Forging method of alloy cast ingots

A technology of alloy ingots and ingots, which is applied in the field of material processing and forging, and can solve the problems that alloy ingots are not easy to open and forge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Φ265×1160mm directionally solidified GH4096 alloy ingot upsetting forging billet

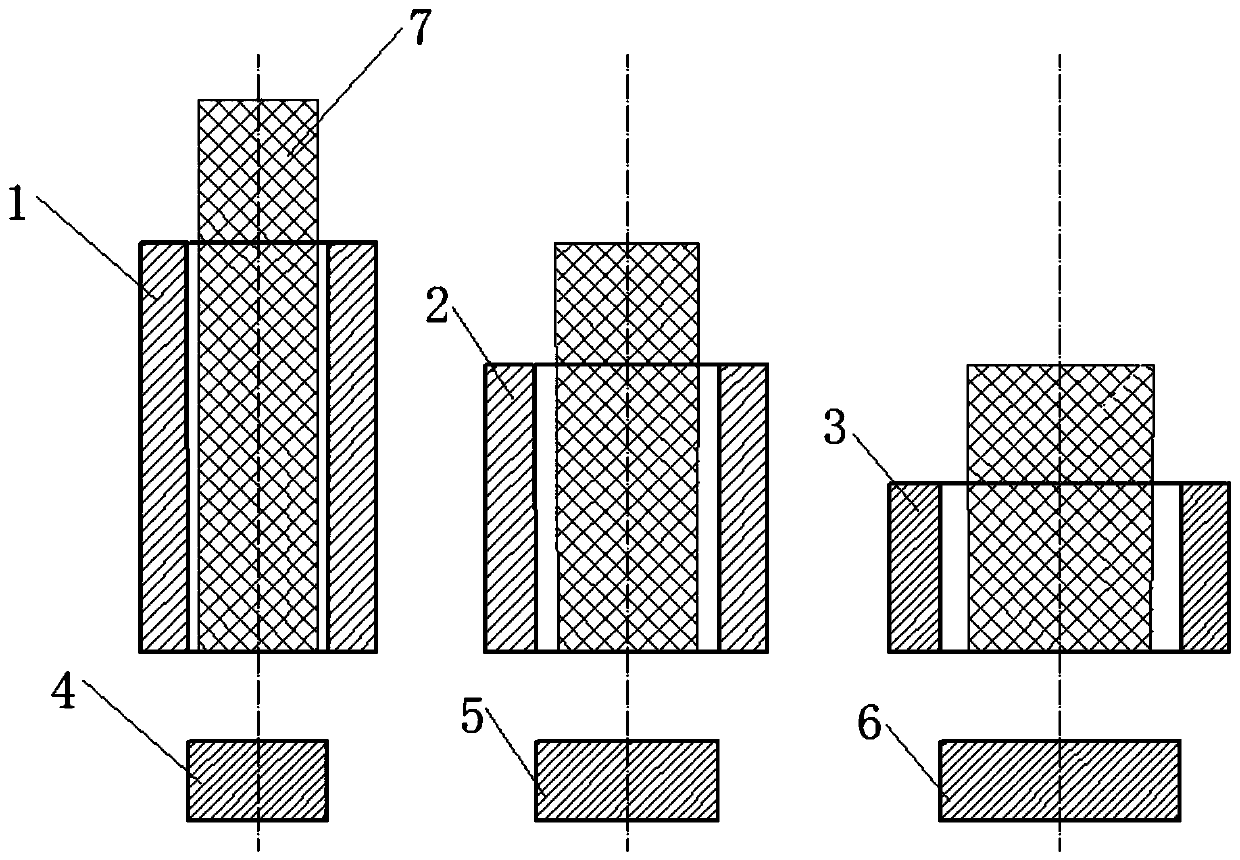

[0056] Three times of upsetting are used to open the billet, three sets of molds and three sets of punches are preheated in the range of 350-500°C respectively, and the preheating time before forging is more than 3h; the inner diameter of the large end and the small end of the first mold 1 are respectively 330mm and 320mm, height 850mm, the diameter of the first punch 4 is 310mm; the inner diameter of the large end and the small end of the second mold 2 are 390mm and 380mm respectively, the height is 550mm, the diameter of the second punch 5 is 370mm; the third mold 3 The inner diameter of the big end and the inner diameter of the small end are 520mm and 510mm respectively, the height is 300mm, and the diameter of the third punch 6 is 500mm. Use the big end of the mold to face up every time, and evenly smear graphite milk on the inner wall for lubrication; the alloy ingot 7 is soft-cove...

Embodiment 2

[0058] Φ175×750mm Directional Solidification GH4096 Alloy Ingot Opening by Upsetting and Forging

[0059] Three times of upsetting are used to open the billet, three sets of molds and three sets of punches are preheated in the range of 350-500°C respectively, and the preheating time before forging is more than 3h; the inner diameter of the large end and the small end of the first mold 1 are respectively 220mm and 210mm, height 600mm, diameter of the first punch 4 is 200mm; inner diameter of the big end and small end of the second mold 2 are 270mm and 260mm respectively, height 400mm, diameter of the second punch 5 is 250mm; third mold 3 The inner diameter of the big end and the inner diameter of the small end are respectively 320mm and 310mm, the height is 250mm, and the diameter of the third punch 6 is 300mm. Use the large end of the mold to face up every time, and evenly smear graphite milk on the inner wall for lubrication; the alloy ingot 7 is soft-covered before forging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com