Star type multi-roller adjustable precision rolling mill

A precision, rolling mill technology, applied in the field of star-shaped multi-roll adjustable precision rolling mills, can solve the problems of roll pass wear, increase roll consumption, affect product surface quality and other problems, achieve small pass wear, good rolling effect, and consistent The effect of product tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

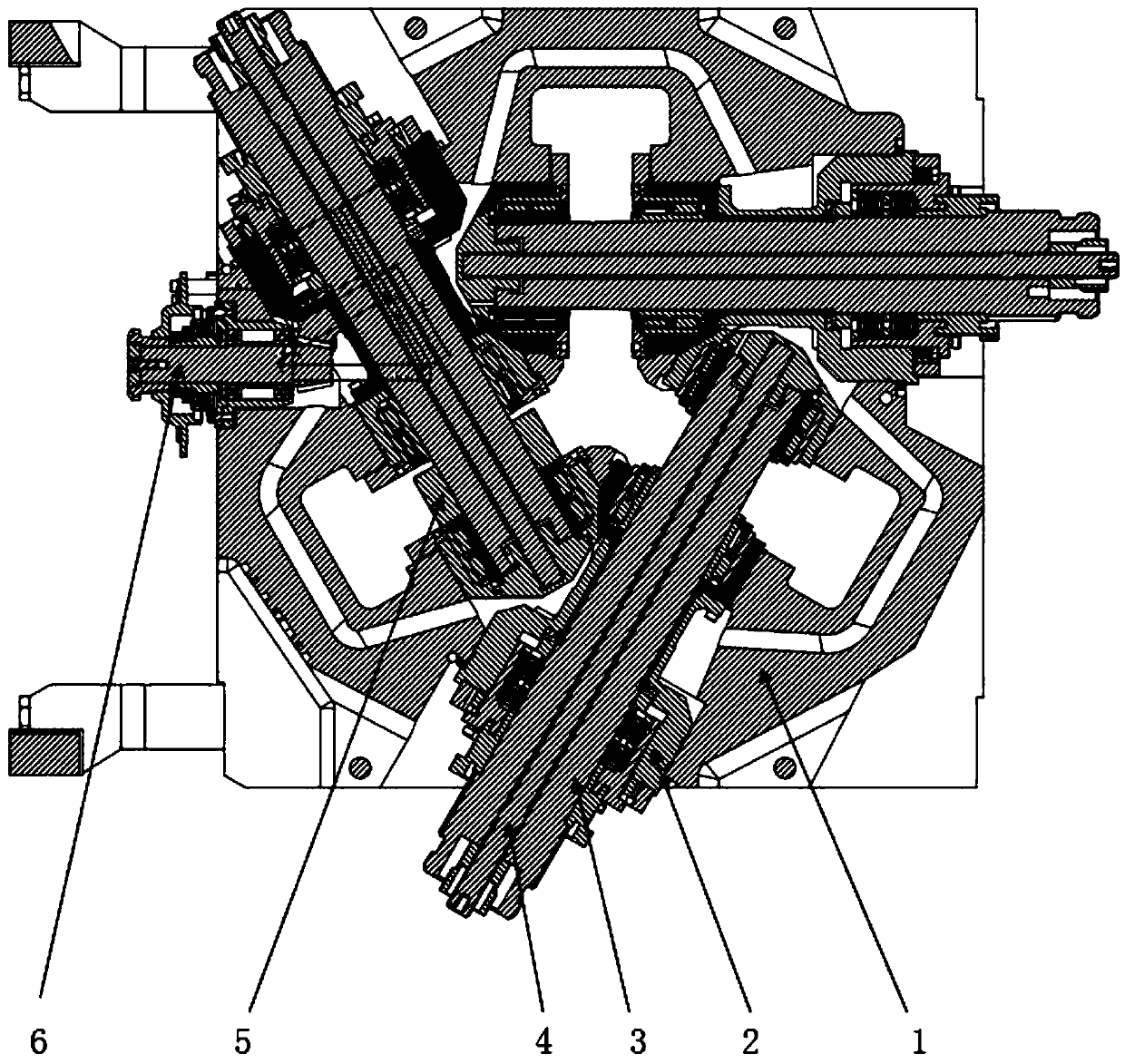

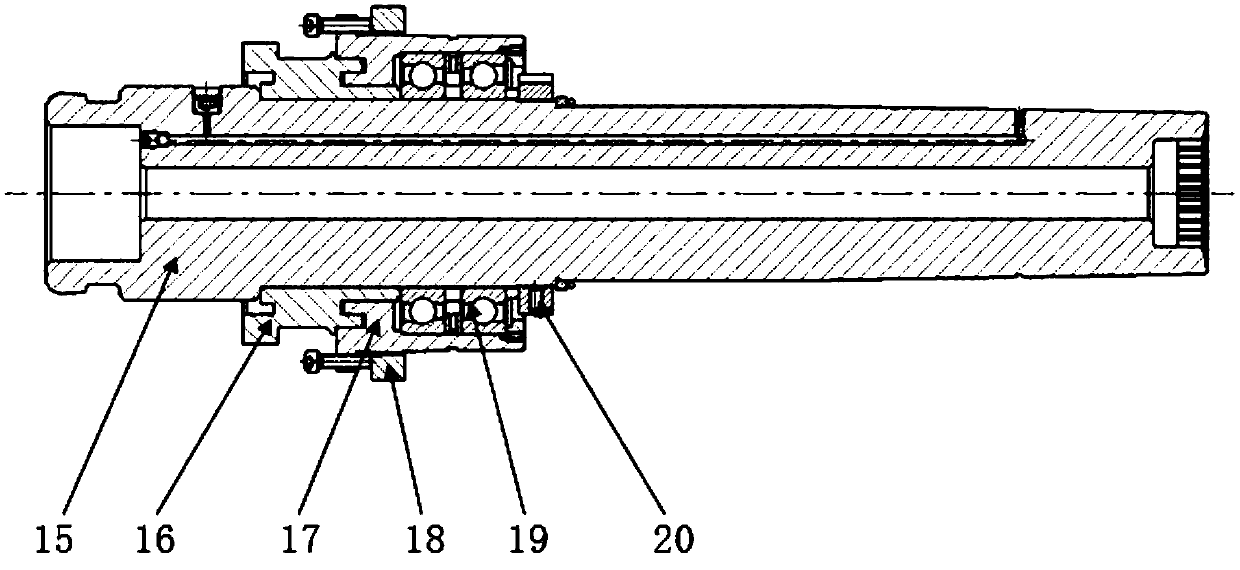

[0031] Such as Figure 1-Figure 4As shown, a star-shaped multi-roll adjustable precision rolling mill includes a main frame 1, three sets of eccentric sleeve assemblies 2 arranged in the main frame at the same angle in a star shape, and a long axis assembly 3 arranged in the eccentric sleeve assembly 2, The adjustment mechanism 6 of the bevel tooth engagement of the eccentric sleeve assembly 2;

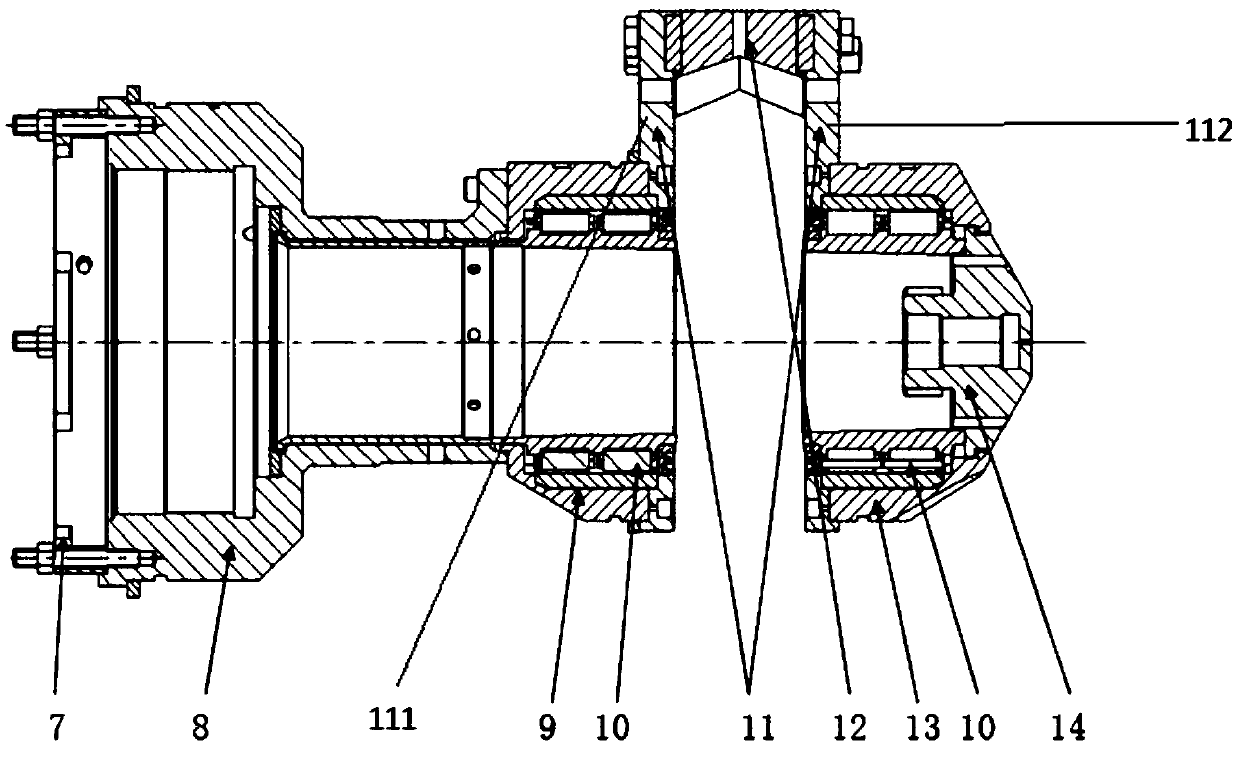

[0032] The eccentric sleeve assembly 2 includes a transition sleeve 8, a support plate 11, a bearing sleeve 9 and an inner eccentric sleeve 13. The transition sleeve 8 and the bearing sleeve 9 are positioned and connected with positioning pins and locked with screws. The bearing sleeve 9 It is connected with the first support plate 111 by positioning pins and screws, and the second support plate 112 is connected with the inner eccentric sleeve 13 by positioning pins and screws. The support block 12 is positioned between the two support plates 11, and the two support plates 11 The gap...

specific Embodiment approach

[0041] Specific implementation method: star-shaped multi-roll adjustable precision rolling mill, such as figure 1 As shown, the main frame 1 has a star-shaped cavity inside, which is used to install and disassemble the tapered sleeve 5 rolls. Three sets of eccentric sleeve assemblies 2 are installed in the holes, and the long axis assembly 3 is installed in the eccentric sleeve assembly 2, and is tightened by the pull rod 4. Each set of long axis assemblies 3 is driven by an external drive mechanism. The roll on the long axis assembly 3 rolls the bar, and the adjustment mechanism 6 is engaged with one of the eccentric sleeve assemblies 2 through the bevel gear. When the adjustment mechanism 6 is rotated and adjusted, the eccentric sleeve assembly 2 engaged with the adjustment mechanism 6 Drive the long axis assembly 3 to rotate, because the outer circle of the eccentric sleeve assembly 2 is eccentric to the axis of the inner hole, the eccentric sleeve assembly 2 rotates around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com