Method and equipment for successive co-orientation solidification casting and manufactured wire rod or plate and belt material

A technology of directional solidification and wire, which is applied in the field of devices, wire or strip materials, and continuous directional solidification casting methods, can solve the problems of unable to manufacture ordinary wires for large current transmission, difficult to grasp the operation process, and difficult to control the operation process. Achieve the effects of wide application, excellent mechanical properties and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

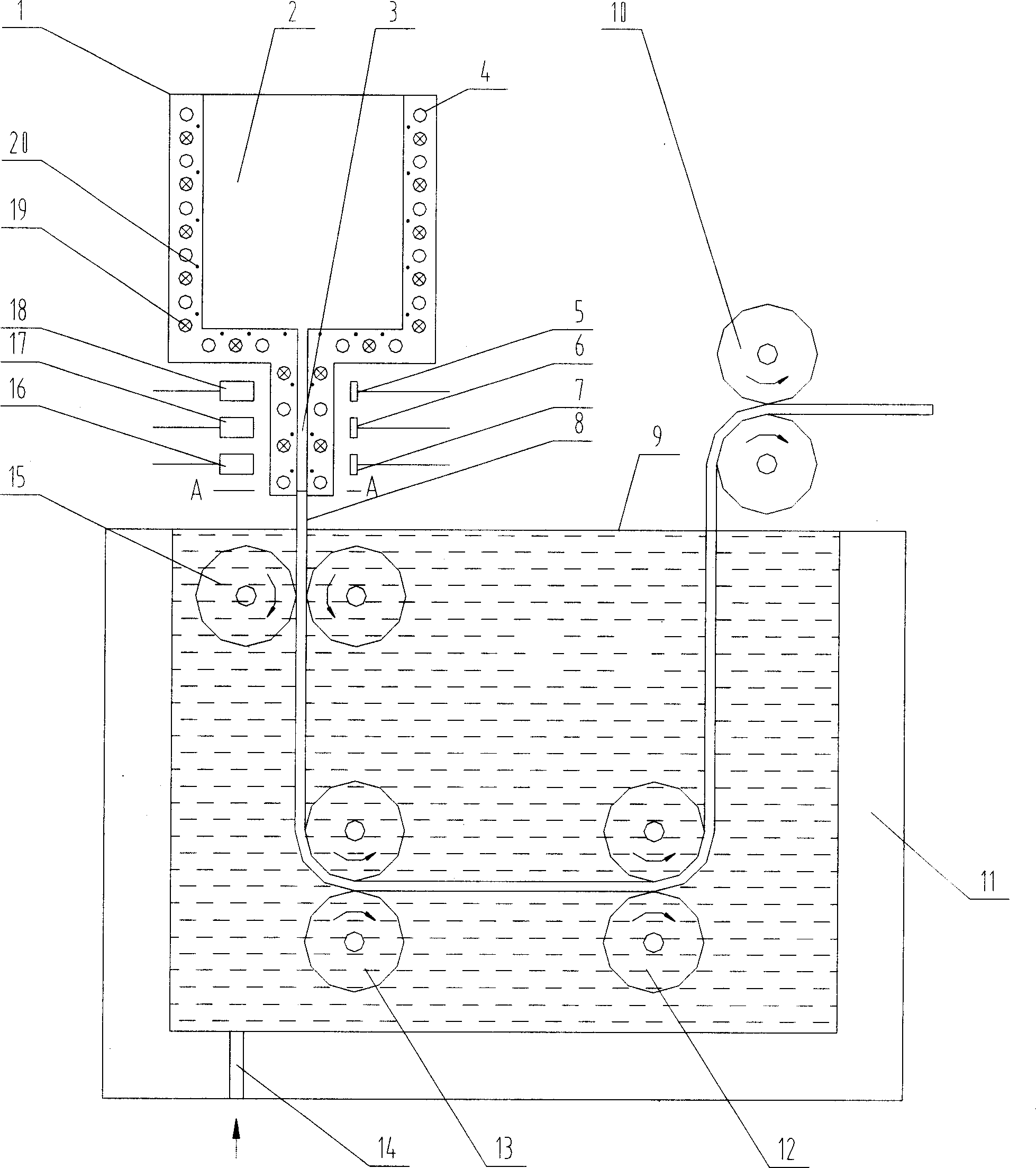

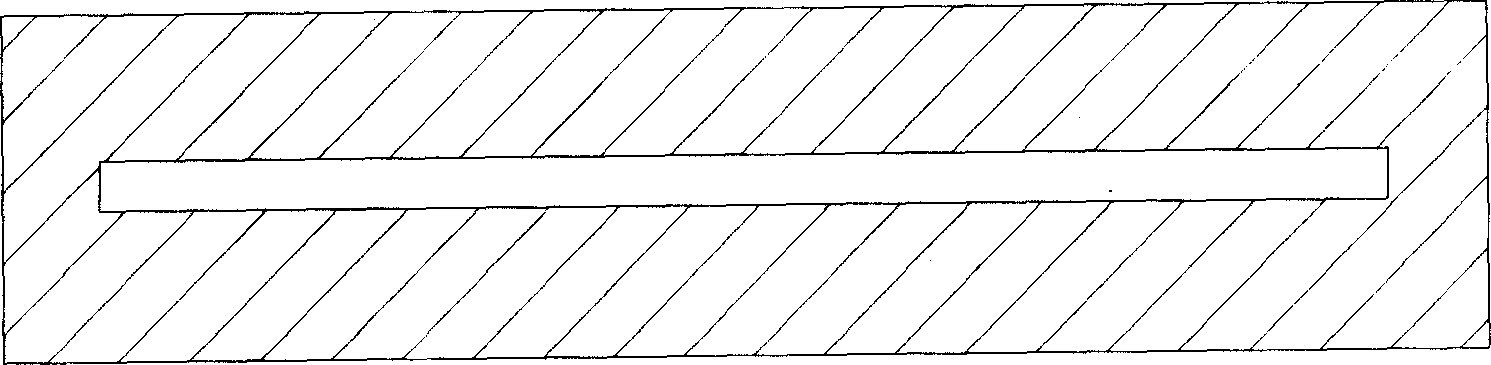

[0032] The specific structure of the continuous directional solidification casting device of the present invention is as figure 1 shown by figure 1 It can be seen that the continuous directional solidification casting device includes a crystallizer 1, a feed plate 8, a water tank 11, four sets of traction rollers 10, 12, 13, 15, X-ray generators 16, 17, 18 and X-ray sensors 5, 6 , 7, the water tank 11 is filled with water 9, the crystallizer 1 is located at the top of the water tank 11, and its bottom end has a crystallization port 3, and the wall of the crystallizer 1 is provided with a hollow cooling channel 4 and a heating wire 19 at the same time. The cooling passage 4 is connected to the cooling liquid supply member through the control valve, the heating wire 19 is connected to the power supply through the switch, and the control valve and the switch are connected to the control member; one end of the guide plate 8 can be extended into the crystallization port 3 to make t...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1 except the following features: figure 1 The cavity 2 of the middle crystallizer is provided with a sealing cover to seal the cavity 2, and then the cavity 2 is evacuated to make the aluminum-magnesium alloy liquid release its dissolved gas, and then compressed gas is injected into the cavity 2 to A compressive stress of 1.5 MPa is applied to the liquid surface of the aluminum alloy in the cavity 2 by the gas.

Embodiment 3

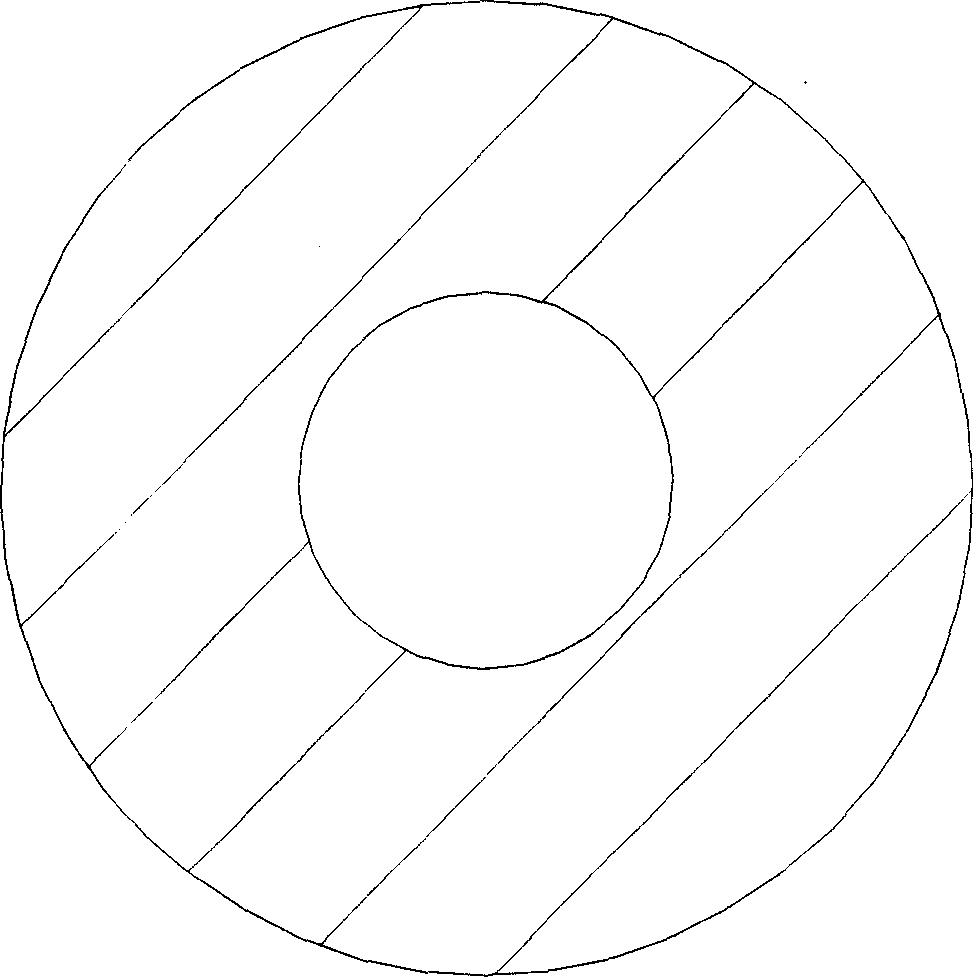

[0037] What this embodiment will prepare is the continuous directional solidification wire rod, and the continuous directional solidification casting device that it adopts is identical with the device that embodiment 1 adopts except following feature: the cross-sectional shape of crystallization port 3 is as follows image 3 As shown, it is a circular hole structure with a diameter of 3 mm, and a lead wire 8 is correspondingly arranged in the crystallization port 3; the four sets of traction rollers 10, 12, 13, 15 adopt a traction structure corresponding to the guide lead wire.

[0038] The specific operation steps of this embodiment are as follows: first, connect the lead wire 8 in the circular crystallization port 3 to form a bottom-closed cavity 2 in the crystallizer 1, and inject water 9 into the water tank 11 through the water inlet 14 on the water tank 11, After the water tank 11 is full, the water overflows from the edge of the upper mouth of the tank 11; the heating wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com