PECVD system with internal heater

An internal heater and heating tube technology, applied in the field of PECVD system, can solve the problems of hidden safety hazards and inconvenient operation of workers, and achieve the effects of simple and compact structure, temperature maintenance, and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

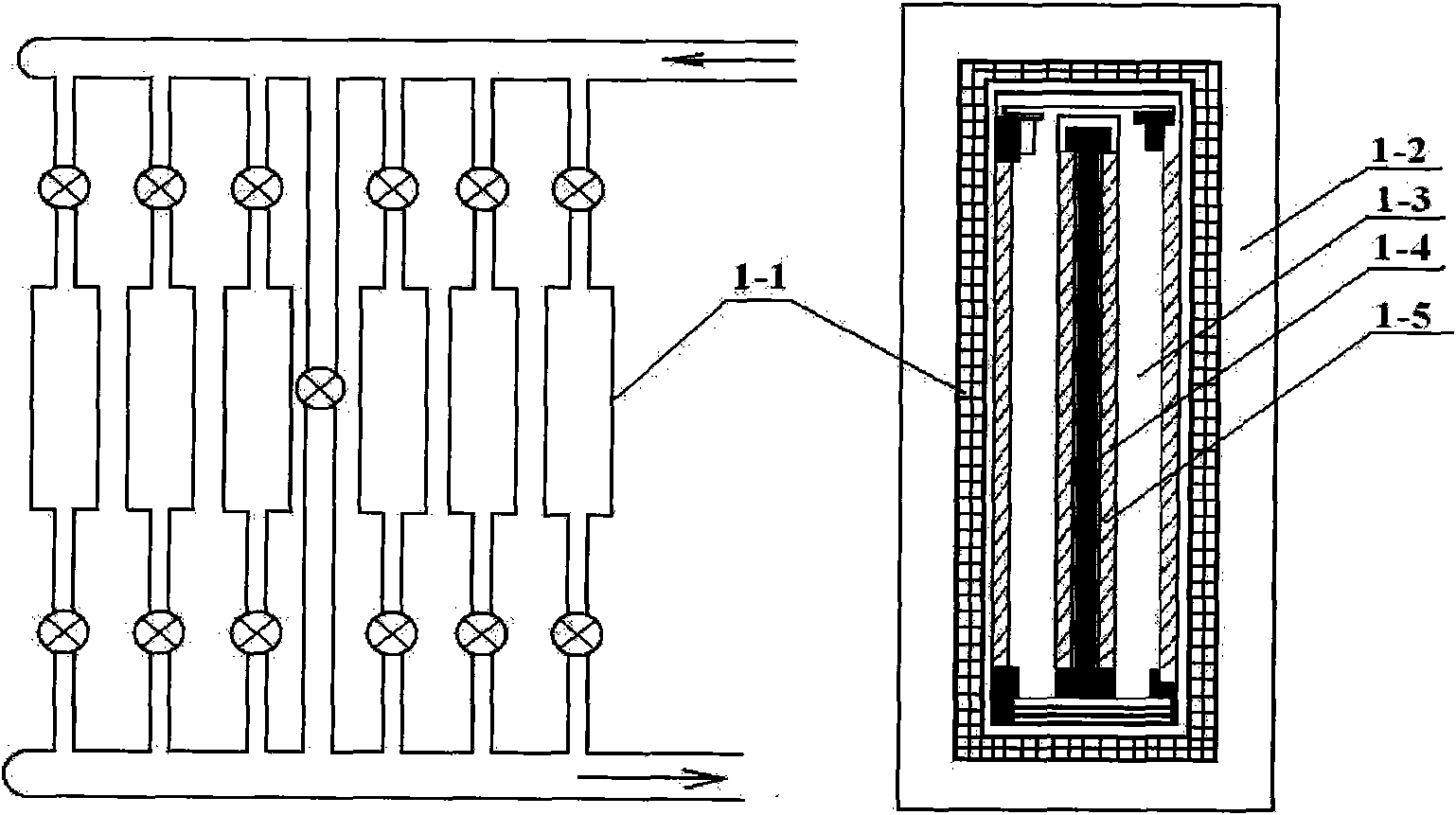

Embodiment 1

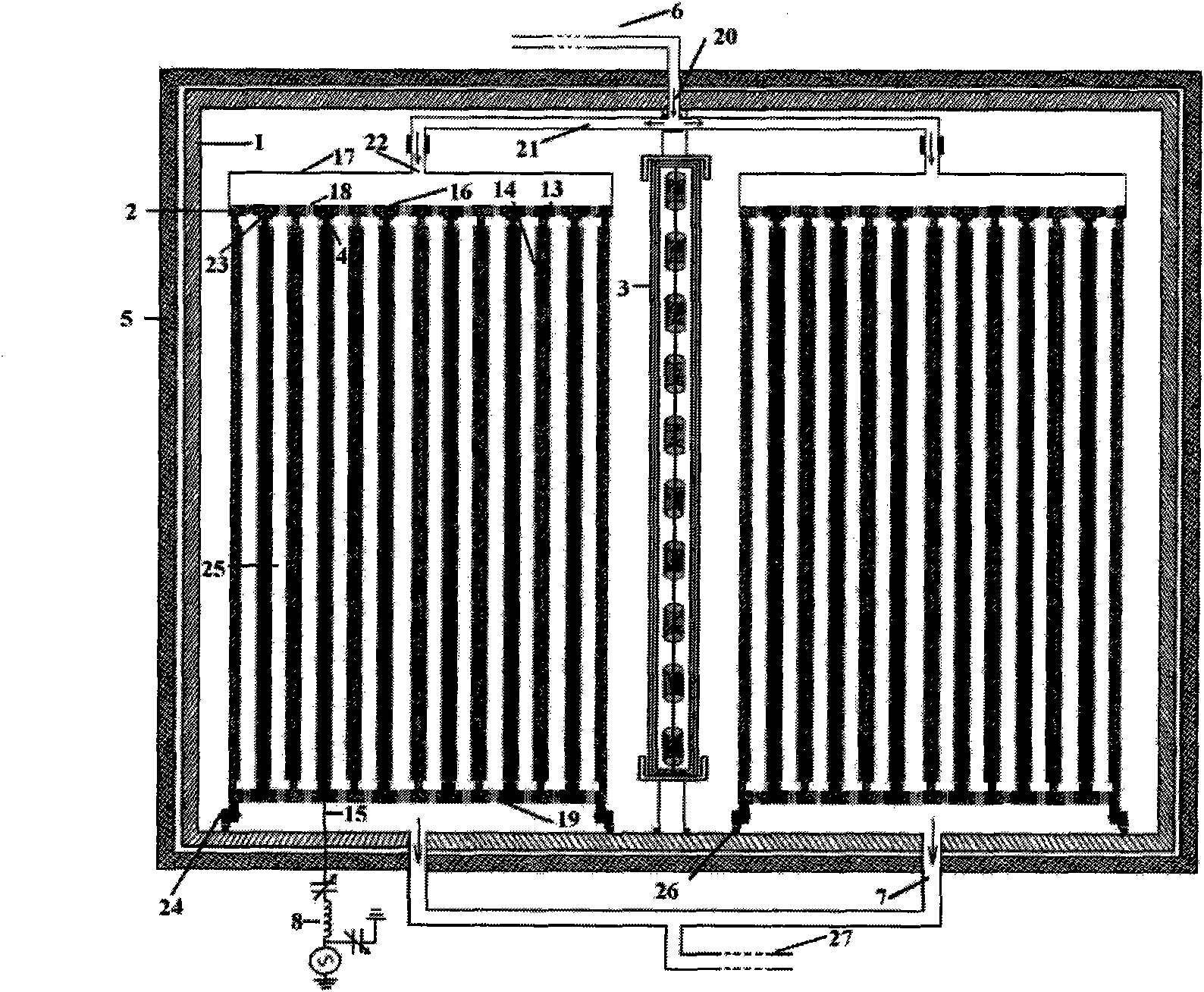

[0036] PECVD system of the present invention adopts computer control, as Figure 3a As shown, the PECVD system adopts a single vacuum chamber, and the vacuum chamber 1 is a rectangular stainless steel outer shell, and its upper end is provided with an air inlet 20, and its lower end is provided with an air outlet 7, and a heating plate 5 is attached on the outer four walls of the vacuum chamber. It is better to adopt an electric heating plate known in the prior art, and the heating plate 5 is in close contact with the outer four walls of the vacuum chamber through a mechanical fastening mechanism (such as rivets or screws), so as to obtain effective heat transfer to the wall surface of the vacuum chamber, and then The movable plasma box 2 in the vacuum chamber is evenly heated. The gas inlet 20 is used to communicate with the gas inlet system 6 so as to input the working gas into the plasma box, and the gas outlet 7 is used to communicate with the pumping system 27 so as to su...

Embodiment 2

[0047] The structure and operation process of the PECVD system described in this example are basically the same as embodiment 1, only difference is:

[0048] Such as Figure 3b As shown, the PECVD system described in this example uses a single vacuum chamber. Two movable plasma boxes are placed in parallel in the vacuum chamber. Each movable plasma box has 8 excitation electrodes and can carry 32 substrates. The whole system can Install 64 substrates, the substrate area is 381×1270mm, there is an internal heater in the middle of the two movable plasma boxes, the size of the heating device is 1500×760×20mm, and the heating power is 3000 watts.

Embodiment 3

[0050] The structure and operation process of the PECVD system described in this example are basically the same as embodiment 1, only difference is:

[0051] Such as Figure 3cAs shown, the PECVD system described in this example uses a single vacuum chamber. Three movable plasma boxes are placed in parallel in the vacuum chamber. Each movable plasma box is equipped with 6 excitation electrodes and can carry 24 substrates. The whole system can Install 72 substrates, the substrate area is 635×1245mm, there is an internal heater in the middle of any two movable plasma boxes, there are two heaters in the whole system, the size of the heater is 1500×950×20mm, each heating device The heating power is 3000 watts.

[0052] The present invention relates to a single chamber, a plurality of movable plasma boxes and a PECVD system using internal heaters, which can increase the yield of a single chamber, reduce production costs, facilitate operation, and improve the quality of manufacture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com