Secondary torsion extrusion device and method for variable cross-section cavity with fine grain

A technology of grain refinement and extrusion device, which is applied in the direction of metal extrusion dies, etc., can solve the problems of the difference in grain size between the edge and the center, adverse effects on material properties, and inability to reflect torsion, etc., to achieve grain refinement , reduce energy consumption and improve deformation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

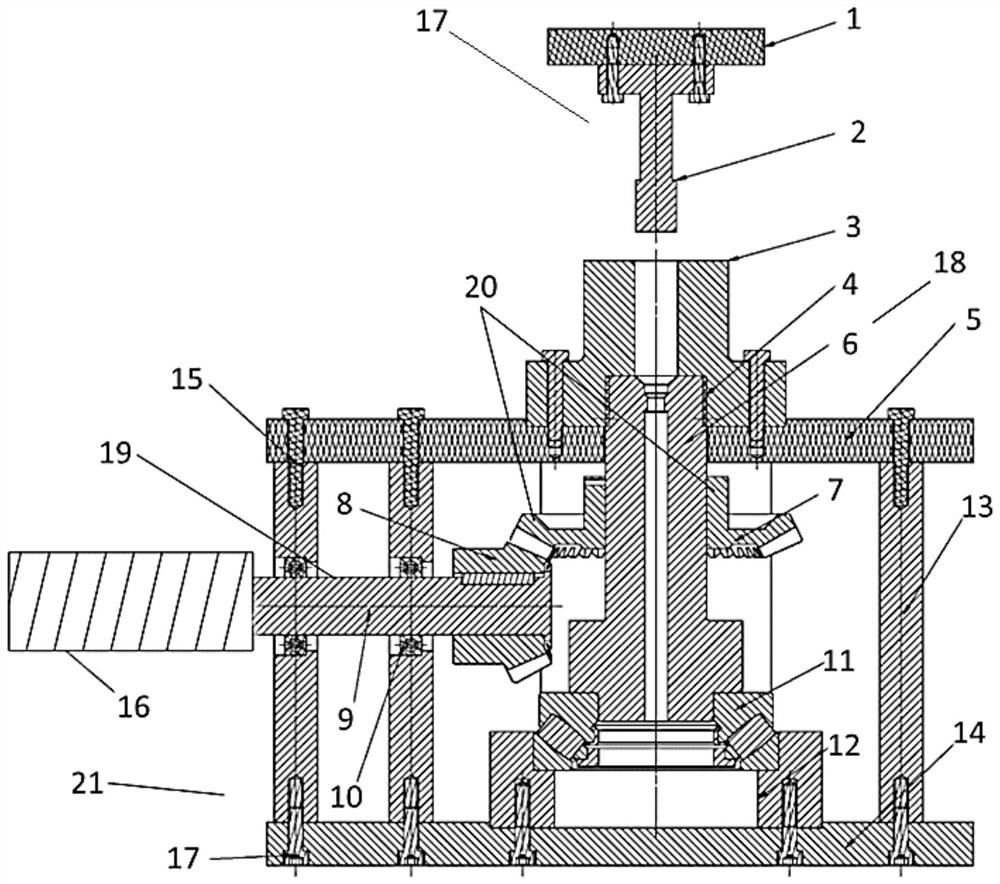

[0025] Such as figure 1 As shown, it is a secondary torsion extrusion device with a variable cross-section cavity for refining grains involved in this embodiment, which includes: a punch part 17, a transmission mechanism 19, a power mechanism 16 and a die part 18, wherein: The punch part 17 is assembled on the slide block of the hydraulic press, the transmission mechanism 19 is connected with the die part 18 , the punch part 17 is connected with the slide block of the hydraulic press, and the power mechanism 16 is connected with the transmission mechanism 19 .

[0026] The male mold part 17 includes: an upper template 1, an upper mold 2; the female mold part 18 includes an upper cylinder 3, an upper plate 5 and a main mold 6, wherein the upper template 1 is arranged on the upper mold 2 by screws 15 , the upper mold 2 is set in the upper cylinder 3 and cooperates with the upper cylinder 3, the upper cylinder 3 is set on the upper plate 5, the main mold 6 is set under the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com