Q500-steel-grade low-alloy structural steel bar and controlled-rolling and controlled-cooling rolling method thereof

A controlled rolling, controlled cooling, and low alloy technology, applied in metal rolling and other directions, can solve the problems of high production costs, achieve the effects of improving yield strength and low temperature impact performance, achieving uniformity, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

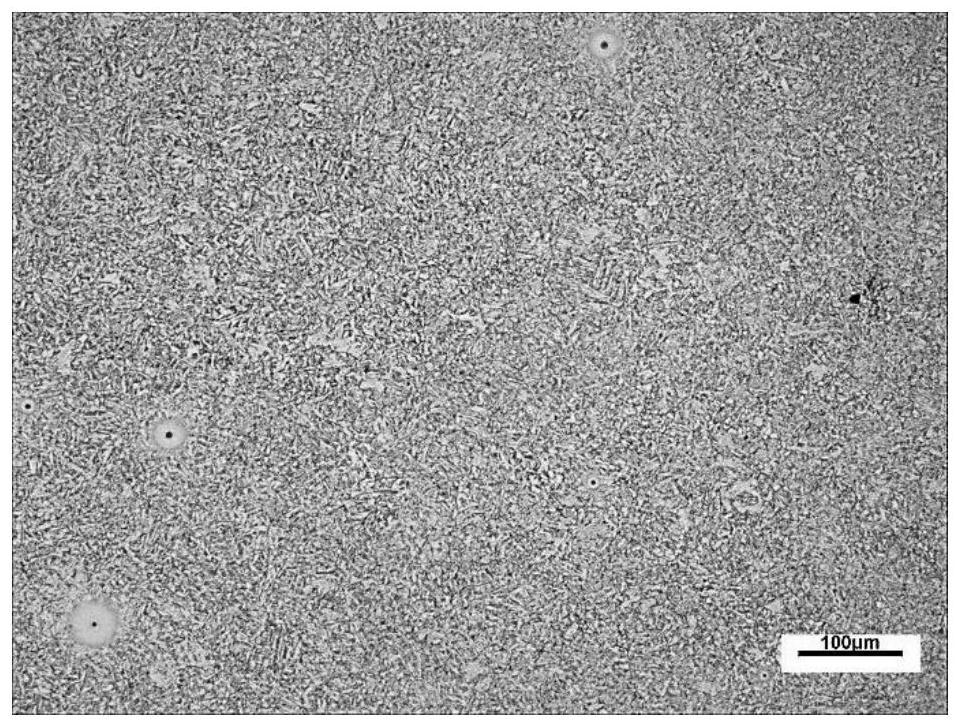

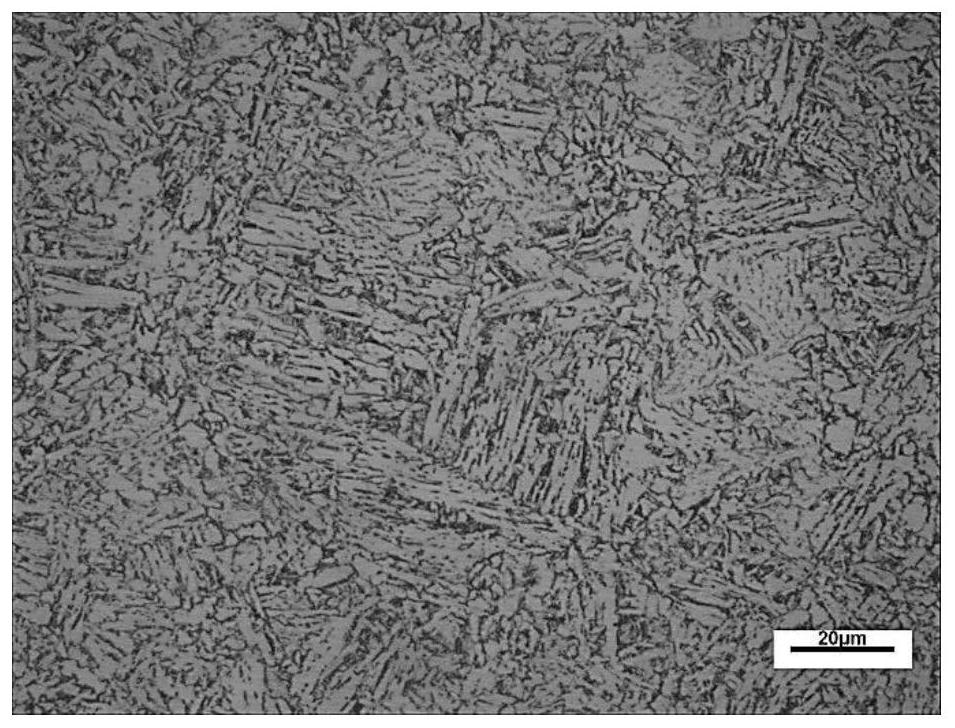

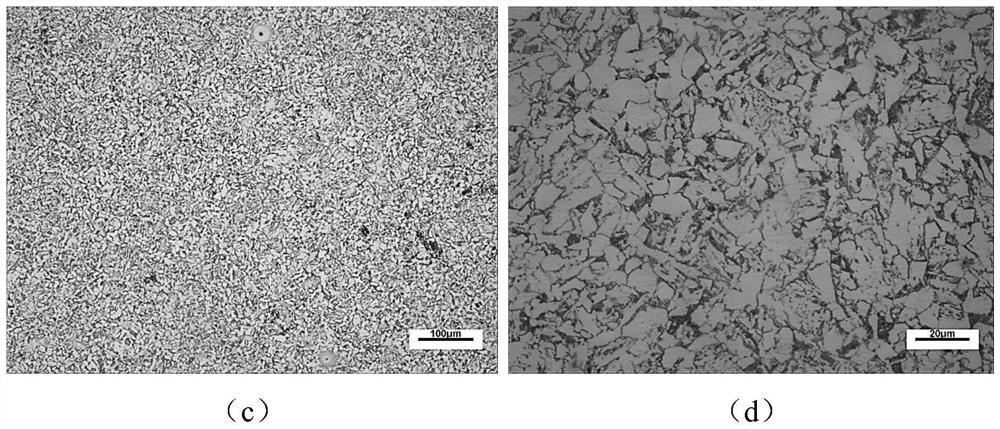

Image

Examples

Embodiment 1

[0056] This embodiment provides a controlled rolling and controlled cold rolling method for Q500 steel grade low-alloy structural steel bars, using a 390 mm steel billet round billet as a raw material to roll a finished product with a specification of 100 mm; the chemical composition of the steel billet (by mass percent, wt%) includes: C: 0.16; Si: 0.30; Mn: 1.40; P: 0.020; S: 0.008; Cr: 0.06; V: 0.06; Iron and unavoidable impurities, and CEV: 0.42.

[0057] The controlled rolling and controlled cold rolling method sequentially comprises the following steps: heating, rolling, spray cooling, KOCKS rolling, and cooling. Specific steps are as follows:

[0058] (1) Heating: Using a segmented heating process, the steel billet is placed in a heating furnace for heating. The preheating temperature is 680°C, the heating temperature of the first stage is 1030°C, the heating temperature of the second stage is 1130°C, and the soaking temperature is 1130°C.

[0059] (2) Rolling: Two-ro...

Embodiment 2

[0083] This embodiment provides a controlled rolling and controlled cold rolling method for Q500 steel grade low-alloy structural steel bars. The steel billet round billet with a specification of 390 mm is used as a raw material. The chemical composition of the billet (by mass percentage, wt%) includes : C: 0.11; Si: 0.35; Mn: 1.45; P: 0.018; S: 0.005; Cr: 0.18; V: 0.08; Al: 0.030; N: 0.0100; 0.404.

[0084]Using the same controlled rolling and controlled cold rolling method as in Example 1, the following steps are successively included: heating, rolling, spray cooling, KOCKS rolling, and cooling. The final bar specification is ∮100mm, and its properties are shown in Table 4. shown. It can be seen from Table 4 that the impact of the steel bar obtained by the present invention through controlled rolling and controlled cooling has reached more than 100J at -40°C, meeting the GB / T1591-2018 standard on Q500 steel grades (three grades of Q500MC, Q500MD and Q500ME) performance req...

Embodiment 3

[0087] This embodiment provides a controlled rolling and controlled cold rolling method for Q500 steel grade low-alloy structural steel bars, using a steel billet with a specification of 300 × 400mm as a raw material, and the chemical composition of the billet is the same as that of the billet in Example 1. The chemical composition is the same.

[0088] The controlled rolling and controlled cold rolling method comprises the following steps in sequence: heating, rolling, spray cooling, KOCKS rolling, and cooling to obtain a finished rolled material with a specification (diameter) of 50 mm. Specific steps are as follows:

[0089] (1) Heating: Using a segmented heating process, the steel billet is placed in a heating furnace for heating. The preheating temperature is 650°C, the heating temperature of the first stage is 1080°C, the heating temperature of the second stage is 1180°C, and the soaking temperature is 1180°C.

[0090] (2) Rolling: Two-roll rolling is adopted, the roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com