Forging method for fine-grain disc part made of GH4169 material

A GH4169, fine-grained technology, applied in the field of forging, can solve the problems of coarse-grained, scrapped, and inconspicuous effects on the surface of forgings, and achieve the effects of improving mechanical properties, reducing deformation dead zones, and improving the uniformity of die forging deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

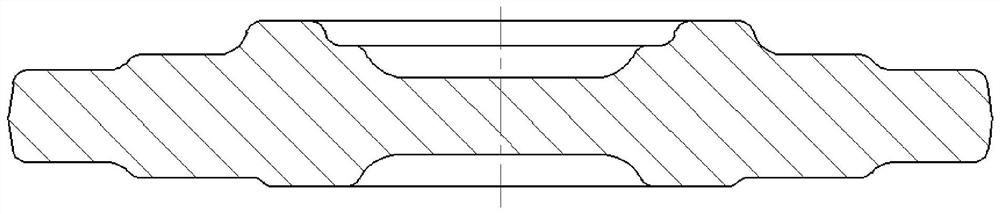

[0052] A method for forging a fine-grain disc piece made of GH4169. The main forging process is: bar upsetting—machine positioning table—die forging—rough machining before heat treatment—heat treatment—physics and chemistry—machining— -flaw detection; the forging produced by this embodiment is as attached image 3 As shown; the program controls the forging heating temperature and uses deform to reversely track the deformation of the coarse-grained part during upsetting, and takes this as the critical deformation. In order to obtain qualified organizations, the key steps in the forging process are now detailed as follows:

[0053] Bar upsetting: The heating temperature is set at 1005°C. When transferring and upsetting the bar, add insulation cotton up and down, and control the forging speed to ≤10mm / s. By controlling the forging parameters, take insulation measures to reduce the generation of coarse-grained areas ;

[0054] Machining positioning table: During free upsetting, ...

Embodiment 2

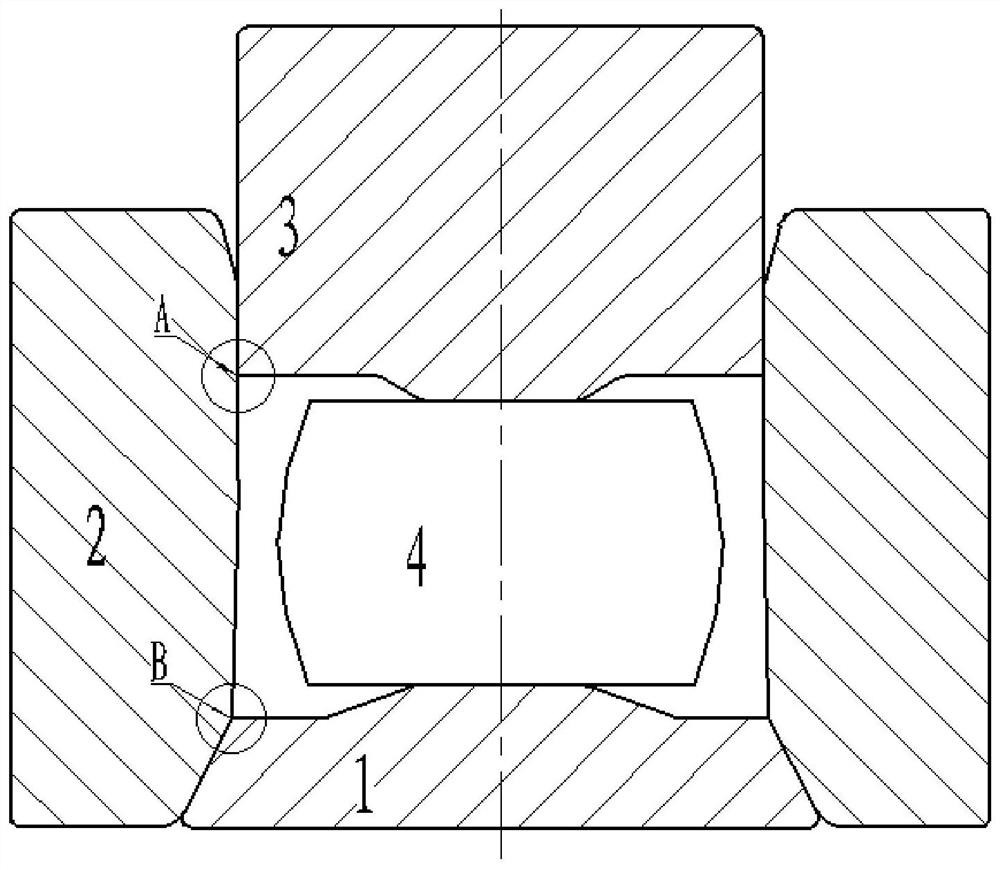

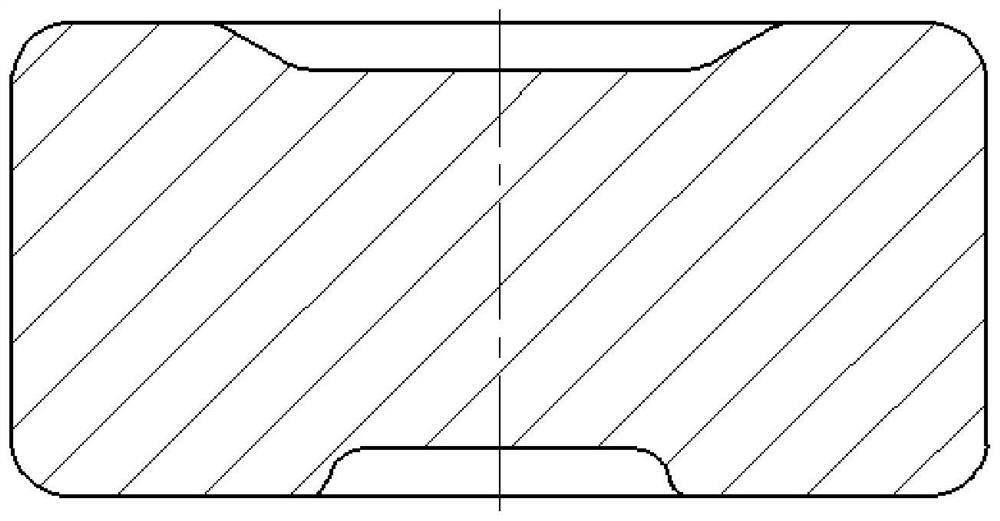

[0058] On the basis of Example 1, the improvement is mainly reflected in the bar upsetting stage, which is described in detail as follows: the bar upsetting is divided into two fires, and the closed upsetting tire mold is used for upsetting. Fire, the bar is freely upsetting, without rounding, the gap between the bulging part of the bar and the inner wall of the upsetting sleeve in the closed upsetting tire mold 1 used later is ≤15mm, which is convenient for the positioning of the second fire; Second fire, use as attached figure 1 The closed upsetting tire mold shown in the figure upsetting the bar to the required size of the biscuit. Using this method to make barren can firstly reduce the dead zone of upsetting deformation to the greatest extent, and secondly save raw materials and simplify the process , which is mainly reflected in the following two aspects: on the one hand, because the closed upsetting tire mold is used, there is no waste such as burrs; Machining; what nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com