Forging method for near alpha-type high-temperature aluminum alloy large-size bar

A high-temperature titanium alloy, large-scale technology, applied in the field of forging, can solve the problems of difficult forging process control, low yield, narrow forging window, etc., to avoid narrow forging window, improve cracking, and improve the effect of core deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

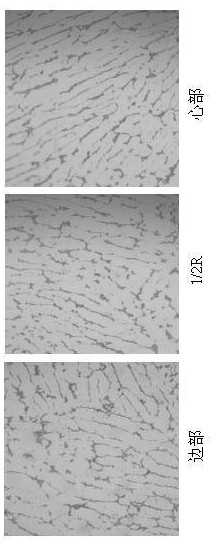

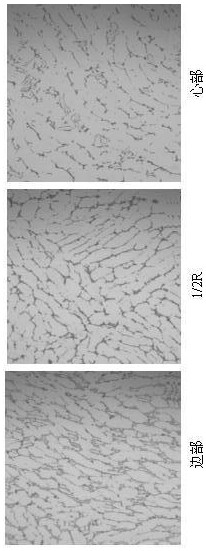

[0035] Material: Ti55 titanium alloy, phase transition point: 1000℃, finished bar size: Φ400mm×L, main equipment: 45MN fast forging machine and three types of electric furnace. Contrast the production process scheme and detection results before and after the application of the present invention below:

[0036] (1) Forging process in the prior art:

[0037] (1) Ingot billet forging

[0038] Preheat the heating furnace to 800°C, put it into the ingot or billet and keep it warm for 1~2h, then slowly raise the temperature to 1100~1150°C, the heating coefficient is 0.3, forging 4 fires, the forging ratio of each fire is 4.5~7.0, upsetting Thickness-height-diameter ratio 1.8~2.3, upsetting reduction rate 10~25mm / s, reduction 100~150mm, air cooling after forging;

[0039] (2) Upsetting of α+β phase region

[0040] Heating at 980°C below the phase transition point, the heating coefficient is 0.6, forging for 5 fires, the forging ratio per fire is controlled at 1.6, the upsetting he...

Embodiment 2

[0060] Material: Ti60, phase transition point: 1045°C, finished forging size: Φ250mm×L, main equipment: 45MN fast forging machine and three types of electric furnace. Contrast the production process scheme and detection results before and after the application of the present invention below:

[0061] (1) Forging process in the prior art:

[0062] (1) Ingot billet forging

[0063] Preheat the heating furnace to 800°C, put it into the ingot or billet and keep it warm for 1~2h, then slowly raise the temperature to 1100~1150°C, the heating coefficient is 0.4, forging 3 fires, the forging ratio of each fire is 2.0~4.5, upsetting The rough reduction rate is controlled at 10mm / s~30mm / s, the reduction amount is 100~150mm, and air cooling after forging;

[0064] (2) Upsetting of α+β phase region

[0065] Preheat the heating furnace to 800°C, put it into ingot or billet and keep it warm for 1~2h, then slowly raise the temperature to 1025°C, the heating coefficient is 0.5, forging 4 f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition point | aaaaa | aaaaa |

| Phase transition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com