Differential-temperature rolling method for AlZnMgCu-series aluminum alloy thick plates

An aluminum alloy and sheet rolling technology, applied in metal rolling, metal rolling, manufacturing tools and other directions, can solve the problem of high equipment requirements, and achieve the effects of low equipment requirements, easy implementation and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

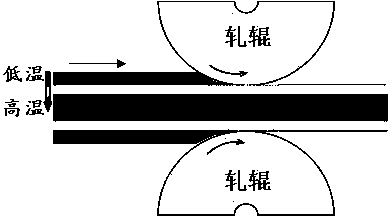

Method used

Image

Examples

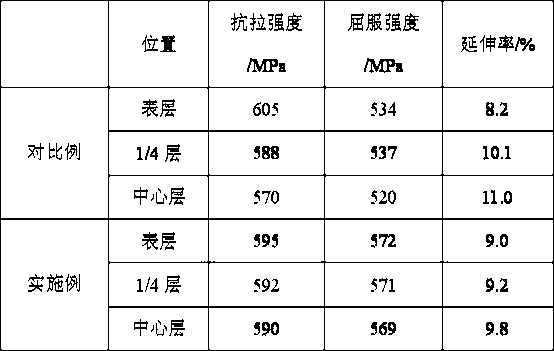

Embodiment 1

[0016] The aluminum alloy thick plate is made of 7050 aluminum alloy with an original thickness of 370mm. The method of differential temperature rolling is adopted. First, the 7050 ingot is hot-rolled to 180mm by ordinary hot rolling method, and then the surface of the thick plate is cooled to 300°C. The thick plate is hot-rolled to 80mm by using a large reduction rolling with a pass deformation of 20mm, and the final size of the thick plate is: 3000×1200×80mm. Solid solution, quenching and three-stage aging T77 treatment were performed on the thick plate. The tensile properties of the surface layer, 1 / 4 layer and core of the thick plate are shown in Table 1.

[0017] surface The tensile properties of comparative example 1 and embodiment 1

[0018]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com