Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94results about How to "Improve deformation uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for improving deformation and permeability in high-thickness standard steel plate hot rolling process

ActiveCN104525588AEvenly distributedIncreased deformation resistanceWork treatment devicesMetal rolling arrangementsCryogenic hardeningSteel ball

A method for improving deformation and permeability in the high-thickness standard steel plate hot rolling process is characterized in that a uniform fast cooling device is arranged at a position close to the opening of a heavy and medium plate mill or hot strip roughing mill with the length being 5 to 15 meters and the cooling total water being 3,000 to 6,000 cubic meters per hour respectively; before rolling, the cooling device conducts asymmetrical uniform fast cooling to the upper and lower surfaces of a plate blank, a low-temperature hardened layer is formed on the surface of the plate blank, the temperature gradient of a core reaches 2 to 3 DEG C per millimeter, before the cooling returns red, the cooling device can quickly enter the mill to conduct differential temperature rolling, and plate blank core deformation is improved; the cooling device is further combined with asymmetrical rolling, while deepening the plate blank core deformation, the cooling device solves the warping problem caused by the asymmetrical rolling through the asymmetrical cooling of the upper and lower surfaces of the plate blank before rolling. For a steel ball needing two-stage control, the uniform fast cooling device can replace a middle cooling device, shortens or even eliminates the temperature waiting time of swinging steel, and improves the production efficiency.

Owner:NORTHEASTERN UNIV

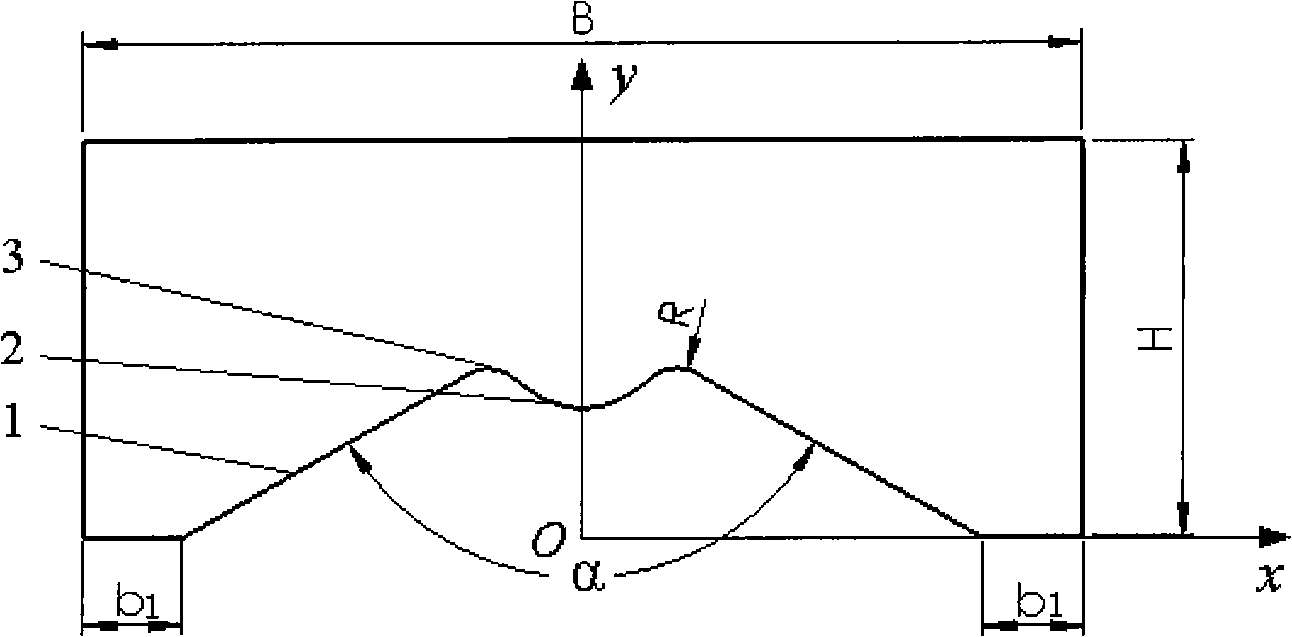

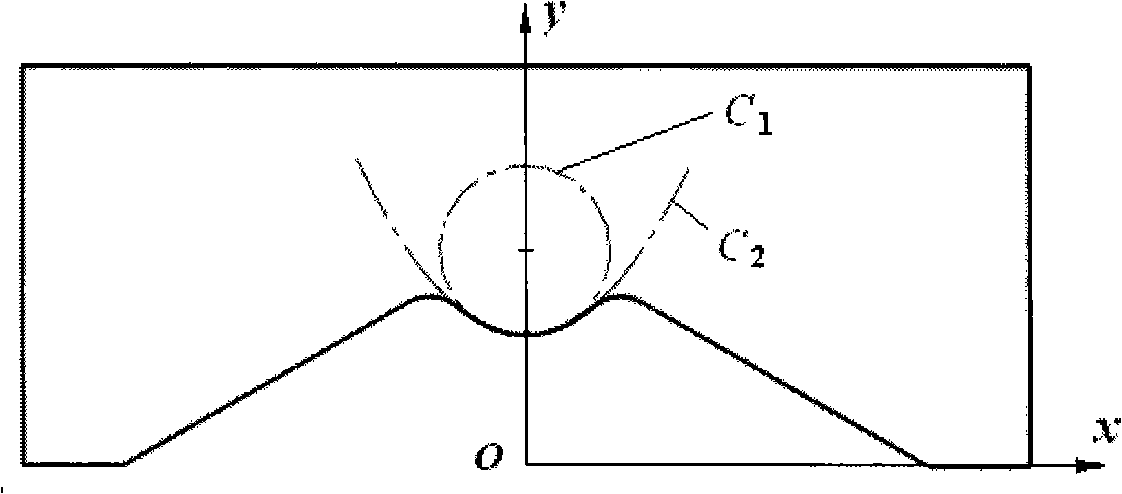

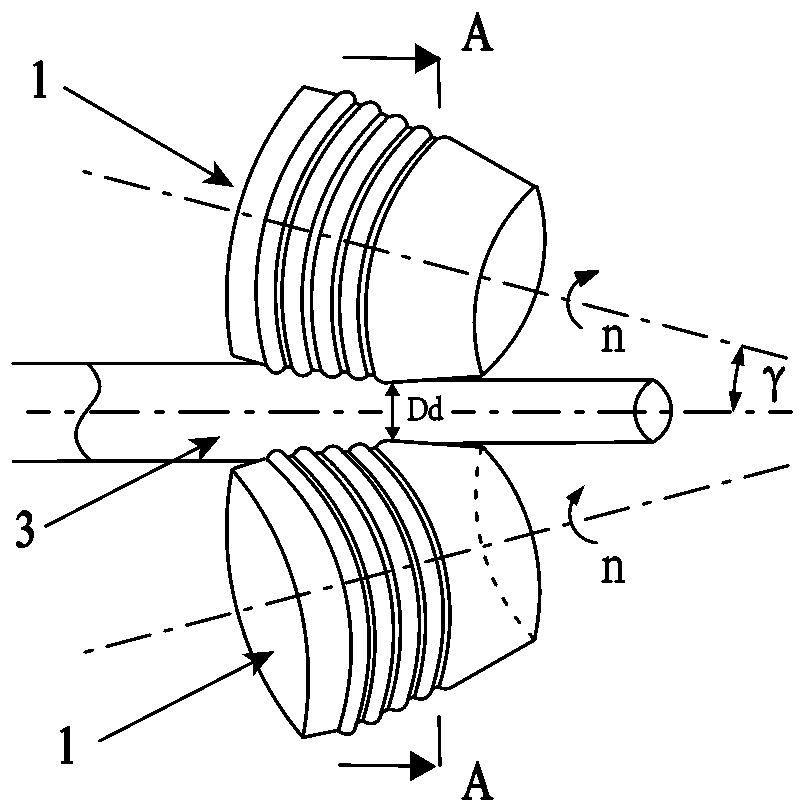

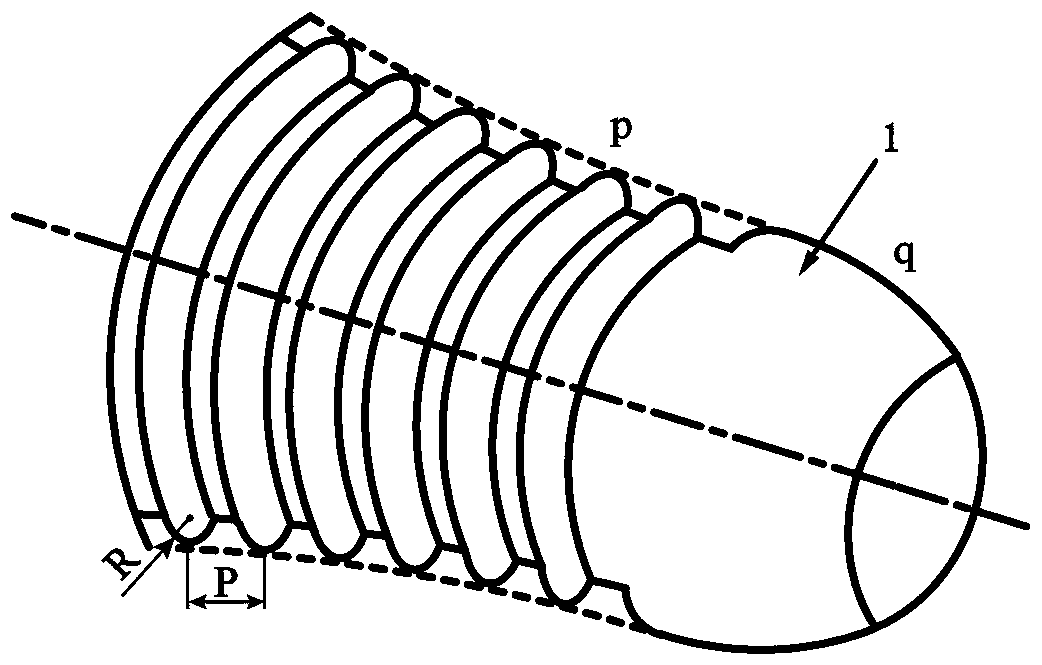

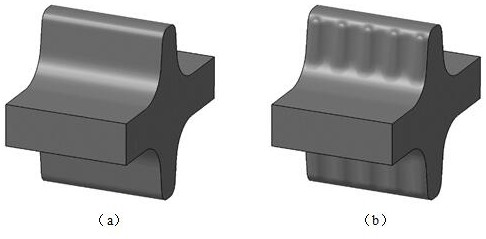

Efficient forging method using curved-surface swage blocks

InactiveCN101513664AEliminate the hard-to-deform area under the anvilImprove deformation uniformityMetal-working apparatusSurface layerStructure property

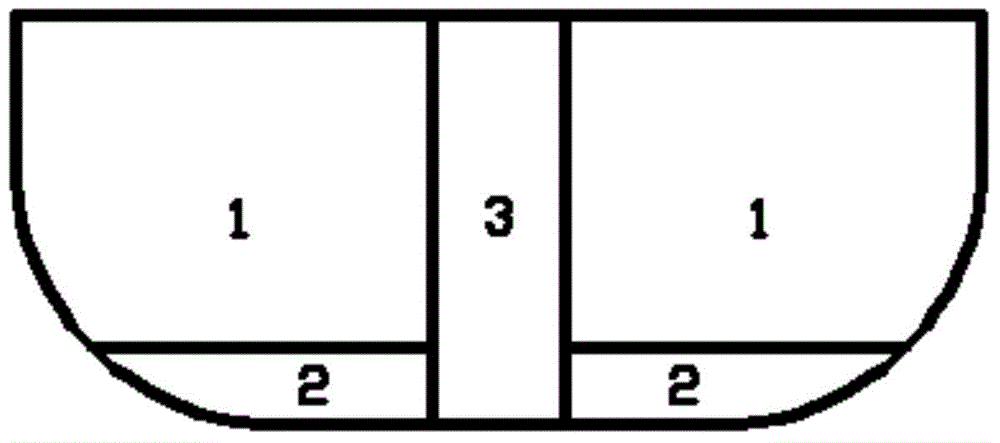

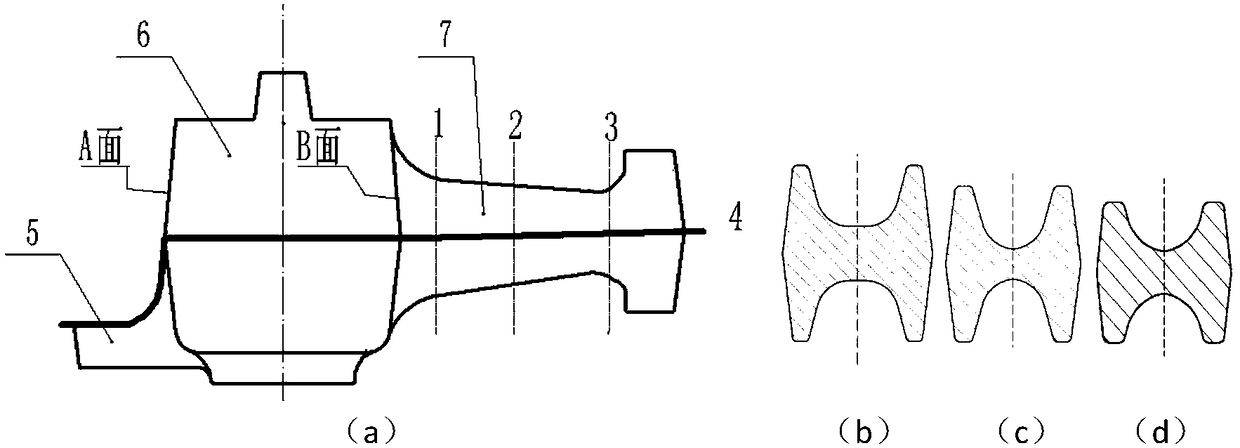

The invention discloses a forging method capable of effectively forging void defects inside heavy forgings and improving the deformation non-uniformity of the surface layer of forging stocks and the core metal. The working surface of a curved-surface swage block adopted by the method is formed by smoothly connecting a side pressure surface (1) and a central cylindrical surface (2) which are symmetrical about the center line through an arc (3), wherein, the central cylindrical surface (2) of the curved-surface swage block can adopt an arc-type central cylindrical surface (C1) or a parabola- type central cylindrical surface (C2); the side pressure surface (1) can adopt a linear-type side pressure surface (C3) or an arc-type side pressure surface (C4); and the included angle alpha of the linear-type side pressure surface (C3) spans from 90 degrees to 180 degrees. The invention takes specific control over the metal deformation of the surface layer, the core part and the sub-surface of the forging stocks by adopting the side pressure surface (1) and the central cylindrical surface (2) of the curved-surface swage block, avoids large-area difficult deformation zones and core forging crack, forges the void defects inside the forgings with lower forging load, improves the deformation uniformity of the forgings and further improves the uniformity of structure properties inside the forgings, thereby realizing the efficient forging.

Owner:YANSHAN UNIV

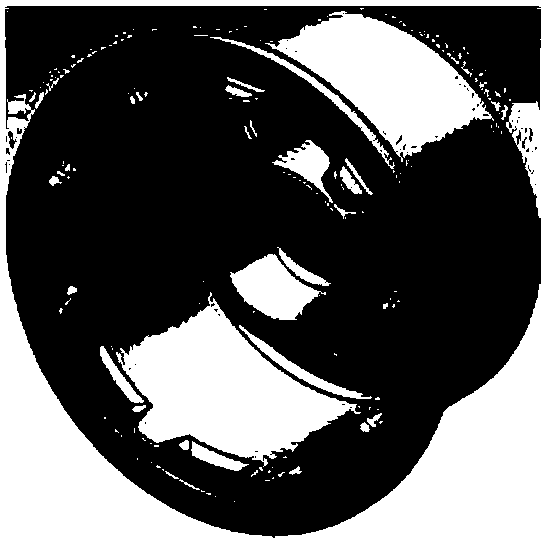

Forging method of thin-wall deep cavity airplane hub die forge piece

ActiveCN108580778APrevents scratches and foldsEasy to locateForging/hammering/pressing machinesWheelsAirplaneThin walled

The invention discloses a forging method of a thin-wall deep cavity airplane hub die forge piece. The forging method comprises a pre-forging method and a final forging method. According to the pre-forging method, a pre-forging die adopted in the method comprises a pre-forging upper male die and a pre-forging lower female die, the depth of the pre-forging lower female die is the same with the depthof a lower female die of a thin-wall deep cavity airplane hub final forging die, the bottom end of the pre-forging lower female die is of a boss structure drawing down from bottom to top, a round groove is formed in the lower surface of the pre-forging upper male die, an annular groove is formed in the edge of the bottom face of the round groove, an annular concave pit is arranged on the outer side of a pre-forging upper male die cavity, bottom surfaces of the annular concave pit and the annular groove are arc, the inclination angle of the outer wall of the pre-forging upper male die is the same with the inclination angle of the outer wall of the upper male die of the thin-wall deep cavity airplane hub final forging die, and the inclination angle of the inner wall of the pre-forging lowerfemale die is the same with the inclination angle of the inner wall of the lower female die of the thin-wall deep cavity airplane hub final forging die.

Owner:SHANDONG UNIV +1

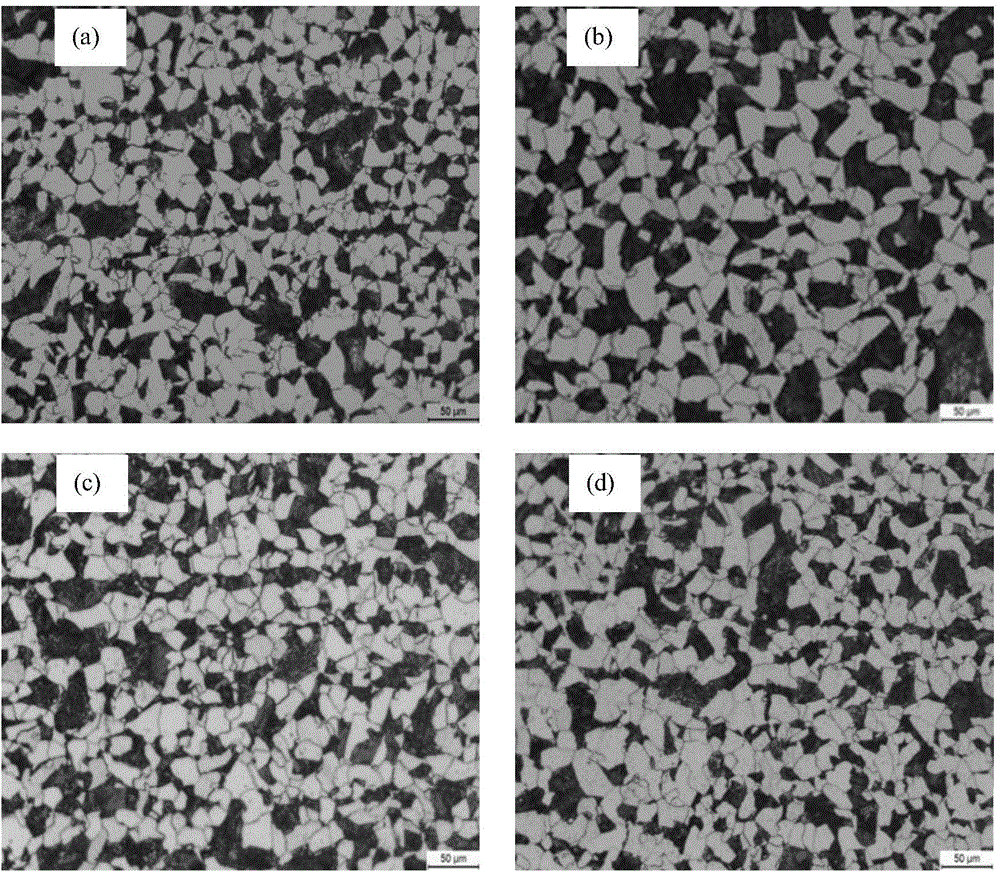

Method for preparing semisolid blank

The invention relates to a method for preparing a semisolid blank, utilizes an improved SIMA (strain induced melt activation) method to prepare the semisolid blank, and belongs to the technical field of metal semisolid blank. The method comprises the following steps of: firstly, measuring a liquid solid phase line point of the semisolid alloy to be prepared, then, heating an alloy blank so as to carry out asynchronization multitrack rolling or pillar squeezing transformation, finally, remelting, and carrying out heat preservation for a long time so as to obtain the required semisolid blank. The asynchronization rolling or pillar squeezing transformation is capable of generating large deformation amount, group bough crystal formed in the blank is destroyed, the asynchronization rolling is utilized to replace pre-deformation processes such as the existing upset, compression, equal diameter angle compression, and the semisolid blank is prepared and has the advantages of uniform formation, high nodularity, and accurate control solid phase rate.

Owner:KUNMING UNIV OF SCI & TECH

Large-wall-thickness X52MS acid-resistant pipeline steel plate produced by LF-RH refining process and manufacturing method thereof

The invention relates to a large-wall-thickness X52MS acid-resistant pipeline steel plate produced by an LF-RH refining process. The steel plate is characterized by being manufactured from the following chemical component percentage by weight: 0.03%-0.07% of C, 0.2%-0.4% of Si, 1.0%-1.4% of Mn, 0.02%-0.04% of Al, 0.02%-0.05% of Nb, less than or equal to 0.02% of V, 0.004%-0.012% of Ti, 0.1%-0.4% of Cr, 0.1%-0.2% of Mo, less than or equal to 0.0005% of B, less than or equal to 0.012% of P, less than or equal to 0.001% of S, less than or equal to 0.005% of [N], less than or equal to 0.005% of [O], less than or equal to 0.0015% of [H] and the balance being Fe and inevitable impurities, wherein the cold crack sensitivity coefficient Pcm is less than or equal to 0.19. The manufacturing method comprises the sequential steps of KR molten iron pretreatment, converter smelting, LF and RH refining, plate blank continuous casting, plate blank heating, rough rolling, intermediate blank cooling, finish rolling, ACC cooling and the like. The manufactured steel plate has thickness being 35.1-44.2 mm, yield strength being 380-440 MPa, tensile strength being 490-570 MPa, and elongation being greater than or equal to 33%, yield ratio being less than or equal to 0.09; an average shear plane ratio of drop hammer under the temperature of minus 5 DEG C is 85% or more; and the large-wall-thickness X52MS pipeline steel can meet the requirement of being used in an acidic environment, and has good HIC resistance and low-temperature toughness.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

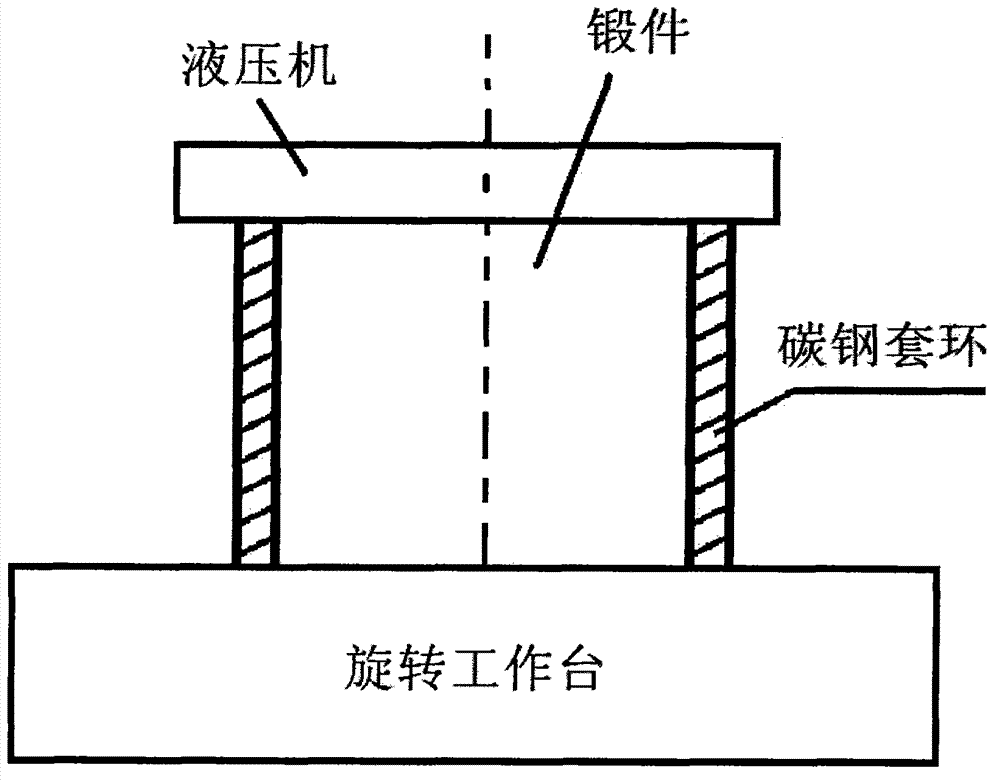

Wind power spindle flange upsetting process

The invention discloses a wind power spindle flange upsetting process, which comprises the following steps of: performing a first upsetting sate by a rotating local upsetting process, and by combining an overturning process; and arranging a loop on the excircle of the forging and continuing to perform a second upsetting stage process. When the process is used, forging cost and labor intensity are reduced, and the nonuniformity of deformation is relieved.

Owner:JIANGSU JINYUAN FORGE

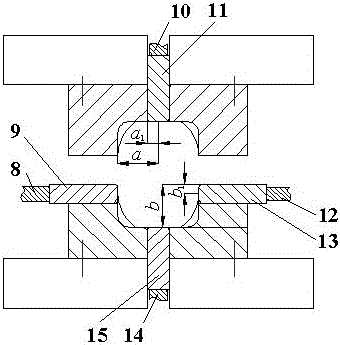

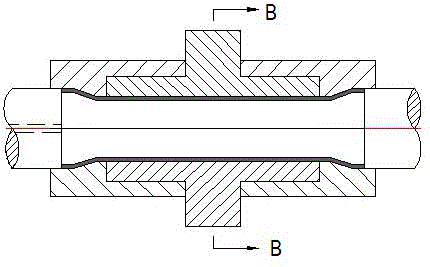

Ring-wave repeated drawing high deformation mold for plate and machining method

InactiveCN107716668AUniform plastic deformationUniform strain distributionGeometric CADShaping toolsWave shapeLarge size

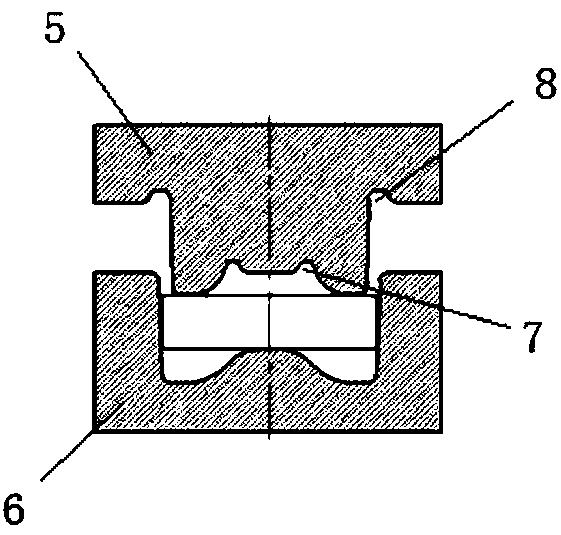

The invention discloses a ring-wave repeated drawing high deformation mold and technology for a plate. The mold comprises two ring-wave mold bodies including the ring-wave mold body A and the ring-wave mold body B, wherein the two ring-wave mold bodies are both of an axially-symmetrical cylindrical structure, the upper surfaces and the lower surfaces of the ring-wave mold bodies are each composedof a plurality rings of convex-concave continuous alternate matchable ring waves, the ring wave radian and length of the axial center are large, the wave height of the axial center is small, and the ring wave radian and length are decreased ring by ring and the wave height is increased ring by ring from the axial center to the exterior. Ring-wave upper mold bodies are movable mold bodies, ring-wave lower mold bodies are fixed mold bodies, and two groups of positioning mechanisms which are radially and symmetrically arranged are arranged at the upper end of each ring-wave lower mold body; and the plate is drawn to be in a set ring wave shape by the ring-wave upper mold bodies and the ring-wave lower mold bodies through mold closing. According to the technology, crystal grains of the plate can be repeatedly drawn, deformed and refined through the mold, and then the size of the crystal grains reaches the micron grade or the submicron grade. The ring-wave repeated drawing high deformationmold is not limited by the plate size, a large-size plate can be machined, and the comprehensive properties of the plate on the physical aspect, the chemical aspect, the mechanical aspect and the likecan be greatly improved.

Owner:YANSHAN UNIV

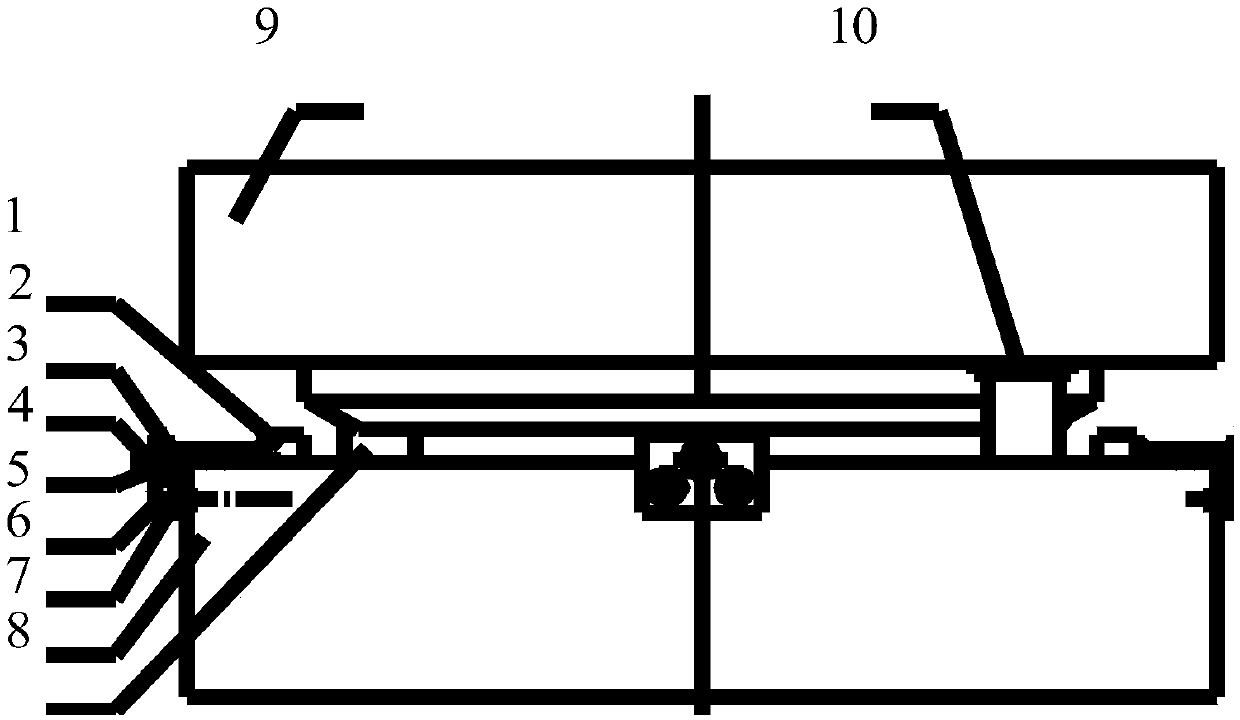

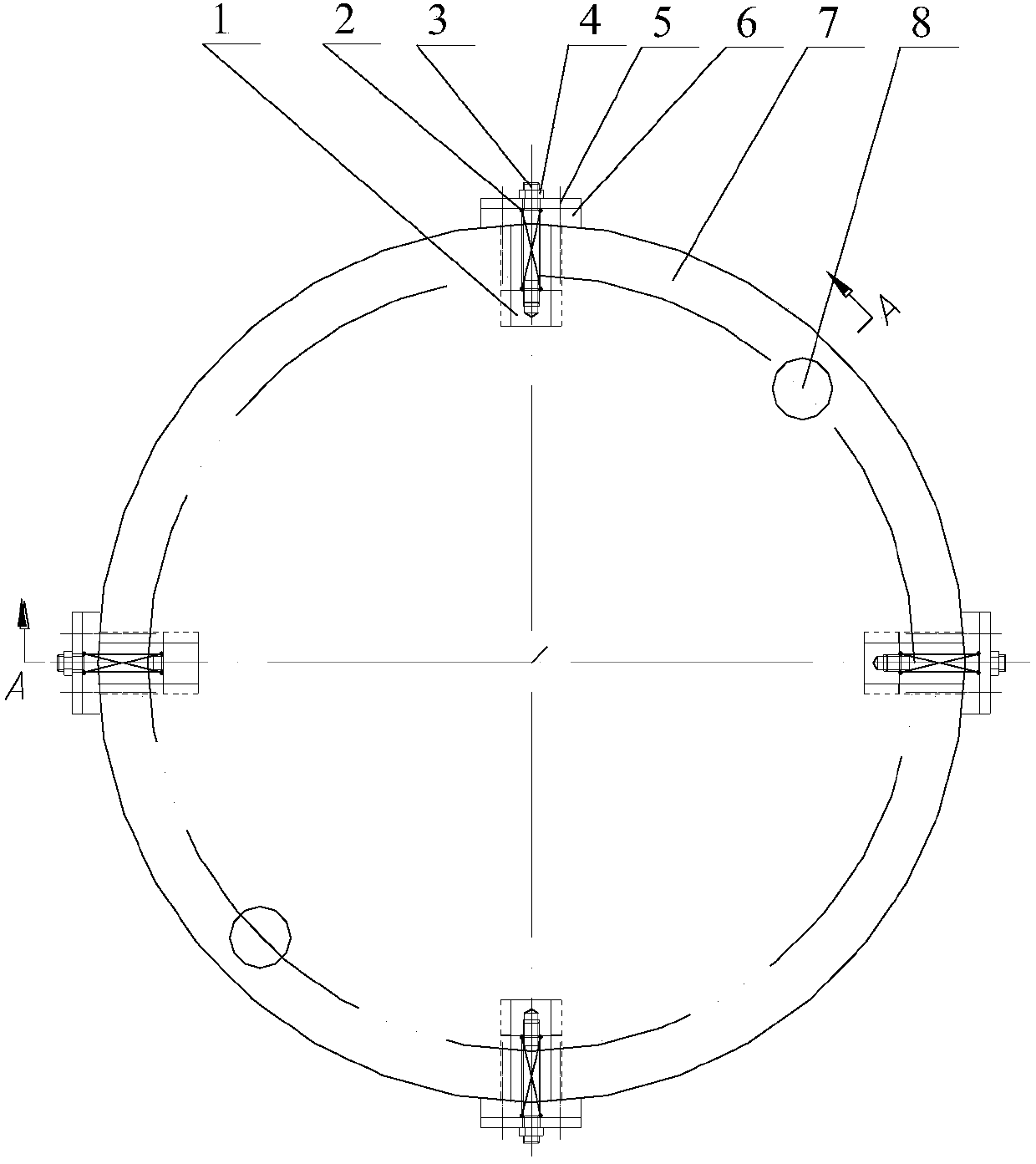

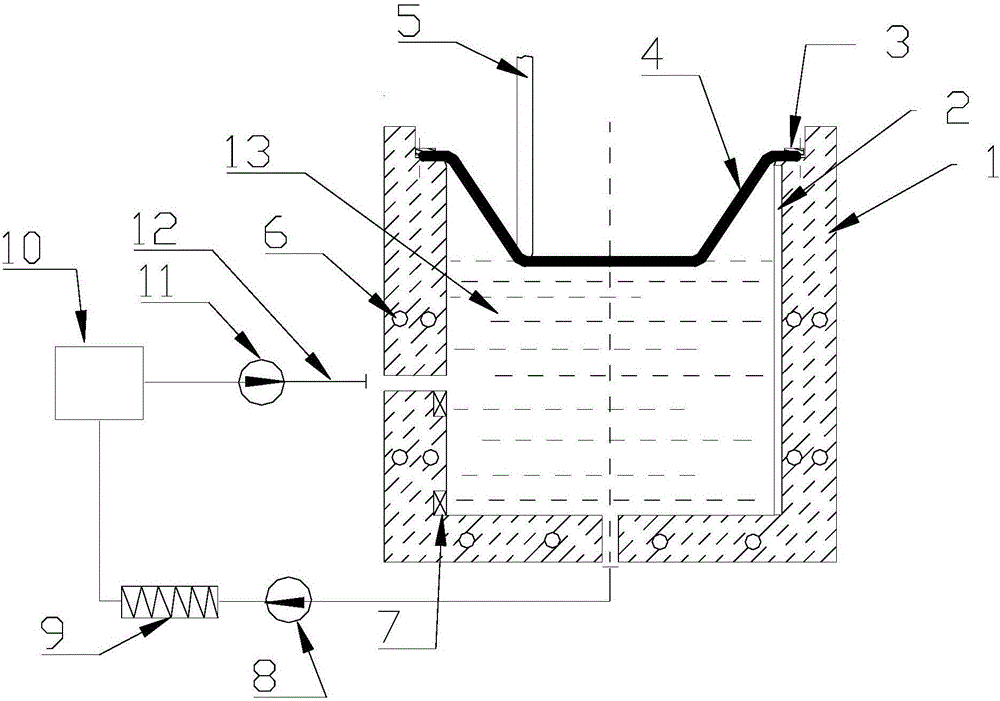

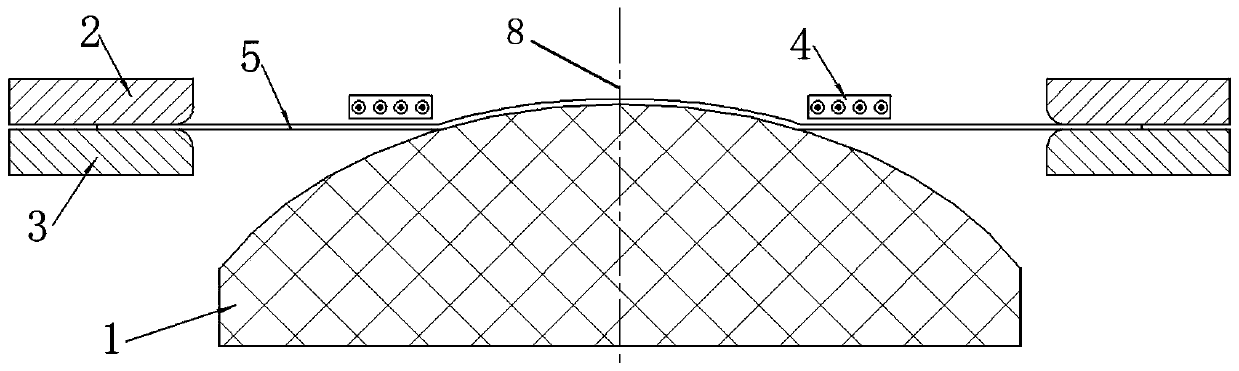

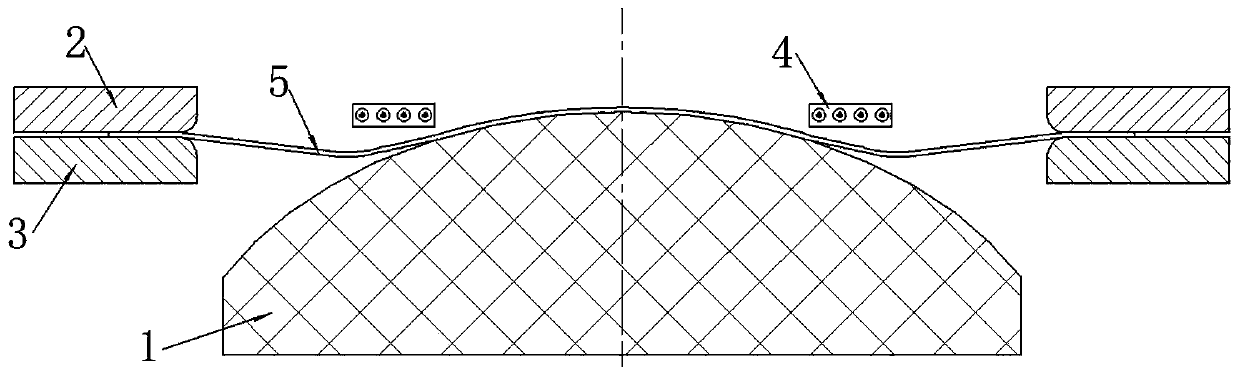

Method and device for carrying out differential temperature incremental forming on aviation light alloy plates

The invention discloses a method and device for carrying out differential temperature incremental forming on aviation light alloy plates. The method comprises the following specific steps: firstly fixing an aviation light alloy plate on a support base which comprises a heat-conducting oil groove, wherein the heat-conducting oil groove comprises a pipeline, a heating device, a temperature control device and an oil liquid level height detection and control system; injecting heat-conducting oil into the heat-conducting oil groove until the heat-conducting oil is in contact with the plate; heating the heat-conducting oil through the heating device and the temperature control device so as to ensure that the temperature of the plate achieves a required temperature and the temperature is uniform; selecting a proper incremental forming process to carrying out differential temperature incremental forming; and in the forming process, measuring the height of the liquid level of the heat-conducting oil in real time through the oil liquid level height detection and control system, and realizing the dynamic adjustment of the height of the liquid level so as to ensure that the unformed part is in contact with the liquid level of the heat-conducting oil all the time to be in the heating state and the formed part is divorced from the liquid level of the heat-conducting oil to undergo online cooling.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

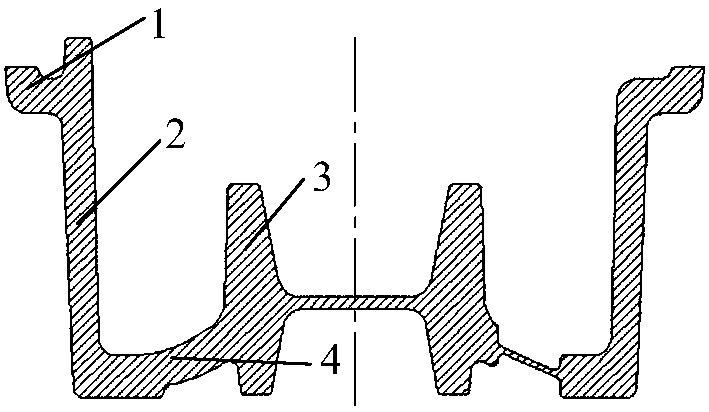

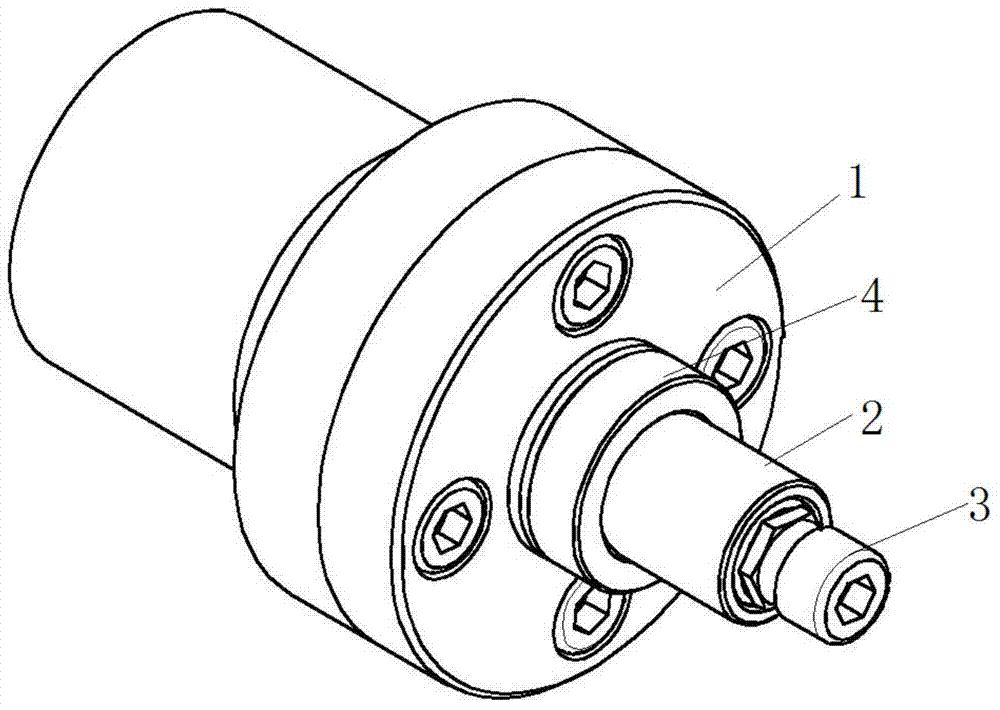

Rotating extrusion forming die for cabin workpiece

InactiveCN110624972AIncrease profitImprove mechanical propertiesExtrusion diesVertical axisMachining

The invention provides a rotating extrusion forming die for a cabin workpiece. The rotating extrusion forming die comprises a male die, a female die, an upper die assembly and a lower die base; a diecavity is formed in the female die, the die cavity can be used for placing a blank, and the female die is rotatably arranged on the lower die base about a vertical axis; the male die is arranged on the upper die assembly and can extend into the die cavity along with the upper die assembly; and the upper die assembly can drive the male die to run in the vertical direction and horizontal direction so as to carry out extrusion forming on the blank in the die cavity. According to the scheme, the cutting machining is avoided, the material utilization rate is greatly improved, the later machining consumption is reduced, then the production cost is reduced, the production efficiency is improved, the mechanical performance of a workpiece main body part is improved, the bearing capacity descendingproblem caused by flow line cutting is avoided, the deformation uniformity is improved, and the wall thickness difference is reduced.

Owner:ZHONGBEI UNIV

Continuous-lubrication extrusion mold

InactiveCN108213104AContinuous and stable lubricationImprove deformation uniformityExtrusion diesMachining processMaterials science

The invention discloses a continuous-lubrication extrusion mold, relates to an extrusion mold, aims to solve the technical problems of undesirable lubrication effect since the surfaces of the mold andblank materials are coated with a lubrication agent, increase of the mold manufacturing cost and difficulty caused by adopting a method of surface coating treatment, and gradual abrasion and separation of the coating on the surface of the mold in a forming process. The continuous-lubrication extrusion mold consists of a lubrication agent storage tank and an extrusion mold, an upper part of the side wall of the lubrication agent storage tank is provided with at least one lubrication agent injection hole; at least on lubrication agent hole is formed on the side wall of the extrusion mold; and the lubrication agent storage tank is sleeved outside the extrusion mold. The continuous-lubrication extrusion mold has the advantages that: the blank and the extrusion mold can keep a good and continuous stable lubrication state in a machining process, the abrasion on the mold is lowered, and the service life of the mold is prolonged. The continuous-lubrication extrusion rod can be applied to themachining field of materials.

Owner:HARBIN INST OF TECH

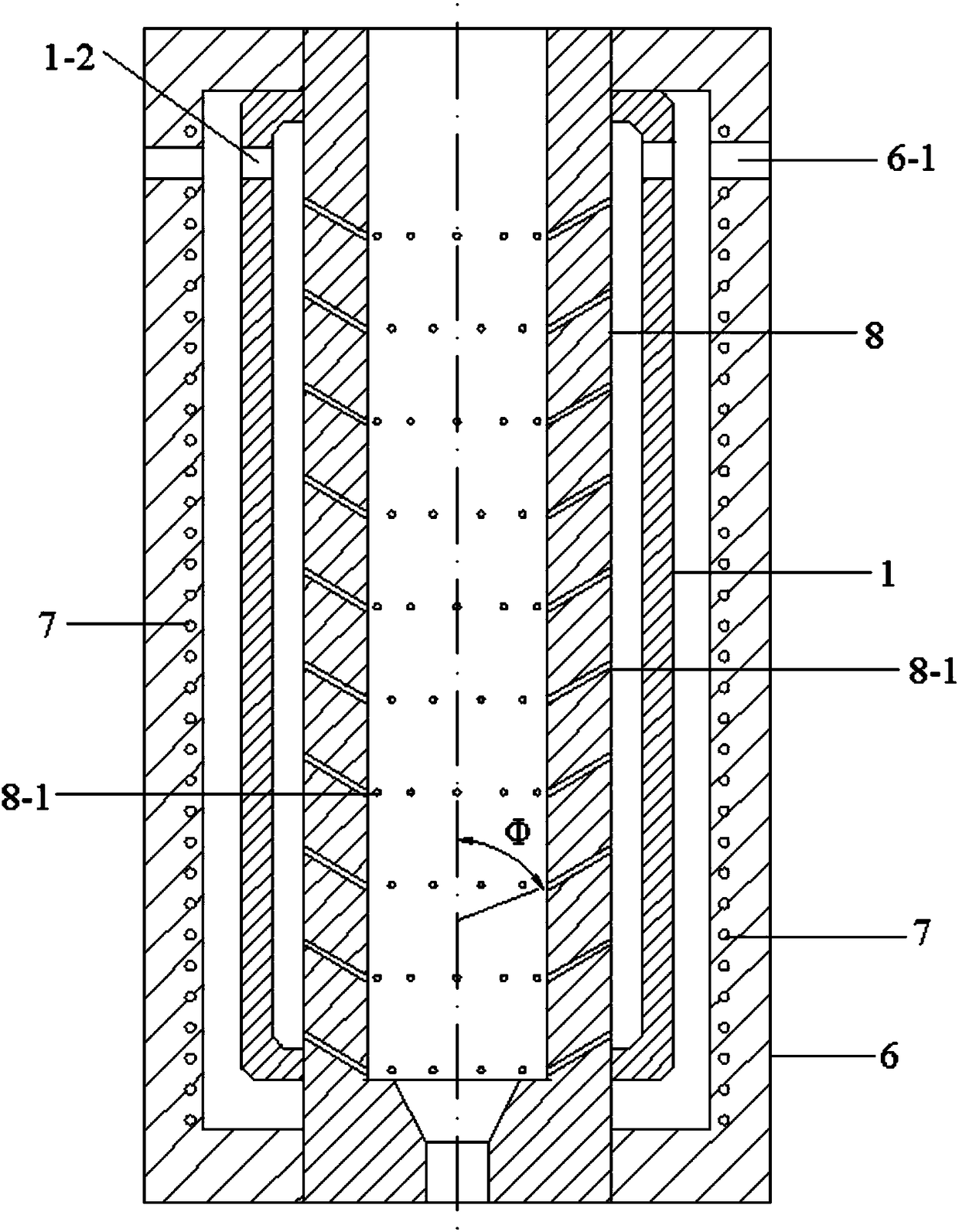

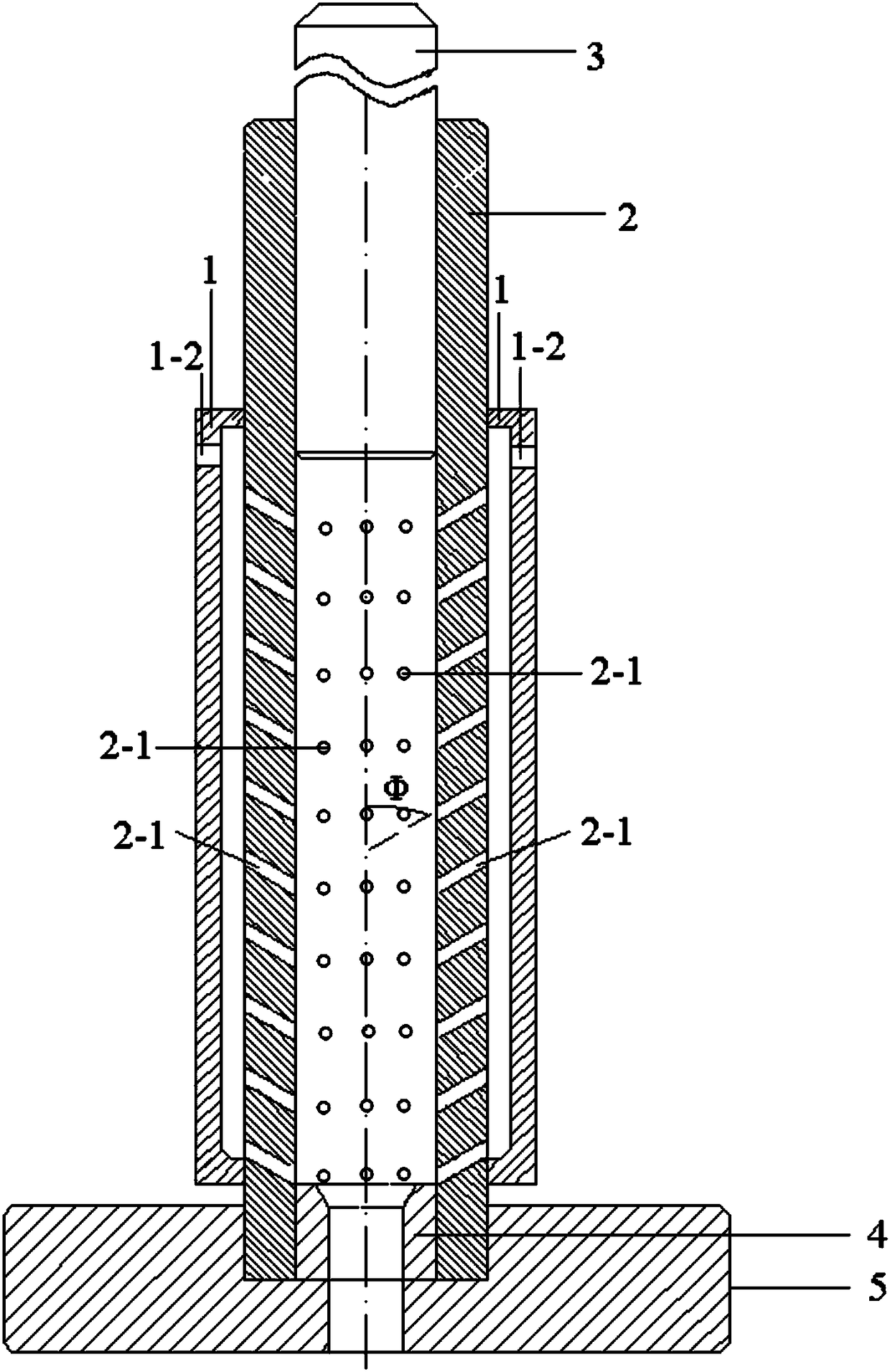

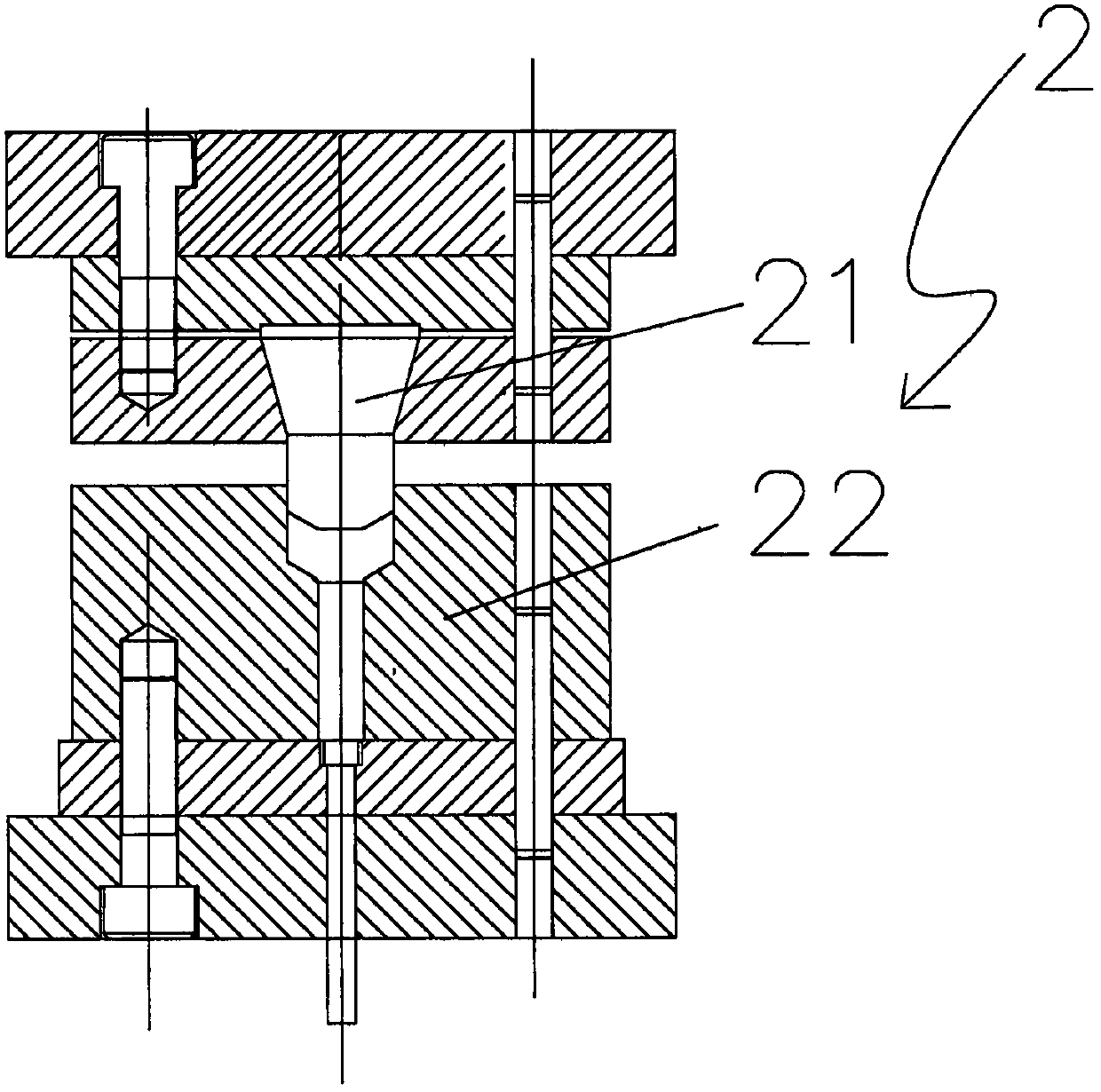

Multi-corner composite equal channel angular twist extrusion die

InactiveCN104014608AIncrease the degree of deformationImprove deformation uniformityExtrusion diesPhysicsEngineering

The invention provides a multi-corner composite equal channel angular twist extrusion die. The die is characterized in that a female die is a cone; an inlet channel, a deformation channel and a spiral channel are arranged inside the cone; the female die is embedded in a die sleeve with identical conicity; the periphery of the die sleeve is sleeved with a heating sleeve; a punch is arranged above the female die in a matching manner; a jack is arranged below the female die. The die has the beneficial effects that the die deforms workpieces put into the inlet channel of the die to a great extent, has high deformation uniformity, low equipment requirement and high work efficiency, meets the requirements of different deformed materials and various deformation temperatures, has the semi-automatic ejection function, is easy to manufacture and can be used for efficiently preparing blocky ultra-fine grain materials with large sizes and high performances.

Owner:XUZHOU UNIV OF TECH

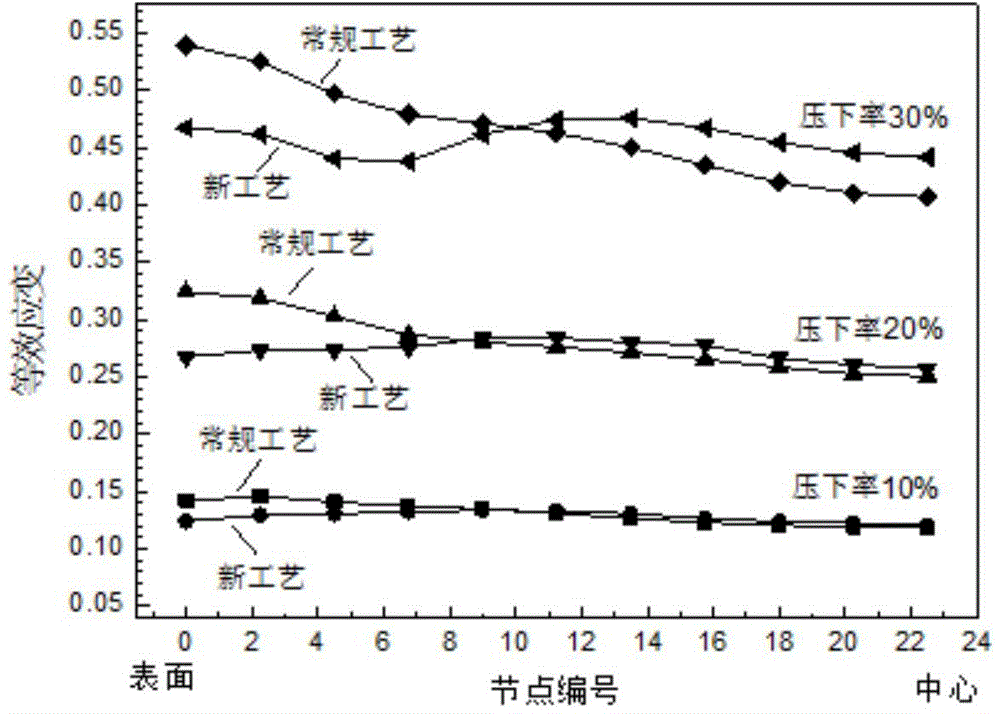

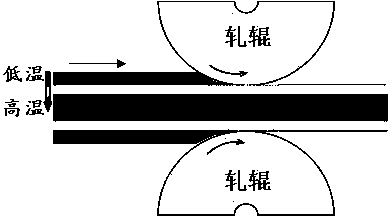

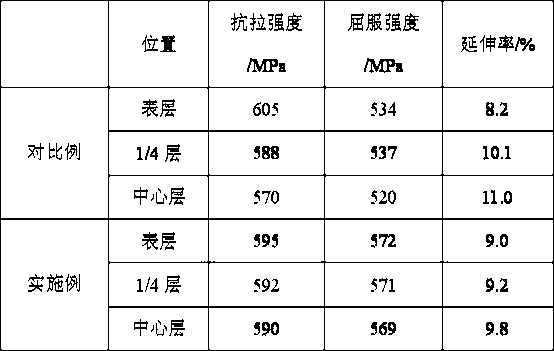

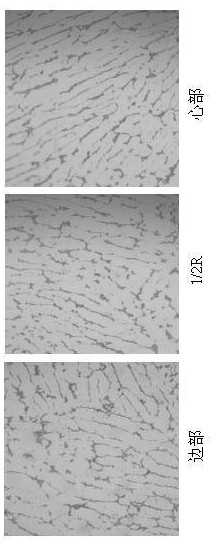

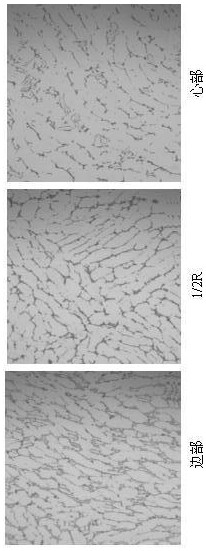

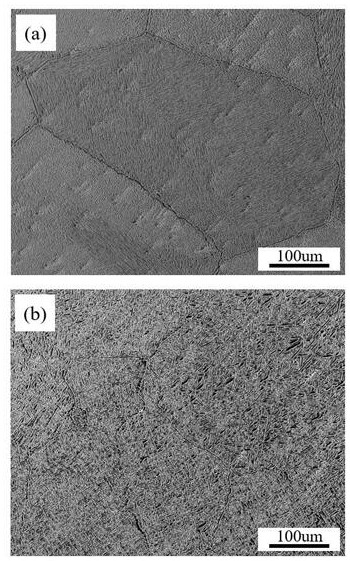

Differential-temperature rolling method for AlZnMgCu-series aluminum alloy thick plates

ActiveCN107931337AImprove deformation uniformityImproves final performance uniformityWork cooling devicesMetal rolling arrangementsSurface layerHot rolled

The invention discloses a differential-temperature rolling method for AlZnMgCu-series aluminum alloy thick plates, and the method is suitable for producing the AlZnMgCu-series aluminum alloy thick plates with thicknesses of 60-120 mm; The differential-temperature rolling method comprises the following steps of: firstly, rolling cast ingots to 180-240 mm by adopting common hot-rolling; cooling surface layers of rolled plates by a spraying mode, and reducing the temperatures of the surface layers of the hot-rolled plates to 300-400 DEG C, wherein the temperatures of the core parts of the hot-rolled plates are higher than those of the surface layers by 50-100 DEG C; and finally, rolling the hot-rolled plates to target thicknesses by adopting large rolling reduction. The method is used for changing deformation resistance of the surface layers and the core parts by utilizing temperature difference between the surface layers of the hot-rolled plates and the core parts of the hot-rolled plates, enables deformation of the surface layers and the core parts of the hot-rolled plates to be uniform, and improves uniformity of the thick plates. The method is simple and convenient to operate, andhas a practical industrial production application value.

Owner:CENT SOUTH UNIV

Forming method of hollow component

The invention relates to a forming method of a hollow component. According to the technical scheme, the forming method of the hollow component comprises the following steps: step one, preparing a die, adding four anti-deformation structures on the die, and mounting a one-way valve on a punch; step two, placing an initial tube blank in a cavity of the die, closing the die and sealing ends; step three, filling a fluid medium inside the tube blank; step four, enabling the anti-deformation structures to move oppositely; and step five, retracting the anti-deformation structures to initial positions, repeating the step four and the step five to form a component in the required shape, relieving internal fluid pressure, opening the die, and taking out a part. The anti-deformation structures are arranged in the die, so that a petal shape is repeatedly and accumulatively used, while the rolling effect of friction is eliminated, forming pressure is reduced, the breakage defect is avoided, and uniformity of the wall thickness is improved.

Owner:李明

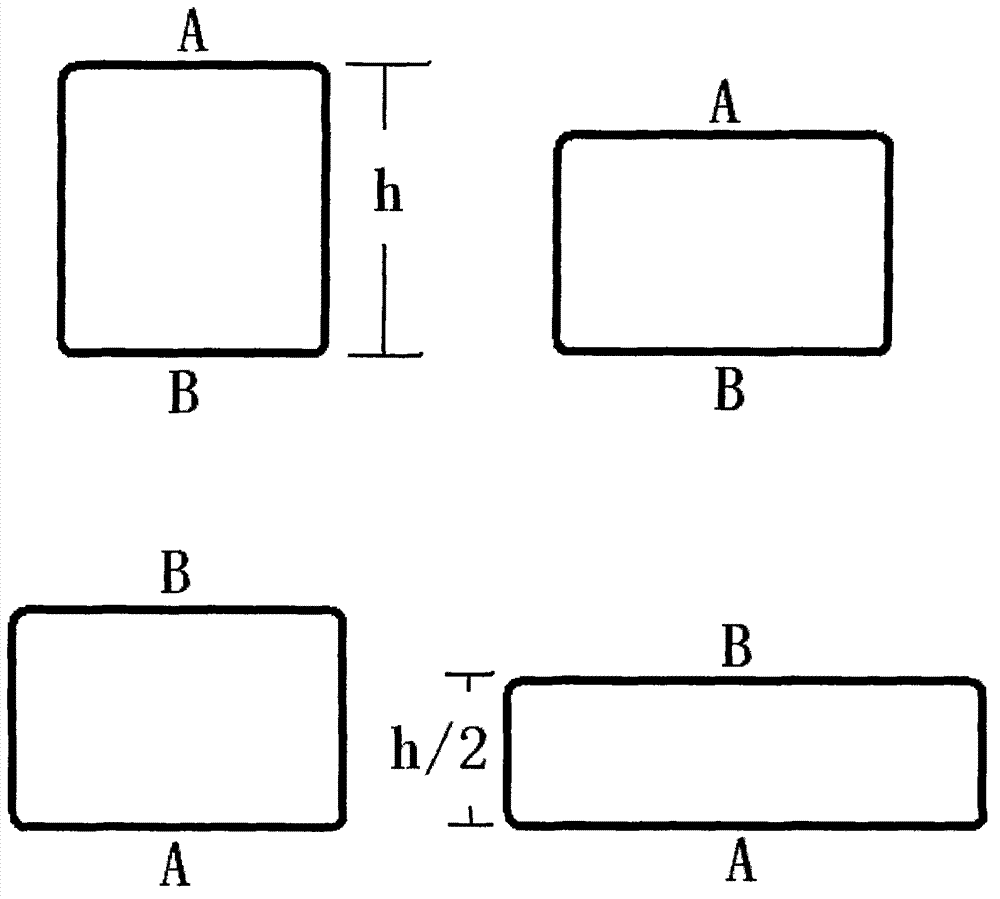

Large plastic shape and deformation blank-making method for eliminating anisotropy of magnesium alloy bar material with large height-diameter ratio

InactiveCN107649629AUniform deformationEnhanced deformation uniformityExtrusion diesForging/hammering/pressing machinesInvoluteDiameter ratio

The invention discloses a large plastic shape and deformation blank-making method for eliminating anisotropy of a magnesium alloy bar material with the large height-diameter ratio. The large plastic shape and deformation method comprises the steps that (1) an upsetting die is used and is formed by combining space curve faces which combine the symmetrical parabolain in the middle portion of the bottom end of an upsetting male die and the involute at the edge portion, the magnesium alloy bar material is placed in the closed upsetting die for upsetting machining, upsetting deformation is conducted on the magnesium alloy bar material under action of stress, and the alloy bar material is lengthened in the radial direction and is shortened in the axial direction; (2) the blank material after upsetting is put into an extruding die for being extruded and deformed, the blank material is shortened in the radial direction and is lengthened in the axial direction, and a bar-shaped blank material is formed; (3) then after the blank material is extruded, defects at the tail part of the blank material are cut off, the blank material with the defects at the tail parts being cut is put into the upsetting die for upsetting deformation again, and one-time upsetting and extruding process is finished; and (4) the workpiece after upsetting deformation is subjected to upsetting and extruding again, and upsetting and extruding process is repeated by three times. According to the large plastic shape and deformation blank-making method for eliminating anisotropy of the magnesium alloy bar material with large height-diameter ratio, uniform upsetting and blank-making of the large height-diameter ratio bar material without anisotropy is achieved by means of upsetting and extruding repeated circulation large deformation.

Owner:ZHONGBEI UNIV

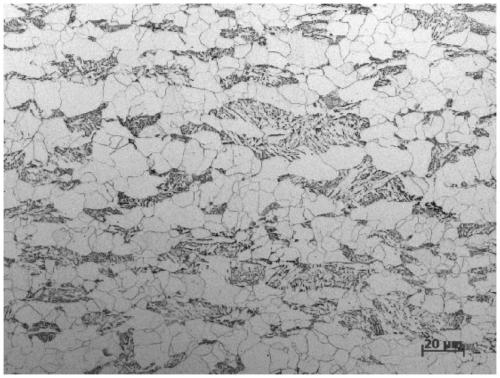

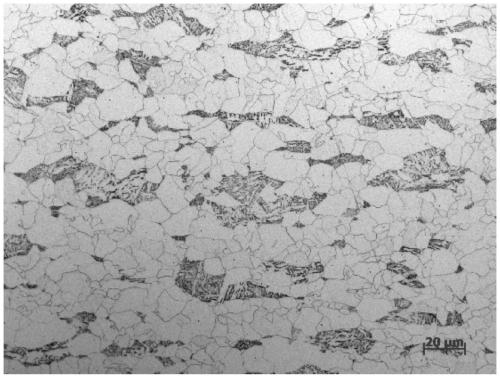

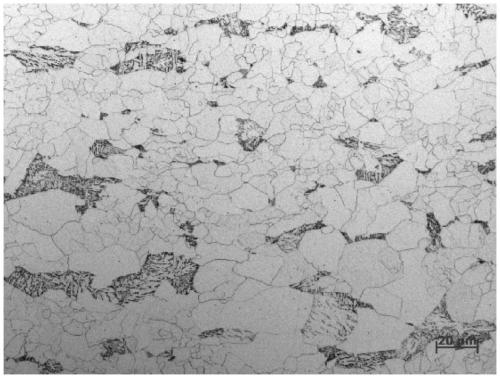

Forging method for near alpha-type high-temperature aluminum alloy large-size bar

ActiveCN112338119AImprove heart deformationImprove deformation uniformityMetal-working apparatusForgingTitanium alloy

The invention discloses a forging method for a near alpha-type high-temperature aluminum alloy large-size bar. A process route of the forging method comprises the following steps: cast ingot upsettingand drawing, first-time alpha and beta phase region upsetting, dynamic beta re-crystallizing and processing, second-time alpha and beta phase region upsetting, alpha and beta phase region stretching,and alpha and beta phase region finished product rounding forming. Dynamic beta re-crystallizing processing is combined in a high-low-high-low forging process, process steps are reasonably designed,and process parameters such as a deformation temperature, deformation amount, a deformation rate and a slenderness ratio are scientifically matched, so that forging deformation of blank is performed to obtain the near alpha-type high-temperature aluminum alloy large-size bar, which has a small and uniform equiaxed structure in core part and side parts, and has good ultrasonic flaw detection uniformity of Phi 250 mm to Phi 500 mm; and moreover, the forging method is short in forging process, is good in yield and is suitable for industrial stable production.

Owner:湖南湘投金天钛业科技股份有限公司

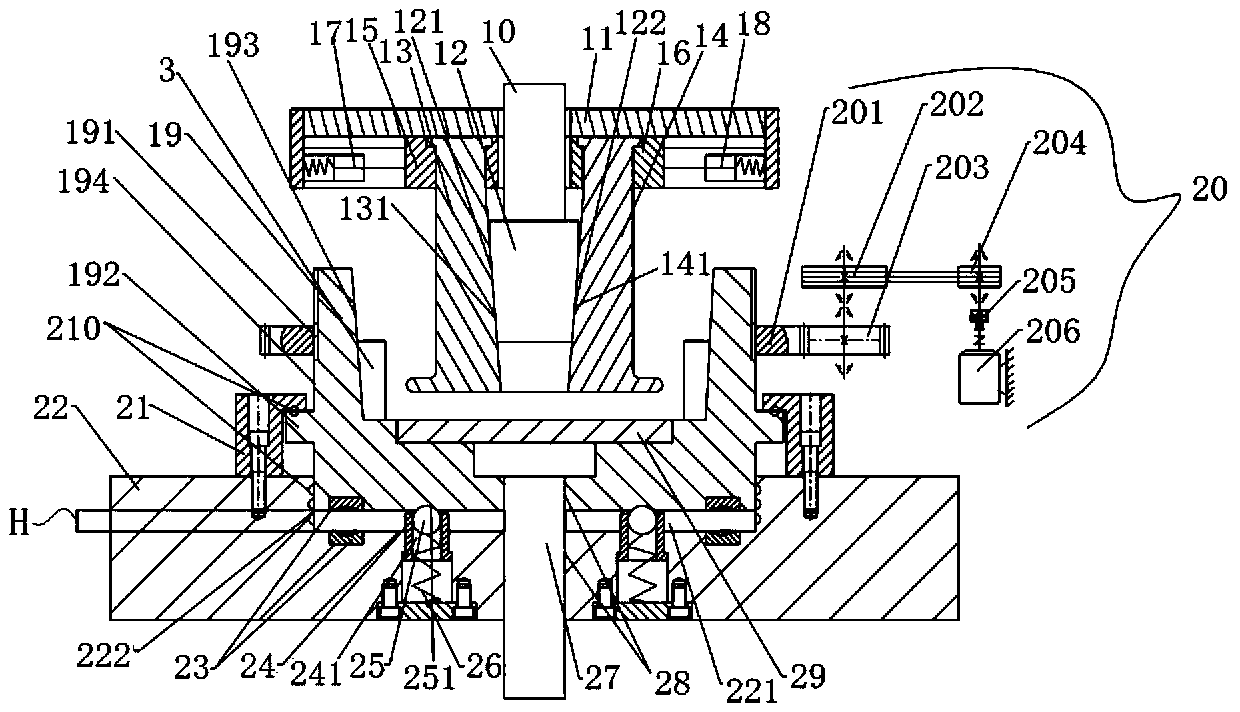

Large size sheet material shaping device with conformal combined type coils and large size sheet material shaping method

ActiveCN110814147AImprove deformation uniformityImprove quality and efficiencyEngineeringToroidal coil

The invention discloses a large size sheet material shaping device with conformal combined type coils and a large size sheet material shaping method. The large size sheet material shaping device withthe conformal combined type coils comprises a mold, a jacking plate which jacks a sheet material to a position above the mold and a pressing plate which presses the sheet material against the jackingplate, and further comprises a plurality of the combined type coils, wherein the combined type coils are laid above the sheet material, and the plurality of combined coils are arranged in the circumferential direction of the mold so as to form toroidal coil structures different in diameter size. The large size sheet material shaping device with the conformal combined type coils can improve deformation uniformity, shaping quality and shaping efficiency of the sheet material on the one hand, can form the toroidal coil structures different in diameter size through the splicing type combined coilsone the other hand, avoids the problem that multiple sets of conformal arrangement coils need to be manufactured at present, then can substantially reduce manufacture cost of the conformal combined type coils, meanwhile is suitable for methods of various electromagnetic shaping processes of first-stretch shaping and last-discharging or first-discharging and last-stretch shaping, improves processing flexibility, and enlarges application scope.

Owner:CENT SOUTH UNIV

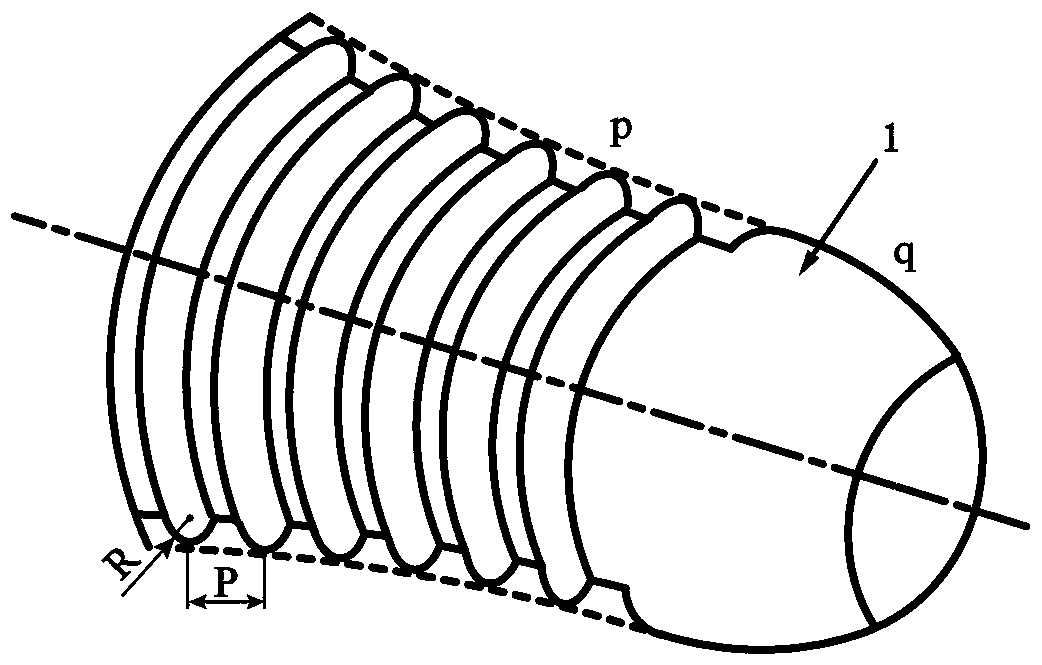

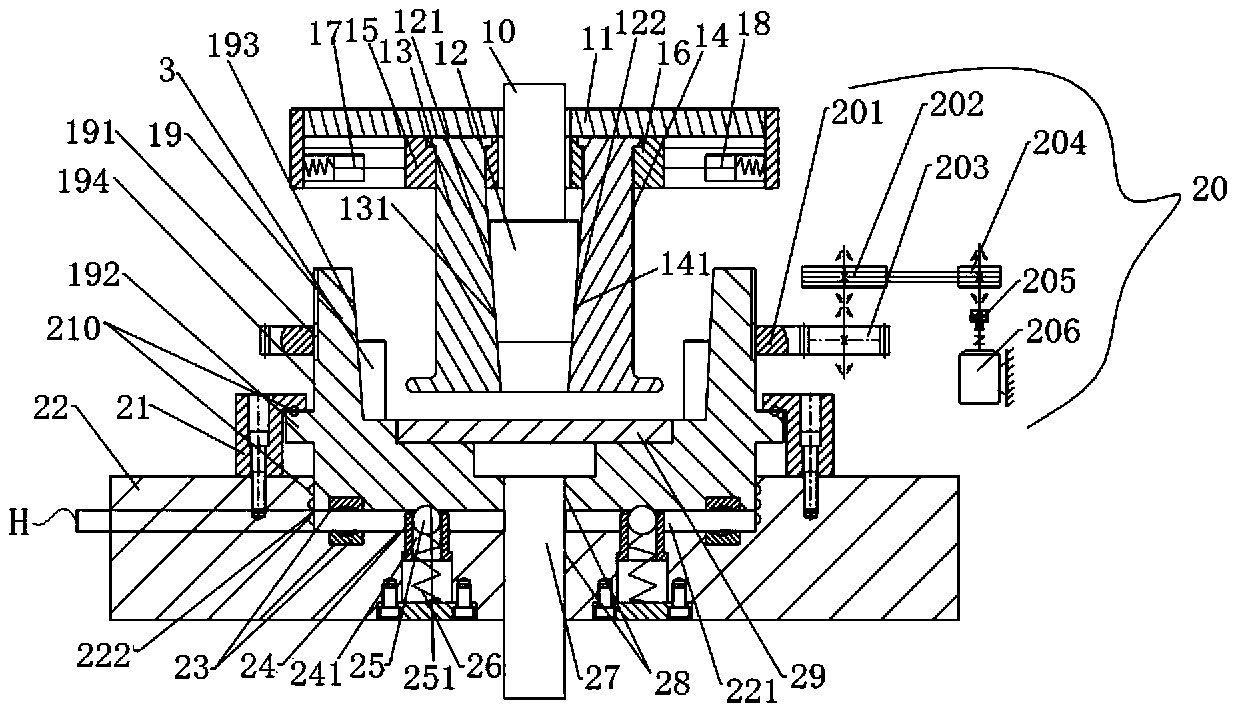

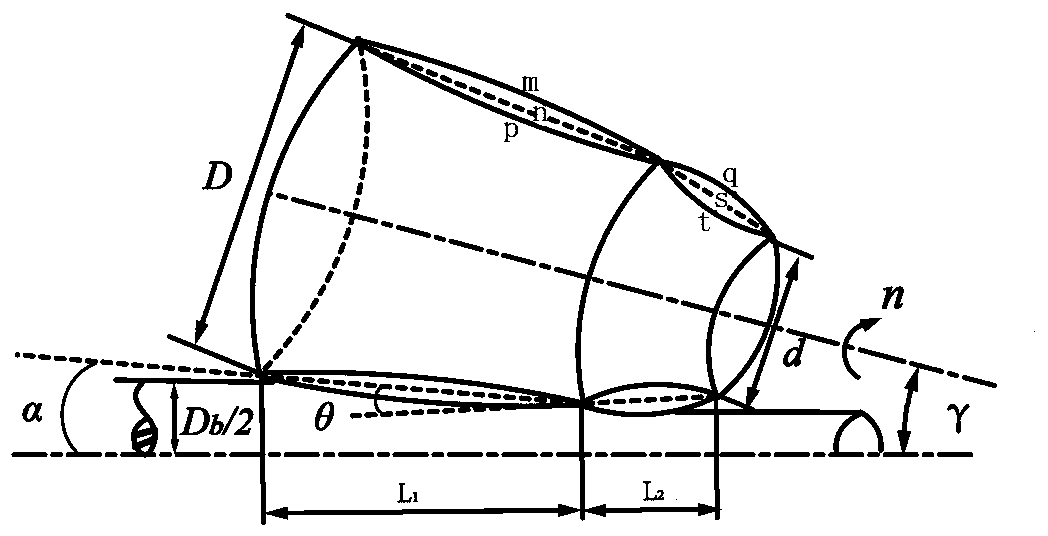

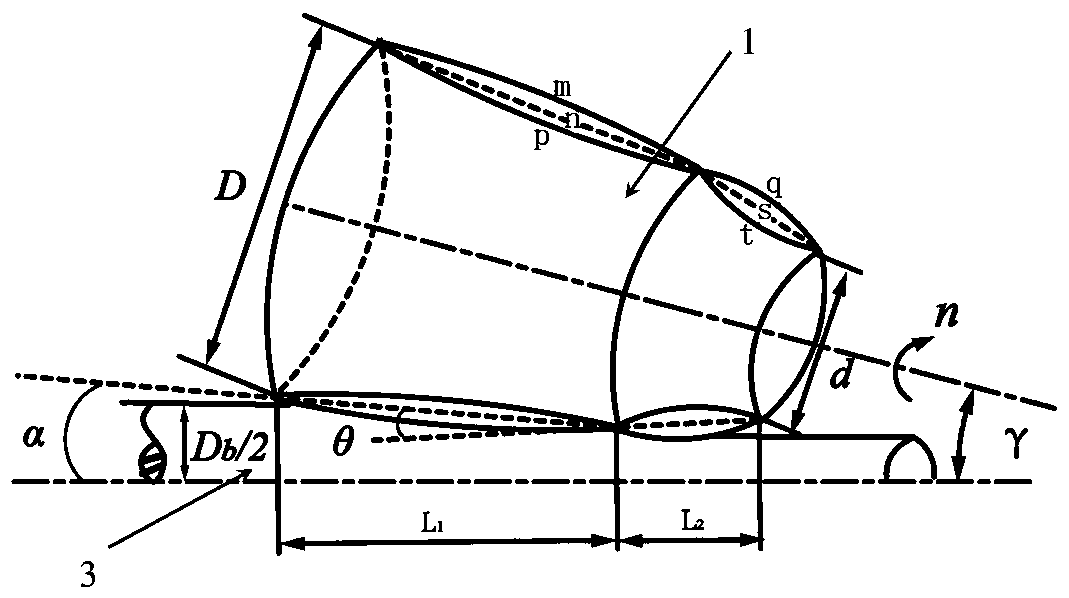

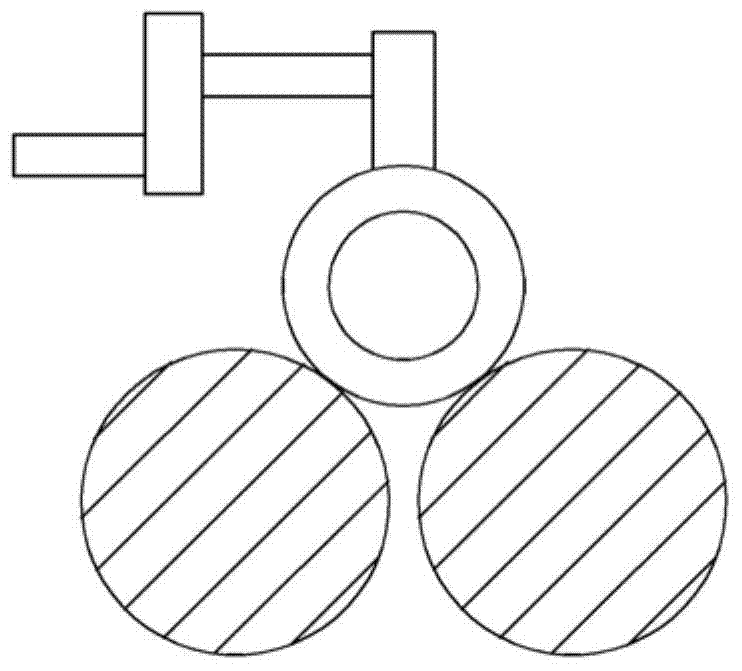

Reversed cone spiral roller ultra-fine grain rolling method of large-sized titanium alloy bar

ActiveCN109909296AReduce the number of repeated rollingReduce tensile stressRollsMetal rolling arrangementsHyperboloidUltra fine

The invention relates to the field of machining, in particular to a reversed cone spiral roller ultra-fine grain rolling method of a large-sized titanium alloy bar. The reversed cone spiral roller ultra-fine grain rolling method of the large-sized titanium alloy bar comprises the following steps that of designing a rolling tool, wherein roller design and guide plate design are involved specifically, and each roller is arranged to be a hyperboloid circular-truncated-cone-like spiral roller; forming a deformation area, wherein the curved faces of the two guide plates are oppositely arranged, thetwo rollers are placed between the two guide plates, and the area defined by the two guide plates and the two rollers is the deformation area; forming a constant-ovality deformation area, wherein theovality in the deformation area is kept constant; and selecting a rolling feeding manner, wherein inverted feeding type rolling manner is adopted. By the adoption of the reversed cone spiral roller ultra-fine grain rolling method of the large-sized titanium alloy bar, by designing the hyperboloid circular-truncated-cone-like spiral rollers and the curved-face guide plates and forming the constant-ovality deformation area, severe plastic deformation can be generated on the premise of remarkably restraining the Mannesmann effect of the core portion.

Owner:安徽东耘智能设备制造有限责任公司

Reverse conical spiral roller ultra-fine grain rolling method of large-size 45 steel bar

ActiveCN109807174AReduce the number of repeated rollingReduce tensile stressTemperature control deviceMetal rolling stand detailsRound tableSteel bar

The invention discloses a reverse conical spiral roller ultra-fine grain rolling method of a large-size 45 steel bar, and relates to the field of machining. The method comprises the following steps that a rolling tool is designed, wherein design specifically comprises roller design and guide plate design, and rollers are designed to be dual-curve-face round-table-shaped spiral rollers; a deformingarea is constructed, wherein curve faces of two guide plates are oppositely placed, the two rollers are placed between the guide plates, and the area defined by the guide plates and the rollers is the deforming area; an equal ovality deforming area is constructed, wherein ovality in the deforming area is kept unchangeable; and the inverted feeding manner is selected, wherein the pouring-in type rolling manner is adopted. According to the reverse conical spiral roller ultra-fine grain rolling method of the large-size 45 steel bar, through design of the dual-curve-face round-table-shaped spiralrollers and the curve guide plates, the equal ovality deforming area is constructed, and the violent plastic deforming is generated on the premise of obviously restraining the heart Mannesmann effect.

Owner:安徽东耘智能设备制造有限责任公司

Rotating extrusion forming method for cabin section workpiece

ActiveCN110743928AIncrease profitReduce the temperatureExtrusion diesExtrusion mandrelsMachiningLubricant

The invention provides a rotating extrusion forming method for a cabin section workpiece. The method comprises the following steps that firstly, a hollow circular truncated cone-shaped blank is prepared; the prepared blank is heated to the forming temperature and subjected to heat preservation, and a female die and a male die are preheated to the temperature higher than the forming temperature andsubjected to heat preservation; then an upper die assembly is assembled on a press; a lubricant is applied to the female die and the male die, and the blank is placed into a die cavity of the femaledie and fixed; a rotating driving device is started to drive the female die to rotate on a lower die seat, and the female die drives the blank to rotate; the press is started, the press moves the maledie down to the machining position of the blank in the die cavity through the upper die assembly, and the inner side wall of the blank is machined; and after the blank is machined and formed, the press moves the male die up to a preset position through the upper die assembly. According to the scheme, cutting machining is avoided, the material utilization rate is improved, the subsequent machiningconsumption is reduced, therefore the production cost is reduced, the production efficiency is improved, and the occurrence of the wall thickness difference is reduced.

Owner:ZHONGBEI UNIV

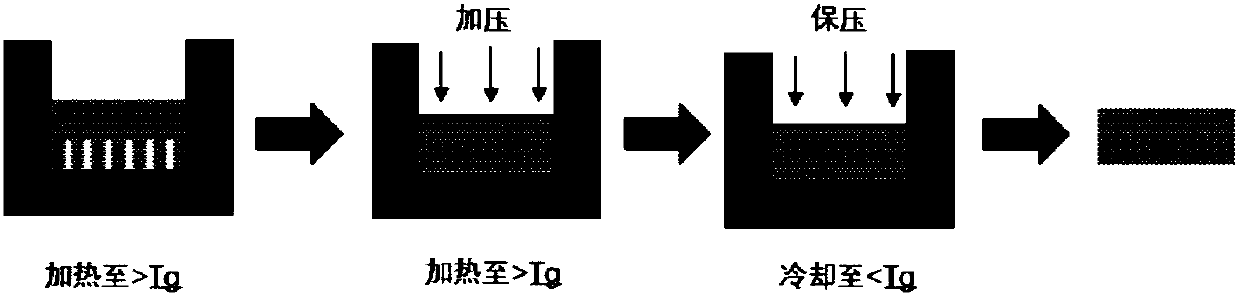

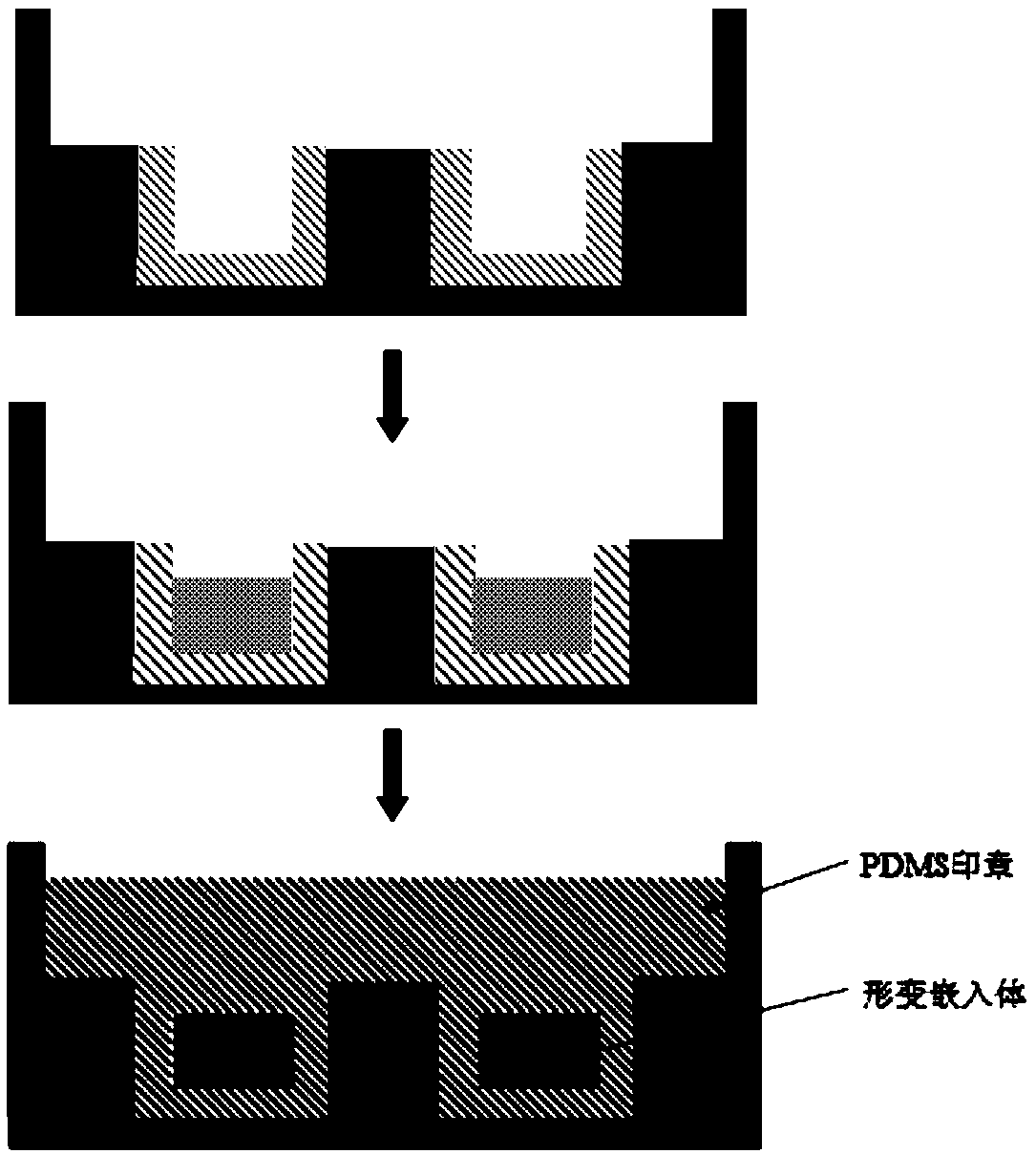

Quantum dot transfer printing method

ActiveCN109927431AImprove deformation uniformityReduce contact areaOther printing apparatusQuantum dotQuantum

The invention belongs to the technical field of quantum dots, and particularly relates to a quantum dot transfer printing method. The quantum dot transfer printing method comprises the following stepsthat a seal is provided, a deformation embedded body is arranged on a seal surface protruding part of the seal, and the deformation embedded body is obtained in the mode that an initial embedded bodymanufactured by materials containing shape memory polymers are deformed; a quantum dot initial film arranged on the surface of a donor substrate is provided, and the initial film is subjected to transfer printing onto the seal surface, provided with the deformation embedded body, of the seal to form a quantum dot patterned film layer; the seal with the quantum dot pattern film layer subjected totransfer printing makes contact with a target substrate, the deformation embedded body is restored to the initial embedded body, and thus the quantum dot pattern film layer is subjected to transfer printing onto the target substrate. According to the quantum dot transfer printing method, part of pattern residues finally caused by nonuniform stress restoring is reduced, the integrity of transfer printing of the quantum dot pattern film layer is improved, and externally-applied stress required by repeated using of the seal is reduced.

Owner:TCL CORPORATION

A method for ultra-fine grain rolling of large size 45 steel bars

ActiveCN109807176BInhibition of the Mannesmann effect in the heartReduce the number of repeated rollingTemperature control deviceMetal rolling stand detailsTectonic deformationMachining

The invention discloses an ultrafine grain rolling method of a large-size 45 steel bar, and relates to the field of machining, particularly to the ultrafine grain rolling method of the large-size 45 steel bar. The ultrafine grain rolling method comprises the following steps of design of rolling tools, specifically comprising design of rollers and design of guide plates: setting the rollers as double-curved surface circular table rollers, specifically, forming generatrices of the rollers through connecting two curves, and setting one surfaces of the guide plates as curved surfaces; constructionof a deformation zone: oppositely placing the curved surfaces of the two guide plates, placing the two rollers between the guide plates, and setting a region refined by the two guide plates and the two rollers as the deformation zone; and selection of rolling feeding manner: selecting reverse feeding rolling manner, and constructing an even-ovality deformation zone. According to the ultrafine grain rolling method of the large-size 45 steel bar provided by the invention, the double-curved surface circular table rollers and the curved surface guide plates are designed, the even-ovality deformation zone is constructed, and severe plastic deformation under the precondition of the Mannesmann effect of a central part can be remarkably inhibited.

Owner:安徽东耘智能设备制造有限责任公司

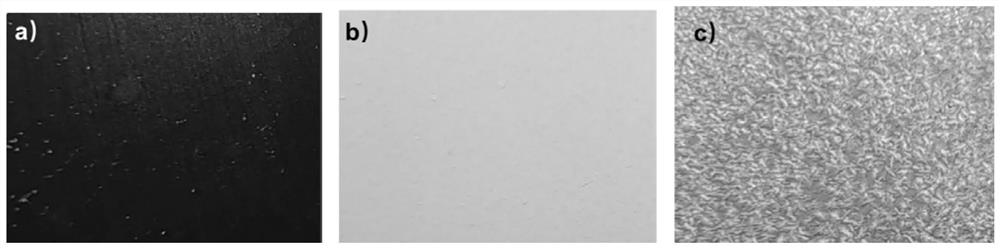

Degradable pure magnesium or magnesium alloy oral biological barrier membrane and preparation method thereof

ActiveCN114225120AImprove deformation uniformityEliminate internal stressAnodisationSurgeryRough surfaceMg alloys

The invention relates to the field of biomedical materials, in particular to a degradable pure magnesium or magnesium alloy oral biological barrier membrane and a preparation method thereof. According to the method, the hole pattern structure design, the pre-forming process and the vacuum annealing treatment are combined, so that the deformation uniformity is improved, the internal stress generated by deformation is eliminated, and the degradation uniformity is greatly improved. A one-film double-coating special surface treatment method is adopted, so that one side of the pure magnesium or magnesium alloy film has a smooth surface, and adhesion and proliferation of epithelial cells or hoof forming tissues are inhibited; on the other hand, a rough surface with an osteogenesis function is obtained, and growth of bone tissues is promoted. In addition, the one-film double-coating further has the asymmetric degradation characteristic, and the corrosion resistance of the smooth surface is more excellent than that of the rough surface; the pure magnesium or magnesium alloy membrane is asymmetrically degraded, so that a stable interface can be obtained on the outer layer of the barrier membrane to shield epithelial cells or hoofing tissues, and meanwhile, the inner layer releases bone ions through controllable degradation to improve bone tissue repair and integration effects.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

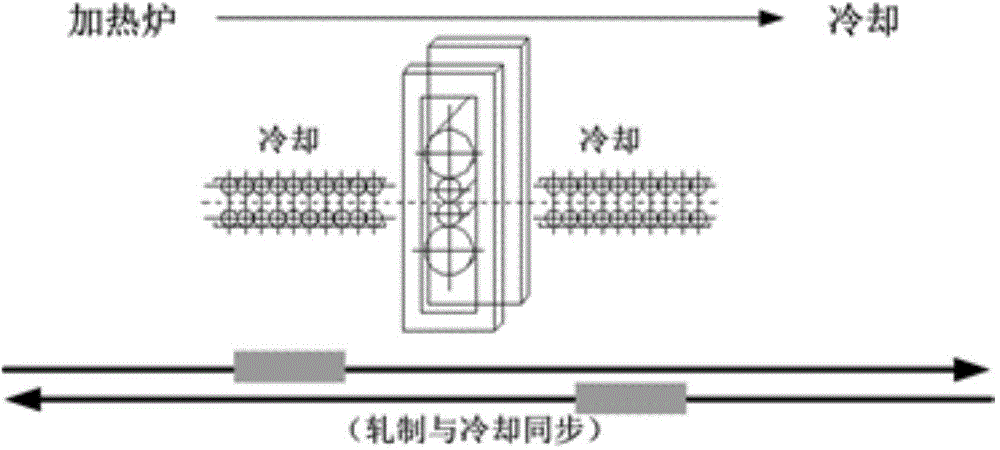

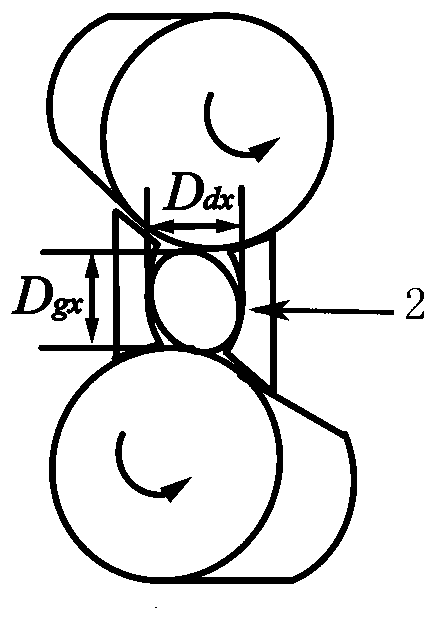

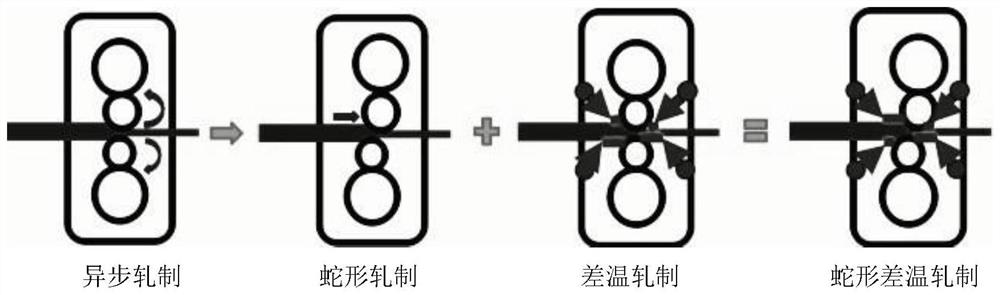

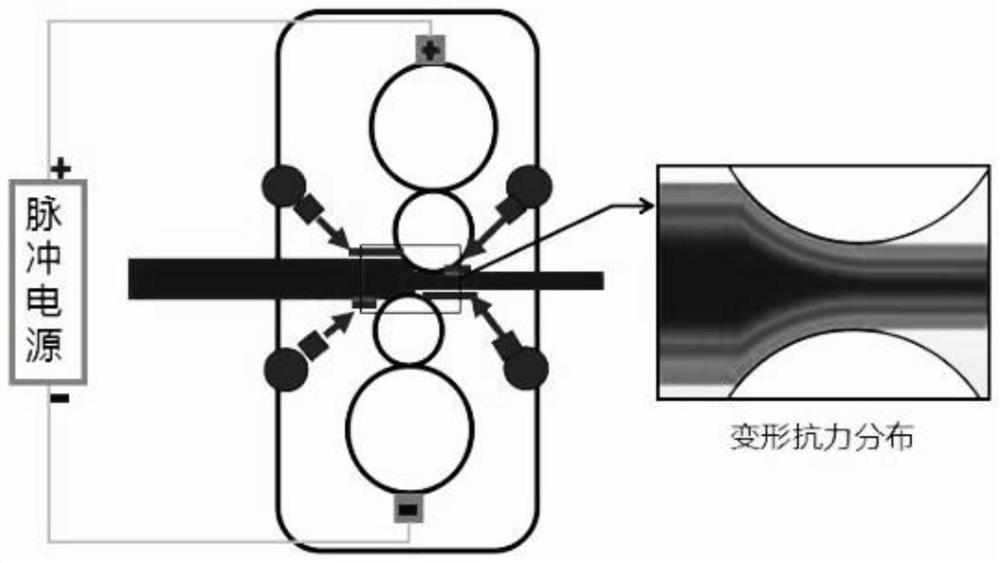

Serpentine differential-temperature rolling method for improving deformation uniformity of hot-rolled plate strip steel

ActiveCN111644464AImprove completenessImprove uniformityWork cooling devicesWork heating devicesShear stressEngineering

The invention discloses a serpentine differential-temperature rolling method for improving the deformation uniformity of hot-rolled plate strip steel. The method comprises the steps that a cross shearzone is formed in a deformation zone through cross shear rolling, and the shear stress generated by the cross shear zone facilitates transfer of the deformation from the surface layer to the center;on the basis of cross shear rolling, a slow working roller moves in the rolling direction or moves a rapid working roller in the opposite direction to form a cross shear zone and an anti-bend zone, and the bending of plate strip steel is restrained by utilizing the anti-bend force of the anti-bend zone to form serpentine rolling; steel plates are subjected to ultra-rapid cooling before rolling toform an outer-hard and inner-soft deformation resistance distribution, and differential temperature rolling is additionally arranged on the basis of serpentine rolling to form serpentine differential-temperature rolling; and a rolling deformation zone is formed in the serpentine differential-temperature rolling zone, and a high-frequency pulse current is applied in the rolling deformation zone. According to the serpentine differential-temperature rolling method, the combined effect of the cross shear rolling, the serpentine rolling, the differential-temperature rolling and the pulse current isfully utilized to improve the deformation uniformity of the plate strip steel in the thickness direction, and meanwhile a good plate shape after rolling is ensured.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for eliminating residual stress of airplane skin panel

InactiveCN103555906AReduce residual stressAvoid deformationFurnace typesProcess efficiency improvementProcess specificationJet aeroplane

The invention belongs to the technical field of aircraft material production, and relates to a method for eliminating the residual stress of an airplane skin panel, which is capable of eliminating the stress of aircraft materials and controlling the surface quality and the like. The method comprises the following steps: carrying out solid solution heat treatment on the airplane skin panel, and carrying out prestretching permanent deformation in the length direction of the airplane skin panel, wherein the deformation is 0.8-1% of the length of the airplane skin panel; then carrying out artificial aging and ultrasonic flaw detection treatment. A novel simple easy-to-operate technology, namely a prestretching manner is used for eliminating the residual stress of the panel so as to solve the problems that after the large-area skin panel is chemically milled, the skin panel deforms, and the surface quality of the skin panel is improved, thus the design and process specification requirements are satisfied.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

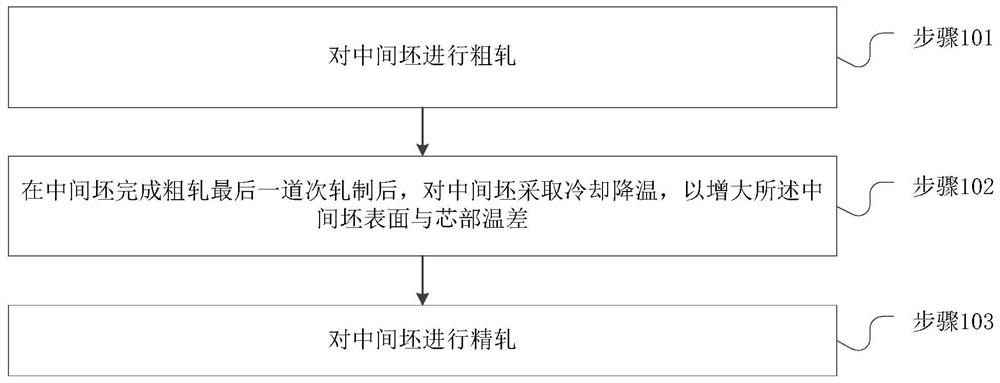

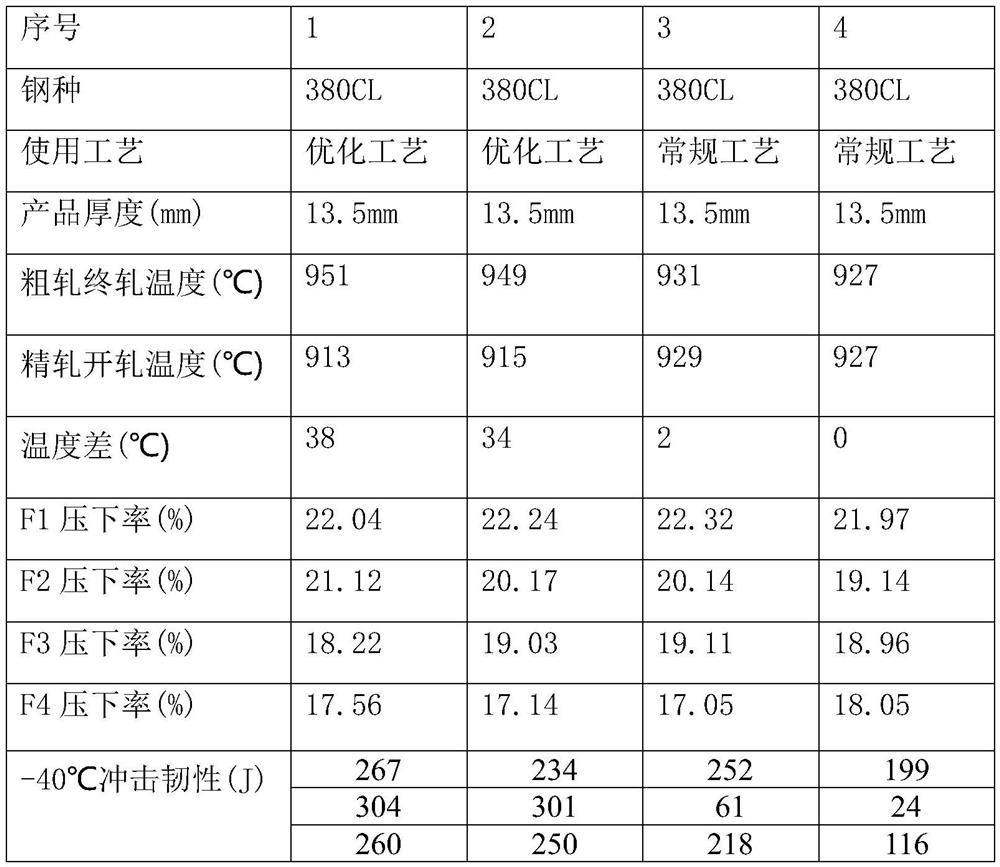

Method for improving low-temperature impact toughness of 380MPa-grade hot-rolled wheel steel

PendingCN112662855AImprove deformation uniformityLarge temperature differenceMetallurgyImpact toughness

The invention discloses a method for improving low-temperature impact toughness of 380MPa-grade hot-rolled wheel steel. The method comprises the following steps that an intermediate billet which is used for manufacturing the 380MPa-grade hot-rolled wheel steel is roughly rolled; after the final pass of rough rolling of the intermediate billet is completed, the intermediate billet is cooled, so that the temperature difference between the surface and the core of the intermediate billet is increased; and the intermediate billet is subjected to finish rolling.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

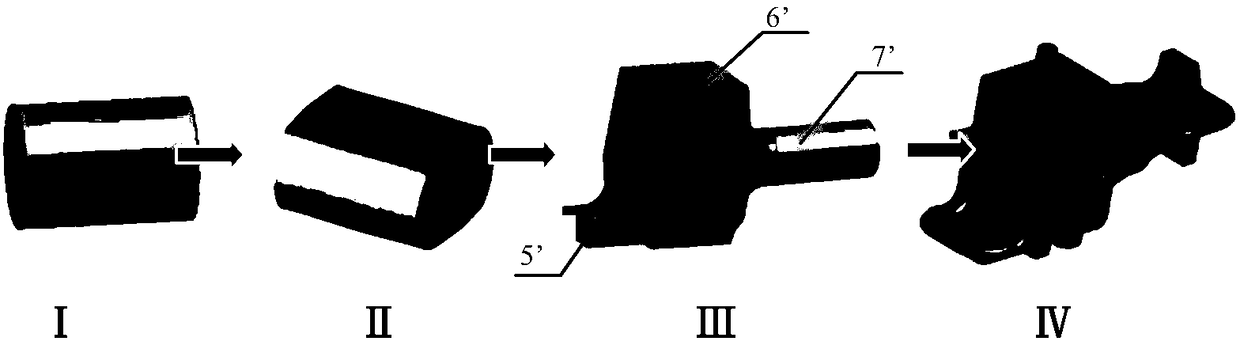

A kind of forging method of high-speed train axle box body

ActiveCN106734799BGood volume distributionEasy to shapeRailway componentsForging/hammering/pressing machinesBar stockManufacturing engineering

The invention discloses a forging method of a high-speed train axle box body. The forging method comprises the following steps that 1, blank blanking is conducted, wherein a blank is a cylindrical extrusion bar, and the blank with the set length is obtained through sawing blanking; 2, transverse flattening upsetting is conducted, wherein transverse flattening upsetting is conducted on the blank to obtain a prefabricated blank; 3 the prefabricated blank is extruded to obtain a pre-forging piece, wherein the pre-forging piece sequentially comprises an end corresponding to the shape of the axle box body, a middle and a rod portion in the length direction, and volume distribution of the pre-forging piece is matched with that of the axle box body; 4, final forging piece molding is conducted, wherein the pre-forging piece is placed in a final forging mold to be subjected to final forging, and a final forging piece is obtained. Volume distribution of the pre-forging piece is well matched with that of the final forging piece, an extrusion process is adopted in pre-forging piece molding, no flash is generated, the pre-forging piece is stably positioned in a final forging mold cavity, and therefore it can be guaranteed that the final forging piece is well molded.

Owner:SHANDONG UNIV +1

A method for ultra-fine grain rolling of large-size titanium alloy rods

ActiveCN109807175BInhibition of the Mannesmann effect in the heartReduce the number of repeated rollingTemperature control deviceMetal rolling stand detailsTitanium alloyMachining

The invention discloses an ultra-fine grain rolling method of a large titanium alloy bar and relates to the field of machining, in particular to the ultra-fine grain rolling method of the large titanium alloy bar. The ultra-fine grain rolling method of the large titanium alloy bar comprises the following steps that rolling tools are designed, roller design and guide plate design are included, eachroller is designed into a double-curved face type circular truncated cone roller, and specifically, a bus of each roller is formed by connecting two curves, and one face of each guide plate is designed into a curved face; a deformation zone is configured, wherein the curved faces of the two guide plates are oppositely arranged, the two rollers are arranged between the guide plates, and a regiondefined by the two guide plates and the two rollers is the deformation zone; an equal ovality deformation zone is configured, wherein ovality in the deformation zone is kept unchangeable; and a rolling feeding manner is selected, wherein a backward advancing rolling manner is adopted. According to the ultra-fine grain rolling method of the large titanium alloy bar, by designing the double-curved face type circular truncated cone rollers and the curved face-shaped guide plates and configuring the equal ovality deformation zone, intensive plastic deformation can be generated on the promise of remarkably restraining a Mannesmann effect of the heart.

Owner:安徽东耘智能设备制造有限责任公司

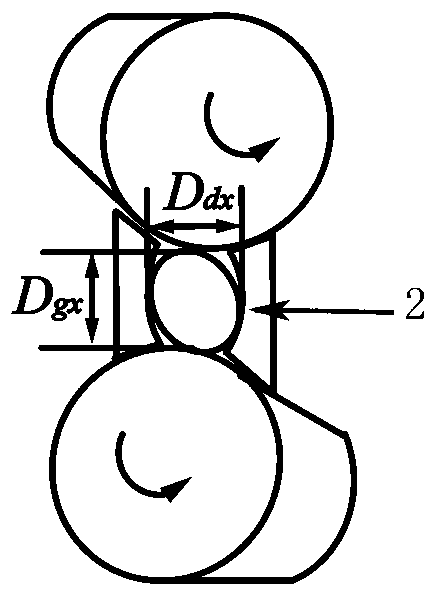

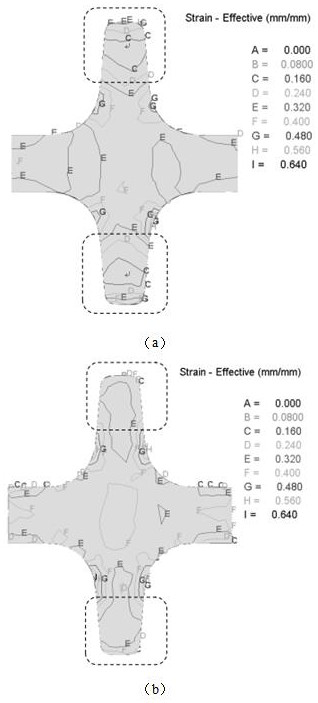

Method for improving quasi-beta forging deformation uniformity of titanium alloy high-rib forge piece

ActiveCN113343534AIncrease the amount of deformationQuality improvementGeometric CADDesign optimisation/simulationTitanium alloySoftware

The invention discloses a method for improving the quasi-[beta] forging deformation uniformity of a titanium alloy high-rib forge piece, which comprises the following steps: S1, before quasi-[beta] forging, performing finite element simulation on an improved pre-forge piece model through software, optimizing the structural size parameters of the improved pre-forge piece model, performing quasi-beta forging simulation calculation, and enabling the deformation amount of a final forging piece model obtained after the improved pre-forging piece model to be subjected to quasi-[beta] forging is within the effective deformation amount range of 20%-40%; S2, performing machining according to the pre-forged piece model data meeting the effective deformation in the step S1, and obtaining an improved pre-forged die; and S3, putting the titanium alloy blank into the improved pre-forging die to be subjected to pre-forging forming, obtaining an improved pre-forged piece, then putting the improved pre-forged piece into a final forging die to be subjected to quasi-[beta] forging, and obtaining a final forged piece. The method can effectively improve the deformation of the high-rib area of the forge piece, so that the deformation of the high-rib part is uniform and consistent with that of the web.

Owner:CHONGQING UNIV +2

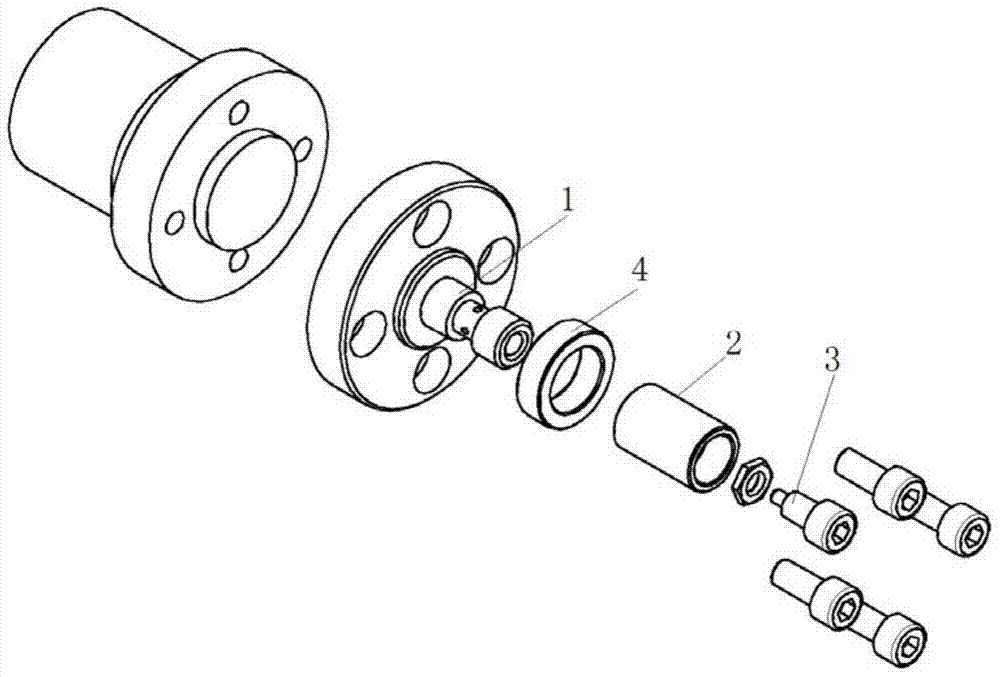

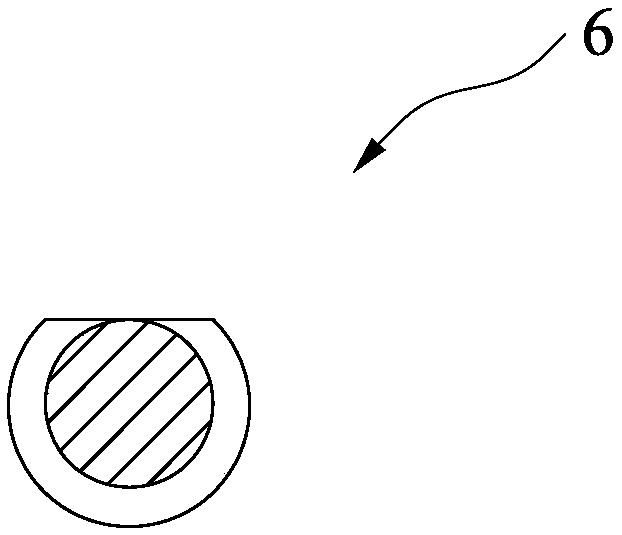

Ultra lapping machining centering fixture for bearing inner ring roller

InactiveCN104511834AGuaranteed coaxialityGuaranteed tightnessGrinding work supportsInterference fitEngineering

The invention relates to an ultra lapping machining centering fixture for bearing inner ring roller, the thin wall sleeve is opened with an inner ring-shaped groove and sleeved outside the fixture body, the connection mode between the thin wall sleeve and the fixture body is the interference fit connection, the inner ring-shaped groove of the thin wall sleeve, the outer ring-shaped groove of the fixture body and the mobile column are respectively poured with the liquidity plastic, the magnitude of interference delta of the interference fit mode between the thin wall sleeve and the fixture body is 0.010 to 0.012mm, the wall thickness S between the inner wall of the inner ring-shaped groove of the thin wall sleeve and the outer wall of the thin wall sleeve is 0.5 to 0.7mm. The ultra lapping machining centering fixture for bearing inner ring roller is good in elasticity, good in deformation uniformity and high in centering precision and is especially suitable for centering and clamping the bearing inner ring. The coaxiality and airtightness of the thin wall sleeve and the fixture body can be guaranteed. The thin wall sleeve with a taper angle R for 0.5-1.5 degrees is adopted, and then the side of the bearing inner ring and the locating block can be tightly located while centering and clamping the bearing inner ring and the axial direction locating precision of the bearing inner ring is raised.

Owner:黄彬

Forming method of Mg-Gd-Y-Zn-Zr magnesium alloy bidirectional expansion equal channel extrusion blank forming

ActiveCN109604359AAchieving shear stress deformationImprove uniformityExtrusion diesMechanical propertyMagnesium alloy

The invention discloses a forming method of Mg-Gd-Y-Zn-Zr magnesium alloy bidirectional expansion equal channel extrusion blank forming and relates to a forming die of the Mg-Gd-Y-Zn-Zr magnesium alloy bidirectional expansion equal channel extrusion blank forming. The die comprises an upper die seat, a male die and a female die, wherein the female die is arranged below the male die, is of an inverted "T" shape and is formed by communicating a vertical cavity and a horizontal cavity with the same diameter; in addition, a spherical cabin is formed in the intersection part of the vertical cavityand the horizontal cavity, small circular beads are respectively arranged in the joint of the spherical cabin and the vertical cavity and the joint of the spherical cabin and the horizontal cavity, and the vertical cavity is used for accessing the male die. A bidirectional equal channel extrusion structure formed by the vertical cavity and the horizontal cavity is adopted, the spherical cabin is arranged in the channel joint and a multi-pass deformation test is carried out, the compound superposition of the shear deformation in a cavity corner and the heading extrusion deformation in the spherical cabin during a material extrusion process is realized, accumulated plastic deformation process of a material is reached, refinement of a microstructure of a Mg-Gd-Y-Zn-Zr magnesium alloy blank isfinally realized, and the mechanical property of an alloy is promoted.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com