Forging production process of 30Cr15MoN high-nitrogen martensitic stainless steel bar

A technology of martensitic stainless steel and high-nitrogen martensite, applied in metal processing equipment, etc., can solve problems such as uneven structure, dependence on imports, poor thermoplasticity, etc., to reduce internal stress damage, reduce forging difficulty, and reduce structural defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

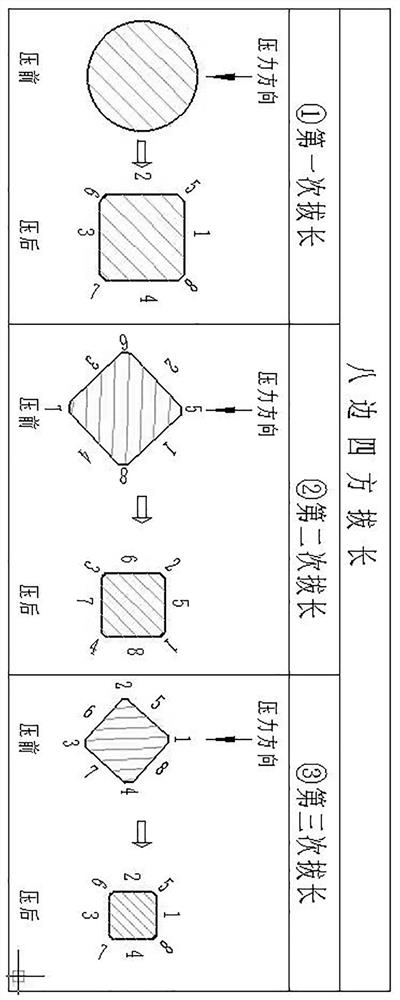

Method used

Image

Examples

Embodiment 1

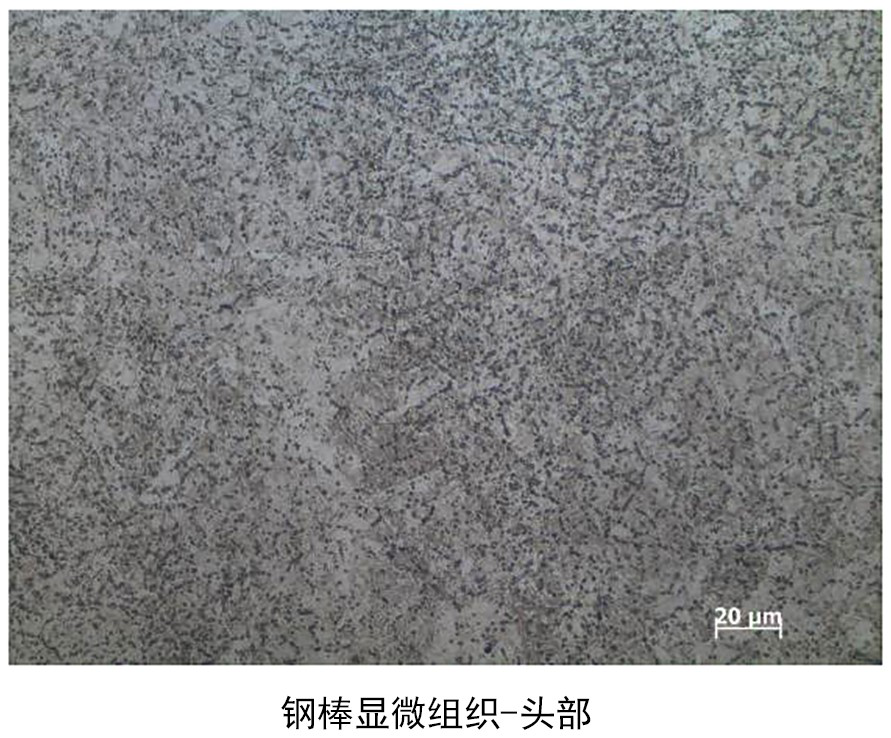

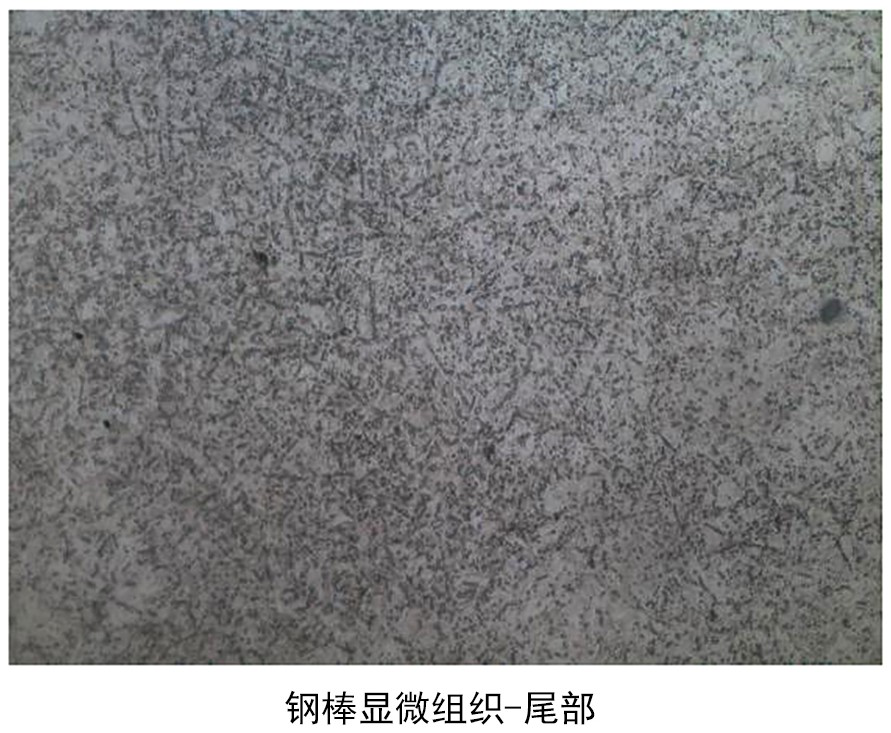

[0029] This embodiment is a preferred embodiment, which provides a forging production process for 30Cr15MoN high nitrogen martensitic stainless steel rods. The 30Cr15MoN high nitrogen martensitic stainless steel includes the following components by mass percentage: C 0.30%, Si0. 65%, Mn 0.45%, P 0.013%, S 0.002%, Cr 15.1%, Ni 0.26%, Mo 1.0%, Cu 0.06%, N 0.38%, the balance is iron and unavoidable impurities; the forging production process described Include the following steps:

[0030] S1. Electroslag remelting: Fill nitrogen until the space pressure reaches above 11Bar, and conduct electroslag remelting on 30Cr15MoN high-nitrogen martensitic stainless steel blanks in the high-pressure nitrogen atmosphere to obtain ¢440mm 30Cr15MoN high-nitrogen martensite Stainless steel round ingot;

[0031] S2. Heating: Preheat the round steel ingot to 700°C first, then keep it warm for 2 hours, heat it to 1220°C at a heating rate not exceeding 80°C / h, and then keep the steel ingot warm for...

Embodiment 2

[0036]A forging production process for 30Cr15MoN high-nitrogen martensitic stainless steel rods, the 30Cr15MoN high-nitrogen martensitic stainless steel includes the following components by mass percentage: C 0.28%, Si 0.30%, Mn 0.30%, P 0.009% , S0.002%, Cr 14.5%, Ni 0.18%, Mo 0.95%, Cu 0.06%, N 0.35%, Al 0.009%, the balance is iron and unavoidable impurities; the forging production process includes the following steps:

[0037] S1. Electroslag remelting: Fill nitrogen until the space pressure reaches above 11Bar, and conduct electroslag remelting on 30Cr15MoN high-nitrogen martensitic stainless steel blanks in the high-pressure nitrogen atmosphere to obtain ¢440mm 30Cr15MoN high-nitrogen martensite Stainless steel round ingot;

[0038] S2. Heating: Preheat the round steel ingot to 700°C first, then keep it warm for 2 hours, heat it to 1100°C at a heating rate not exceeding 80°C / h, and then keep the steel ingot warm for 3 hours;

Embodiment 3

[0043] A forging production process for 30Cr15MoN high-nitrogen martensitic stainless steel rods, the 30Cr15MoN high-nitrogen martensitic stainless steel includes the following components by mass percentage: C 0.34%, Si 0.80%, Mn 0.60%, P 0.02% , S0.01%, Cr 16%, Ni 0.25%, Mo 1.1%, Cu 0.18%, N 0.44%, Al 0.032%, Ti 0.003%, O 0.0020%, the balance is iron and unavoidable impurities; The forging production process includes the following steps:

[0044] S1. Electroslag remelting: Fill nitrogen until the space pressure reaches above 11Bar. In the high-pressure nitrogen atmosphere, the 30Cr15MoN high-nitrogen martensitic stainless steel billet is subjected to electroslag remelting treatment to obtain ¢640mm 30Cr15MoN high-nitrogen martensite Stainless steel round ingot;

[0045] S2. Heating: Preheat the round steel ingot to 700°C first, then keep it warm for 2.5 hours, heat it to 1220°C at a heating rate not exceeding 80°C / h, and then keep the steel ingot warm for 5 hours;

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com