Wind power spindle flange upsetting process

A wind power spindle and wind power flange technology, which is applied in the field of wind power spindle flange upsetting technology, can solve problems such as uneven deformation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

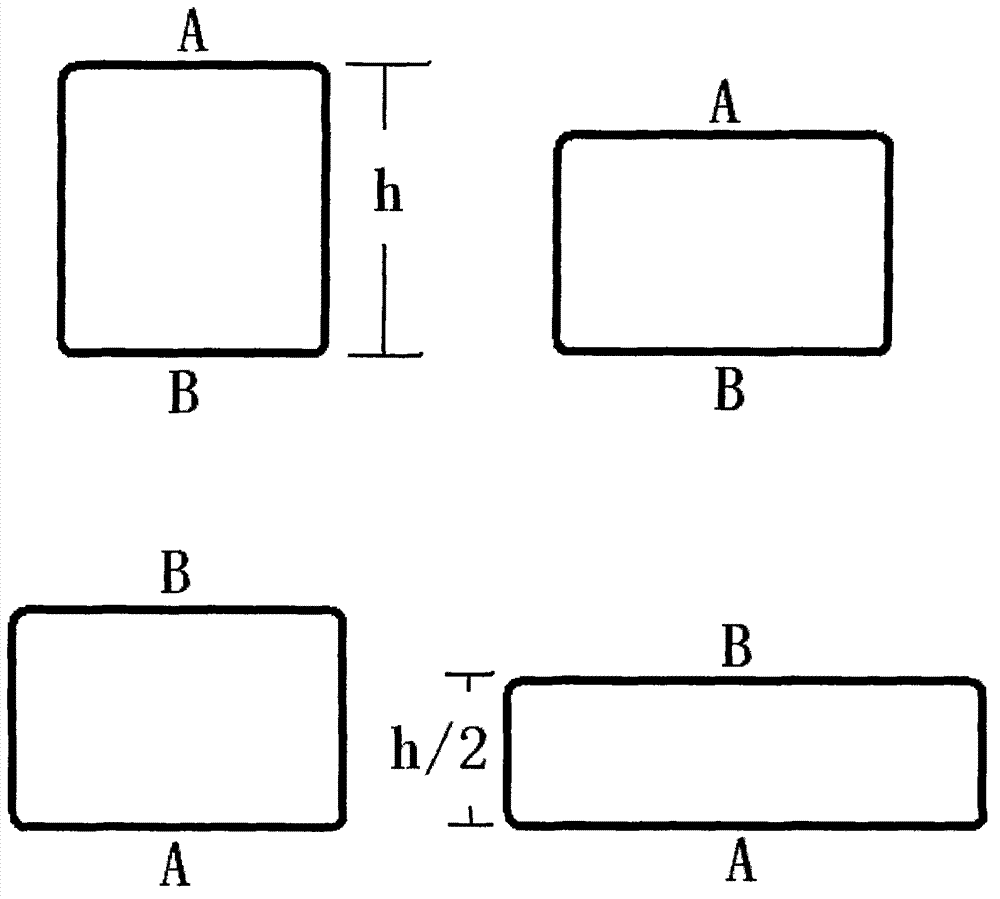

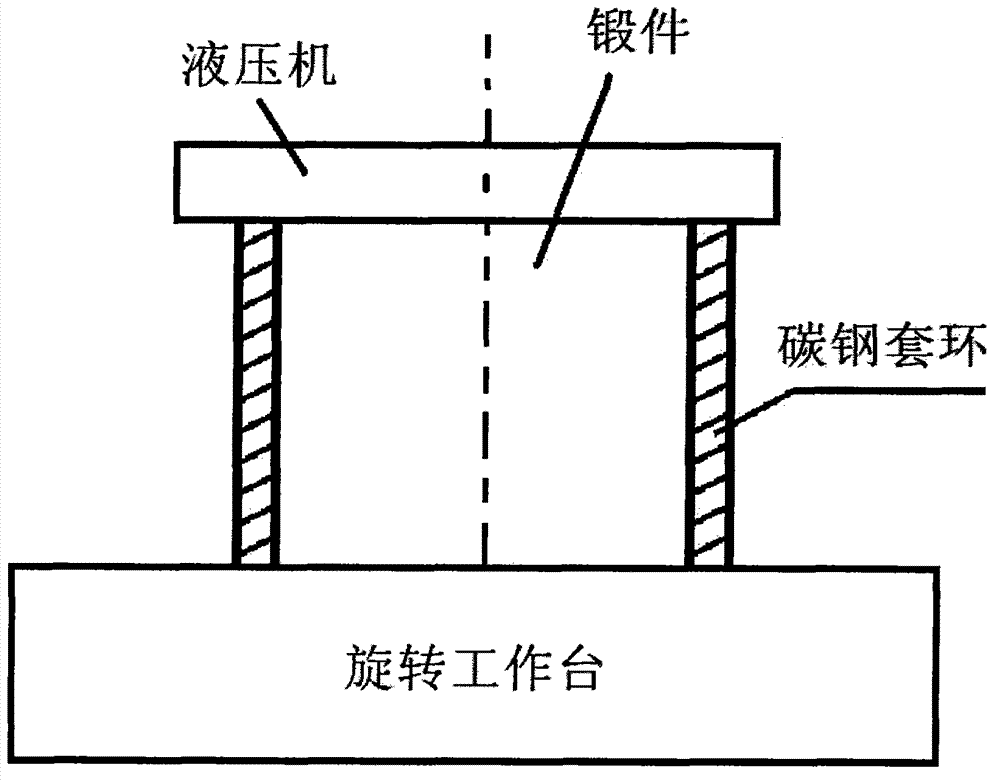

[0015] The upsetting process of the wind power flange of the present invention comprises the following steps:

[0016] Firstly, the billet used for the flange of the wind power main shaft according to the present invention is prepared in a steelmaking furnace. Raise the temperature to 1300°C in the steelmaking furnace, add steelmaking raw materials to refine it into a low-alloy high-strength steel billet for wind power flanges, and the chemical composition of the low-alloy high-strength steel is: carbon: 0.25-0.60wt%, silicon: 0.35~0.50wt%, manganese: 1.2~1.70wt%, phosphorus: 0.015~0.025wt%, sulfur: 0.012~0.02wt%, chromium: 0.30~0.80wt%, molybdenum: 0.10~0.30, vanadium: 0.15~0.30wt% %, nickel: 0.30-0.50wt%, copper: 0.15-0.3wt%, nitrogen: 0.015-0.05wt%, titanium: ≤0.2wt%, niobium: ≤0.06wt%, and the balance is iron; then the low Alloy high-strength steel blanks are continuously cast into Φ1500mm blanks, which are forged to obtain forgings for wind power flanges;

[0017] Then,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com