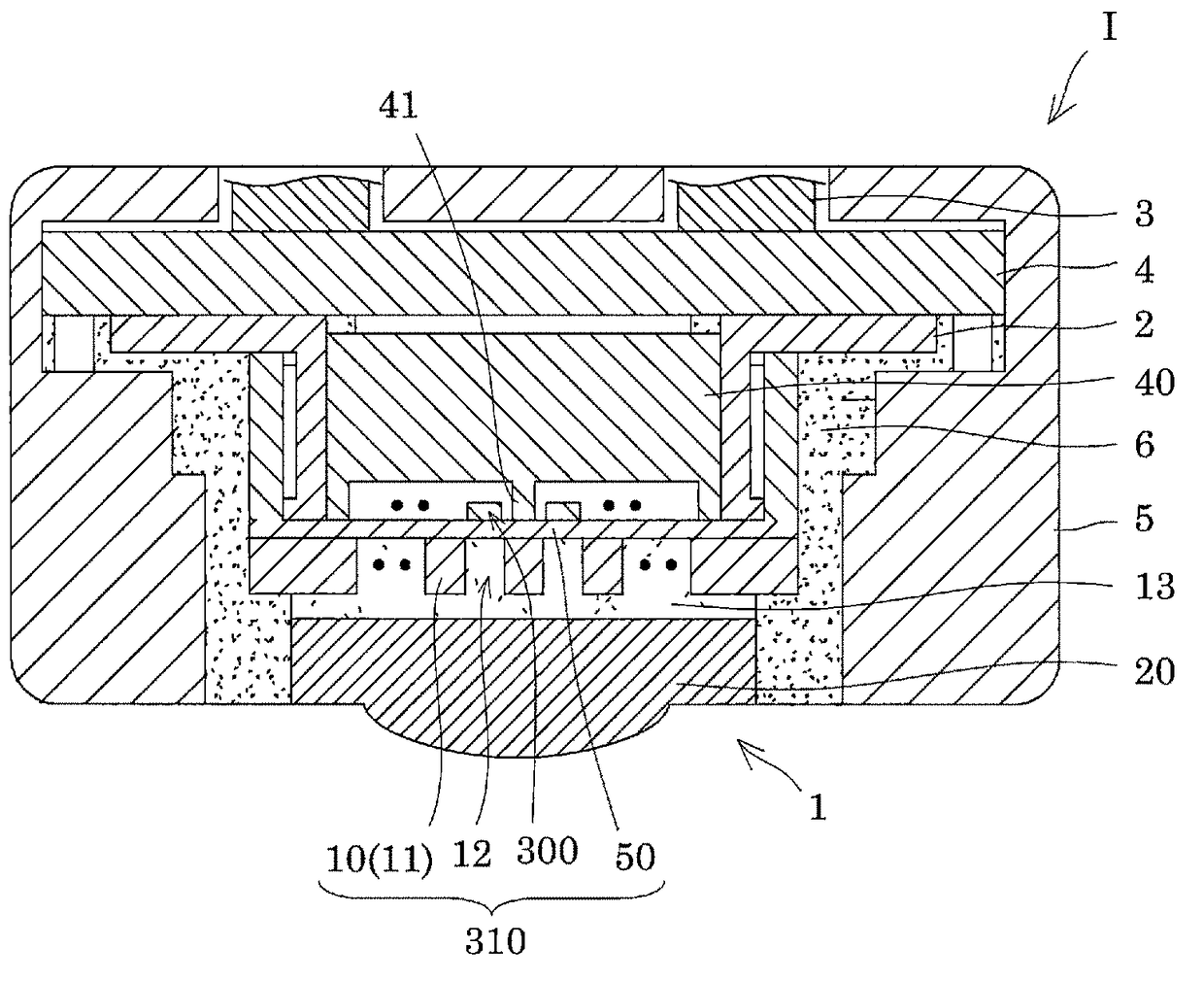

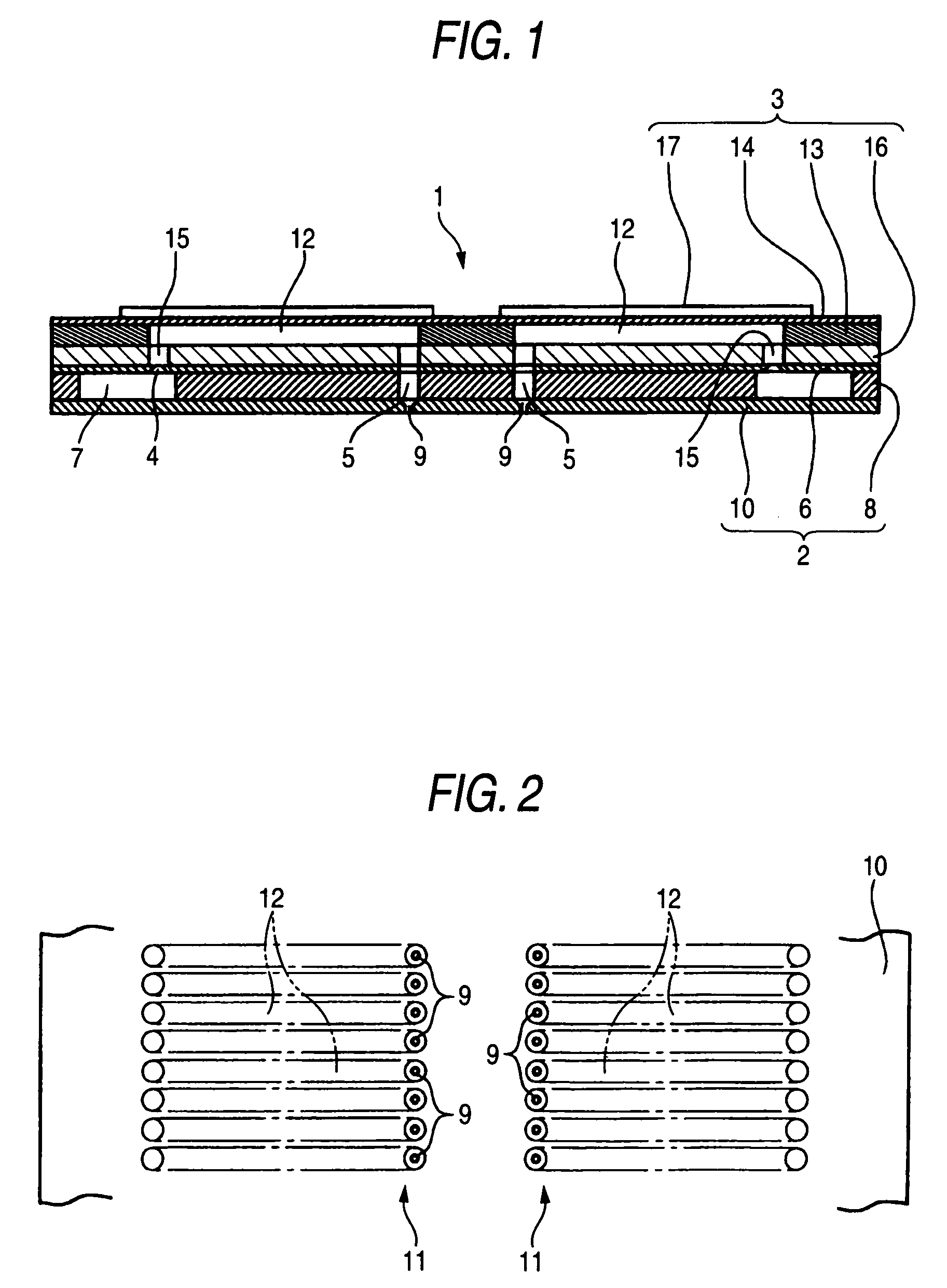

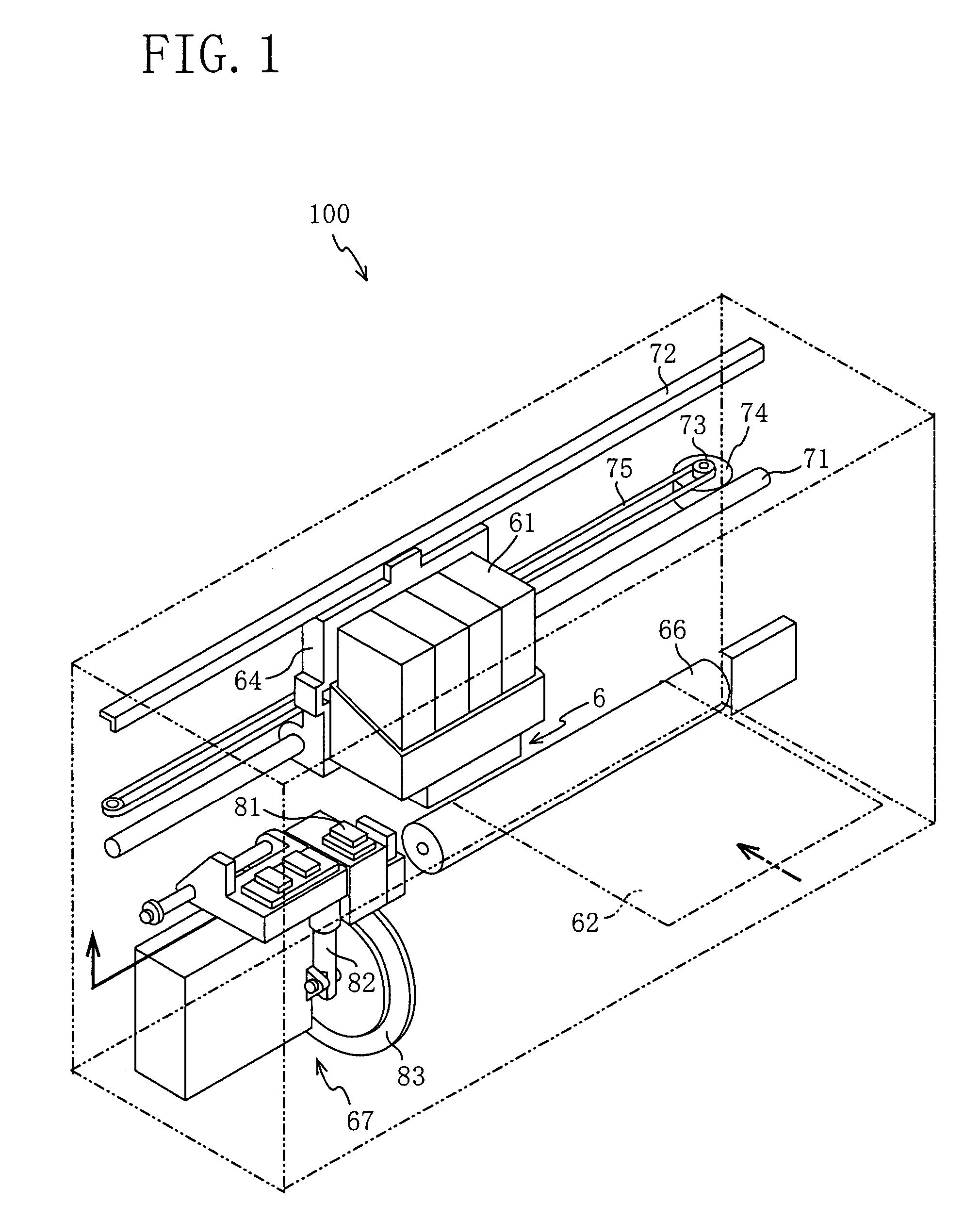

Droplet ejecting apparatus

Since two polarizing external electrodes sandwich a portion of a sheet-stacked piezoelectric body that is located between first and second internal electrodes, that portion of the stacked piezoelectric body is polarized in a direction perpendicular to a direction in which the first and second internal electrodes are opposed to each other, when a polarizing voltage is applied to the two polarizing electrodes. Subsequently, the two polarizing electrodes are electrically connected to the second internal electrodes. Thus, the sheet-stacked piezoelectric body can be manufactured without needing to remove the polarizing electrodes. When a drive voltage is applied to the first and second internal electrodes, intermediate piezoelectric sheets of the stacked piezoelectric body are deformed in a “shear” mode, i.e., are curved toward a pressure chamber in which ink is accommodated. Since, simultaneously, an electric field parallel to the direction of polarization of the stacked piezoelectric body is produced in an outermost piezoelectric sheet of the stacked body, the outermost sheet is elongated in the direction of stacking of the piezoelectric sheets, whereby the amount of deformation of the stacked piezoelectric body toward the pressure chamber is increased.

Owner:BROTHER KOGYO KK

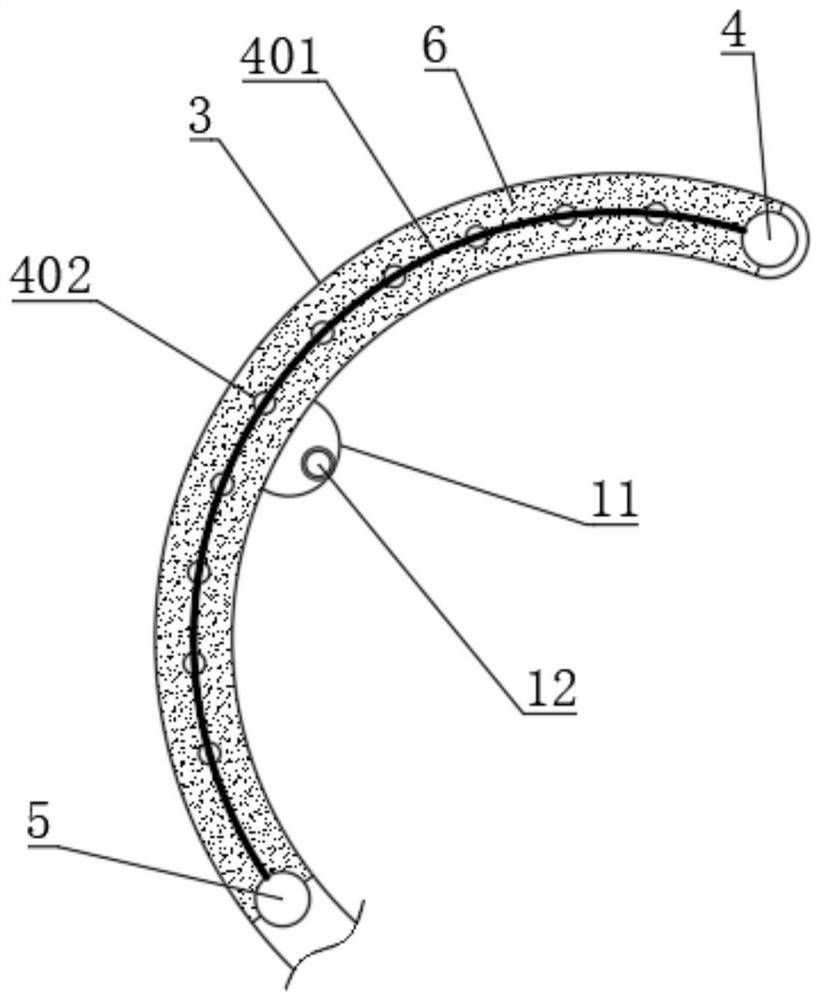

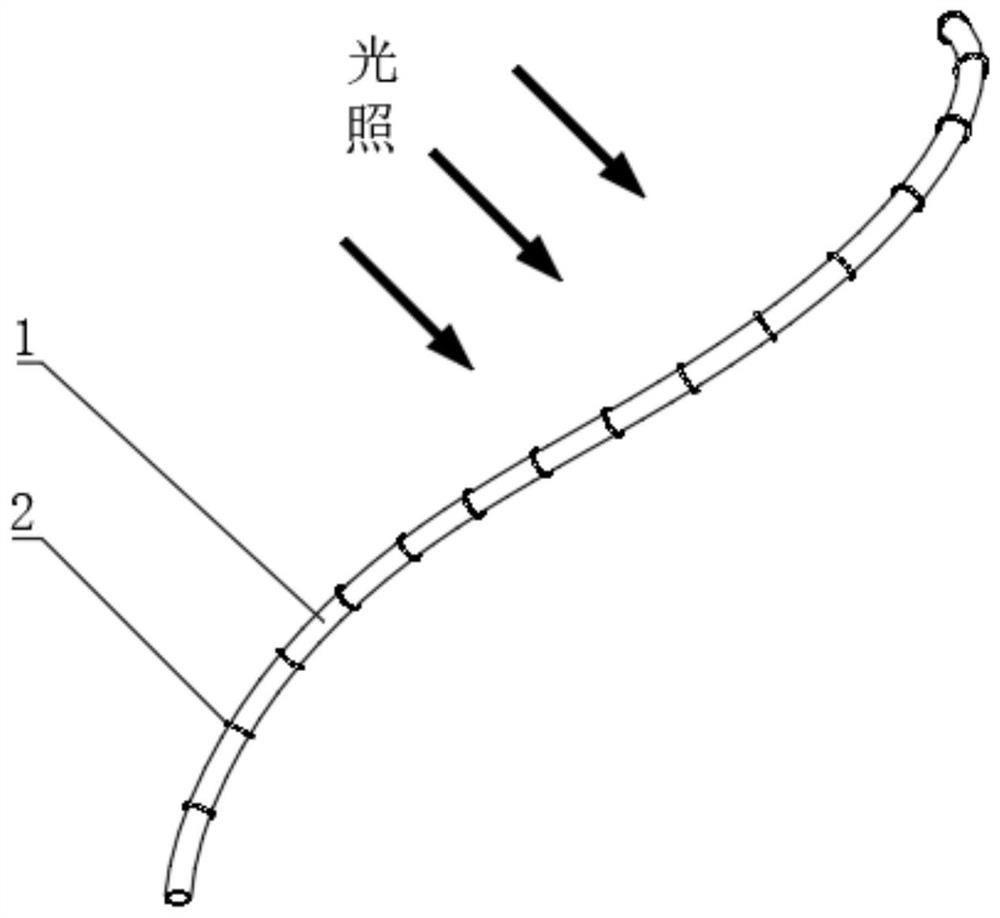

Phase-change thermal radiation absorption and storage type outdoor cable

InactiveCN112037977AIncrease air pressureExtended service lifeClimate change adaptationInsulated cablesLight reflectionEngineering

The invention discloses a phase-change thermal radiation absorption and storage type outdoor cable, belongs to the technical field of cables, and aims to promote ammonium chloride powder in an arc-shaped shading bag sheet to be heated and decomposed through irradiation of sunlight on the arc-shaped shading bag sheet, so that the air pressure in the arc-shaped shading bag sheet is increased, and the arc-shaped shading bag sheet extends outwards to wrap the surface of the cable. On one hand, the contact area between light and the surfaces of the wires and the cables can be reduced, and on the other hand, the ammonium chloride powder in the arc-shaped shading bag pieces can be used for replacing the wires and the cables to absorb heat radiation by means of the heat absorption effect of the ammonium chloride powder, further, the possibility of premature aging of the wire and cable is reduced, the service life of the wire and cable is prolonged, the high-temperature phase state of the wireand cable is recovered after the temperature of the traction metal rope rises, a light reflection ball in a spherical storage groove is driven to be exposed, and the heat radiation quantity received by the wire and cable can be reduced by means of the reflection effect of the light reflection ball on light.

Owner:闫山

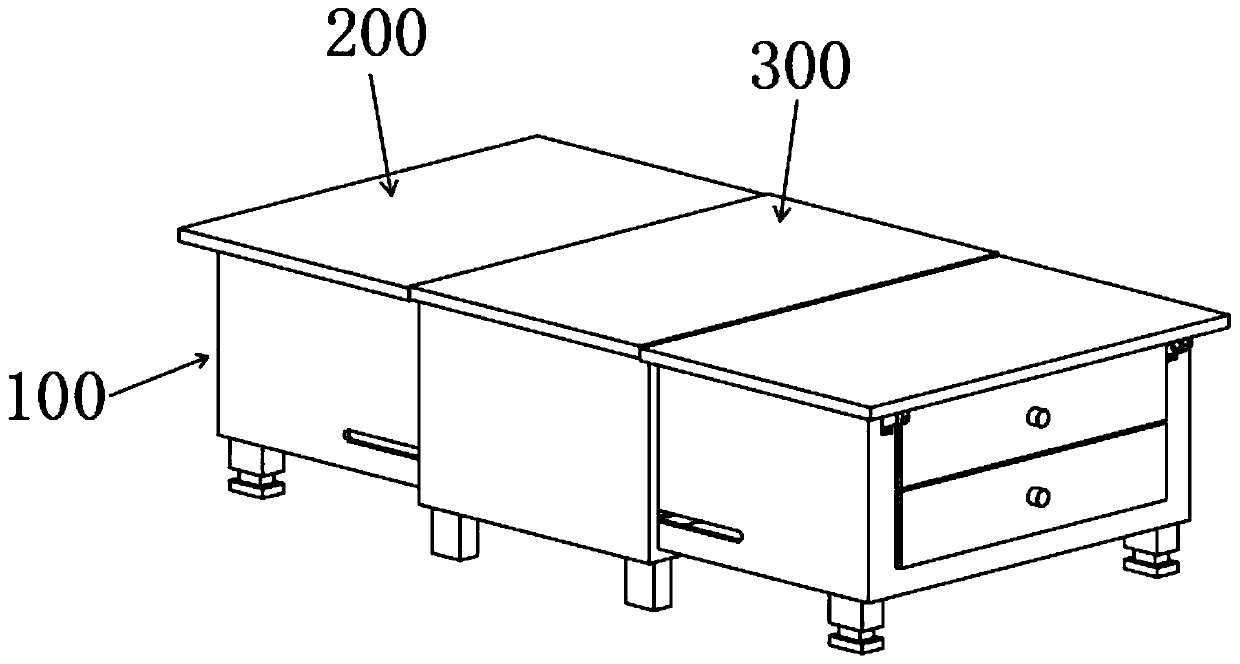

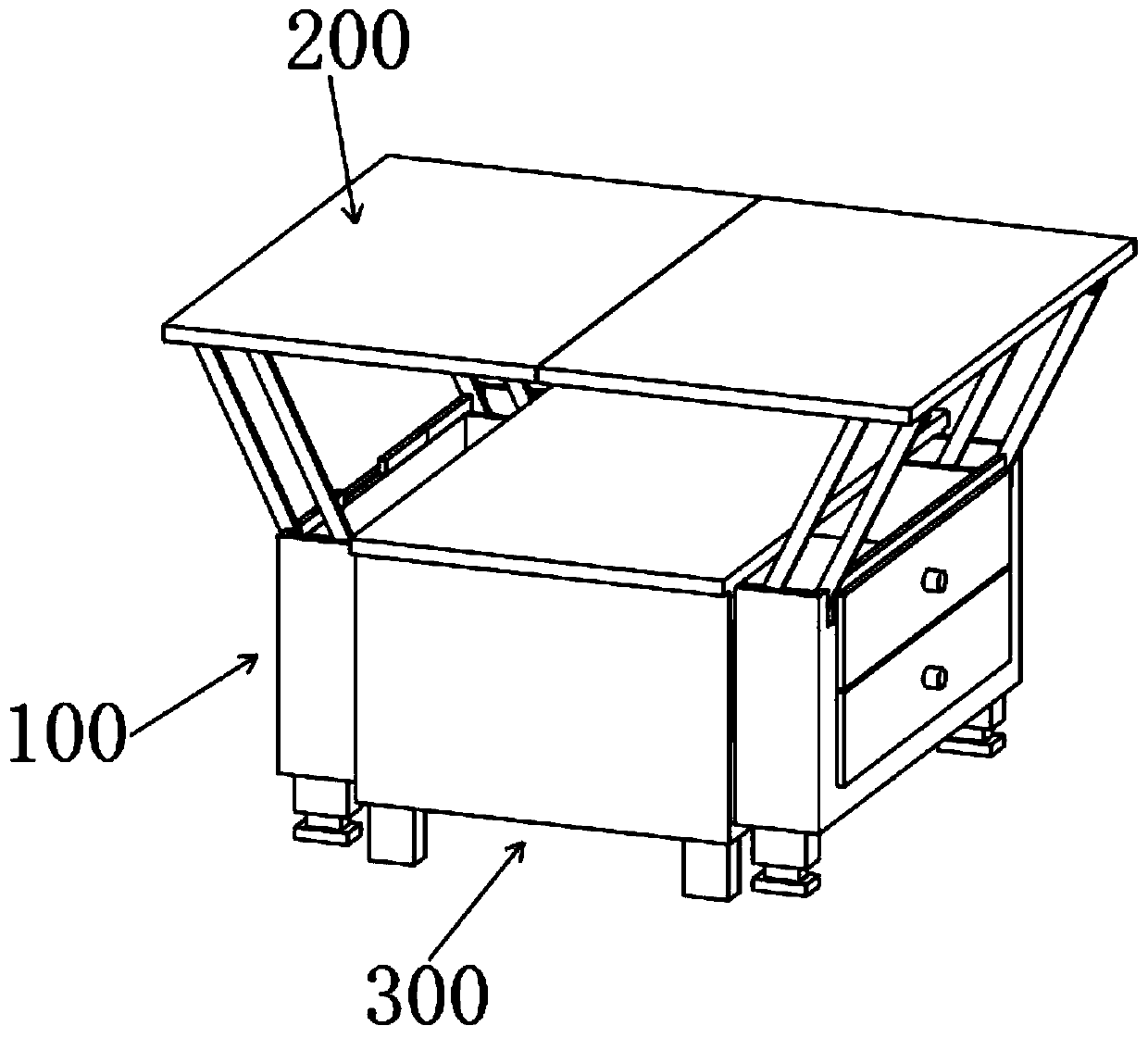

Tea table facilitating fine adjustment of height of supporting leg

InactiveCN111513470AEasy to useShorten the lengthServing tablesVariable height tablesEngineeringStructural engineering

Owner:李其红

Q500-steel-grade low-alloy structural steel bar and controlled-rolling and controlled-cooling rolling method thereof

ActiveCN114058944AAchieve uniformityImprove uniformityMetal rolling arrangementsChemical compositionMaterials science

The invention discloses a Q500-steel-grade low-alloy structural steel bar and a controlled-rolling and controlled-cooling rolling method thereof, the Q500-steel-grade low-alloy structural steel bar comprises the following chemical components by weight percentage: 0.05%-0.18% of C, 0.20%-0.40% of Si, 1.00%-1.60% of Mn, less than or equal to 0.030% of P, less than or equal to 0.030% of S, less than or equal to 0.20% of Cr, less than or equal to 0.20% of Ni, less than or equal to 0.10% of Mo, less than or equal to 0.15% of Cu, 0.02-0.10% of V, less than or equal to 0.05% of Nb, less than or equal to 0.02% of Ti, less than or equal to 0.004% of B, 0.005-0.012% of N, 0.02-0.04% of Al and less than or equal to 0.45% of CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. According to the method, the initial rolling temperature of rolling ranges from 1000DEG C to 1050DEG C; by adopting the method, the uniformity of rolled piece structure can be realized.

Owner:DAYE SPECIAL STEEL CO LTD

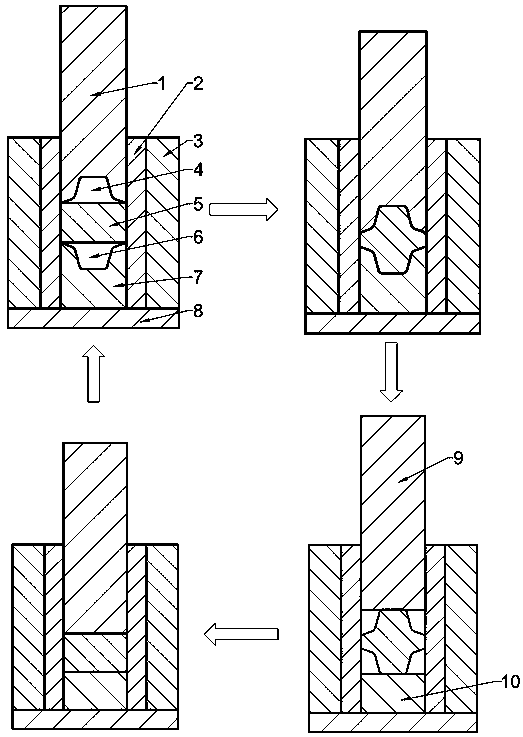

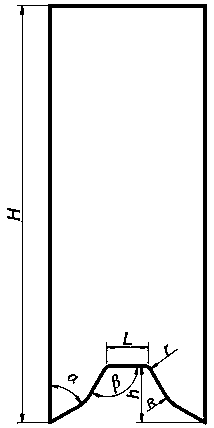

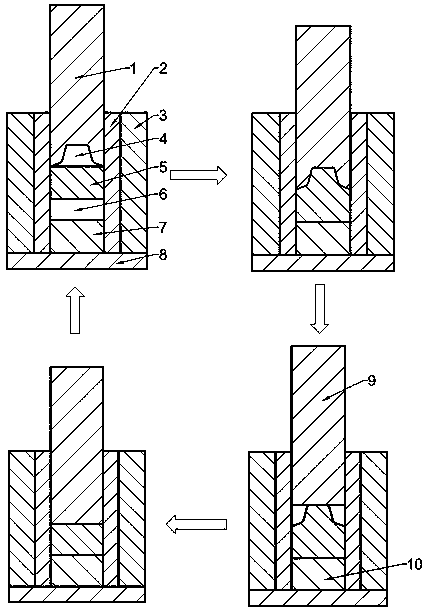

Repeatedly extruding upsetting die and method for preparing block ultrafine-grained material

InactiveCN109047363AOvercoming Strain ConcentrationReduce deformation dead zoneExtrusion diesForging/hammering/pressing machinesMachiningMetal

The invention discloses a repeatedly extruding upsetting die and method for preparing a block ultrafine-grained material, and belongs to the technical field of metal plastic machining. The repeatedlyextruding upsetting die includes an upper extrusion head, a lower extrusion head, a female die body, a female die body prestress ring, a base plate, an upper flattening male die body and a lower flattening male die body. The upper extrusion head and the lower extrusion head are placed in a female die body passage, a trapezoidal groove is formed in the upper end of the lower extrusion head, a sametrapezoidal groove is formed in the lower end of the upper extrusion head, and a workpiece is located between the upper extrusion head and the lower extrusion head. The method for preparing the blockultrafine-grained material by adopting the device comprises the steps that the upper extrusion head moves downwards, the workpiece is pressed into the grooves of the upper extrusion head and the lowerextrusion head, the two extrusion heads are removed, the upper flattening male die body and the lower flattening male die body are replaced, and the workpiece is pressed back to the original shape. The material structure can be refined by repeating the processes. The repeatedly extruding upsetting die is simple in structure, convenient to machine and easy to operate, can be realized on conventional pressure machining equipment, and can obtain uniform deformation in the material, and is applicable to a wide range of materials.

Owner:JIANGSU UNIV OF SCI & TECH

A chrome-zirconium-copper contact wire for electrified railways and its processing technology

ActiveCN104342575BMaximum total rolling deformationLow costSingle bars/rods/wires/strips conductorsMetal/alloy conductorsContact lineSolid solution

The invention discloses a preparation method of an electrified railway chromium-zirconium-copper contact line. Copper is taken as a substrate, 0.30-0.70% of Cr and 0.10-0.35% of Zr in percentage by weight are added into the substrate, and the total sum of impurities is no greater than 0.05%. The preparation method comprises the following steps: performing vacuum melting and vacuum horizontal continuous casting, thereby obtaining a long-length large cross section chromium-zirconium-copper continuous cast blank; performing full hot continuous rolling and on-line solid solution, thereby obtaining a long-length chromium-zirconium-copper line rod disc; drawing and peeling the disc, and performing cold continuous rolling, thereby reducing the diameter; further performing aging treatment to reinforce the disc; further performing cold continuous rolling by using a Y-type rolling machine, thereby pre-forming the line; and finally performing fine drawing formation once. The chromium-zirconium-copper contact line produced by using the preparation process is fine and uniform in grain, free of defect, high in strength, high in conductivity and high in softening temperature, and applicable to industrialized production.

Owner:YANTAI WANLONG VACUUM METALLURGY

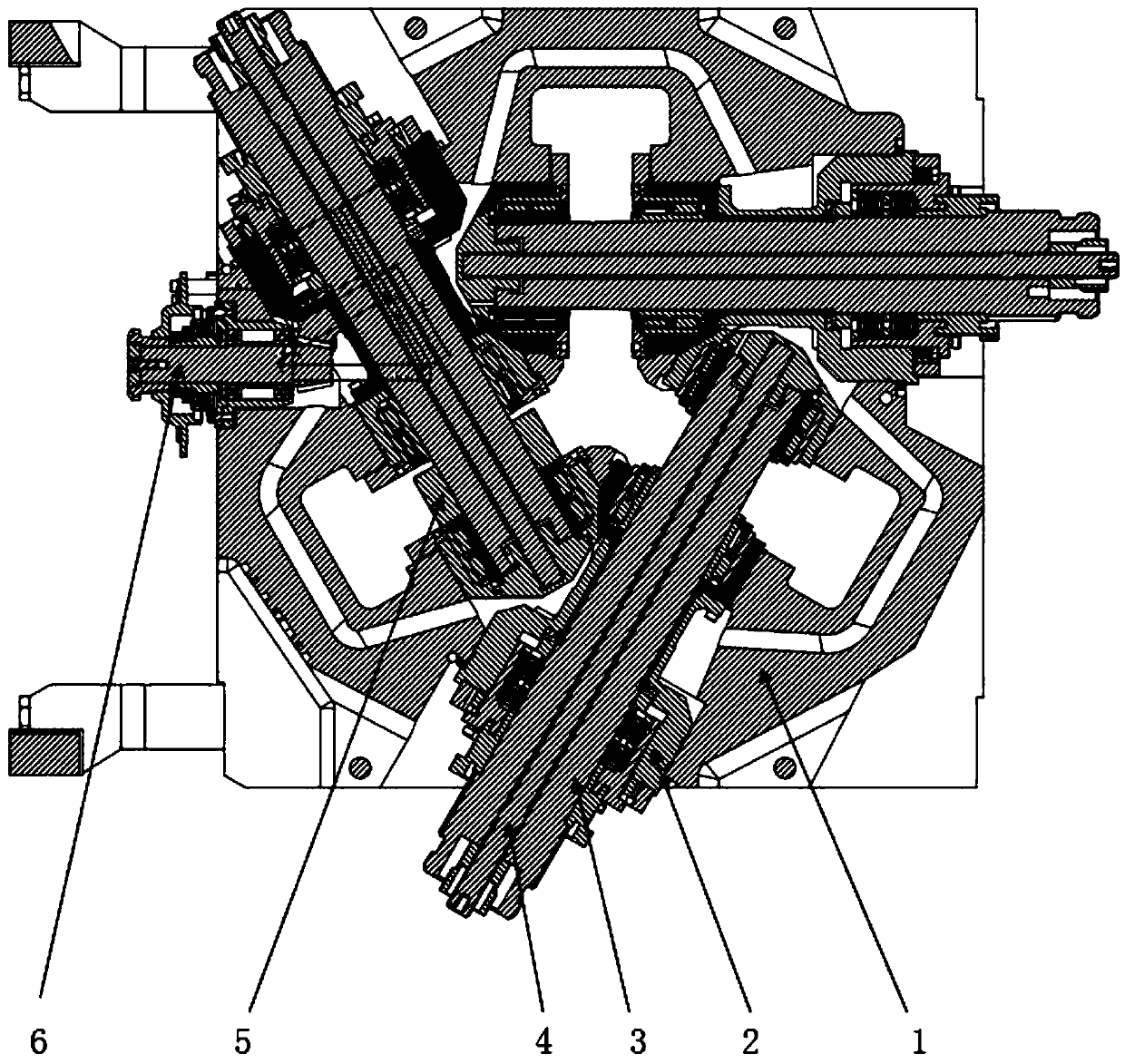

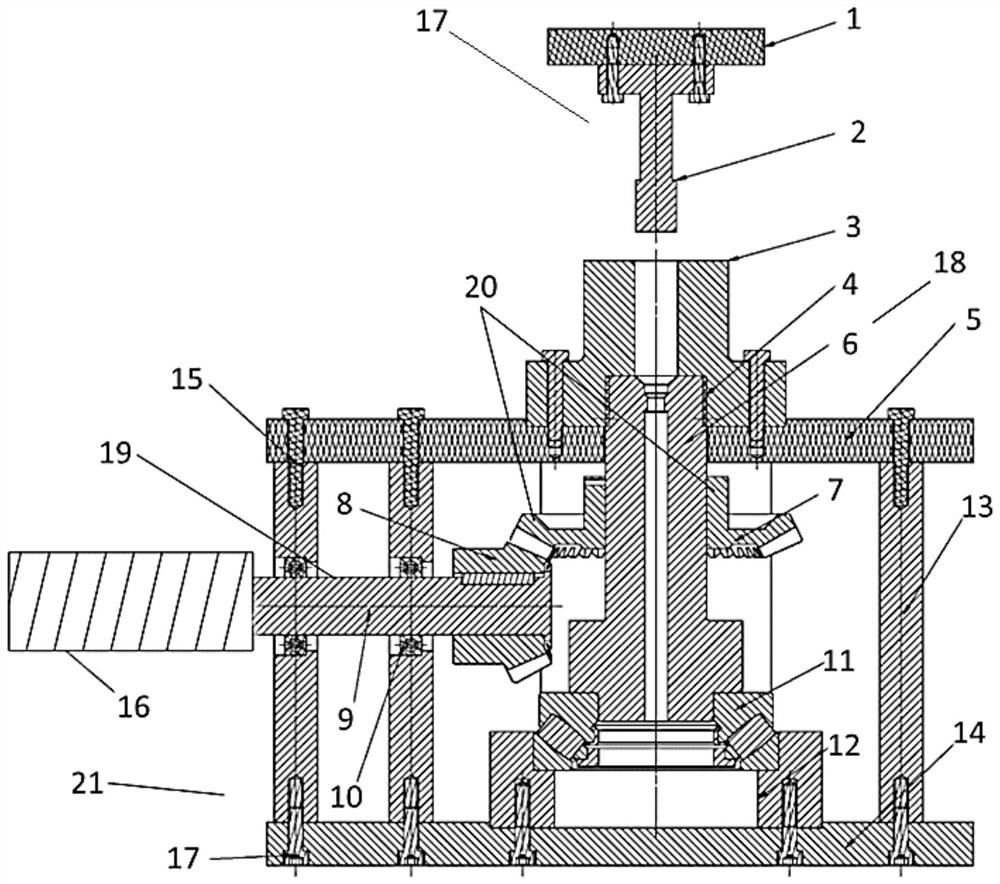

Star type multi-roller adjustable precision rolling mill

PendingCN109570237AHigh deformation efficiencyBetter Tolerance and More ConsistentMetal rolling stand detailsMetal rolling arrangementsRolling millEngineering

The invention relates to a star type multi-roller adjustable precision rolling mill which solves the technical problems of large rolling extension widths, fixed hole types, rough quality and the likein the prior art. The star type multi-roller adjustable precision rolling mill is suitable for being popularized and used by adopting the technical route that the precision rolling mill comprises a main machine frame, three sets of eccentric bushing assemblies arranged in the main machine frame in a star type with the same angle, long shaft assemblies arranged in the eccentric bushing assemblies and adjusting mechanisms in bevel-gear meshing with the eccentric bushing assemblies.

Owner:四川易尚天交实业有限公司

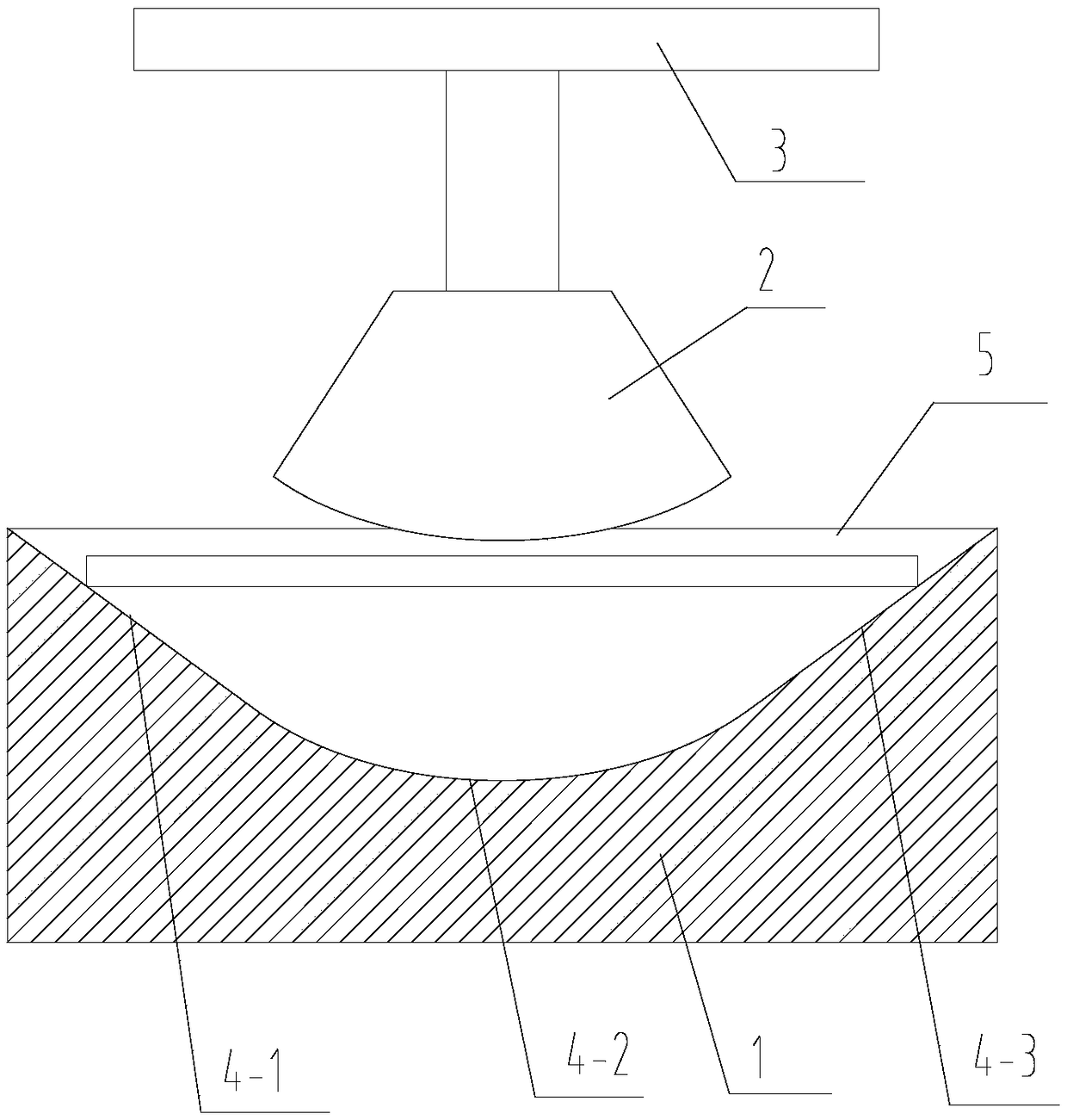

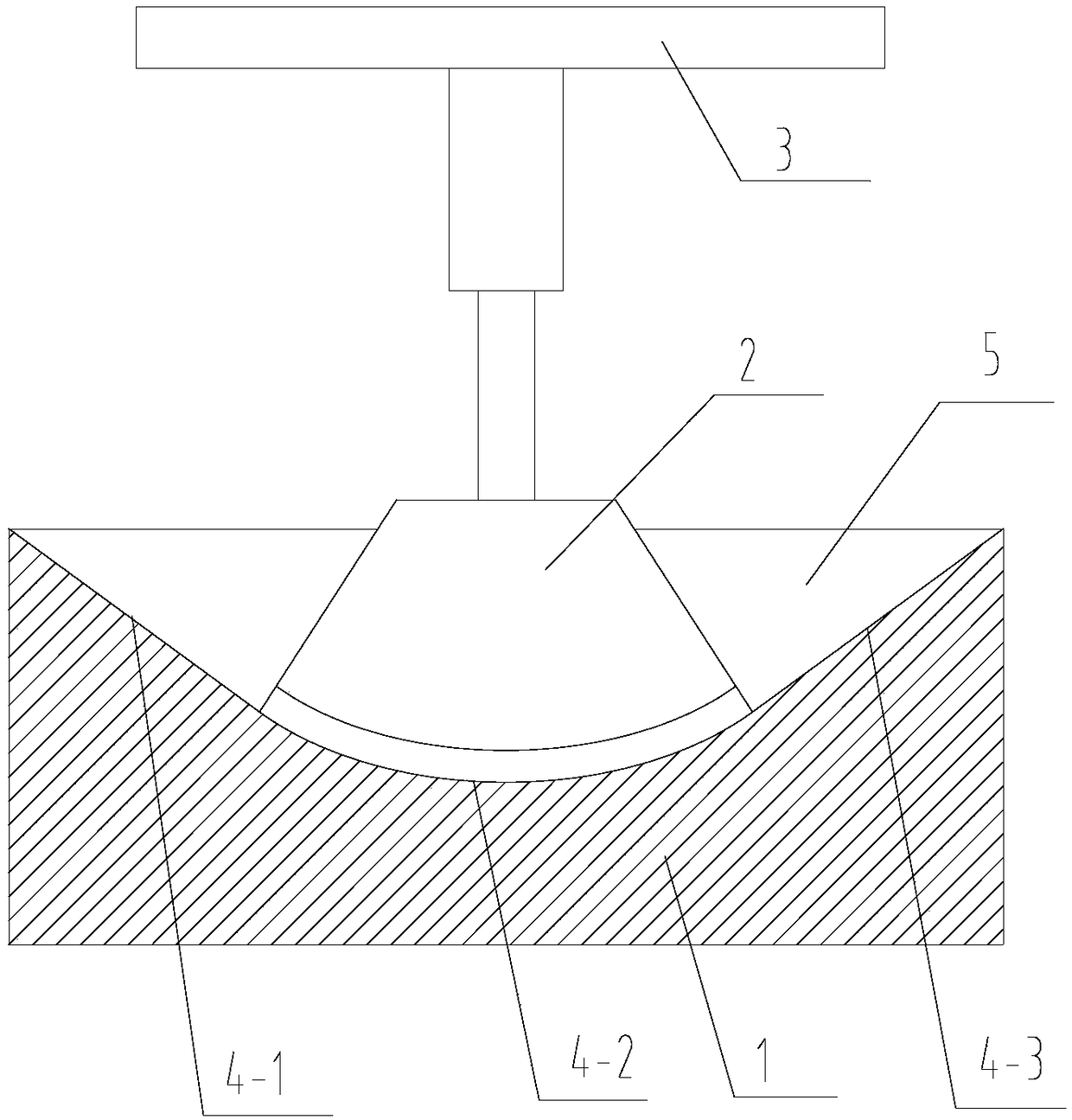

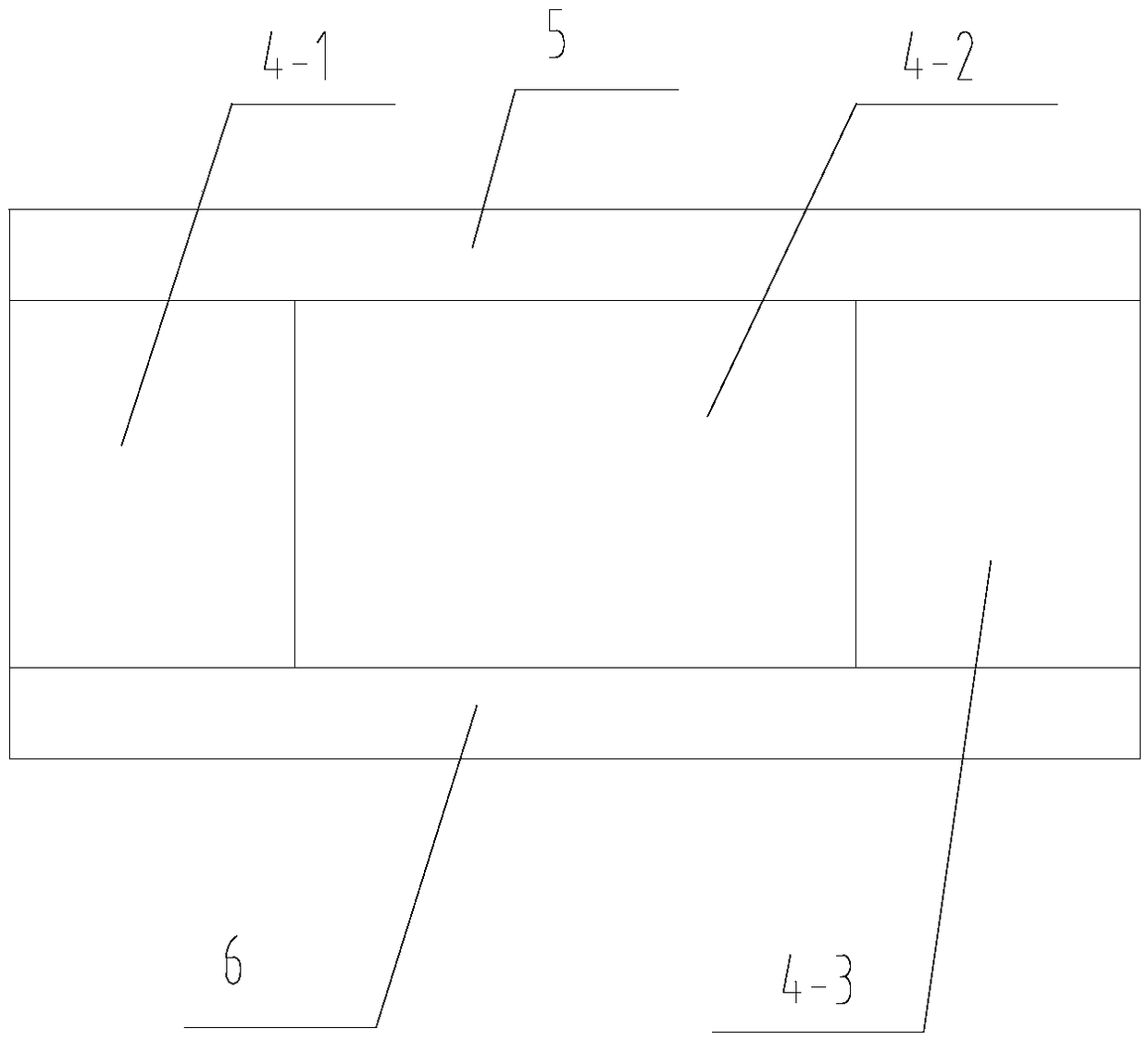

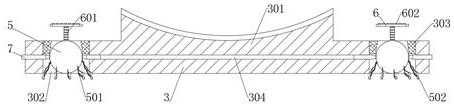

Downward-pressing arc-shaped steel plate processing device

The invention provides a downward-pressing arc-shaped steel plate processing device which comprises a die seat, a punching die and a supporting seat. In the process of bending a steel plate prefabricated member, the punching die squeezes a steel plate prefabricated member from top to bottom; in the process of punching, utilizing of dead weight of the punching die and the steel plate prefabricatedmember to improve deformation efficiency is facilitated, so that energy consumption is lowered. A groove is arranged to integrate a die with a clamp, so that processing steps and structure of the processing device are simplified, lowering of operation difficulty is facilitated, and processing cost is lowered.

Owner:芜湖同创模具机械有限公司

Electric railway contact line and machining process thereof

InactiveCN105063410AReduce transmission lossConducive to energy saving and emission reductionMetal/alloy conductorsCable/conductor manufactureCeriumContact line

The invention discloses an electric railway contact line and a machining process thereof. The raw materials include 0.08-0.40% of zirconium, 0.05-0.10% of cerium, 0.05% of total impurities or less and the balance copper. According to the machining process of the contact line, a large-length and large-section continuous casting billet is obtained through vacuum melting and vacuum horizontal continuous casting; a large-length wire rod is obtained through full hot continuous rolling and on-line solid solution; the wire rod is subjected to drawing and stripping and then subjected to thermo-mechanical treatment for reducing; aging treatment reinforcement is carried afterwards; cold continuous rolling pre-formation is carried out at room temperature through a Y-type rolling mill; finally, finish drawing formation is carried out. The electric railway contact line produced through the process is fine and uniform in grain, free of defects, high in strength, electric conductivity and softening temperature and suitable for large-scale industrial production.

Owner:YANTAI WANLONG VACUUM METALLURGY

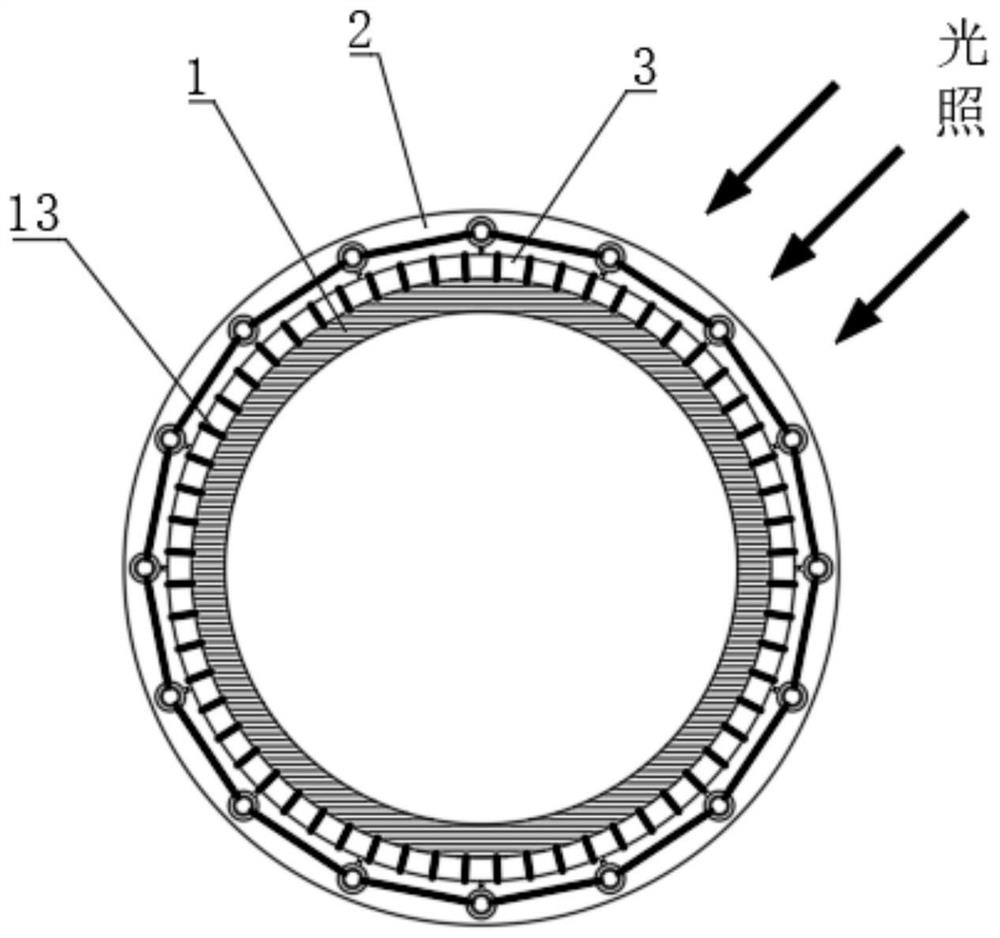

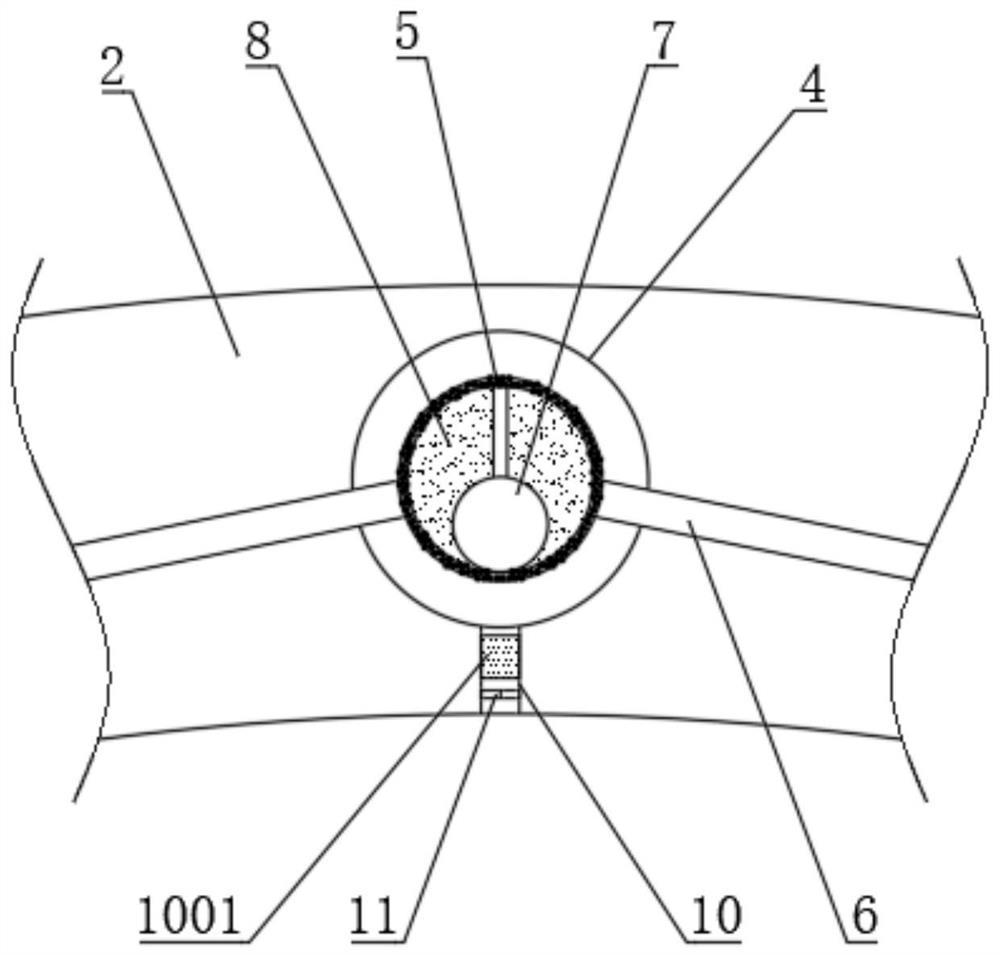

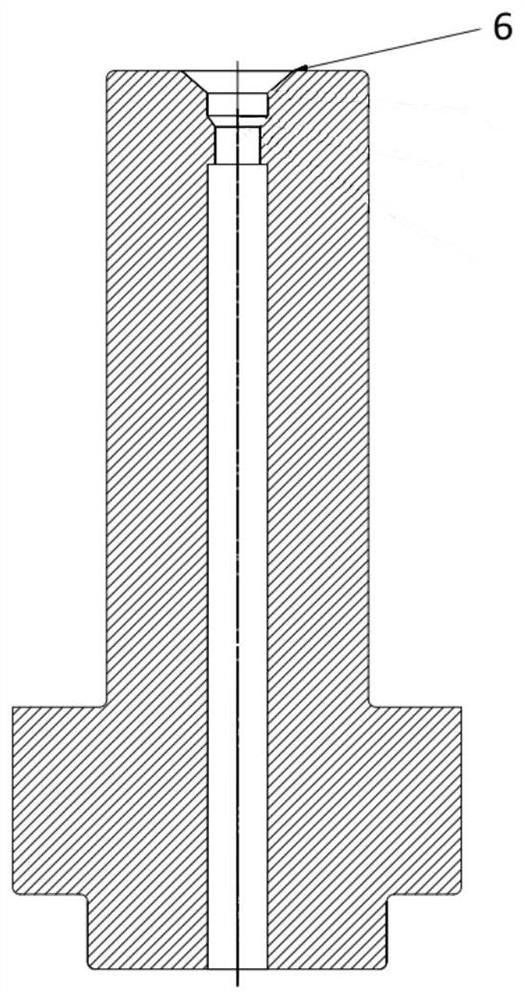

Outdoor cable based on phase-change thermal radiation reflection

InactiveCN112133477AReduce heat radiationImprove cooling effectDispersed particle filtrationElectrostatic cleaningElectric power equipmentCooling effect

The invention discloses an outdoor cable based on phase-change thermal radiation reflection, and belongs to the technical field of power equipment. According to the scheme, an outdoor cable body is illuminated by light, so that thermal decomposition of ammonium chloride powder in a rubber encapsulated ball in an illuminated area can be promoted, and the air pressure in the rubber encapsulated ballis increased. The magnetic shielding state of traction magnetic balls is removed by means of expansion of the rubber encapsulated ball, and the outdoor cable body can be deformed to be elliptical bymeans of attraction between the adjacent traction magnetic balls and extrusion of an upper connecting pressing rod, so that on one hand, the illuminated area of the outdoor cable body can be reduced,and the amount of heat radiation absorbed by the outdoor cable body is reduced, and on the other hand, air in a built-in pneumatic cavity can be extruded out by means of deformation of the rubber encapsulated ball, eject open a rubber sealing sheet and then is released outwards by means of airflow exchange holes, and therefore the outdoor cable body on the outer side is blown, and the cooling effect on the outdoor cable body is improved.

Owner:兰宝

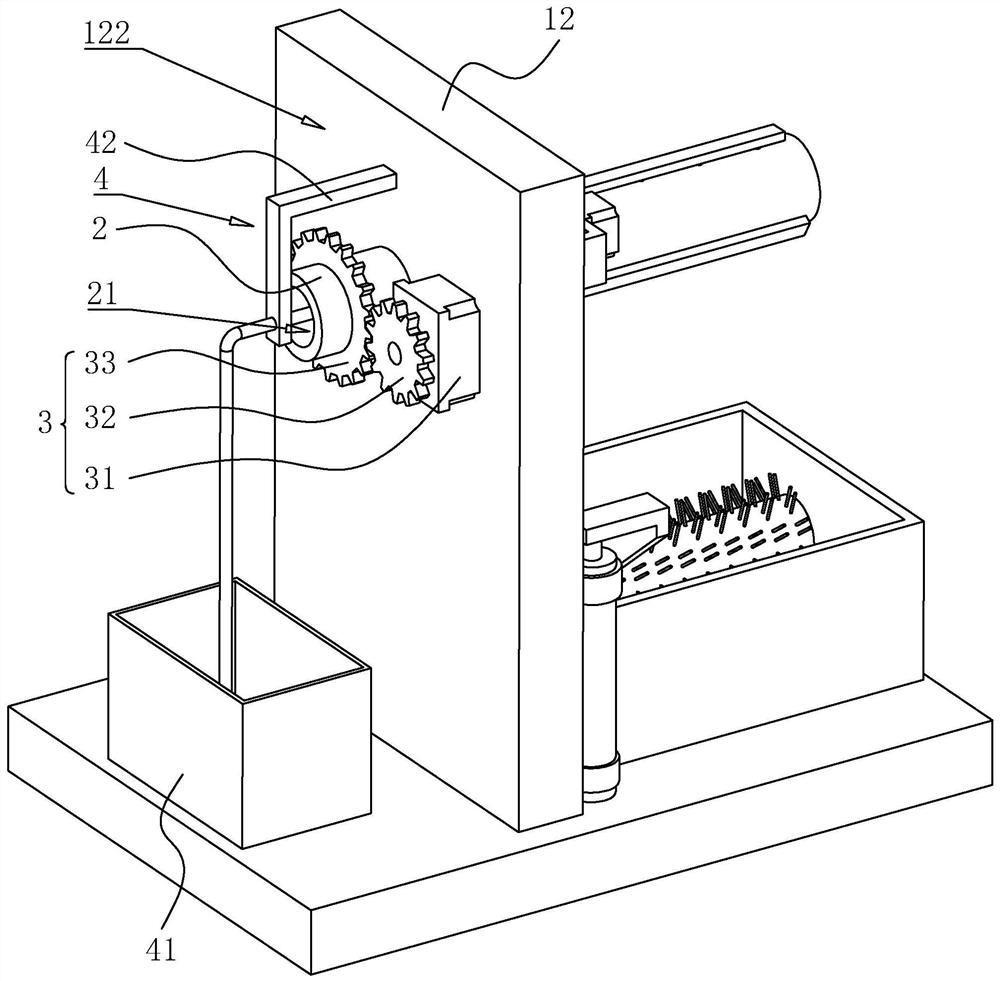

Two-time torsion extrusion device and method with variable-section cavity for grain refining

ActiveCN111889528ASevere and uniform plastic deformationGrain refinementExtrusion diesShearing deformationSevere plastic deformation

The invention discloses a two-time torsion extrusion device and method with a variable-section cavity for grain refining. The device comprises a male die part, a transmission mechanism, a power mechanism and a female die part, wherein the male die part is matched with the female die part, and the power mechanism is connected with the transmission mechanism; and the male die part comprises an upperdie plate and an upper die, the female die part comprises an upper cylinder, an upper plate and a main die, the upper die plate is arranged on the upper die, the upper die is matched with the upper cylinder and enters the upper cylinder and the main die in a working state under the action of a hydraulic press sliding block, the upper cylinder is arranged on the upper plate, the main die is arranged below the upper plate and connected with the upper cylinder, and the upper die enters the upper cylinder in the working process. According to the two-time torsion extrusion device and method, by changing the shape of the section of the inner cavity of the rotating die, the die with the variable-section cavity is rotated during extrusion, a material has both extrusion deformation and shearing deformation brought by die rotation, severe plastic deformation is realized, forming force is small, deformation efficiency is high, and a good grain refining effect can be achieved.

Owner:SHANGHAI JIAO TONG UNIV

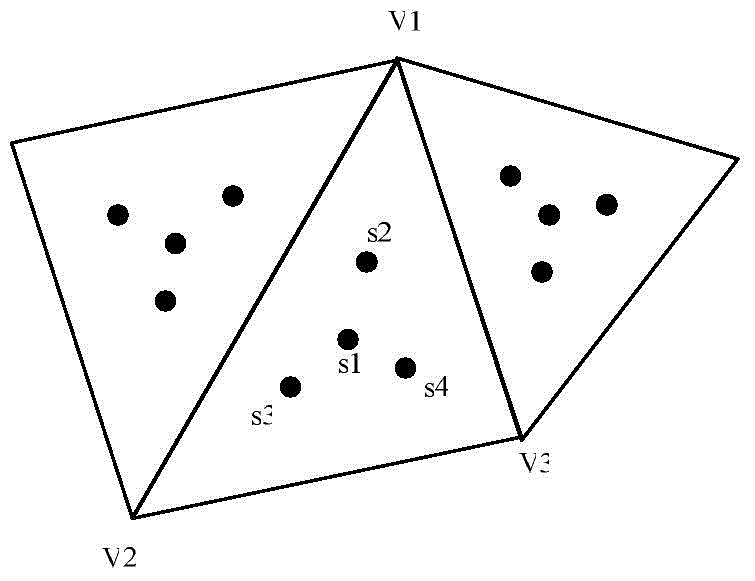

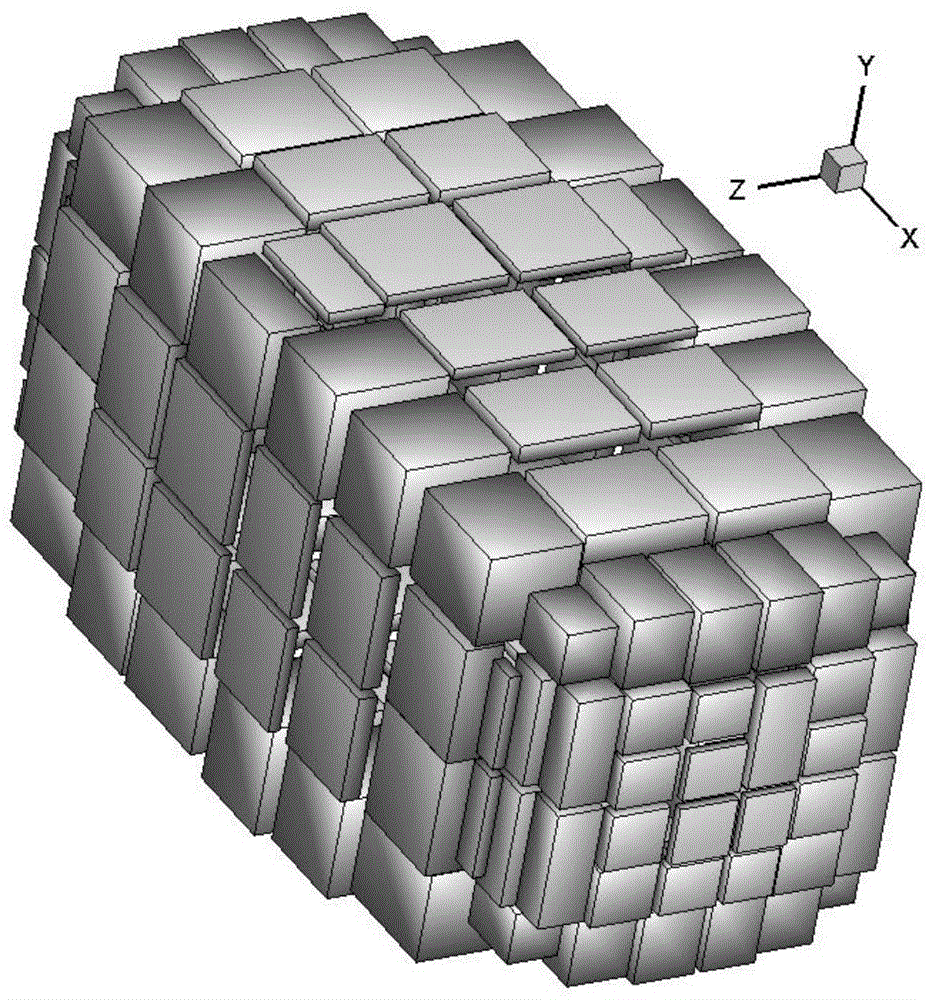

Sample simplifying method of radial basis function support points

ActiveCN105631920AShorten the timeReduce the number of times3D-image rendering3D modellingComputational scienceGrid deformation

The invention belongs to the technical field of structured grids, structured / unstructured hybrid grids and point clouds, and specifically relates to a sample simplifying method of radial basis function support points. The data sample simplifying scheme of the invention comprises the following steps: boundary grid points are grouped through a group of cuboids firstly, the number of each group of grouped grid points is about 100, and an average position and an average deformation amount of each group of the grid points are calculated; and, when the next group of sample points are searched, the group is taken as a unit firstly, 3-5 groups the grid points of which have the maximum deformation amount error of the average position of the various groups of the grid points, the grid points in the 3-5 groups are then searched one by one, the grid point having the maximum grid deformation amount error in each group is determined, and the grid point, having the maximum grid deformation amount error in each group, as a new sample is added to a sample space. Time for search the sample points can be reduced through adoption of the technical scheme.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

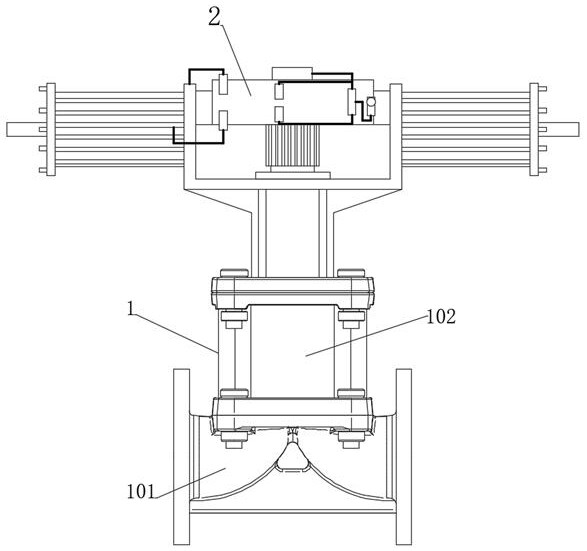

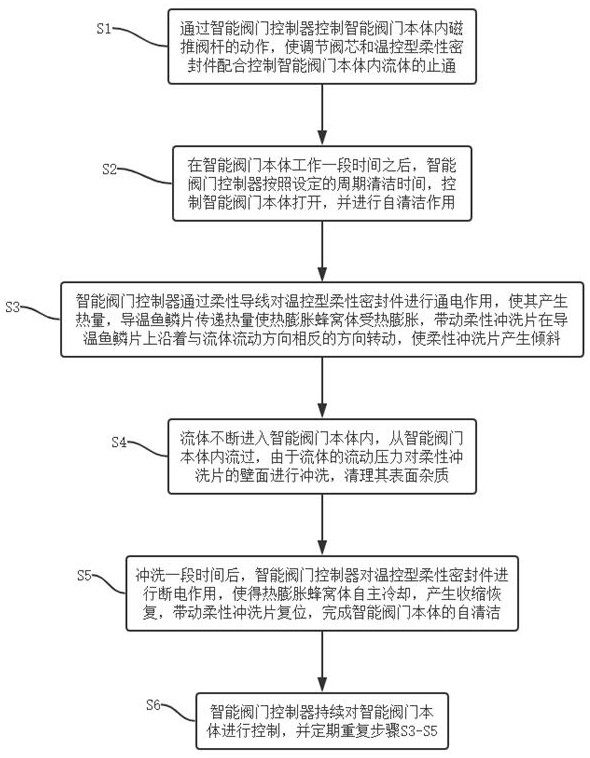

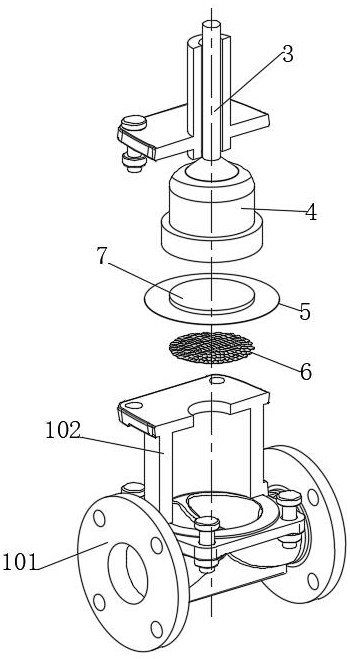

Intelligent valve and using method thereof

InactiveCN113389914AImprove sealingExtended service lifeDiaphragm valvesOperating means/releasing devices for valvesTemperature controlEconomic benefits

The invention discloses an intelligent valve and a using method thereof, and belongs to the field of intelligent valves. The intelligent valve comprises an intelligent valve body and an intelligent valve controller fixedly installed at the upper end of the intelligent valve body, and a temperature control type flexible sealing piece matched with the intelligent valve body is arranged between the intelligent valve body and an intelligent valve deck; a self-cleaning fish scale set is connected with the lower end of the temperature control type flexible sealing piece, the self-cleaning fish scale set can be washed through the matching effect of the temperature control type flexible sealing piece and the self-cleaning fish scale set by means of fluid pressure, residues of impurities on the wall face of the self-cleaning fish scale set are reduced, damage of the impurities to the temperature control type flexible sealing piece is reduced, the sealing effect of the intelligent valve body is improved, and the service life of the intelligent valve body is prolonged; and the self-cleaning effect is achieved through flowing resistance, the control difficulty of an intelligent valve controller is reduced, the manufacturing cost of the intelligent valve body is reduced, and the economic benefits of the intelligent valve body are improved.

Owner:JIANGSU INTELLIGENT SPECIAL VALVE CO LTD

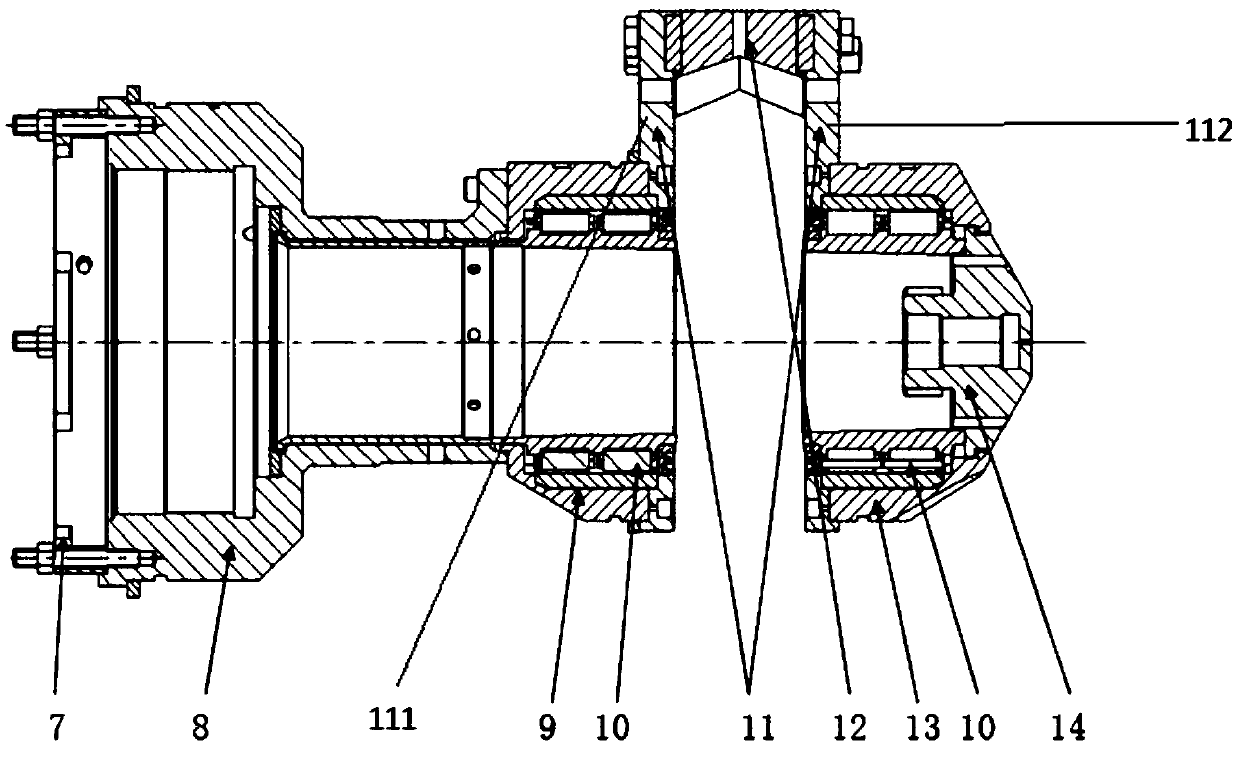

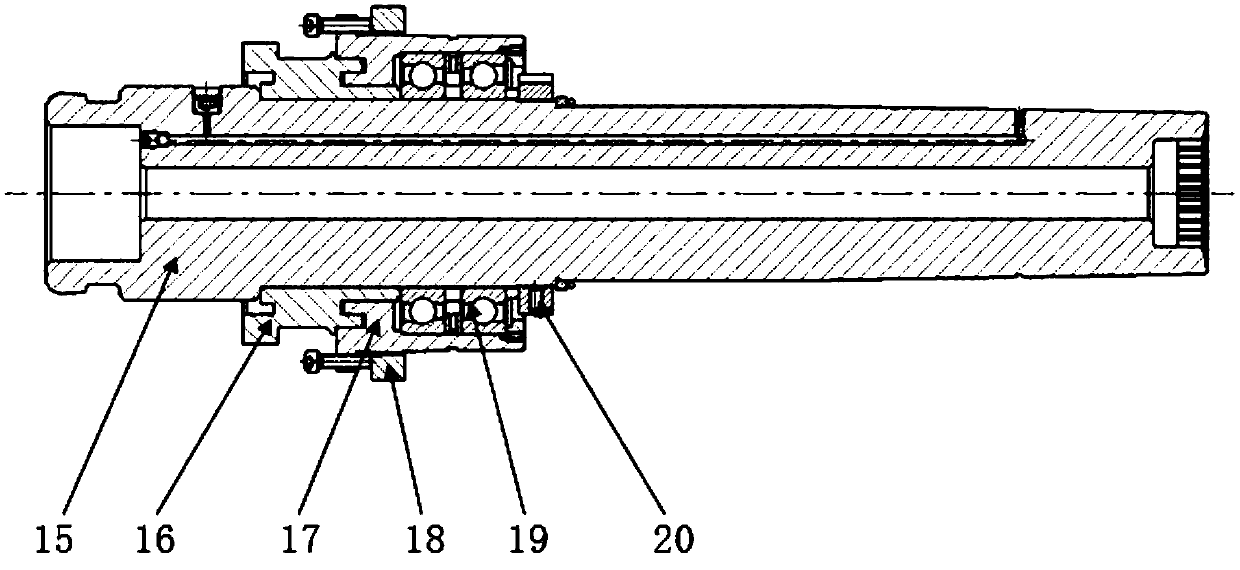

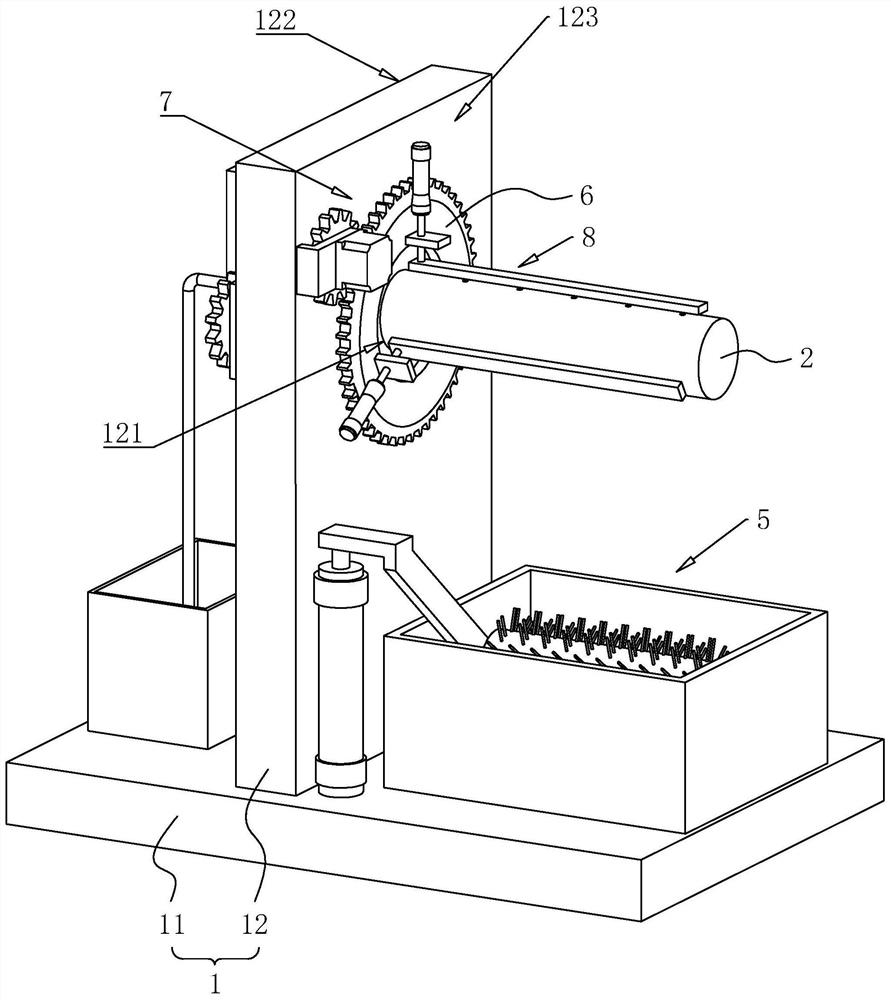

Forging and pressing equipment and forging and pressing process thereof

ActiveCN112548009AReduce frictionHigh deformation efficiencyForging press detailsMetallurgyElectric machinery

The invention relates to forging and pressing equipment and a forging and pressing process thereof, and relates to the field of forging and pressing. The equipment comprises a rack, a mandrel, a firstmotor and an oiling assembly, wherein the mandrel is rotatably connected with the rack, the first motor is used for driving the mandrel to rotate, and the oiling assembly comprises a first lubricating oil tank, a lifting frame, a brush and a first driving cylinder; in a normal state, the brush is located in the first lubricating oil tank and is fixedly connected with the lifting frame, and the first driving cylinder is used for driving the brush to slide to the outer wall of the mandrel from the interior of the first lubricating oil tank; and during operation, lubricating oil is smeared on the inner wall of a cylindrical workpiece firstly, then the cylindrical workpiece is heated, lubricating oil is smeared on the outer wall of the mandrel, the outer wall of the mandrel is sleeved with the heated cylindrical workpiece, and finally the cylindrical workpiece is extruded. The equipment has the effect of improving the deformation efficiency of the cylindrical workpiece on the mandrel.

Owner:陕西三原正泰锻压有限公司

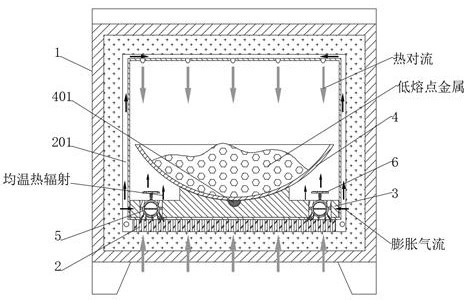

Balanced heating type resistance furnace

ActiveCN113532120AImprove transfer efficiencyImprove balanceFurnace typesElectric heating for furnacesPhysicsHeat transfer efficiency

The invention discloses a balanced heating type resistance furnace, and belongs to the field of electric furnaces, the balanced heating type resistance furnace comprises a resistance furnace body, the lower inner wall of the resistance furnace body is fixedly connected with a partition temperature-equalizing plate located on the upper side of an electric heating element, and a plurality of temperature-equalizing adjusting holes are formed in the partition temperature-equalizing plate; a plurality of air-equalizing holes communicated with the temperature-equalizing adjusting holes are formed in the partition temperature-equalizing plate, air drum type supporting force bags are arranged in the temperature-equalizing adjusting holes, and heat generated by the electric heating element can be subjected to contact type heat conduction and partition heat radiation under the action of the air drum type supporting force bags and a heat radiation plate, so that the heat transfer efficiency of the electric heating element is improved; and thus, auxiliary heat conduction is conducted on a material shielding position area in the furnace, the balance of the temperature in the furnace is effectively improved, the heating efficiency of the resistance furnace body on the materials is improved, the material heating uniformity is effectively improved, the material smelting quality is improved, meanwhile, the energy loss of the resistance furnace body is reduced, and the environment friendliness of the resistance furnace body is improved.

Owner:南通海门鑫瑞船舶配件有限公司

Secondary torsion extrusion device and method for variable cross-section cavity with fine grain

ActiveCN111889528BSevere and uniform plastic deformationGrain refinementExtrusion diesEngineeringShearing deformation

A secondary torsion extrusion device and method for refining crystal grains with a variable cross-section cavity, including: a punch part, a transmission mechanism, a power mechanism and a die part, wherein: the punch part cooperates with the die part, and the power mechanism It is connected with the transmission mechanism; the punch part includes the upper template and the upper mold, the concave mold part includes the upper cylinder, the upper plate and the main mold, the upper template is set on the upper mold, the upper mold is matched with the upper cylinder and the working state is in the hydraulic press Under the action of the slider, it enters the upper cylinder and the main mold. The upper cylinder is set on the upper plate, the main mold is set under the upper plate and connected with the upper cylinder, and the upper mold enters the upper cylinder when it is working. In the present invention, by changing the cross-sectional shape of the inner cavity of the rotating mold, the variable-section cavity mold is rotated at the same time of extrusion, and the material has both extrusion deformation and shear deformation caused by the rotation of the mold, thereby realizing severe plastic deformation and high forming force. Small, high deformation efficiency, can achieve good grain refinement effect.

Owner:SHANGHAI JIAOTONG UNIV

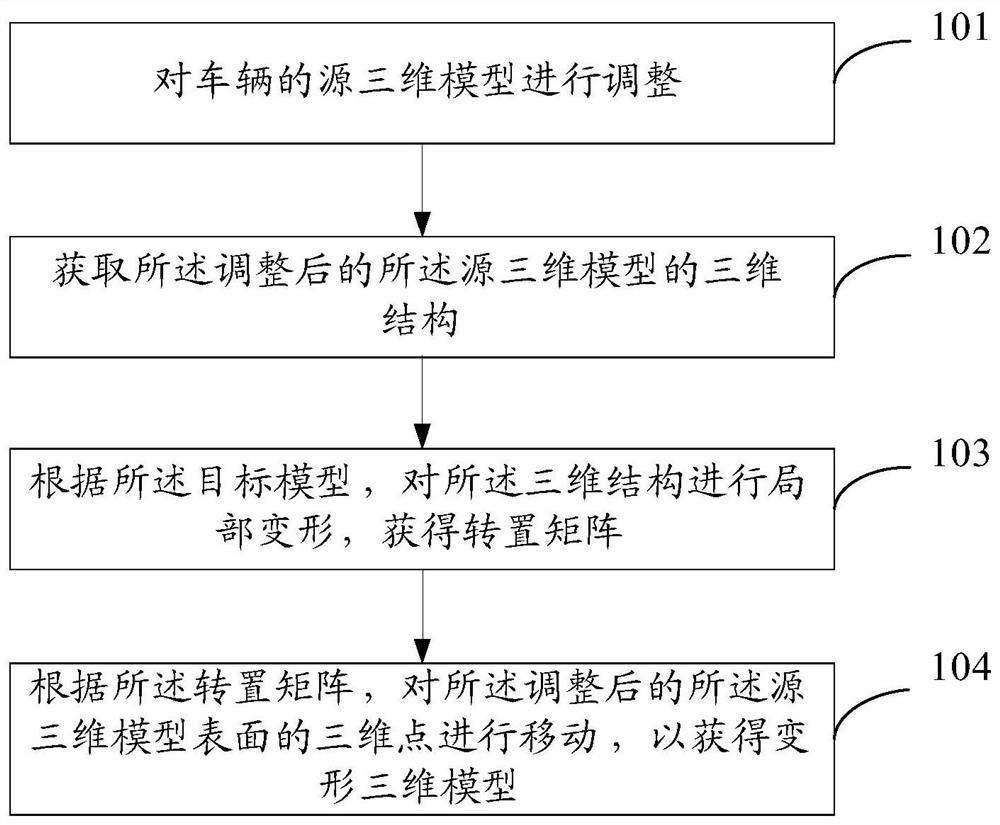

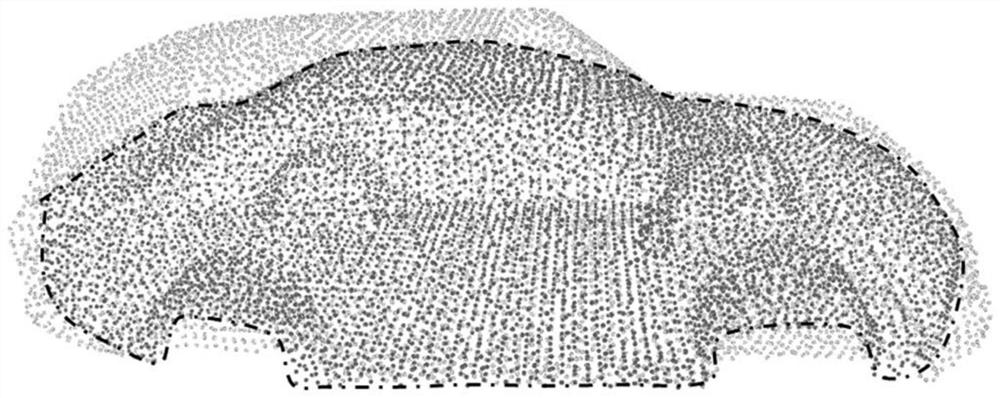

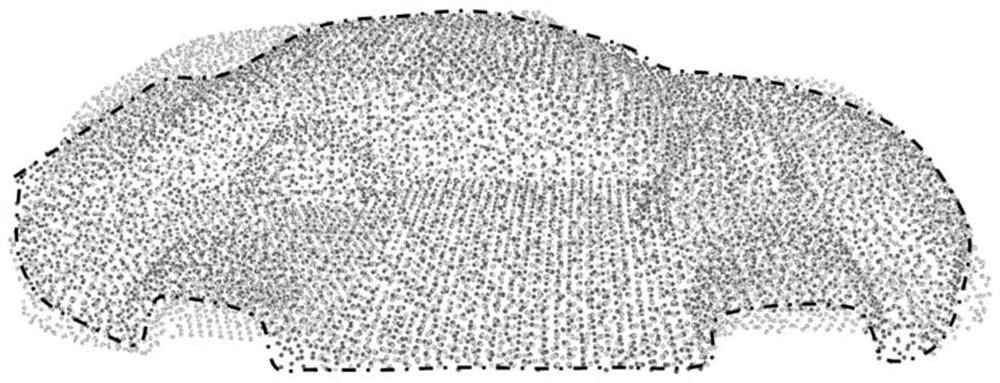

Vehicle three-dimensional model deformation method and device and electronic equipment

ActiveCN113129456AHigh deformation efficiencySustainable transportationImage generationImaging processingAlgorithm

The invention discloses a vehicle three-dimensional model deformation method and device and electronic equipment, and relates to the technical field of image processing. According to the specific implementation scheme, adjusting a source three-dimensional model of a vehicle, so that a three-dimensional bounding box of the source three-dimensional model is aligned with a three-dimensional bounding box of a target model; obtaining a three-dimensional structure of the adjusted source three-dimensional model; according to the target model, performing local deformation on the three-dimensional structure to obtain a transposed matrix; and according to the transpose matrix, moving the adjusted three-dimensional points on the surface of the source three-dimensional model to obtain a deformed three-dimensional model. Since the source three-dimensional model of the vehicle is deformed according to the target model, manual participation is not needed in the process of obtaining the deformed three-dimensional model, and the model deformation efficiency is improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Method for removing residual formic acid in epoxidized fatty acid methyl esters or epoxidized soybean oil by use of eutectic solvent

The invention belongs to the field of chemical technology and specifically relates to a method for removing residual formic acid in epoxidized fatty acid methyl esters or epoxidized soybean oil by the use of a eutectic solvent. The method provided by the invention comprises the following specific steps: sending crude epoxidized fatty acid methyl esters or crude epoxidized soybean oil which contains 0.2-15wt% of formic acid and is obtained by a epoxidation process through a formic acid method into an extraction kettle, adding a certain amount of an extractant under the condition of stirring, stirring for a period of time, standing for layering, sending a material on the upper layer into a vacuum dehydration kettle for further dehydration and refining, pouring an extract on the lower layer into an extractant regeneration kettle; heating under the condition of pressure reduction to distill formic acid in the extract, recycling the formic acid steam after being condensed in a condenser, and sending residual extractant left in the extractant regeneration kettle into the extraction kettle for recycling. The method provided by the invention has advantages of no discharge of waste water, high formic acid removal rate, simple technological operation, environmental protection, safety and low cost, and is suitable for both small-scale device and large-scale device production.

Owner:石家庄搏澳增塑材料科技有限公司

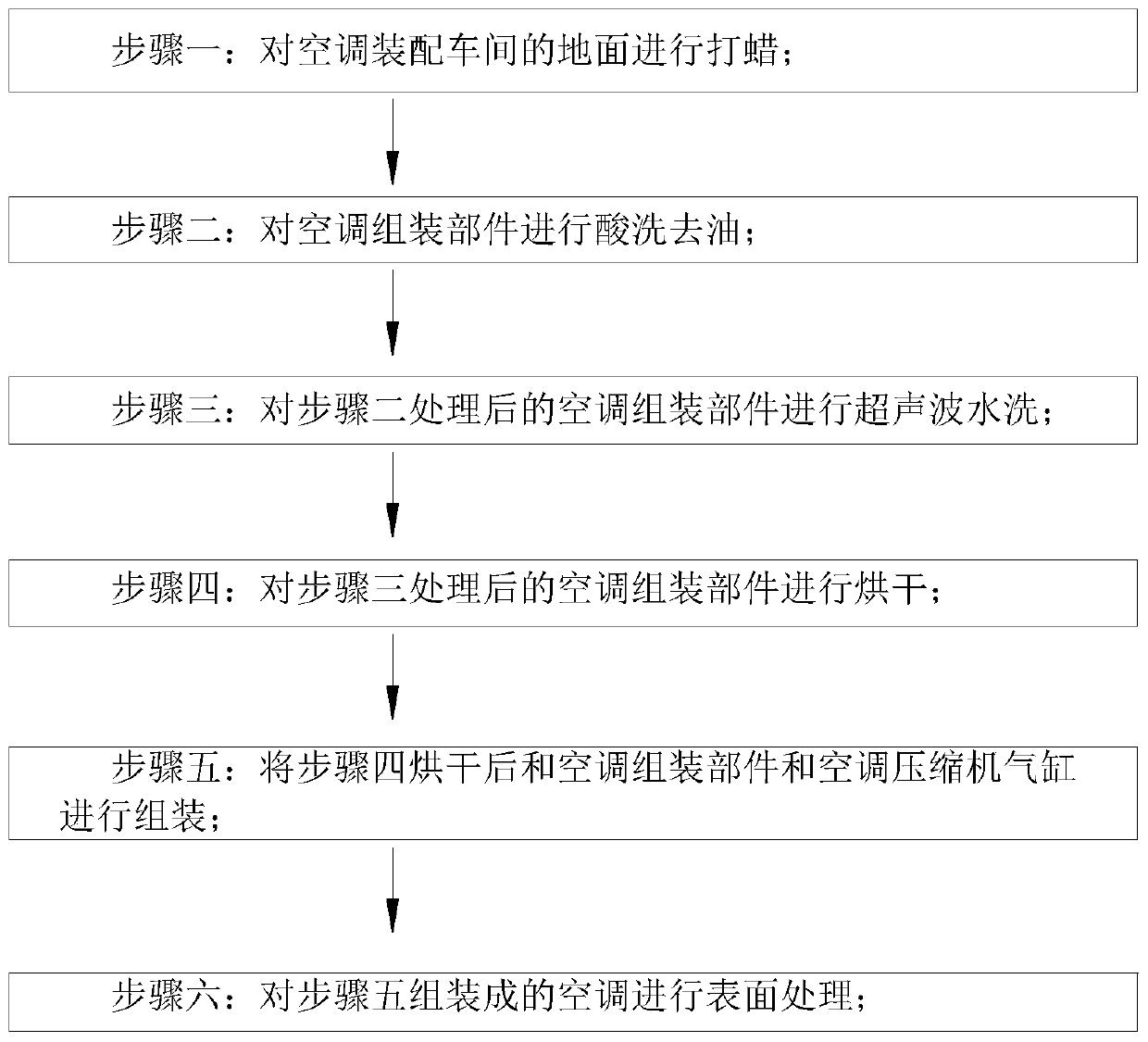

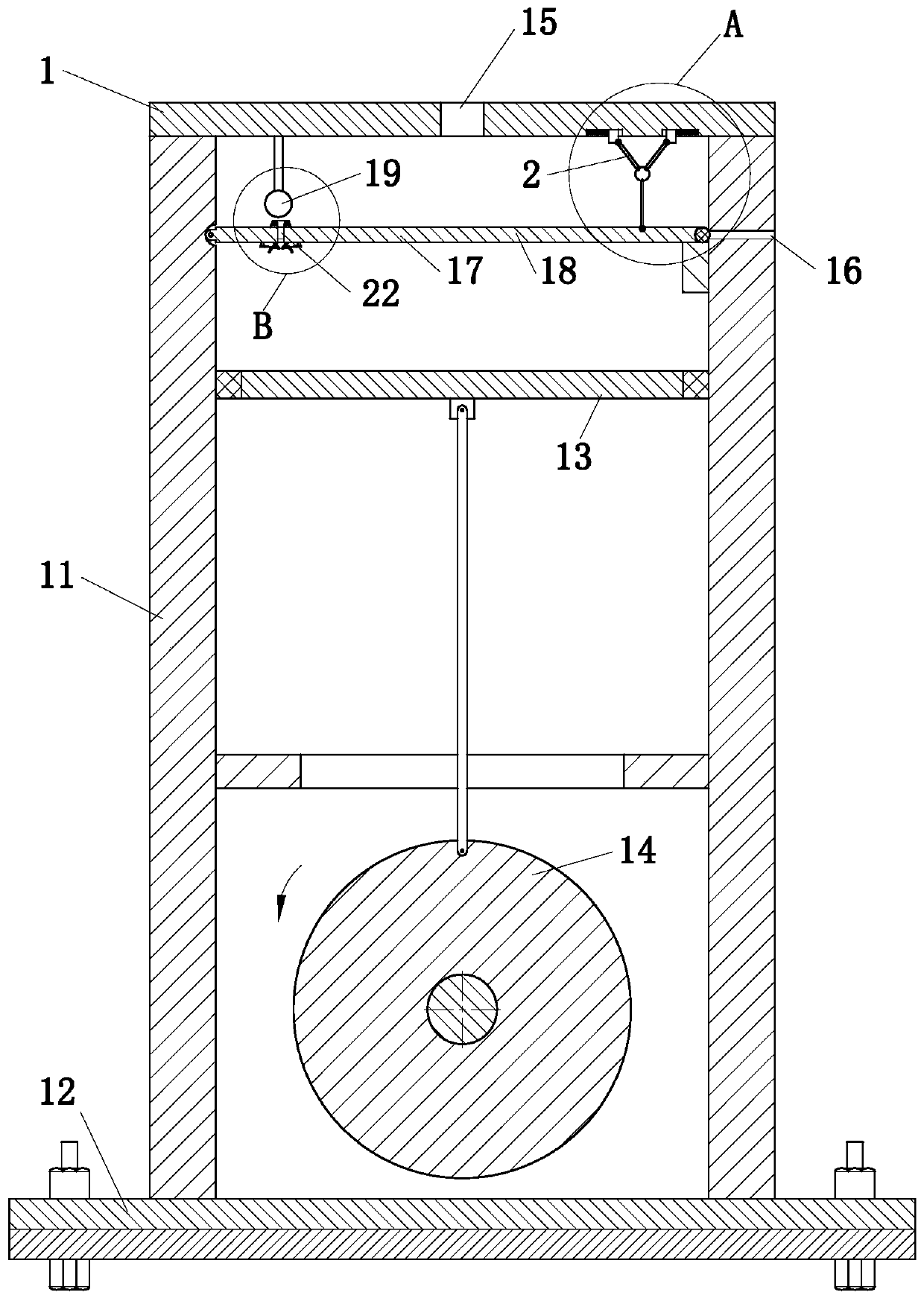

A method to improve the service life of air conditioner

ActiveCN108825473BPrevent outflowImprove efficiencyPositive displacement pump componentsPositive-displacement liquid enginesAir compressionEngineering

The invention belongs to the technical field of air-conditioning compressors and particularly relates to a method for prolonging the service life of an air conditioner. According to the method, in theair cylinder of the adopted air-conditioning compressor, an airflow control unit is arranged between a piston plate and an upper bottom plate and is used for being matched with the piston plate for use; the airflow control unit comprises a baffle plate, a pushing component and a sealing column; the left end of the baffle plate is hinged to a side plate; a rubber column is arranged at the right end of the baffle plate; when the baffle plate in a horizontal position, the rubber column can block an air outlet; the pushing component can seal the right end of the baffle plate; the sealing column is fixedly mounted on the lower surface of the upper bottom plate through a mounting rack; an air hole is formed in the left side of the baffle plate; the sealing column is used for sealing the air hole; and the pushing component is used for pushing the baffle plate and enables the rubber column on the baffle plate to block the air outlet. With adoption of the method, the air in the air-conditioning compressor is compressed to improve the air compression efficiency and prolong the service life of the air conditioner.

Owner:山东软核节能科技有限公司

Model processing method, deformation control method and related equipment

ActiveCN111768504AAvoid the problem of lack of rigidityHigh deformation efficiencySustainable transportation3D modellingEngineeringTarget weight

The invention discloses a model processing method. The model processing method comprises the following steps: taking target energy reaching a preset condition as an iteration target, taking the weightof the target model as a variable, and performing iterative optimization on the weight to obtain the target weight, wherein the weight of the target model is used for indicating the position relationbetween a drawing handle and a vertex in the target model, and the target energy is used for indicating the difference degree between K deformation models obtained after deformation of the target model and a given corresponding expected sample model in a database, and the weight is used for obtaining the K deformation models based on the target model; calculating a deformation result of the target model by utilizing the target weight; and displaying a deformation result of the target model. The embodiment of the invention further provides a corresponding deformation control method and relatedequipment. According to the technical scheme, a data driving method is adopted to iteratively optimize the weight, and the target weight is obtained and used for calculating the deformation result, and a more reasonable deformation result can be generated, and the problem that the deformation result lacks rigidity is solved.

Owner:HUAWEI TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com