3D printing forming method and device for metal parts under action of magnetic field

A technology of 3D printing and metal parts, which is applied in the field of technology manufacturing, and can solve the problems of uneven composition of metal powder materials and obvious grain orientation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

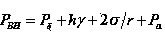

[0032] The present invention applies electromagnetic force outside the molten pool to change the force condition of the molten pool during the interaction between the high-energy beam and the metal powder. defects in the part, thereby improving the performance of the part.

[0033] The characteristics of the electromagnetic field attached to the outside of the molten pool are: the magnitude and direction of the current can be controlled, and the strength, direction and frequency of the magnetic field can be adjusted according to requirements; the current range in the test is continuously adjustable from 0-400A, and the frequency of the magnetic field can be less than A low-frequency magnetic field of 20K Hz can also be a high-frequency magnetic field with a frequency greater than 20 KHz. When we want to get as many columnar crystals as possible, we can use lower current and frequency, and if we want to get more equiaxed crystals, we can use high current and high frequency.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com