Large size sheet material shaping device with conformal combined type coils and large size sheet material shaping method

A forming device and forming method technology, which is applied in the field of large-size sheet metal forming devices, can solve problems such as difficult application of sheet materials, poor flexibility, and narrow adaptation range, so as to improve flexibility and application range, reduce manufacturing costs, and improve deformation uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

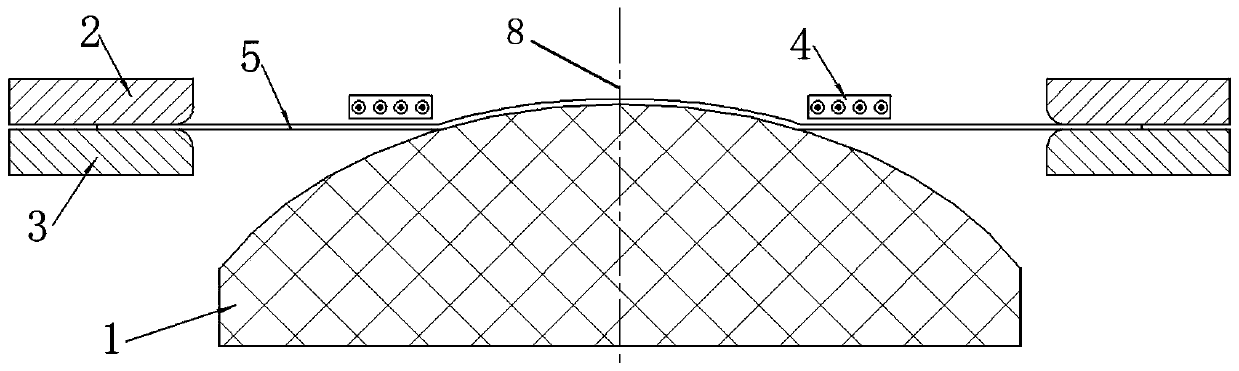

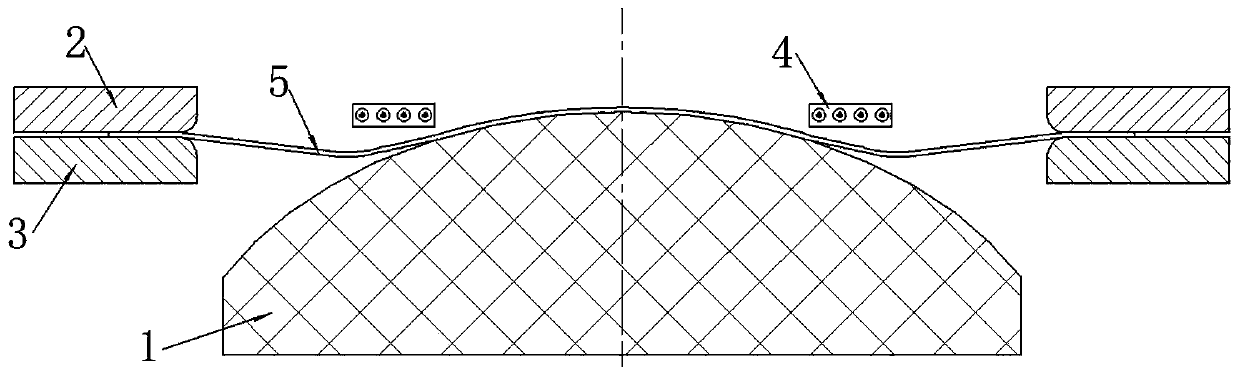

[0045] Such as Figure 1-16 As shown, the embodiment of the present invention first discloses a large-size sheet material forming device provided with conformal combined coils, including a mold 1, a supporting plate 3 for lifting the sheet 5 above the mold 1, and holding the sheet 5 The pressing plate 2 pressed on the supporting plate 3 can be clamped by a hydraulic cylinder. At the same time, the supporting plate 3 and the mold 1 can move relative to each other to deform by pulling and compressing. Specifically, a hydraulic oil cylinder can be used to drive up and down movement, including multiple A combined coil 4, the combined coil 4 is an arc-shaped segmented structure, the combined coil 4 is arranged on the top of the sheet material 5, and a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com