Method for eliminating residual stress of airplane skin panel

A residual stress and skin plate technology, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., to achieve the effect of improving surface quality, small deformation, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

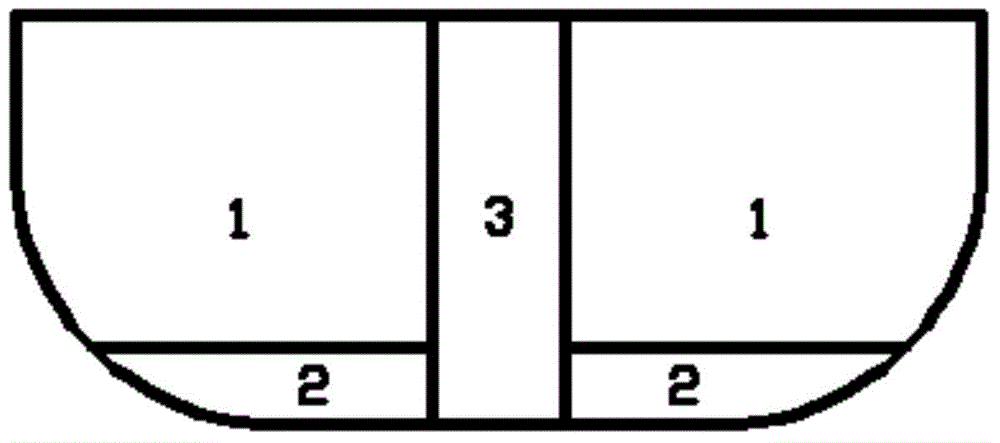

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings. figure 1 It is a typical aircraft sheet metal chemical milling part structure. The central area of this part is non-chemical milling area 3, and the upper and lower sides of the part need large area chemical milling areas 1 and 2, and the thickness requirements of different areas after chemical milling are different. Similarly, if the traditional skin plate (thin plate without stress relief) is used, there will be the following problems after chemical milling: first, the actual parts are deformed after chemical milling, and there are many agitation deformation areas; second, wrinkles, agitation, etc. Surface quality problems; adopt the manufacturing method proposed by the present invention to avoid the above problems.

[0009] Main steps of the present invention are as follows:

[0010] Ingot casting, melting casting (flat ingot)→rolling→edge trimming→etchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com