Downward-pressing arc-shaped steel plate processing device

A technology of arc-shaped steel plate and processing device, applied in the field of steel plate processing, can solve the problems of complex bending device, large floor space, unreasonable space utilization, etc., and achieve the effects of reducing processing cost, simplifying structure, and improving deformation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

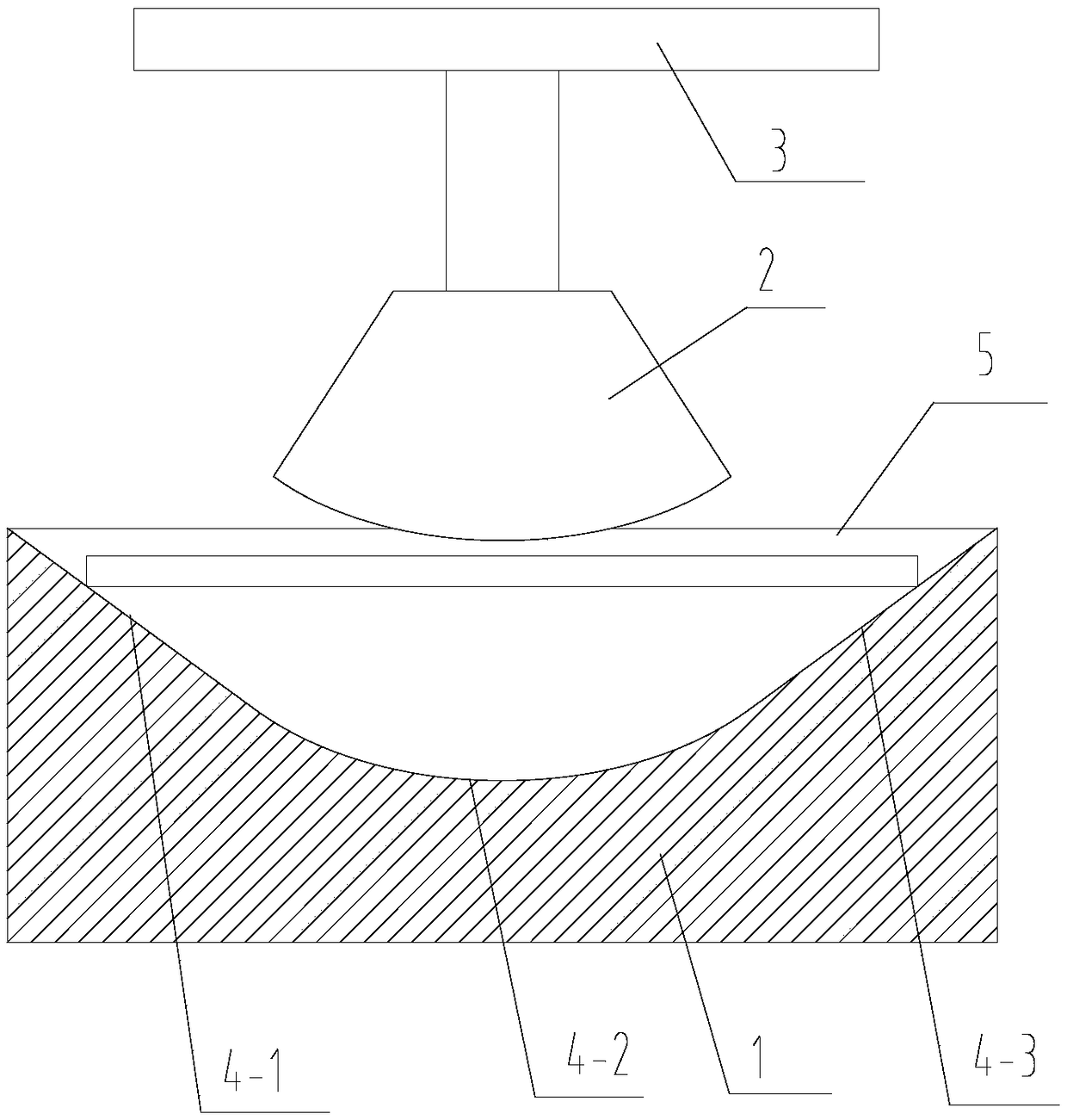

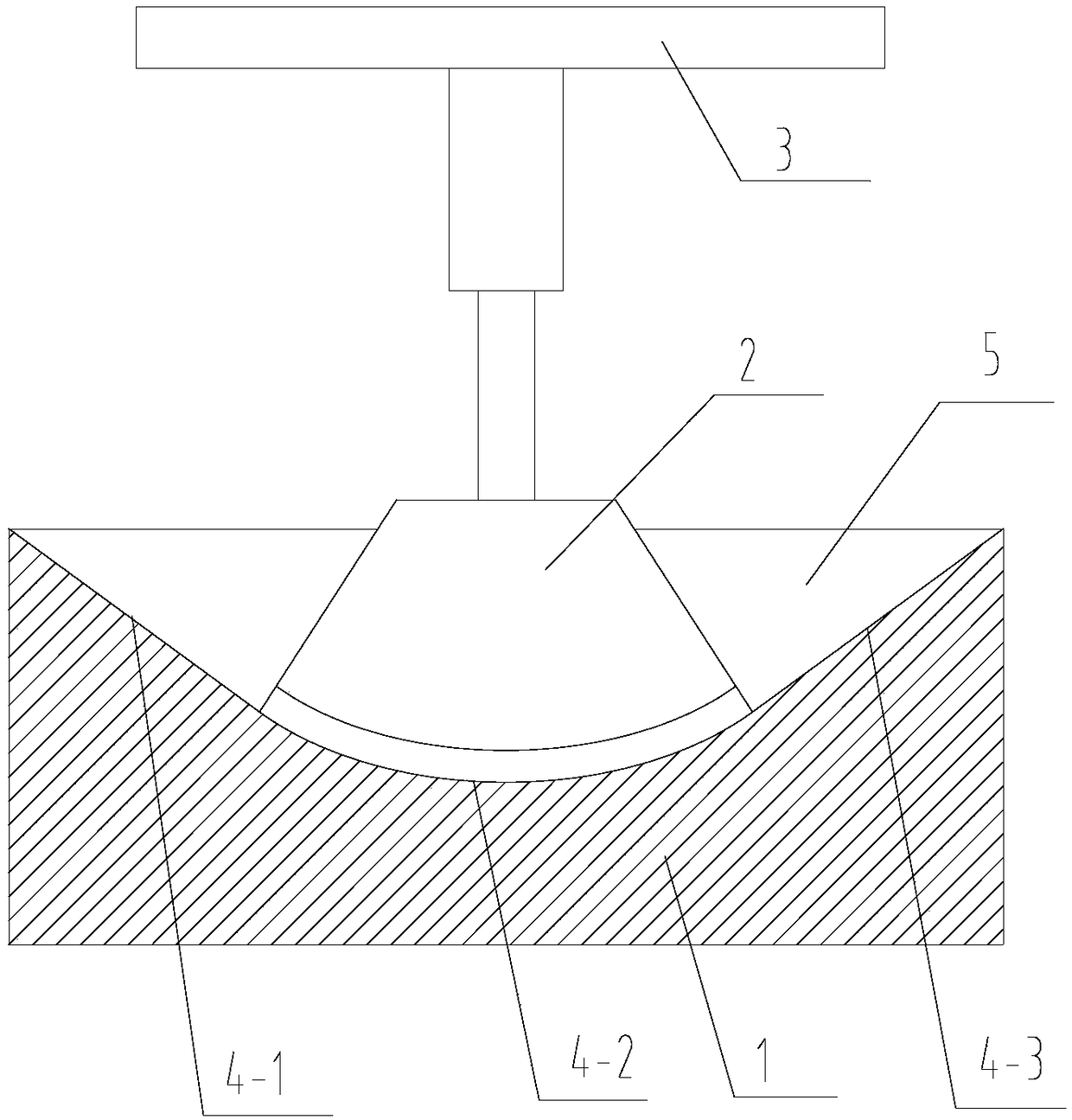

[0018] refer to figure 1 , The present invention proposes a downward-pressing arc-shaped steel plate processing device, including: a mold base 1, a stamping die 2 and a support base 3.

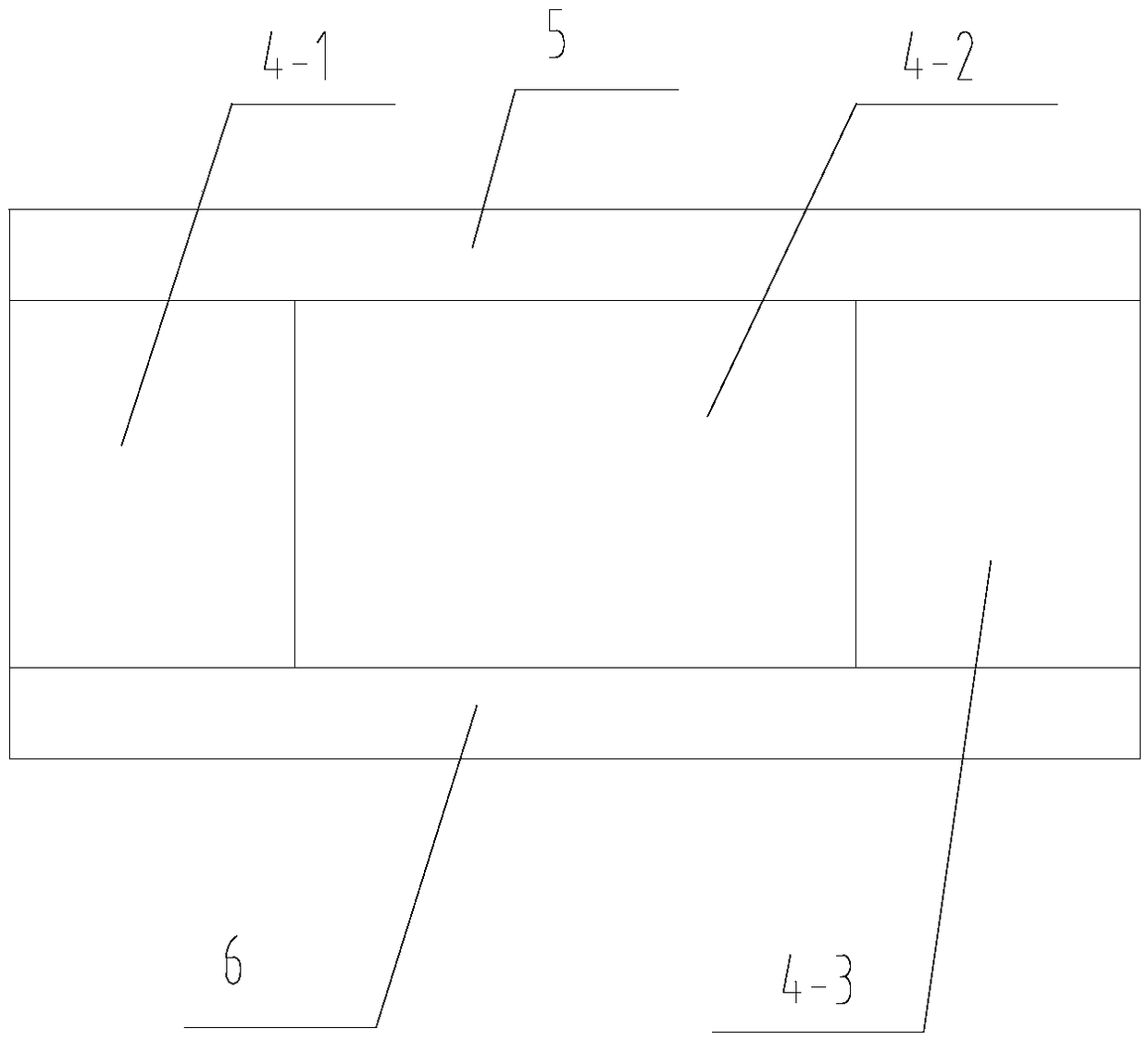

[0019] The mold base 1 is provided with a groove with an opening facing upwards, the inner surface of the groove is a smooth transition curved surface, and the inner surface of the groove is divided into a first part 4-1, a second part 4-2 and a third part 4-3 , the second part 4-2 coincides with the outer surface of the arc-shaped steel plate molding that abuts against the inner wall of the groove, and the first part 4-1 and the third part 4-3 are formed by the opposite sides of the second part 4-2 respectively Formed along a tangential extension. The length of the line connecting the opposite sides of the groove is greater than or equal to the length of the steel plate prefabricated part to be stamped. The steel plate preform is a flat steel plate. In this embodiment, during the deformati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com