Repeatedly extruding upsetting die and method for preparing block ultrafine-grained material

A technology of ultra-fine grain and block, applied in the direction of metal extrusion dies, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult deformation and high equipment requirements, and achieve improved material performance, high deformation efficiency, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

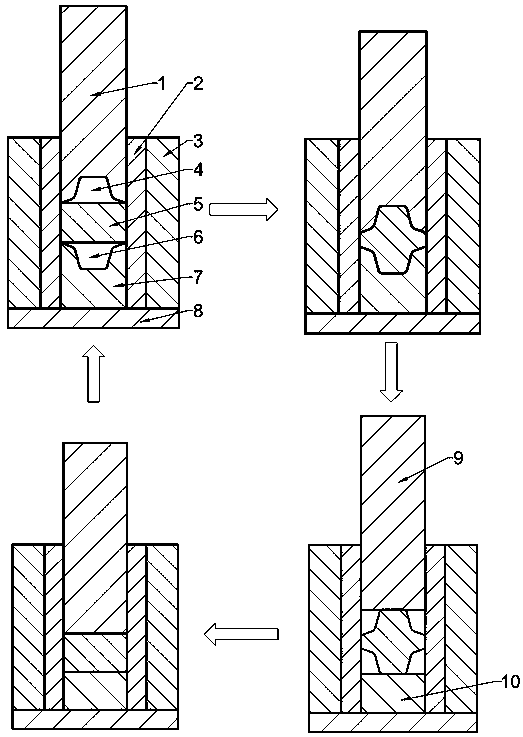

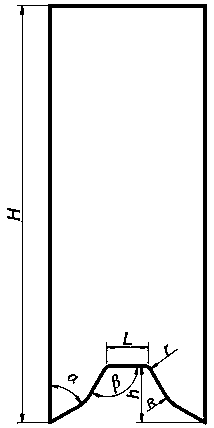

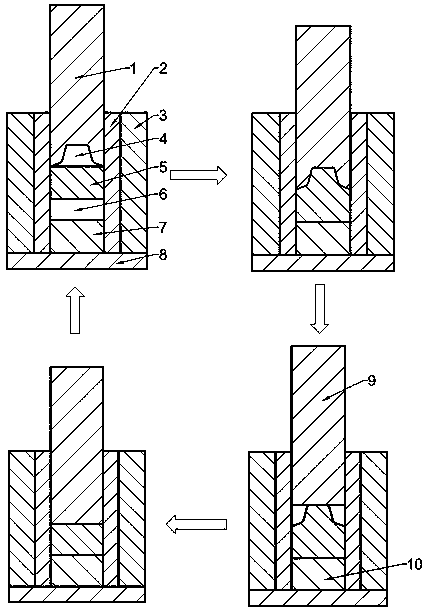

[0036] Example: such as figure 1 , figure 2 and image 3 As shown, a repeated extrusion die for preparing bulk ultrafine-grained materials includes an upper extrusion head 1, a lower extrusion head 7, a die 2, a die prestressing ring 3, a backing plate 8, an upper pressing flat convex Die 9, lower flattening punch 10; die 2 has a through passage along the vertical center, the cross section of the passage is rectangular, die 2 is provided with die prestressing ring 3, die 2 and die prestressing ring 3 is placed on the backing plate 8; the cross-sectional shape of the lower extrusion head 7 is rectangular, and its upper end is provided with a trapezoidal groove 6 that runs through it horizontally, and the lower extrusion head 7 is placed in the square channel of the die 2; the upper extrusion head 1. The cross-sectional shape is rectangular, and its lower end is provided with a transversely penetrating trapezoidal groove 4. The upper extrusion head 1 is placed in the square c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com