Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Increased self-corrosion potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

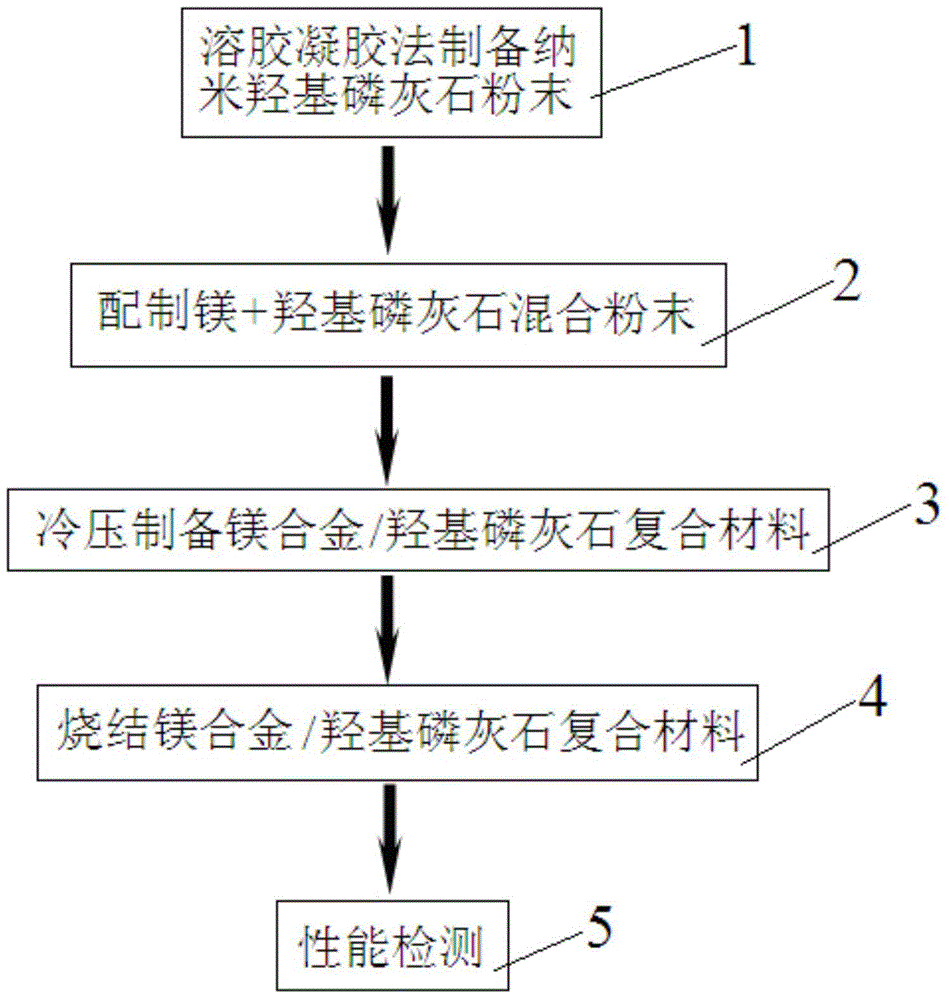

Preparation method of magnesium alloy/hydroxyapatite composite

InactiveCN103599561ADegradability adjustableDegradative regulationSurgical adhesivesProsthesisSolubilityCardiovascular stent

The invention relates to a preparation method of a magnesium alloy / hydroxyapatite composite, which comprises the steps of firstly preparing nano hydroxyapatite powder by a sol-gel process, and then uniformly mixing the magnesium powder with the nano hydroxyapatite powder; putting the mixture into a mould and performing cold pressing; putting the cold-pressing formed sample into a vacuum heat treatment furnace for sintering to obtain the magnesium alloy / hydroxyapatite composite. Compared with the prior art, in the method provided by the invention, the magnesium alloy is used as a metal matrix, the hydroxyapatite with the same chemical composition as the human skeleton and having low solubility in the human body environment is used as a reinforcing body, and the method aims at preparing a magnesium alloy / calcium phosphate composite biomedical material by use of a powder metallurgical process; the material is mainly applied to clinical medicine as a degradable endosteal fixing material, a porous bone repair material, a dental implantation material, an oral repair material, a cardiovascular stent and the like, and has broad prospects in terms of bone tissue defect repair.

Owner:TONGJI UNIV

Method for reducing diffusion temperature of magnesium alloy surface spraying coating

InactiveCN101161853AIncreased diffusion rateImprove diffusion abilityMolten spray coatingNano sizeThermal spraying

The invention provides a method for reducing the diffusion temperature of spraying coating of magnesium alloy surface. First, nanocrystallization treatment is done on the magnesium alloy surface before the hot spray coating is done on the magnesium alloy matrix surface, which ensures the thinning of the crystal grain on the magnesium surface to the size of nanometer and eliminates the roll scale of the magnesium surface and coarsening to increase the mechanical riveted bonding force of matrix and coating; and then the magnesium alloy surface is hot sprayed by aluminum or zinc or a zinc / aluminium complex coating; finally, the magnesium alloy is treated to preserve heat in an ordinary heat treatment furnace at a temperature of 200 to 400 degrees, which facilitates the coating and the matrix to form metallurgical bonding. The invention adopts the surface nanocrystallization technique, which can not only reduce the diffusion temperature of spraying coating of magnesium alloy surface, but also avoid the necessary sand blasting pretreatment technology before spray finishing. In addition, special processing step is not needed, which eliminates the roll scale of the matrix surface and coarsening surface and ensures that a layer of nanocrystal is formed on the magnesium alloy matrix surface, thereby saving the processing time before spray finishing and raising the productivity effect.

Owner:重庆工学院

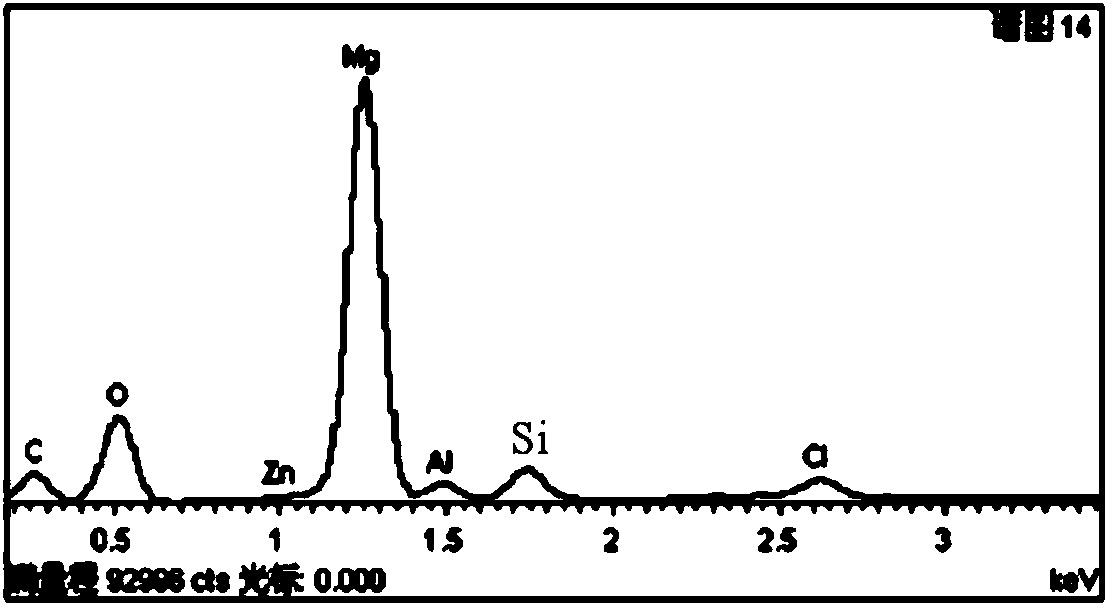

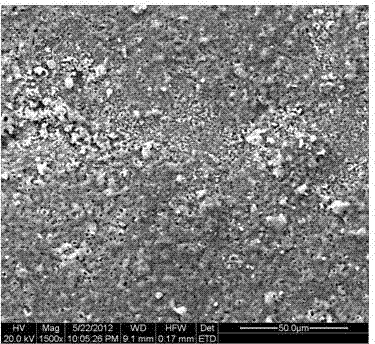

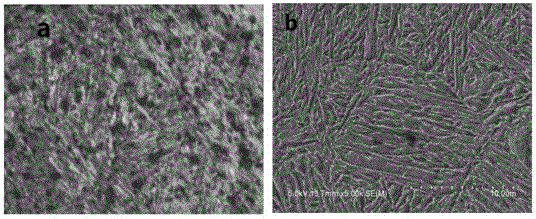

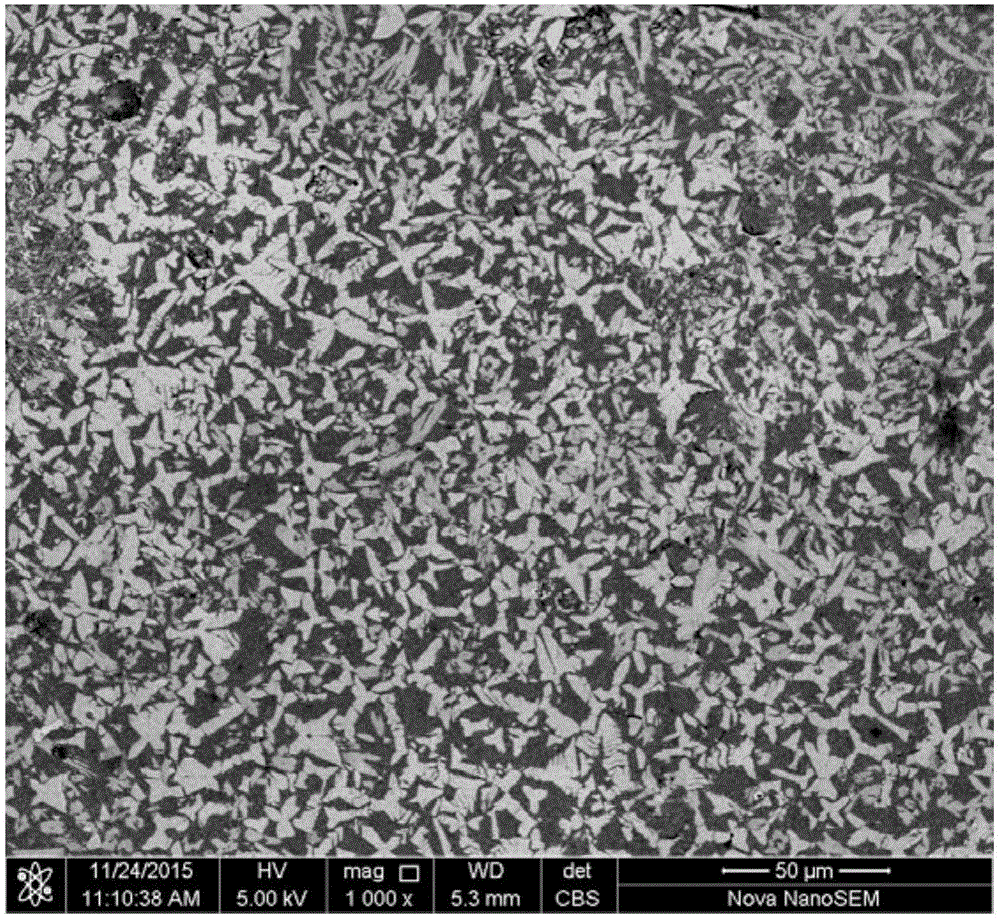

Method for preparing biodegradable magnesium alloy surface modification fluoridated hydroxyapatite coating

InactiveCN103463681AImprove corrosion resistanceConvenient researchMetallic material coating processesCalcium nitrate tetrahydrateMg alloys

The invention relates to a method for preparing a biodegradable magnesium alloy surface modification fluoridated hydroxyapatite coating. The method comprises the following steps of: pretreating a magnesium alloy substrate, wherein the adopted transfer solution is prepared from sodium dihydrogen phosphate dehydrate and calcium nitrate tetrahydrate; soaking a substrate sample obtained by pretreatment in the transfer solution for 5-100 hours, thus obtaining a calcium-phosphorus coating; soaking a calcium-phosphorus coating sample in an alkali fluoridated transfer solution for 10-48 hours, so as to obtain a fluoridated calcium-phosphorus coating, wherein the alkali fluoridated transfer solution is prepared from sodium hydroxide and sodium fluoride, the concentration of the sodium hydroxide is 3-4g / L, the concentration of the sodium fluoride is 4-5g / L, and heat treatment is not performed; performing heat treatment on the fluoridated calcium-phosphorus coating at the temperature of 300-350 DEG C for 2-5 hours, thus obtaining the fluoridated hydroxyapatite. According to performance detection, the fluoridated hydroxyapatite (FHA) coating prepared by combining a heat treatment process is shaped like a slender sheet and is divergently arranged from the center to the periphery; the electrochemical test proves that the self-corrosion potential of the substrate is improved through the FHA coating; the immersed corrosion experiment proves that an actual protective effect of the FHA coating on the magnesium alloy substrate is better than that of a fluoridated apatite (FA) coating.

Owner:TONGJI UNIV

Preparation method of anticorrosion epoxy resin embroidered coating containing coupled, dispersed and modified pigment fillings

InactiveCN107779052AGood dispersionImprove surface conditionFireproof paintsAnti-corrosive paintsEpoxySlurry

The invention discloses a preparation method of an anticorrosion epoxy resin embroidered coating containing coupled, dispersed and modified pigment fillings. The preparation method is characterized bycomprising the following steps: mixing talcum powder, iron oxide red, zinc phosphate and aluminum triphosphate, adding a dispersing agent, a titanate coupling agent and deionized water, dispersing, and grinding to obtain pigment slurry; adding a mixed solvent and KH550 into a graphene nanosheet, and carrying out uniform ultrasonic treatment, so as to obtain coupled and modified graphene nanosheetslurry; uniformly mixing KH560, ethyl orthosilicate and isopropanol, so as to obtain a component A; mixing isopropanol with deionized water, dropwise adding the mixed solution into the component A, and carrying out hydrolysis and polycondensation, so as to obtain hybridized silicon sol; dropwise adding diethanol amine and polyether amine into epoxy resin for reaction, dropwise adding glacial acetic acid for reaction, adding deionized water, stirring for emulsification so as to obtain an epoxy resin emulsion, mixing the epoxy resin emulsion with the obtained materials in foresaid steps, addinga polyurethane flatting agent, a film forming aid and a defoaming agent, uniformly mixing, and mechanically dispersing, so as to obtain the coating.

Owner:马鞍山天宇船舶制造有限公司

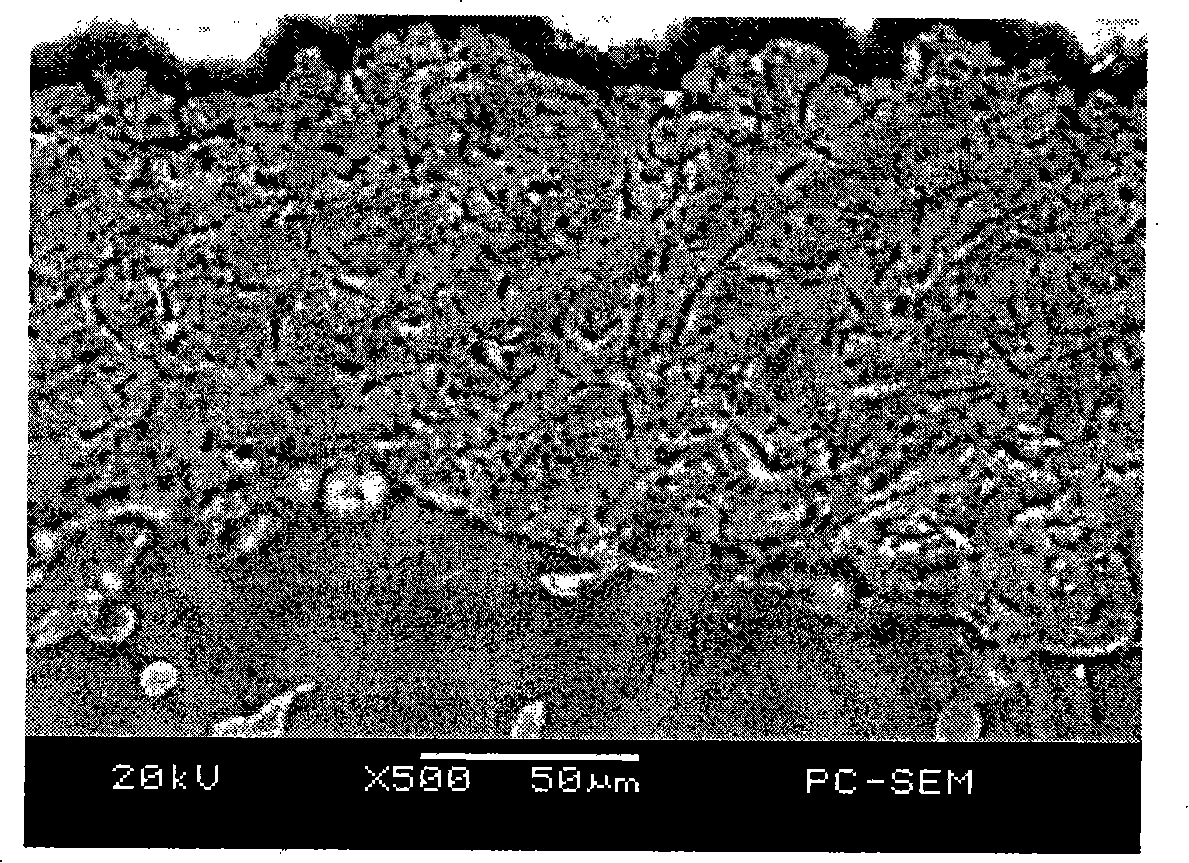

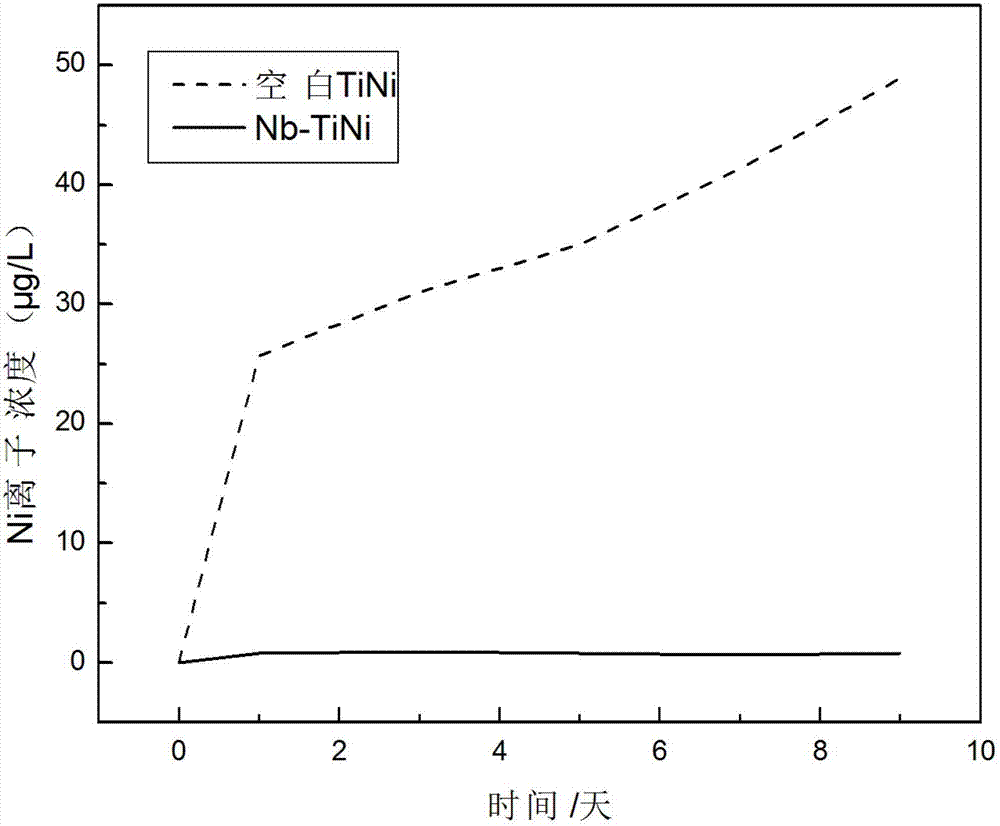

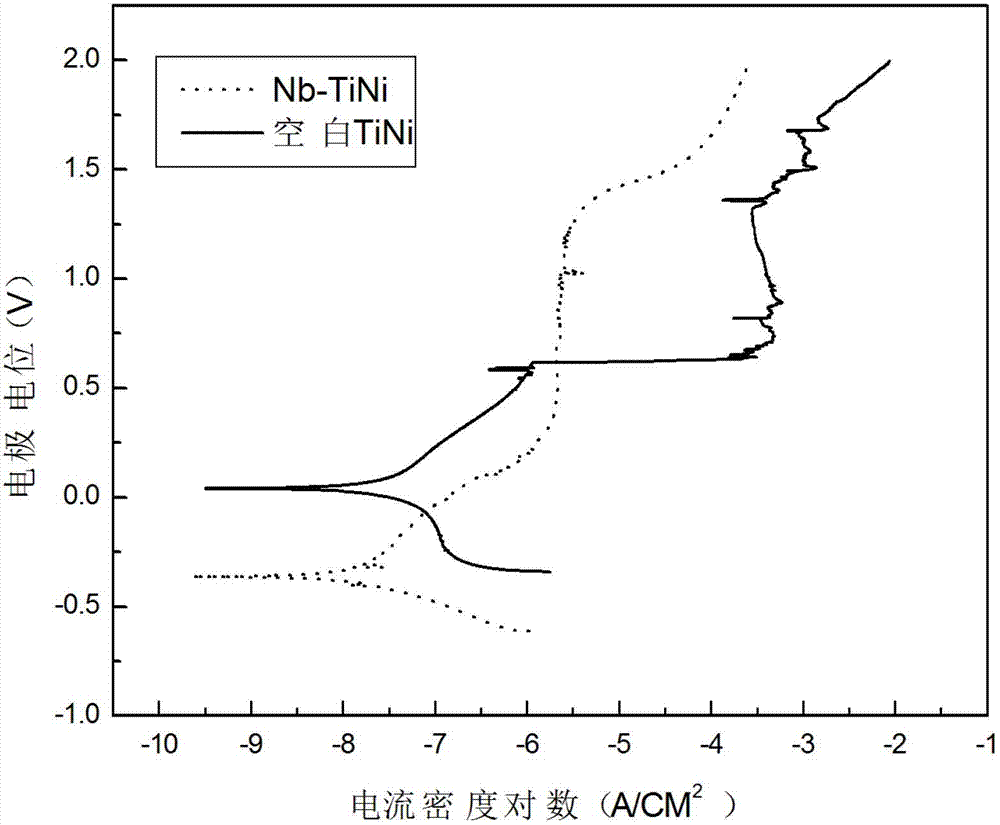

Method for conducting surface modification on medical titanium nickel (TiNi) shape memory alloys through niobium (Nb) ion injection deposition

ActiveCN102828157AGood biocompatibilityLow toxicityVacuum evaporation coatingSputtering coatingNiobiumBiocompatibility Testing

The invention discloses a method for conducting surface modification on medical titanium nickel (TiNi) shape memory alloys through niobium (Nb) ion injection deposition. The method compounds two methods of ion injection and ion beam strengthening deposition, wherein a transition layer formed by an ion injection method is mainly composed of TiO2 and Nb2O5, and an ion beam strengthening deposition method is that a pure Nb metal film layer is formed on the basis of the transition layer. After the surface modification is carried out on the alloys through the method of selecting appropriate parameters, the obtained shape memory alloys can completely prevent Ni ions from dissolving out from a matrix, and simultaneously the method has good shape memory effects which are not second to the matrix and stain resistance and biocompatibility superior to the matrix.

Owner:BEIHANG UNIV

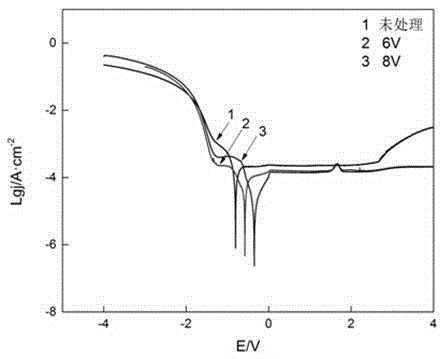

Titanium and titanium alloy surface anodic oxidation coloring method

InactiveCN105239133ASimplify the anodizing processIncreased self-corrosion potentialSurface reaction electrolytic coatingElectrolysisTitanium

The invention discloses a titanium and titanium alloy surface anodic oxidation coloring method and belongs to the technical field of metal surface treatment. The method includes the following steps that a cleaned commercial pure titanium sample is put in a solution with a proportion of HF: HNO3: H2O for electrolytic polishing; the cleaned and dried sample is put in a mixed solution of concentrated sulfuric acid and methanesulfonic acid for anodic oxidation treatment; and the sample obtained after being subjected to the anodic oxidation treatment is rapidly cleaned through ethyl alcohol and deionized water and then dried under the vacuum condition so that the colored sample can be obtained. Anodic oxide films in different colors are obtained through control over anodic oxidation voltage and treatment time, and the anodic oxide films are bright and uniform in color and luster and good in corrosion resistance.

Owner:KUNMING UNIV OF SCI & TECH

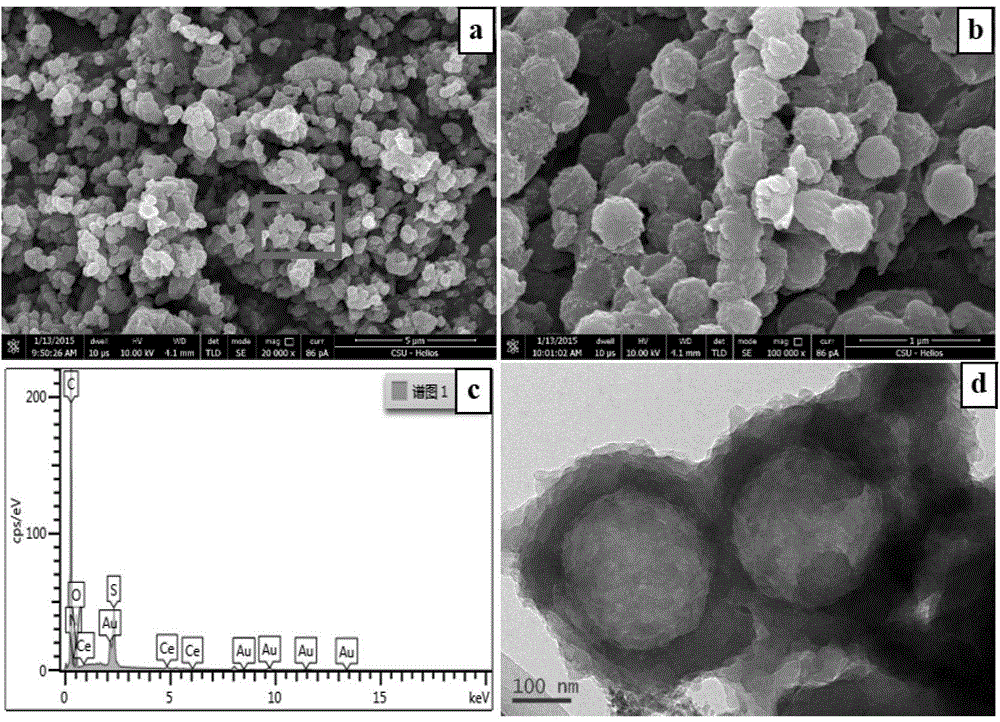

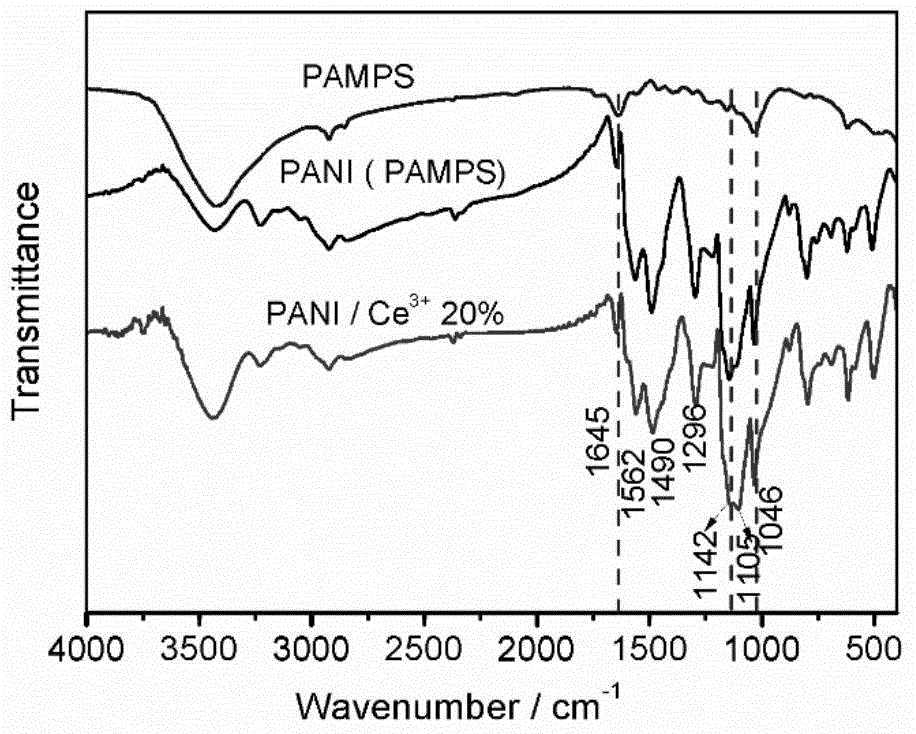

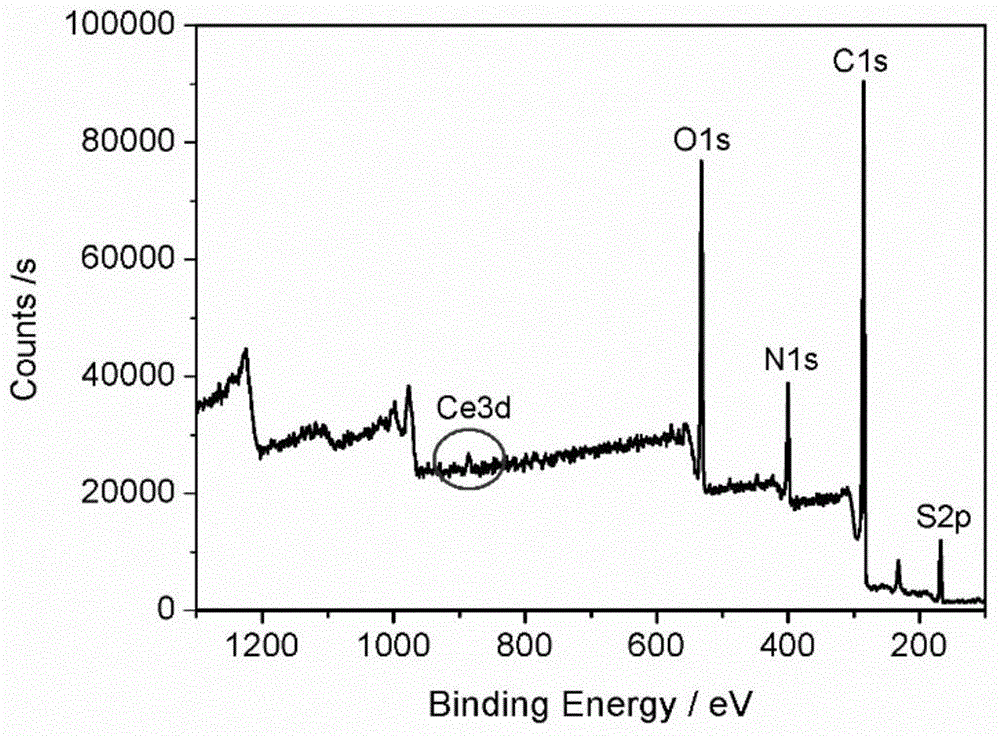

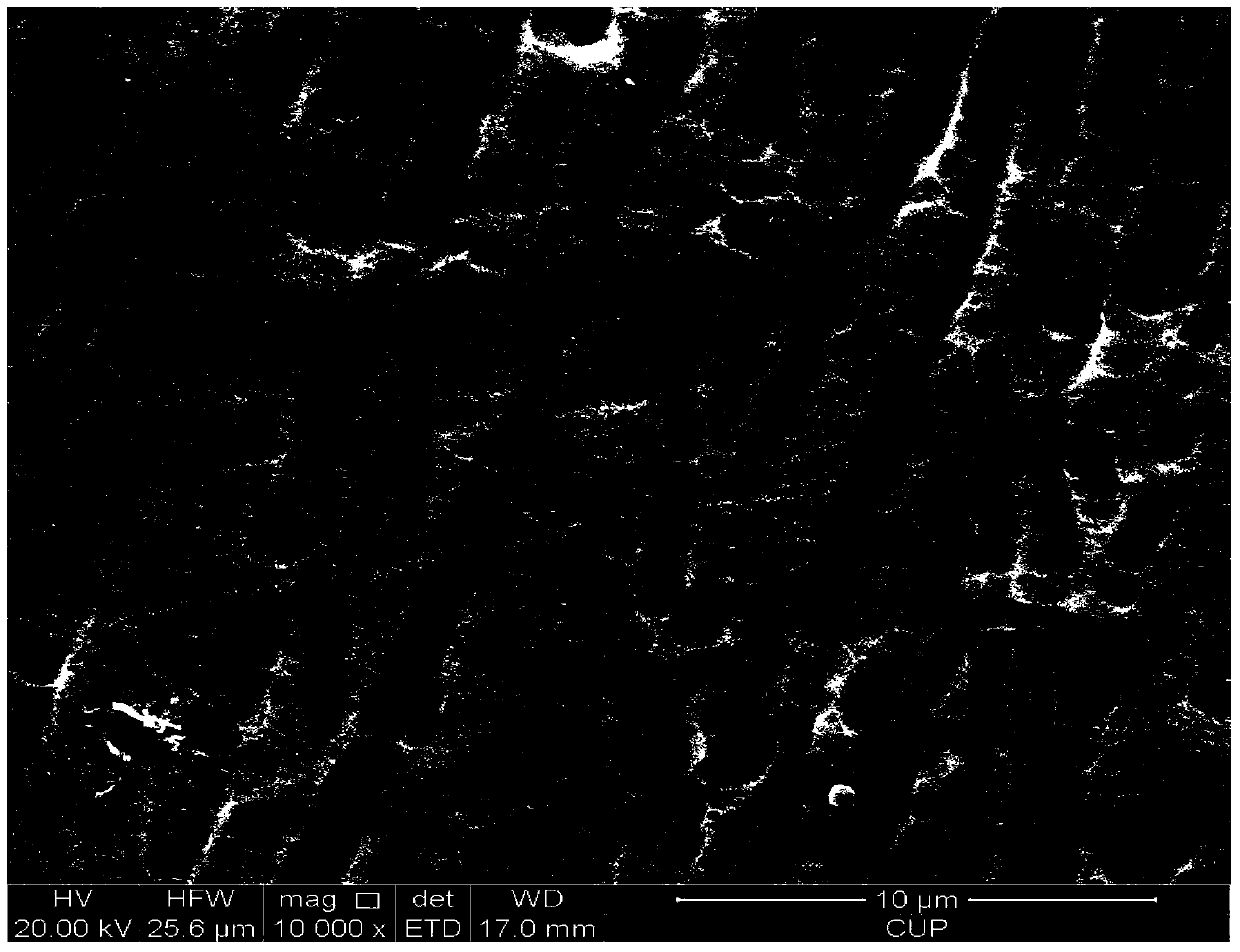

Preparation method of polyaniline hollow microspheres with rare earth cerium ions loaded on surfaces

InactiveCN104629071AImprove anti-corrosion performanceRegular structureAnti-corrosive paintsPolyamide coatingsNitrateMicrosphere

The invention discloses a preparation method of polyaniline hollow microspheres with rare earth cerium ions loaded on the surfaces. The method is prepared by rapidly adding an ammonium persulfate solution in a mixed solution consisting of poly (2-acrylamide-2-methylpro panesulfonic acid), aniline, ethanol and water to react, so that after the reaction is completed, polyaniline hollow microspheres are obtained; and putting the obtained polyaniline hollow microspheres in a cerous nitrate (III) solution, and carrying out stirring and doping, so that polyaniline hollow microspheres with rare earth cerium ions loaded on the surfaces are obtained. The prepared polyaniline hollow microspheres with rare earth cerium ions loaded on the surfaces are neat in structure, regular in morphology, large in specific surface area, and high in electric conductivity, and the preparation method is simple, efficient, and easy to control, therefore, the method is suitable for industrialized production.

Owner:CENT SOUTH UNIV

Method for carrying out surface modification upon biodegradable magnesium and magnesium alloy through iron ion implantation deposition

ActiveCN103498129AHigh bonding strengthImprove corrosion resistanceVacuum evaporation coatingSputtering coatingBiocompatibility TestingIon beam

The invention discloses a method for carrying our surface modification upon biodegradable magnesium and magnesium alloy through iron ion implantation deposition. The method belongs to the technical field of surface treatment. According to the invention, through ion implantation, a composite transition layer doped with iron ions is formed on the surface of magnesium and magnesium alloy. The transition layer is composed of Fe2O3 and MgO, and has a thickness of 20-50nm. An iron film with a thickness of 100-500nm is prepared on the transition layer with an ion-beam-assisted enhanced deposition technology. The transition layer preparation method provided by the invention assists in ensuring good bonding strength between the deposited iron film and the substrate. With the method provided by the invention, corrosion resistance, biocompatibility, and mechanical properties of magnesium and magnesium alloy are improved.

Owner:DONGGUAN MEIANMEIYE TECH CO LTD

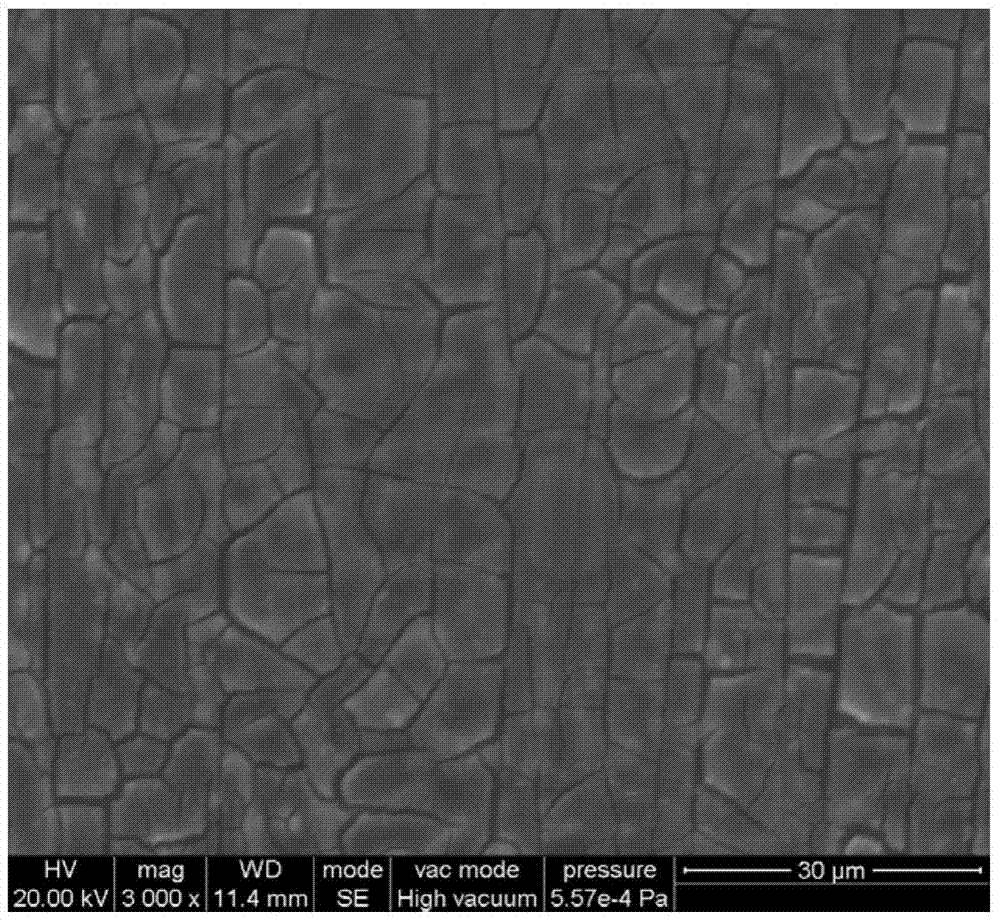

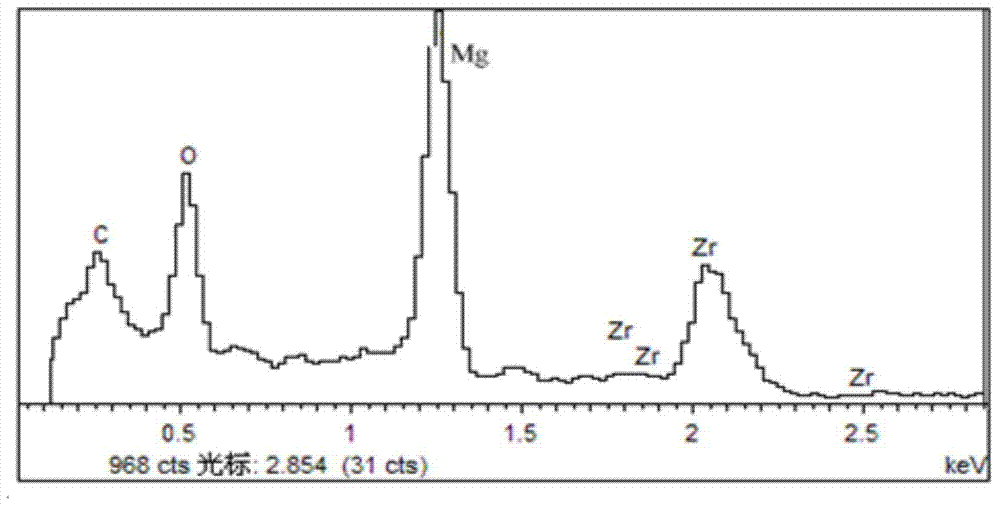

Treatment liquid and treatment method for preparing zirconium-based colored conversion film on magnesium alloy surface

The invention discloses treatment liquid for preparing a zirconium-based colored conversion film on a magnesium alloy surface, wherein each liter of treatment liquid contains 0.2-2.5 g of zirconium-containing main film forming agent, 0.2-1.5 g of zirconium-containing film forming oxidant, 0.5-1.5 g of film forming aid, 0.5-3.0 g of complexation colorant, 0.5-2.0 g of solution pH buffer agent and 0.01-0.05 g of solution pH regulator; the zirconium-containing main film forming agent is composed of fluorozirconic acid and fluorozirconate, which are mixed in any proportion; the zirconium-containing film forming oxidant is zirconium oxychloride; the film forming aid is any one of fluorotitanic acid, potassium fluotitanate, ammonium fluorotitanate or sodium fluorotitanate; the complexation colorant is tannic acid or citric acid. The invention further discloses a treatment method for preparing zirconium-based colored conversion film on the magnesium alloy surface by utilizing the treatment liquid. The conversion film generated by using the treatment liquid and the treatment method disclosed by the invention is good in corrosion resistance, colored, high in film forming speed and environmental-friendly.

Owner:东莞市镁皓镁合金科技有限公司

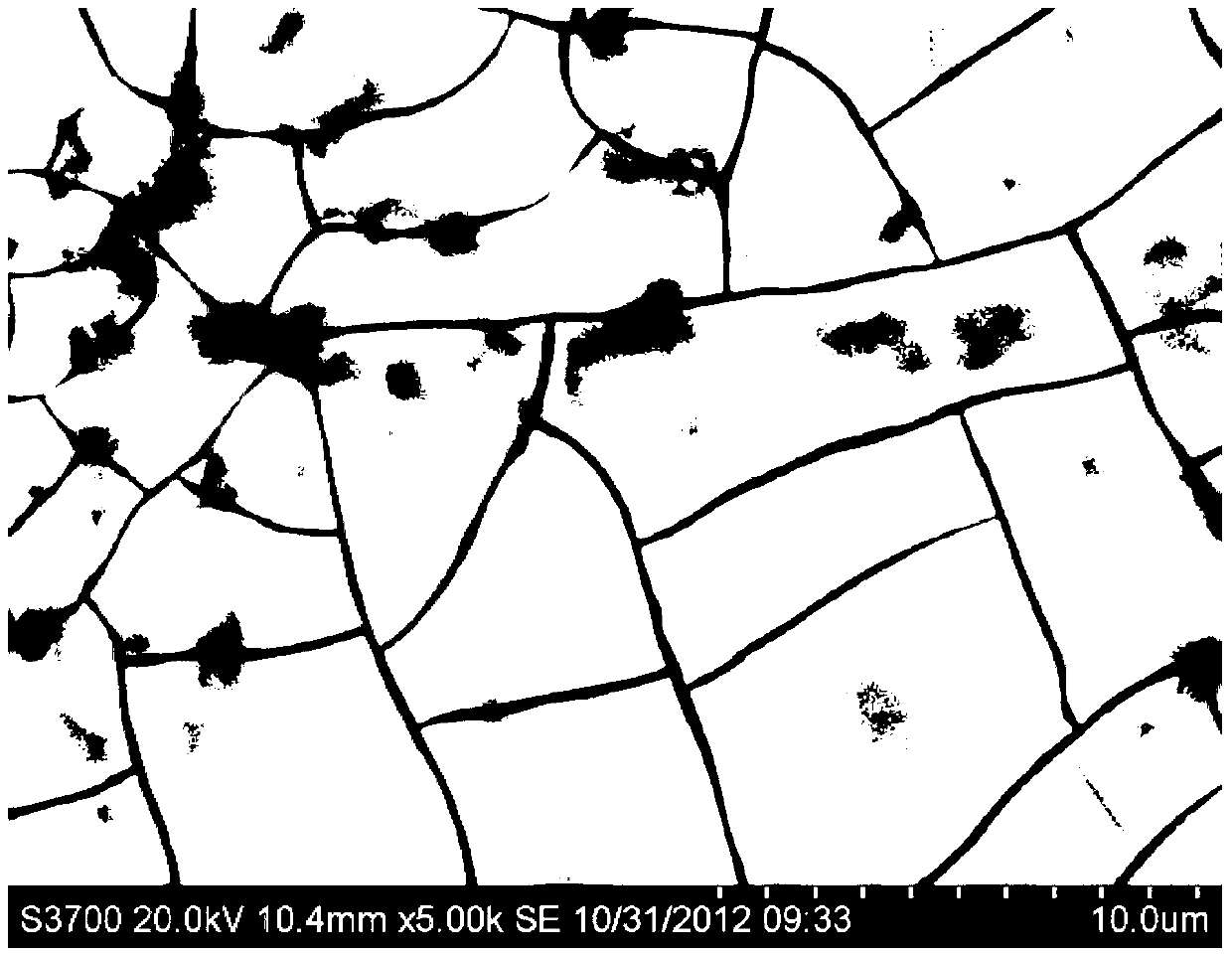

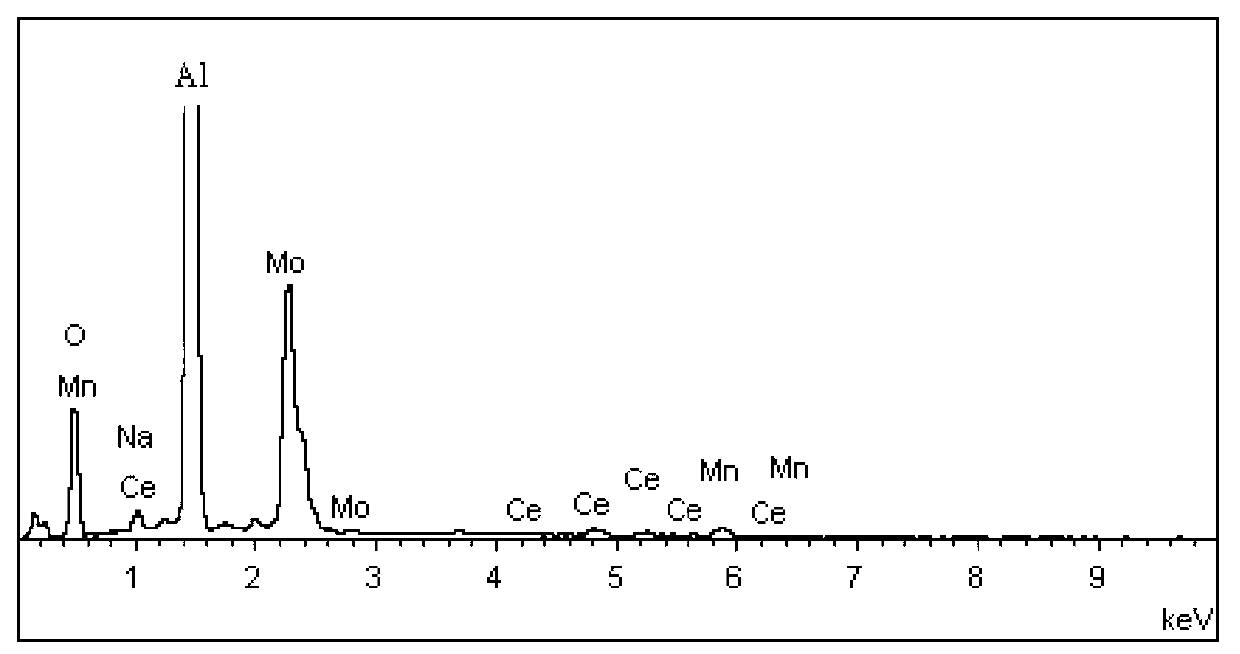

Method for preparing cerium-manganese/molybdenum multi-element composite conversion coating on surface of aluminum alloy

ActiveCN103276387AReduce the temperatureSave energyMetallic material coating processesWeather resistanceCerium

The invention discloses a method for preparing a cerium-manganese / molybdenum multi-element composite conversion coating on the surface of aluminum alloy. The method comprises the following steps of: (1) pretreating and activating the aluminum alloy; and (2) placing the aluminum alloy treated in the step (1) in Ce-Mn conditioning fluid so as to prepare the golden cerium-manganese conversion coating on the surface of the aluminum alloy; and (3) placing the aluminum alloy treated in the step (2) in Mo-containing conditioning fluid to obtain the cerium-manganese / molybdenum multi-element composite conversion coating. The conditioning fluids adopted in the method do not contain toxic substances. The multi-element composite conversion coating with excellent corrosion resistance and weather resistance as well as relatively good wear resistance can be prepared on the surface of aluminum alloy. The method is relatively simple in technology, simple and convenient to operate, low in cost and easy to industrialize.

Owner:SOUTH CHINA UNIV OF TECH +1

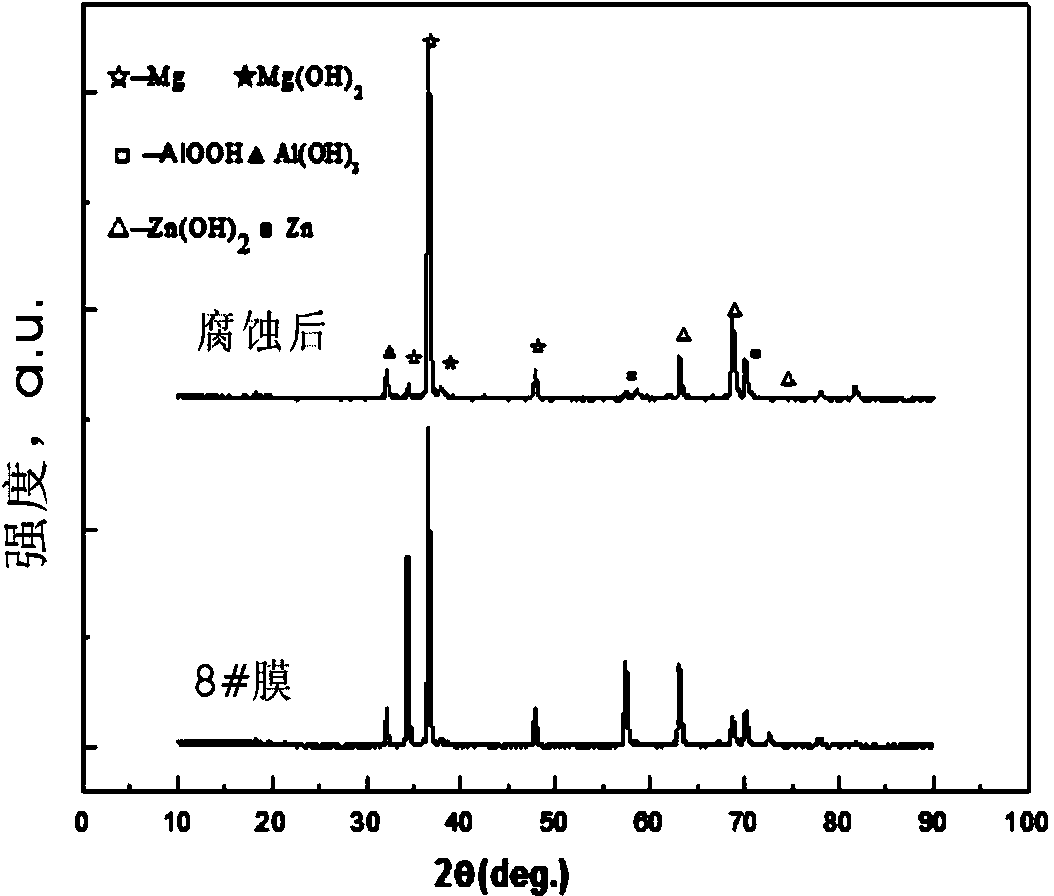

Corrosion resistant film prepared by magnesium alloy surface hydrothermal method and preparation technology thereof

ActiveCN103614717ASmall atomic radiusImprove polarization performanceMetallic material coating processesSolubilityLithium

The invention discloses a corrosion resistant film prepared by a magnesium alloy surface hydrothermal method and a preparation technology thereof, belongs to the technical field of magnesium surface processing, and solves the problem of bad corrosion resistant property of magnesium alloy in the prior art. The technology provided by the invention comprises the following steps: placing a processed magnesium alloy sample into a hydrothermal reactor, then injecting a treating fluid into the reactor according to a certain filling degree, and putting the reactor into a thermotank to maintain the temperature. The treating liquid comprises sodium hydroxide and lithium salt, sodium hydroxide provides a proper alkaline environment for film forming, lithium salt has a large solubility in water, Li+ can hydrolyze in water with a great amount at a certain temperature, so the pH value of the solution is improved so as to promote the film forming reactions on the magnesium alloy surface to move in the positive direction, the obtained film in situ grows on the magnesium alloy surface; the force between the film and the substrate body is excellent, the film is uniform, compact and ultra-thin, and has an excellent corrosion resistant property; the corrosion current density of the conversion film is increased by five magnitude orders compared to that of the substrate body, and reaches 10<-9> A / cm<2> magnitude grade.

Owner:曾荣昌

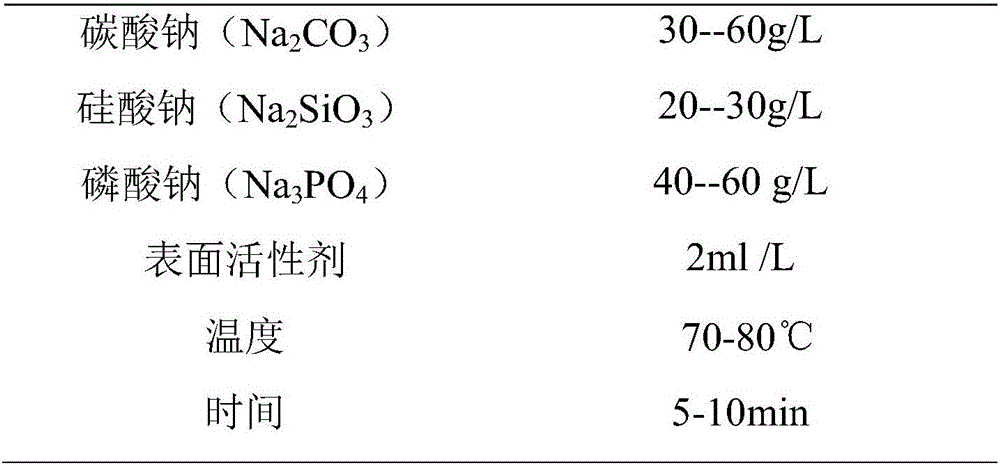

Preparation method of sintered neodymium-iron-boron permanent-magnet surface ceramic coating

InactiveCN103710739AImprove corrosion resistanceImprove wear resistanceAnodisationMicro arc oxidationCeramic coating

The invention relates to a preparation method of a sintered neodymium-iron-boron permanent-magnet surface ceramic coating. The preparation method comprises steps of: (1) chamfering and polishing, namely, subjecting a sintered neodymium-iron-boron permanent-magnet material to surface polishing processing by utilization of a mechanical vibration grinding and barreling chamfering method; (2) degreasing and removing oil, namely, adding the chamfered and polished magnet into an alkaline oil removing agent to remove oil and degrease; (3) removing rust by acid-washing namely, adding the magnet into an acid solution to remove rust by acid-washing; (4) performing micro-arc oxidation, namely, adding the permanent magnet rust of which is removed by acid-washing into an electrolyte and performing micro-arc oxidation; and (5) washing and drying, namely, washing the permanent magnet processed by micro-arc oxidation with distilled water and naturally drying, thus finally forming an oxidized ceramic coating on the surface of the neodymium-iron-boron permanent magnet. The preparation method achieves simple and feasible industrial application and is low in production cost, is free from influence of appearance structures of the magnet material and is free from pollution to the environment. The preparation method can effectively improve the corrosion resistance and wear resistance of the neodymium-iron-boron permanent magnet and prolong the service lifetime of the magnet.

Owner:NANCHANG HANGKONG UNIVERSITY

Proton exchange film fuel cell stainless steel bi-polar plate and production thereof

InactiveCN101488574AImprove performanceLong-term protectionCell electrodesFinal product manufactureMetallurgyPolypyrrole

The invention provides a stainless steel bipolar plate of a proton exchange membrane fuel cell and the preparation thereof. The surface of the stainless steel bipolar plate is covered with a corrosion resistant and conductive complex coating of polypyrrole / polyaniline with the thickness of the coating standing at 10-25mum and the thickness ratio of a bottom polypyrrole coating and a top polyaniline coating standing between 1:1 and 1:4. The invention has the advantages of simple technique, no limitation by the shape of the workpiece structure, low processing coat, excellent corrosion resistant performance of the coating in sour environment and the like, thereby being capable of improving the corrosion resistant performance of metal and lowering contact resistance of the metal. The coating is for the first time applied to the protection of the stainless steel bipolar plate of the proton exchange membrane fuel cell.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing wear-resistant coating of ball mill lining plate

ActiveCN105063539ABroaden your optionsHigh bonding strengthMolten spray coatingWear resistanceBall mill

The invention discloses a method for preparing a wear-resistant coating of a ball mill lining plate, and belongs to the field of remanufacturing of engineering machines. The wear-resistant coating comprises a base and a coating layer. The base comprises, by weight, 0.30%-0.44% of C, 1.50%-2.0% of Si, 0.8%-1.40% of Mn, 2.0%-2.8% of Cr, equal to or less than 0.3% of Mo, equal to or less than 0.3% of Ni, 0.02% of Re, 0.04% of P and S, and the balance Fe. The coating layer comprises, by volume fraction, 95%-98% of WC-Co powder and 2%-5% of Cr. The weight ratio of Cr to Co is 0.2-0.5. The method enables a part to have wear resistance, corrosion resistance and other special performance, the reliability of the part is improved, the service life of the part is prolonged, and especially the wear resistance of the working surface of the ball mill lining plate is improved.

Owner:ANHUI POLYTECHNIC UNIV

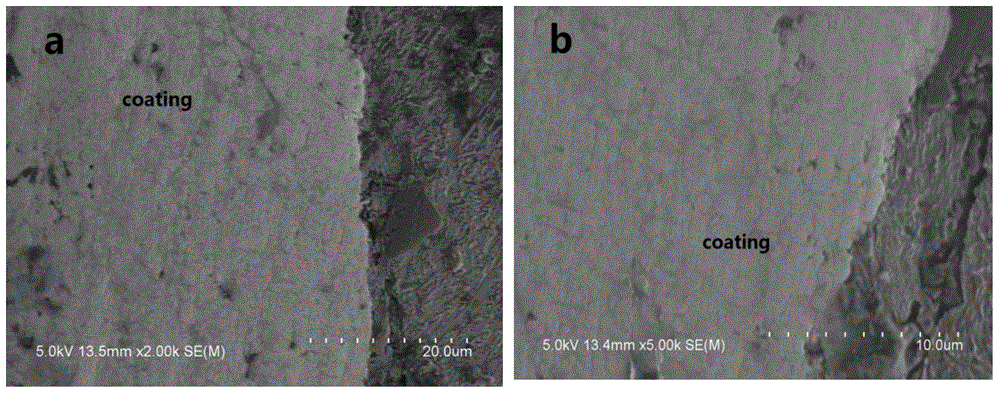

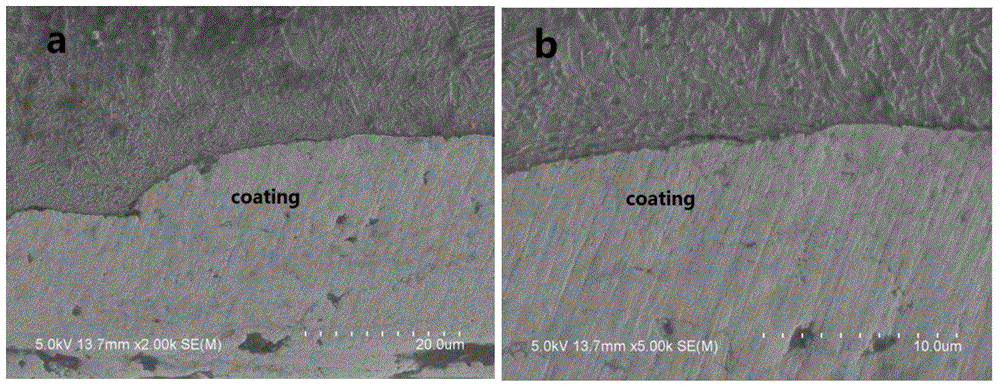

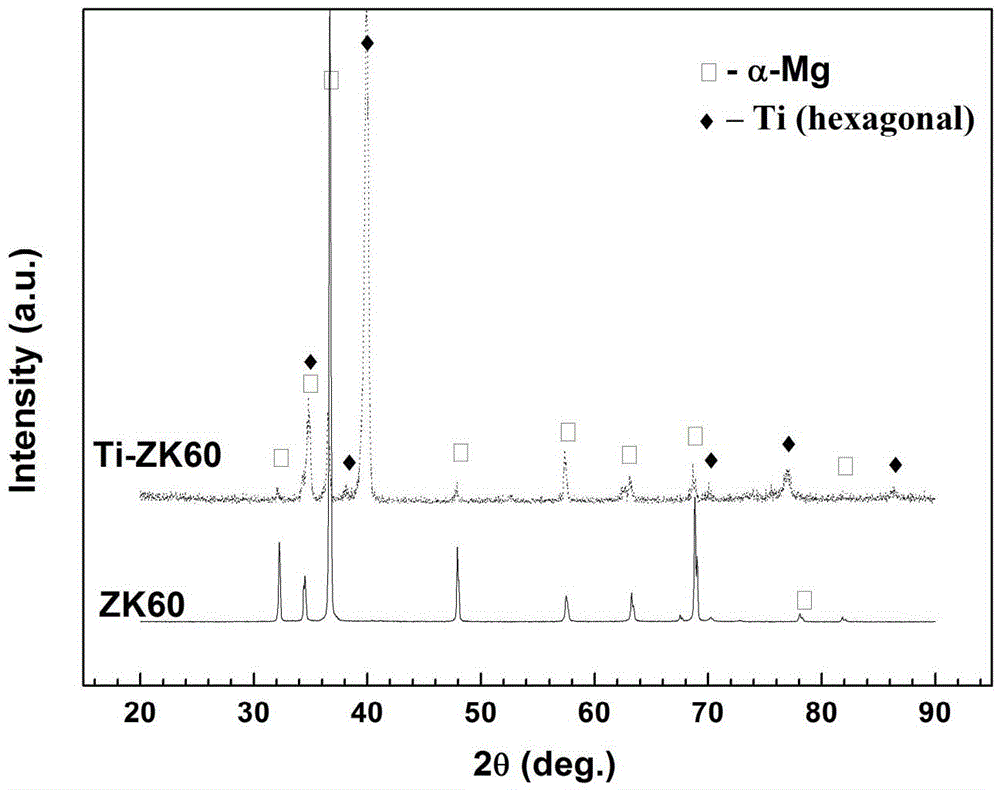

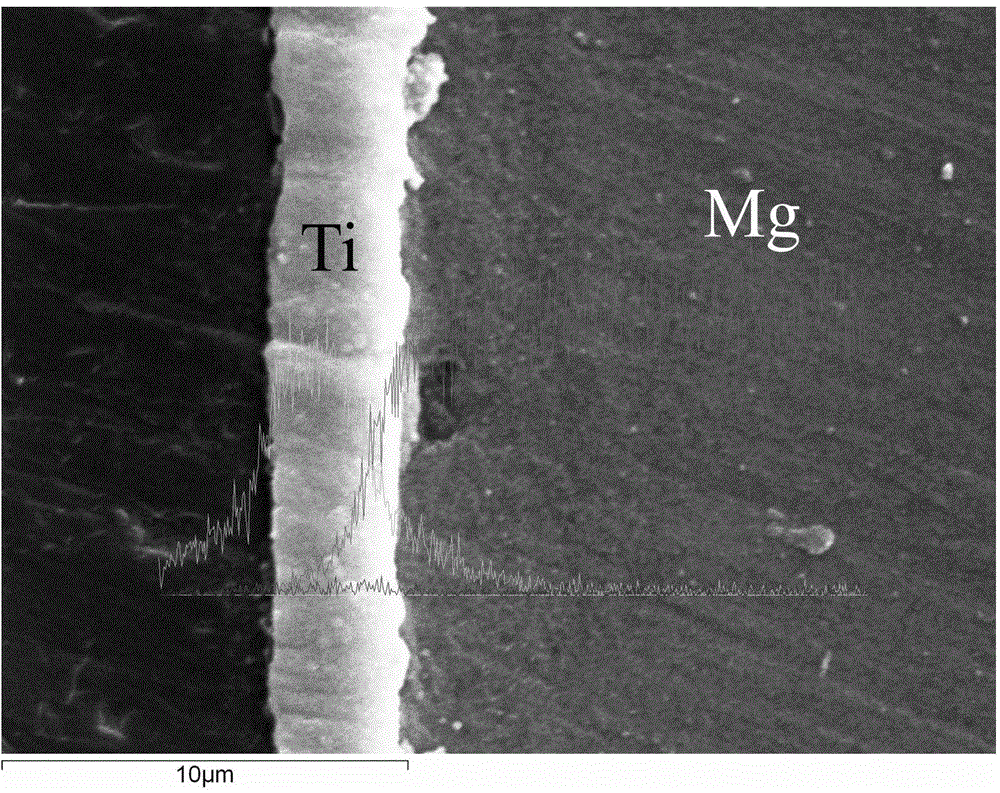

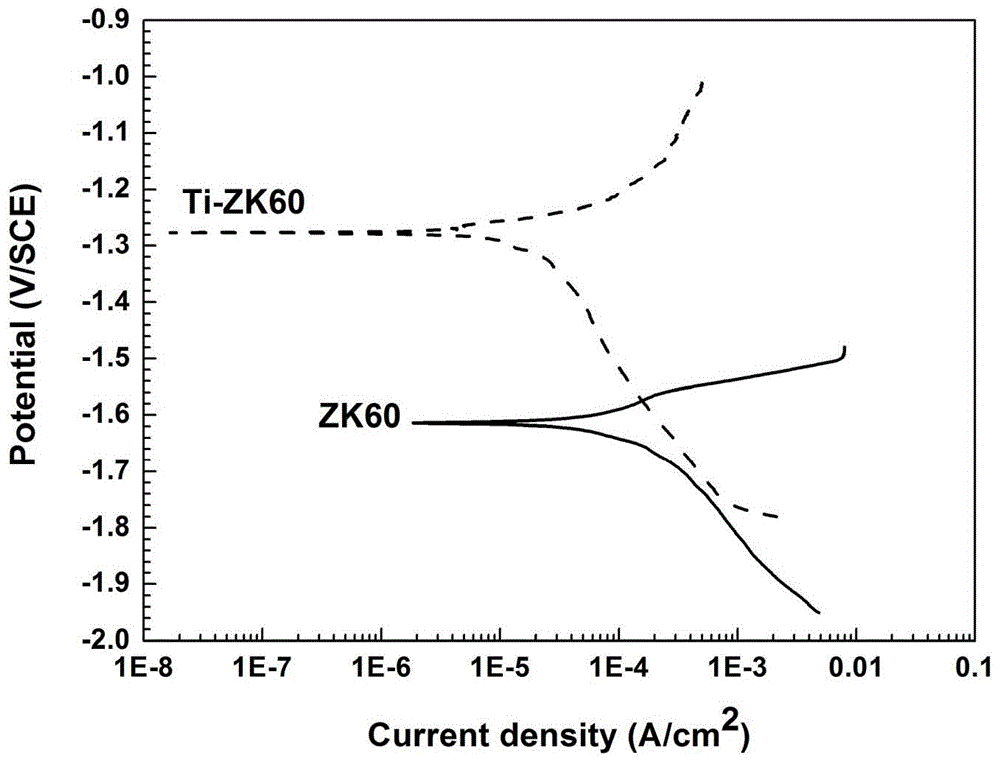

Method for modifying surfaces of biodegradable magnesium and magnesium alloy through titanium ion implantation and deposition

InactiveCN104878362AHigh bonding strengthReduce corrosion rateVacuum evaporation coatingSputtering coatingMixed oxideIon beam

The invention discloses a method for modifying surfaces of biodegradable magnesium and magnesium alloy through titanium ion implantation and deposition, and belongs to the technical field of surface treatment. The method is that mixed oxide transition layers are formed on the magnesium and magnesium alloy surfaces by the ion implantation method, wherein the transition layer is composed of titanium oxide and magnesium oxide and is 3 to 6 microns in thickness; then 2-4 microns titanium films are prepared on the transition layers by the ion beam reinforcing depositing technology. According to the method, the transition layers are prepared to ensure the high combination strength of the titanium depositing film layer and a matrix; the titanium deposition film and the transition layers can improve the corrosion resistance of the magnesium and the magnesium alloy.

Owner:BEIHANG UNIV

Method for surface treating stainless steel double polar plate of proton exchanging film fuel cell

InactiveCN1787262AImprove corrosion resistanceIncreased self-corrosion potentialCell electrodesPolypyrroleSulphate Ion

The invention is a surface processing method for the stainless steel dipolar plates of a proton exchange fuel battery, characterized in that the surfaces of the dipolar plates is covered with a synthesized corrosion resistant, conductive sodium dodecyl sulphate-doped polypyrrole coating whose thickness is 10 mum-30 mum. The method synthesizes a corrosion resistant, conductive polypyrrole coating, which can be applied to the surfaces of various stainless steels (such as 18-8. 316 and 310 stainless steels). The conductivity of the polypyrrole coating is about 10S / cm, and as the thickness of the polypyrrole coating reaches about 15 micron, it can play the role in long-time protecting the stainless steel substrate.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

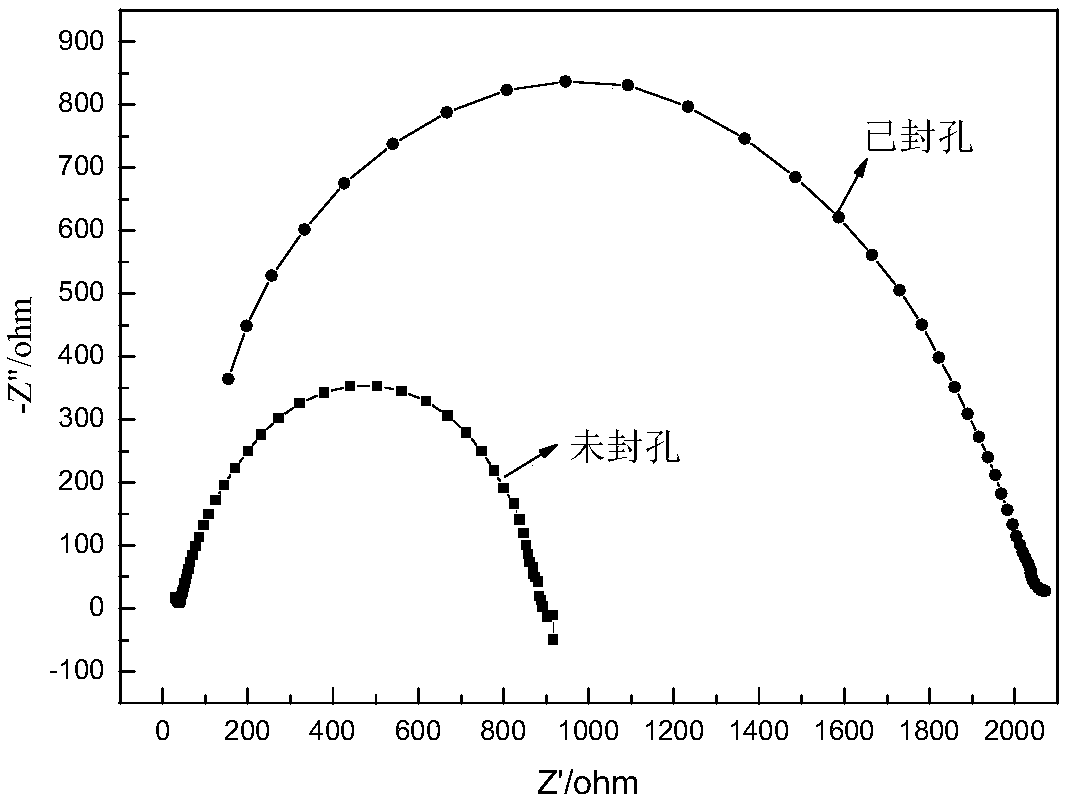

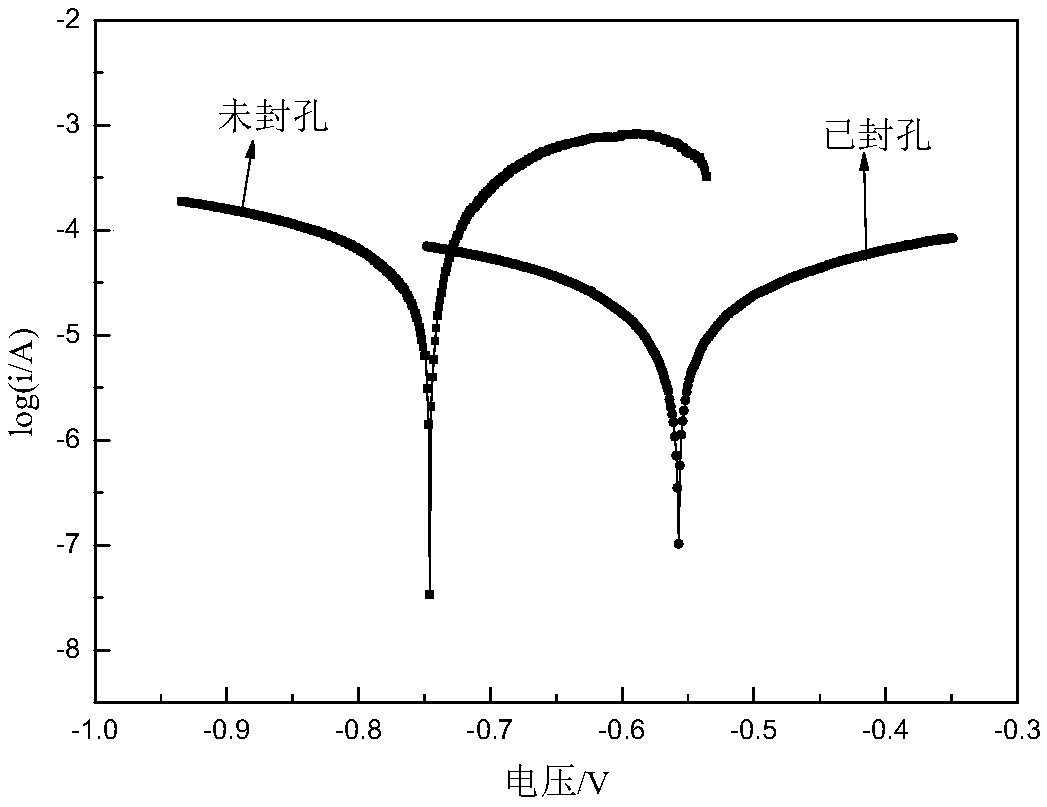

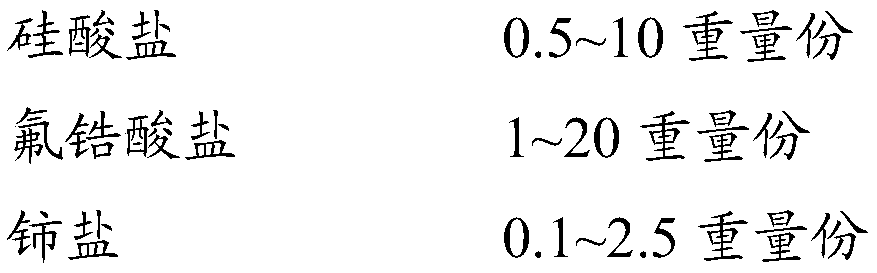

Confining liquid for aluminum or aluminum alloy anode oxide film, and application thereof

InactiveCN109183122AIncreased self-corrosion potentialImprove corrosion resistanceSurface reaction electrolytic coatingHuman healthAmmonia

The invention provides a confining liquid for an aluminum or aluminum alloy anode oxide film. The confining liquid for the aluminum or aluminum alloy anode oxide film comprises the following components in parts by weight: 0.5-10 parts by weight of silicate, 1-20 parts by weight of fluozirconate, 0.1-2.5 parts by weight of cerate, 0.01-0.5 part by weight of surfactant, 0.05-1 part by weight of complexing agent, 1-5 parts by weight of ammonia water and 1000 parts by weight of water. The confining liquid for the aluminum or aluminum alloy anode oxide film does not contain nickel ions and free fluorine ions, and is environment-friendly, and free from causing harm to human health. Moreover, the confining liquid for the aluminum or aluminum alloy anode oxide film is capable of confining at roomtemperature, and low in energy consumption. The confining liquid for the aluminum or aluminum alloy anode oxide film has a great confining effect on the aluminum or aluminum alloy anode oxide film, and the confined aluminum alloy is high in corrosion resistance.

Owner:YANSHAN UNIV

Nickel-tungsten graphene oxide (GO) composite plating solution, plated film and preparation method thereof

InactiveCN104726907AImprove mechanical propertiesEffective dispersionElectrolytic coatingsComposite plateMechanical property

The invention discloses a nickel-tungsten graphene oxide (GO) composite plating solution, a plated film and a preparation method thereof. According to the plating solution, GO which has good mechanical properties and can be effectively dispersed is introduced into the plating solution and is effectively deposited and dispersed in a Ni-W matrix during electroplating. A Ni-W-GO composite plated film is successfully prepared on a carbon steel base body by a pulse electroplating codeposition method. Graphene oxide is dispersed in the Ni-W matrix, so that the coefficient of friction is effectively lowered. The competitive relation between crystal nucleation and growth is effectively changed during codeposition, so that the structure of the plated film is improved, a deposited film layer can become more uniform and denser, intercrystalline corrosion is weakened, the diffusion path of a corrosive medium is prolonged, the self-corrosion potential is increased, local corrosion is effectively inhibited, the stability of a passivation film is improved, and thus, the corrosion resistance of the composite plated film is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Nickel, tungsten and graphene composite plating solution, plated film and making method of plated film

InactiveCN104911652AImprove mechanical propertiesEffective dispersionElectrolytic coatingsComposite plateNucleation

The invention discloses a nickel, tungsten and graphene composite plating solution, a plated film and a making method of the plated film. GE with good mechanical performances and effective dispersion property is introduced into the plating solution, and the GE is effectively deposited and dispersed in a Ni-W matrix in the electroplating process. The Ni-W-GE composite plated film is successfully made on a carbon steel matrix through a pulse plating codeposition technology. Graphene is dispersed in the Ni-W matrix, and the structure of the plated film is improved by effectively changing the competition relation between crystal nucleation and growth in the codeposition process in order to make a deposited film layer uniform and compact, so the intercrystalline corrosion is weakened, the diffusion path of a corrosion medium is prolonged, the self-corrosion potential is improved, local corrosion is effectively inhibited, and the stability of a passive film is improved, thereby the corrosion resistance of the composite plated film is improved.

Owner:SOUTHWEST PETROLEUM UNIV

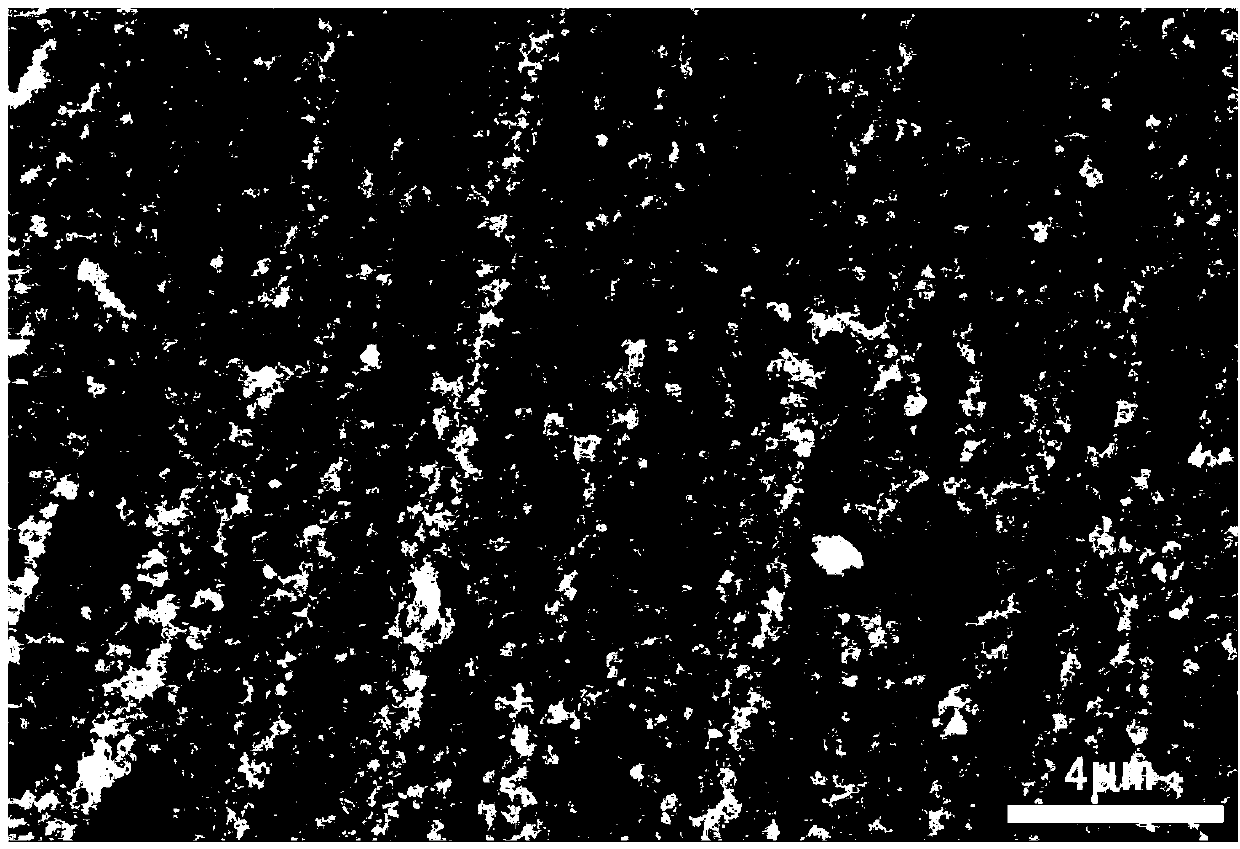

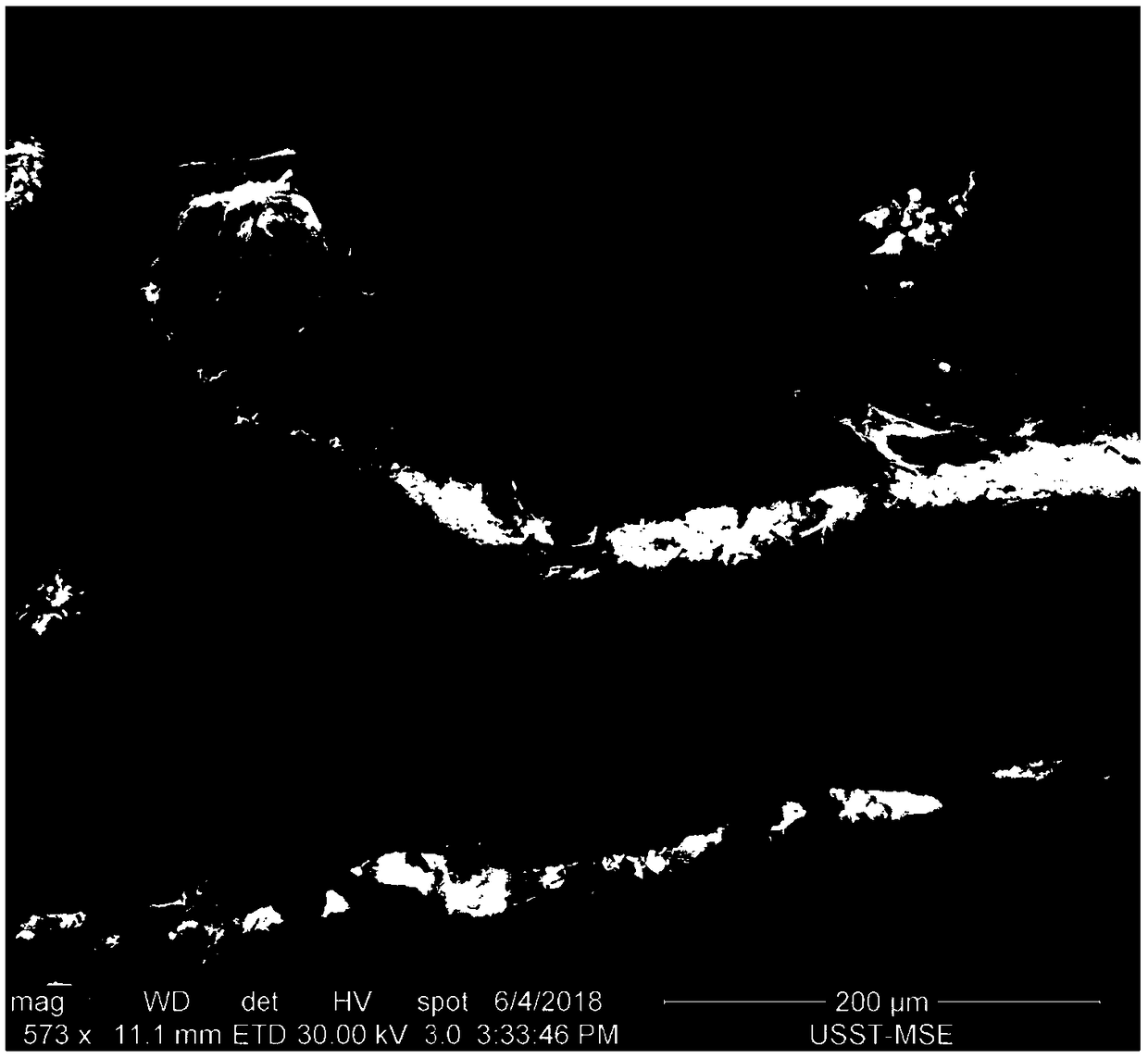

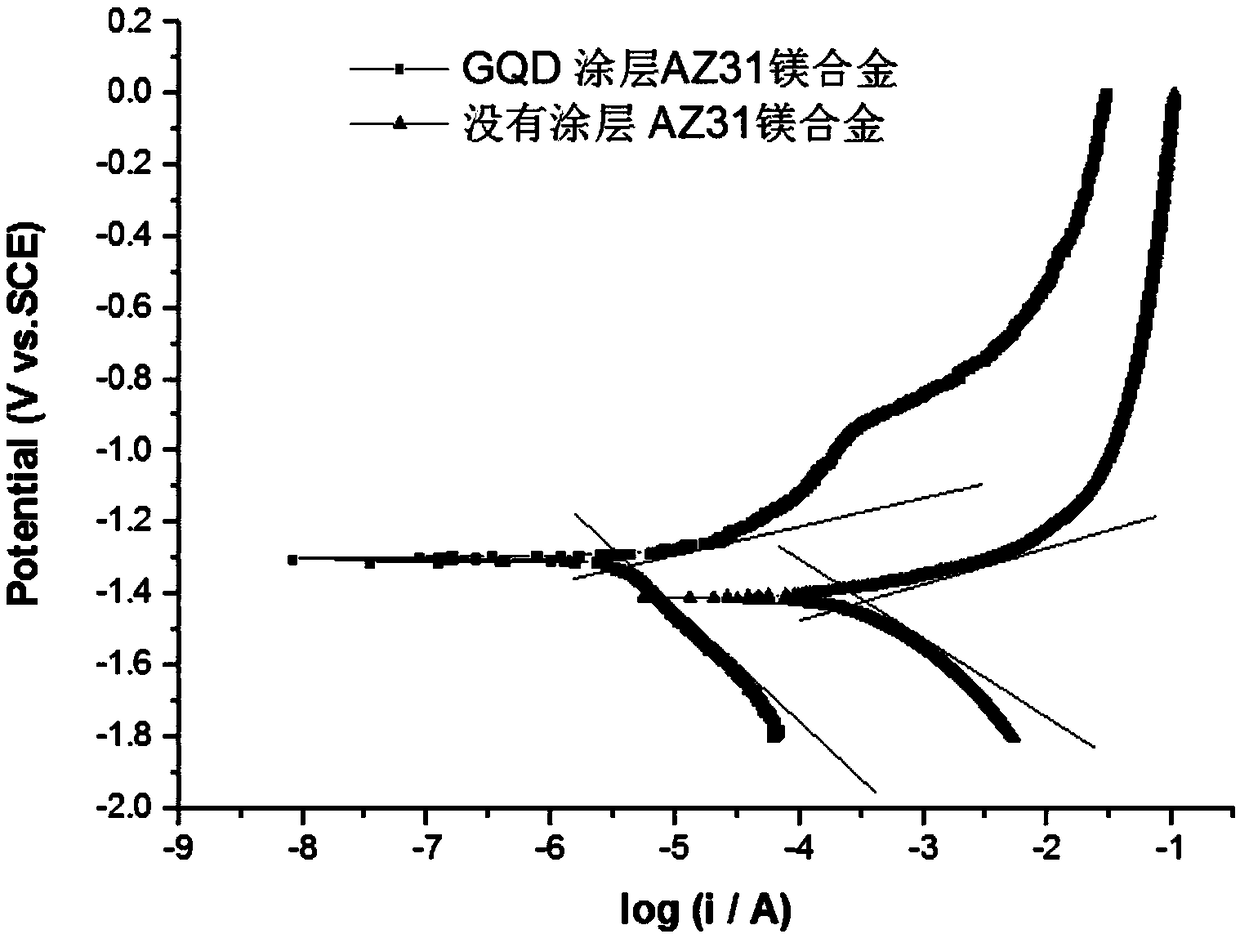

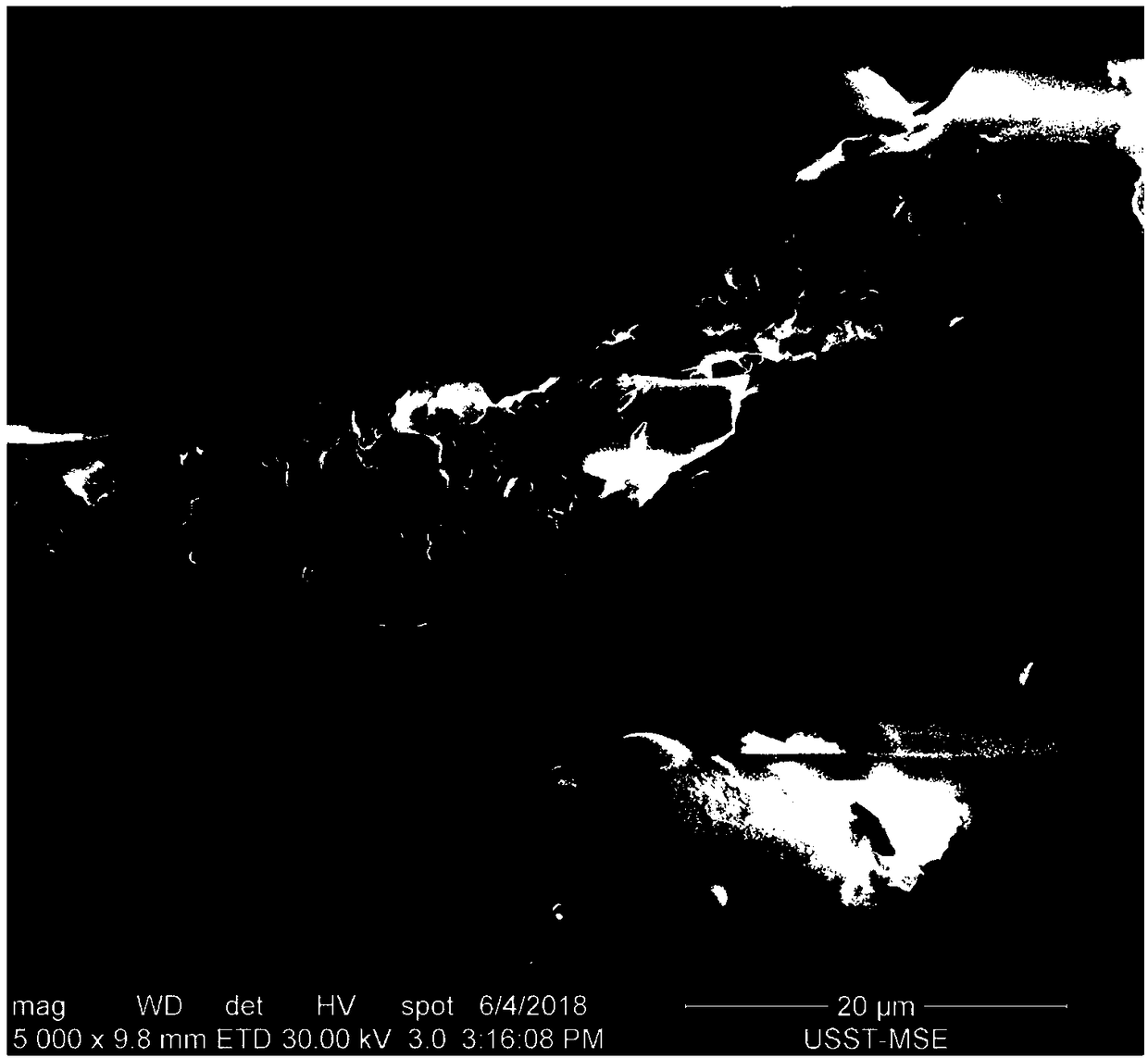

Method for improving corrosion resistance of magnesium alloy by adopting nitrogen doped graphene quantum dot coating

ActiveCN108796571AImprove bindingHigh densityElectrolytic inorganic material coatingMetallic material coating processesDoped graphenePotassium

The invention provides a method for improving corrosion resistance of a magnesium alloy by adopting a nitrogen doped graphene quantum dot coating. The method comprises the following steps of: taking agraphene quantum solution as an electrolyte solution; adopting a tri-electrode system; taking a magnesium alloy as a working electrode; taking a saturated potassium chloride / calomel electrode as a reference electrode, taking a platinum electrode as an auxiliary electrode, electrochemically depositing a nitrogen doped graphene quantum dot on the surface of the magnesium alloy, placing the deposited nitrogen doped graphene quantum dot coating in a silylation solution, drying the magnesium alloy subjected to silylation treatment, thereby forming the nitrogen doped graphene quantum dot coating onthe surface of the magnesium alloy, wherein the silylation treatment temperature is 40-55 DEG C and the silylation standing time is 1-2 hours. According to the method provided by the invention, the nitrogen doped graphene quantum dot is uniformly and electrically deposited on the surface of the magnesium alloy, and binding force between the magnesium alloy and the nitrogen doped graphene quantumdot is improved through silylation treatment, so that the nitrogen doped graphene quantum dot coating which is high in compactness and is tightly combined is obtained on the surface of the magnesium alloy.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

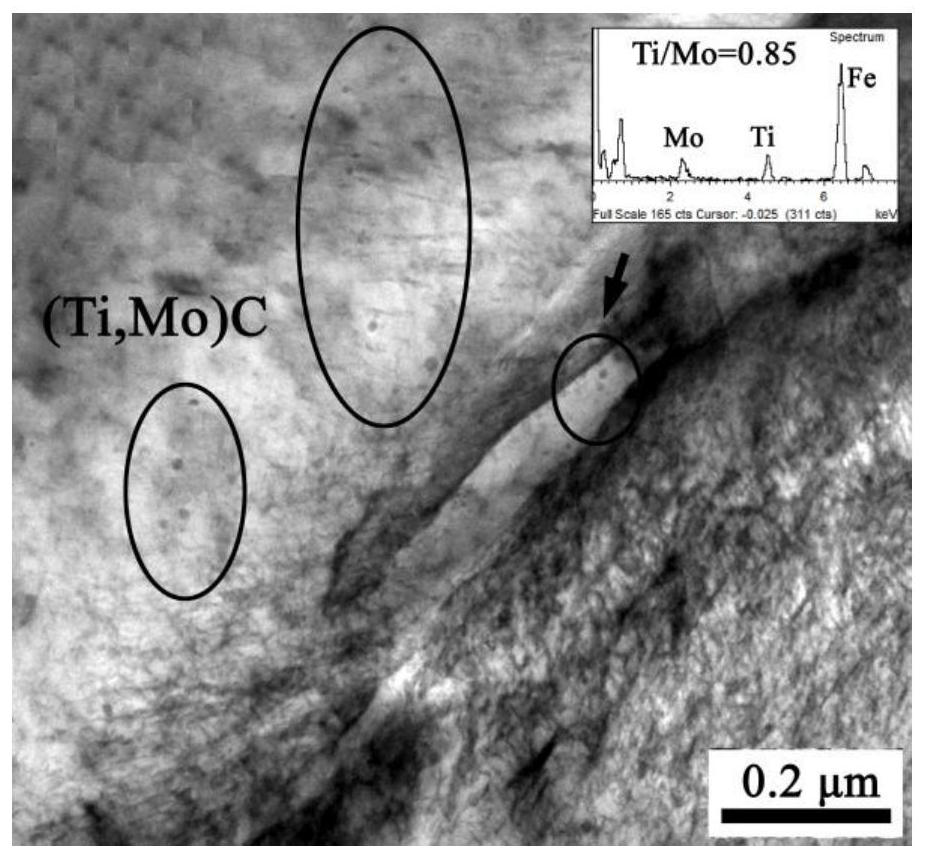

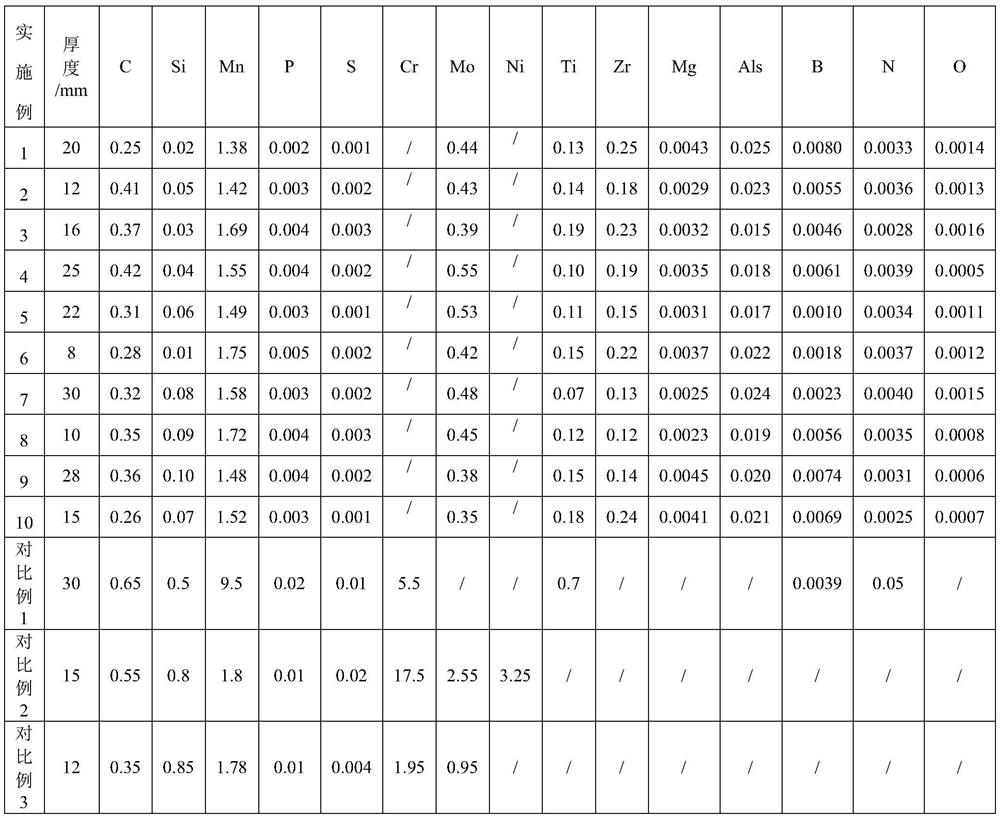

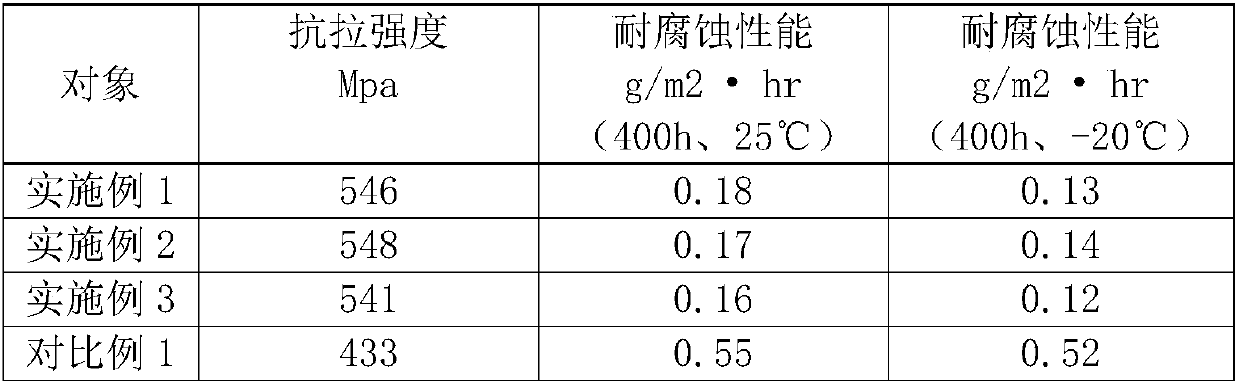

High-strength and high-toughness weldable corrosion-resistant and abrasion-resistant steel plate and preparation method thereof

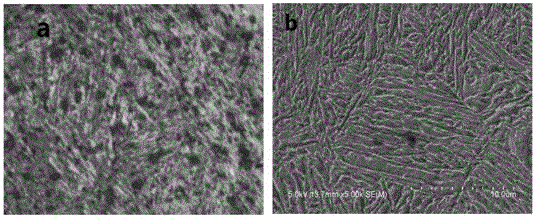

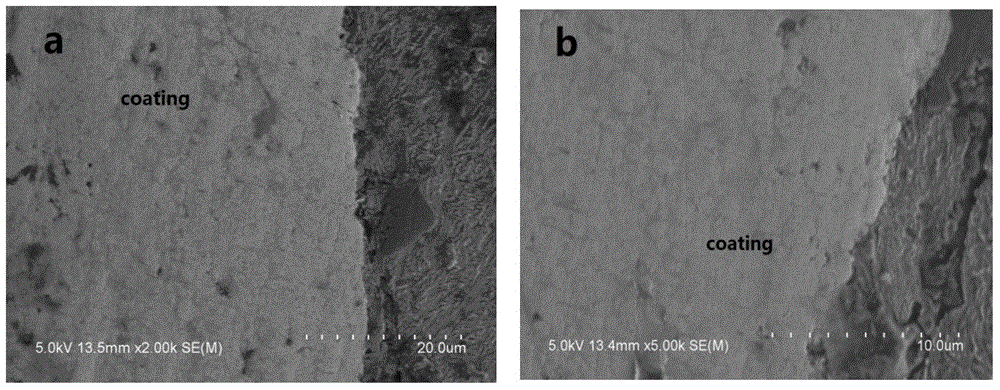

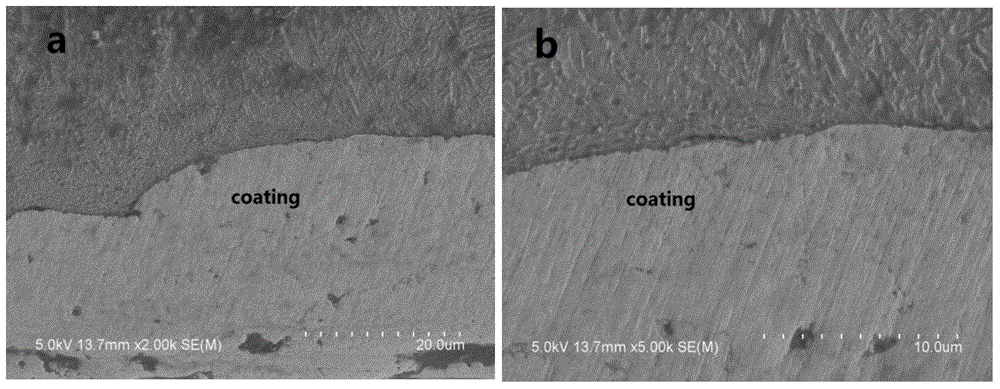

The invention discloses a high-strength and high-toughness weldable corrosion-resistant and abrasion-resistant steel plate and a preparation method thereof. According to the technical scheme, the steel plate comprises, by mass, 0.25-0.42% of C, 0.01-0.10% of Si, 1.35-1.75% of Mn, not greater than 0.005% of P, not greater than 0.002% of S, 0.35-0.55% of Mo, 0.07-0.19% of Ti, 0.12-0.25% of Zr, 0.0023-0.0045% of Mg, 0.015-0.025% of Als, 0.001-0.008% of B, 0.0025-0.0040% of N, 0.0005-0.0015% of O, and the balance Fe and trace impurity elements, wherein the ratio of Mo to Ti is 1.8-7.0, and the ratio of Ti to Als is 3-13. According to the high-strength and high-toughness weldable corrosion-resistant and abrasion-resistant steel plate and the preparation method thereof, the alloy adding amount is small, the welding performance is improved, and the production cost is reduced; and through whole-process technological control of rolling, online quenching, offline quenching and low-temperature tempering, the grain size is refined, precipitation and dispersion distribution of nanoscale Ti-containing second-phase particles are promoted, and the toughness and corrosion-resistant and abrasion-resistant performance of the product are improved.

Owner:WUHAN UNIV OF SCI & TECH

Surface coating part for reproduction of ball mill liner plate and manufacturing method for surface coating part

ActiveCN105063499ABroaden your optionsHigh bonding strengthMolten spray coatingGrain treatmentsBall millMaterials science

The invention discloses a surface coating part for reproduction of a ball mill liner plate and a manufacturing method for the surface coating part, and belongs to the field of reproduction of engineering machines. The surface coating part comprises a substrate and a coating layer. The substrate comprises, by weight, 0.30-0.44% of C, 1.50-2.0% of Si, 0.8-1.40% of Mn, 2.0-2.8% of Cr, 0.3% of Mo or less, 0.3% of Ni or less, 0.02% of Re, 0.04% of P and S and the balance Fe. The coating layer comprises, by volume, 95-98% of WC-Co powder and 2-5% of Cr, and the weight ratio of Cr to Co is 0.2-0.5. The surface coating part for reproduction of the ball mill liner plate and the manufacturing method for the surface coating part can give the special properties like abrasion resistance and corrosion resistance to parts, improve the reliability of the parts, prolong the service life of the parts and especially improve the abrasion resistance of a work surface of the ball mill abrasion-resistant liner plate.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Biotoxicity-free Zr-based amorphous alloy and preparation method thereof

The invention discloses a biotoxicity-free Zr-based amorphous alloy and a preparation method thereof, and relates to the technical field of amorphous alloys. The biotoxicity-free Zr-based amorphous alloy is composed of the following elements: Zr, Cu, Al, Ti, Fe and Ni, wherein the percentage content of Zr atoms is 56%, the percentage content of Cu atoms is 24%, the percentage content of Al atoms is 9%, the percentage content of Ni atoms is 1-6%, the percentage content of Ti atoms is 4%, and the percentage content of Fe atoms is 1-7%. The Zr-based amorphous alloy has the beneficial effects thatthe defect that common toxic elements Nb, Pb, B and V exist in an existing common Zr-based amorphous alloy and have alloy components which are toxic to organisms is overcome, excellent corrosion resistance and high strength of the amorphous alloy are reserved, and the alloy is low in cost, easy to prepare and wide in adaptability.

Owner:NANJING TECH UNIV

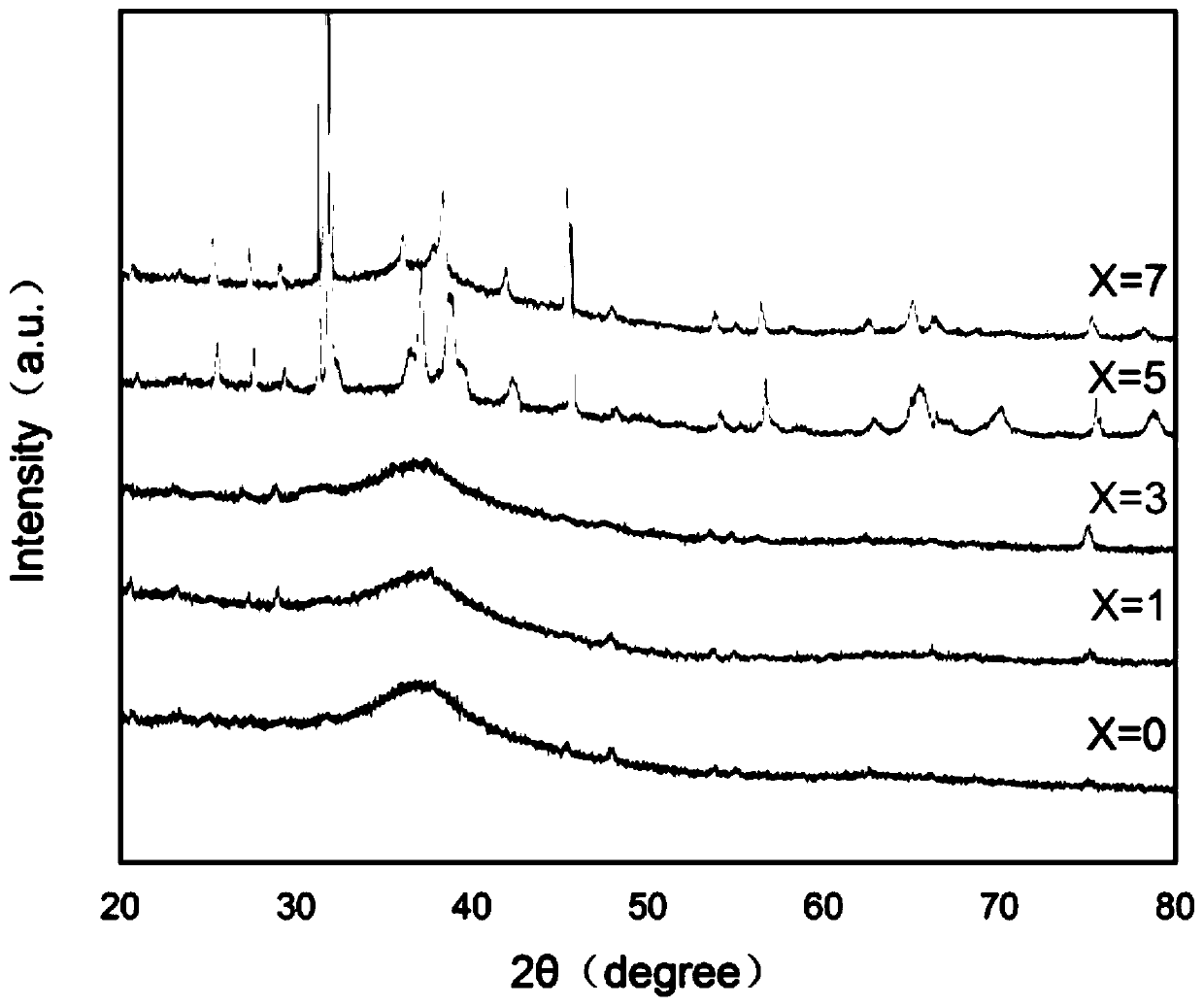

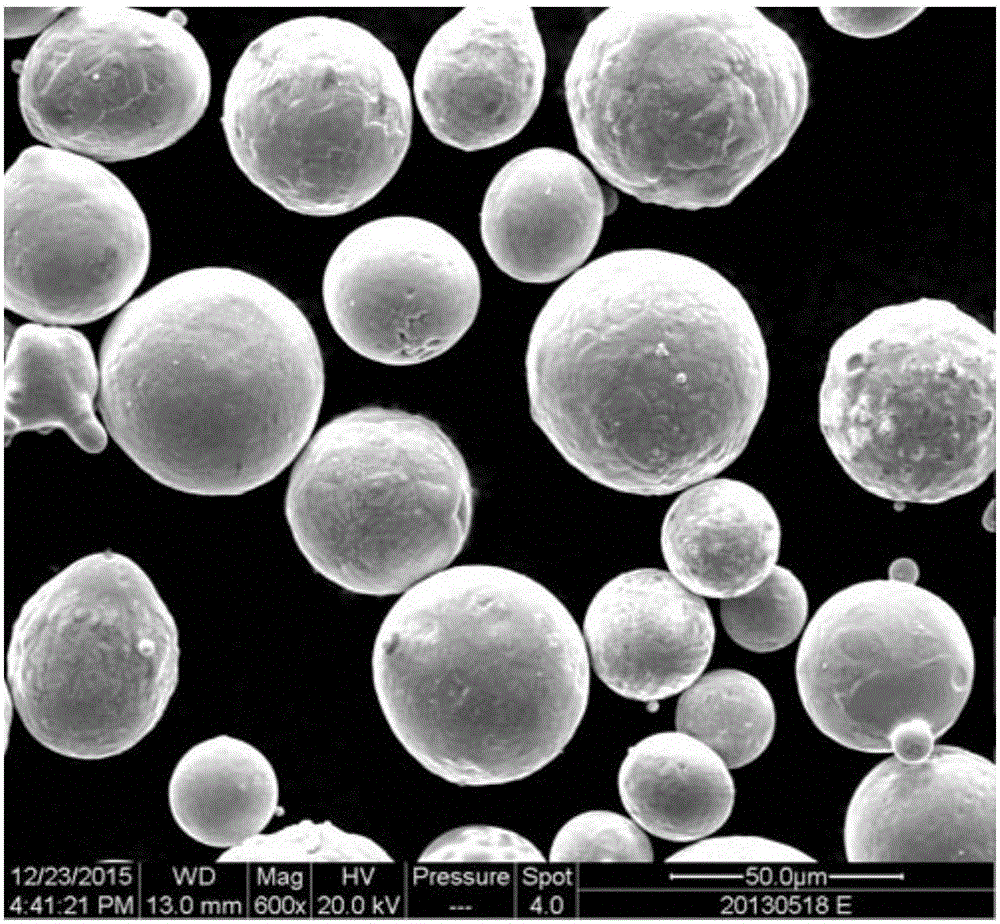

Aluminum-based metal glass cladding layer and preparation method thereof

InactiveCN106148948AHigh sphericityImprove liquidityTransportation and packagingMetallic material coating processesAlloyMaterials science

The invention discloses an aluminum-based metal glass cladding layer and a preparation method thereof. The aluminum-based metal glass cladding layer is prepared from aluminum-based amorphous alloy powder serving as a raw material through a magnetic field stirring laser cladding forming technique. The element composition of the aluminum-based amorphous alloy powder is as follows: 5 wt%-8 wt% of Ni, 3 wt%-6 wt% of Y, 1 wt%-5 wt% of Co, 0.5 wt%-3 wt% of La and the balance Al; the particle size range of the aluminum-based amorphous alloy powder ranges from 25 micrometers to 71 micrometers; and the oxygen content of the aluminum-based amorphous alloy powder is below 1,000 ppm. The adopted aluminum-based amorphous alloy powder is high in degree of sphericility, good in fluidity and proper in particle size, and the added alloy components have the characteristics of being high in amorphous forming ability and stable in structure; and the amorphous phase content of the aluminum-based metal glass cladding layer prepared in the manner that the alloy powder is combined with the magnetic field stirring laser cladding forming technique reaches up to 30% or above, and meanwhile the aluminum-based metal glass cladding layer further has excellent mechanical performance and abrasion-resistant and corrosion-resistant performance.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

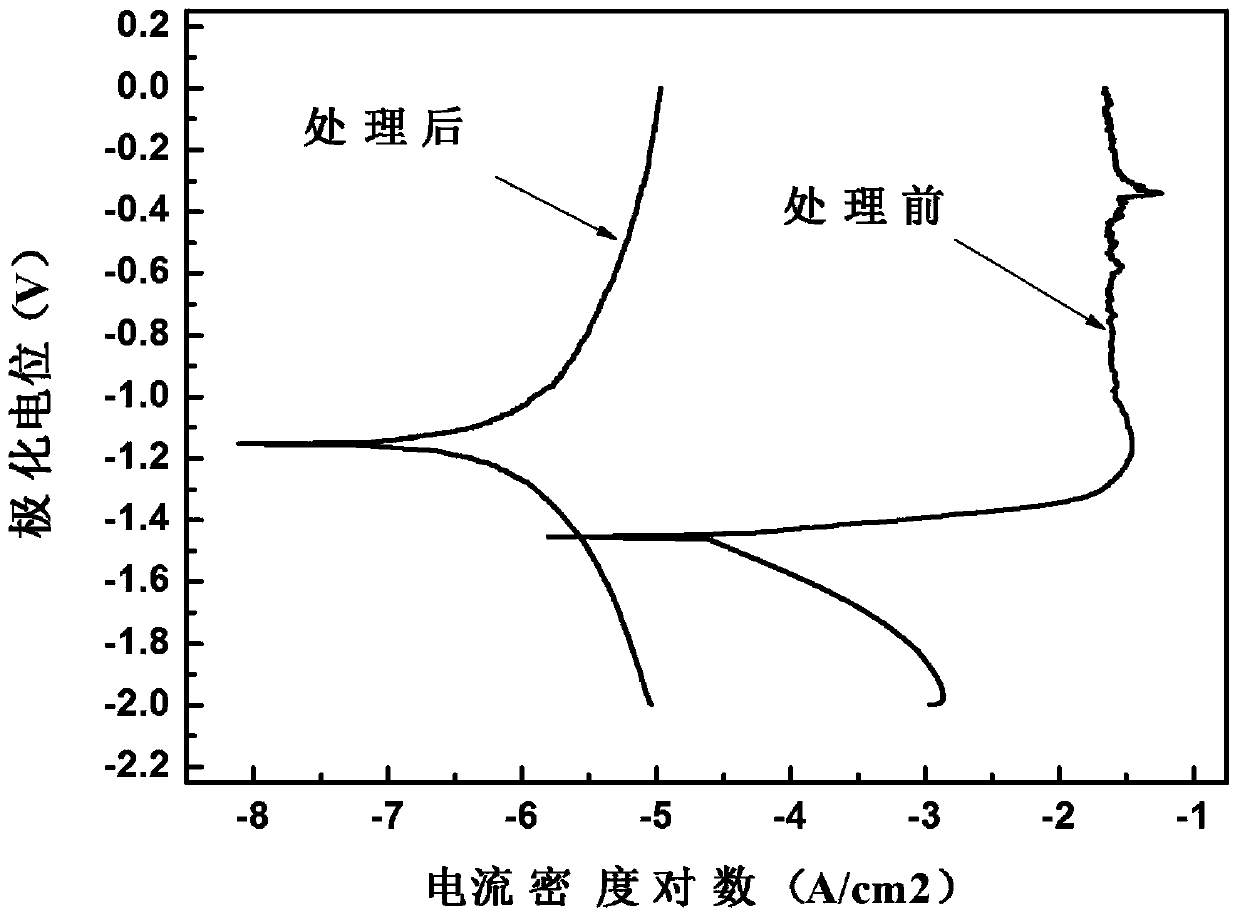

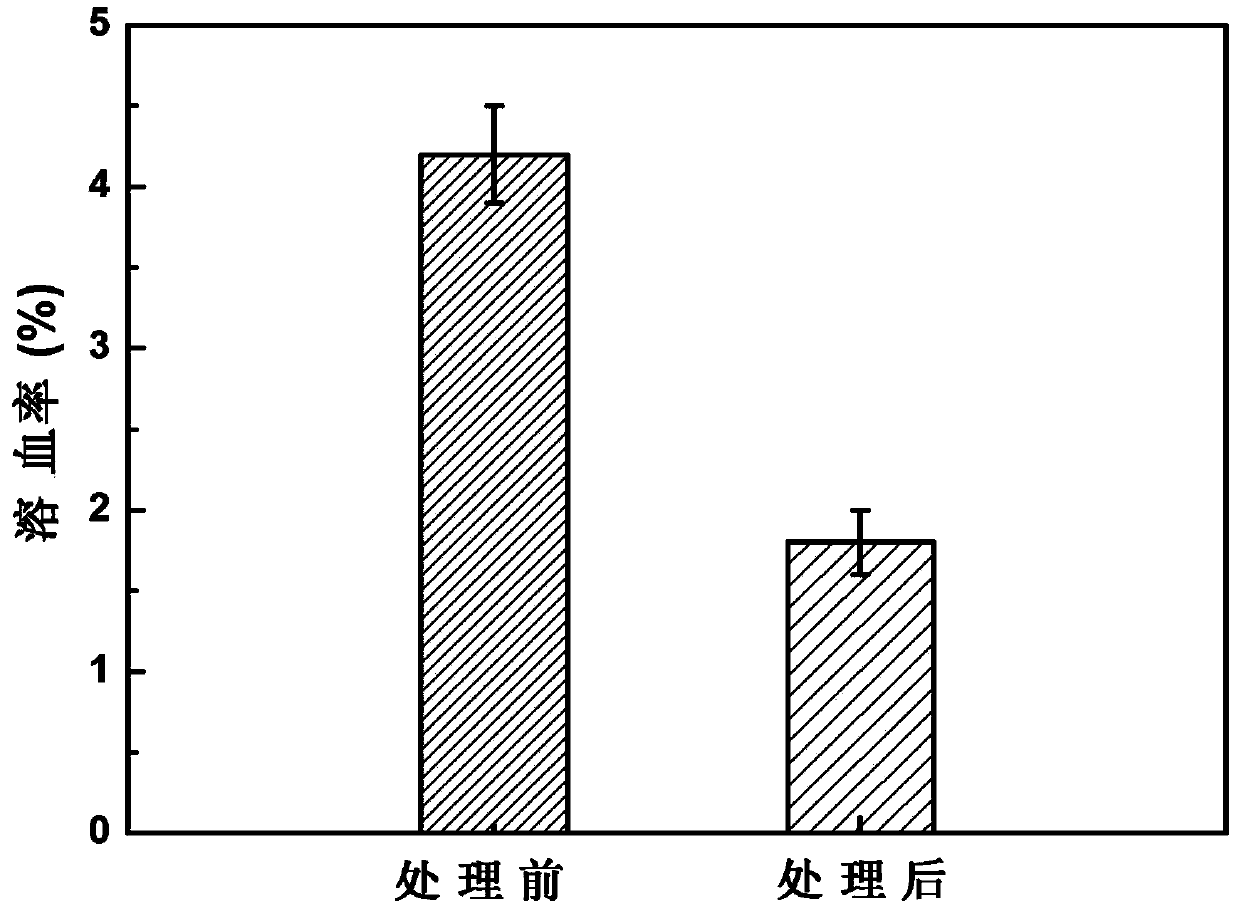

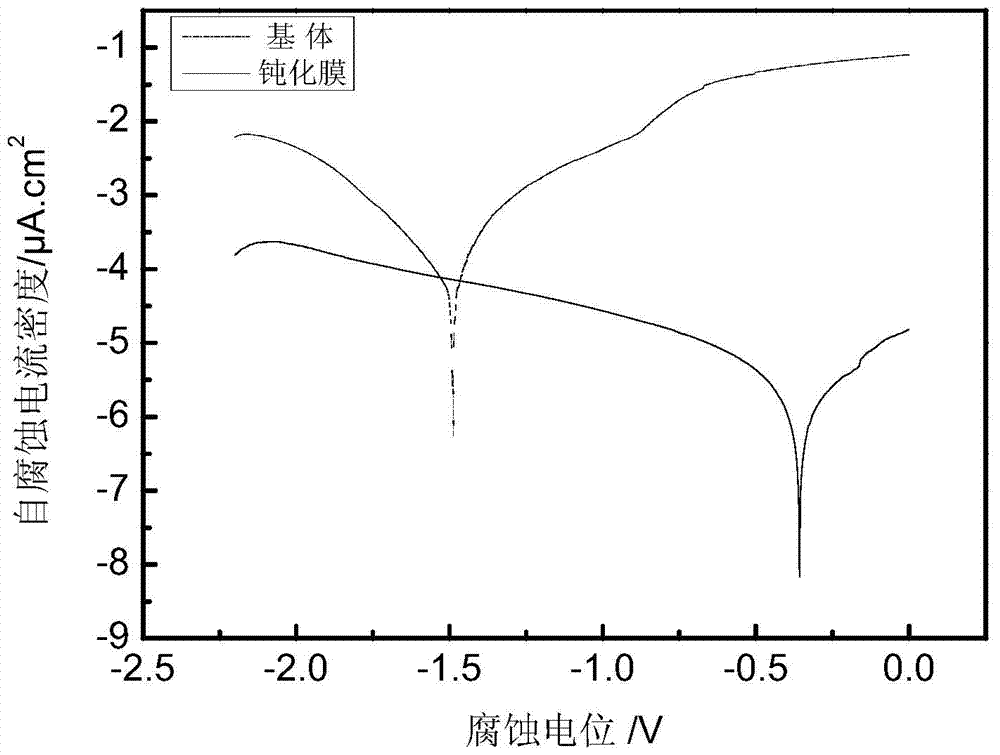

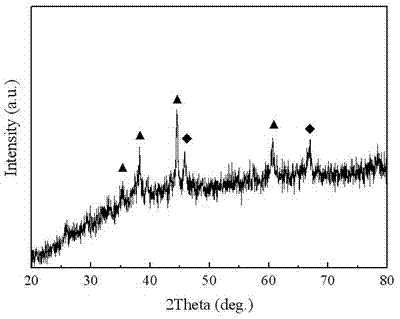

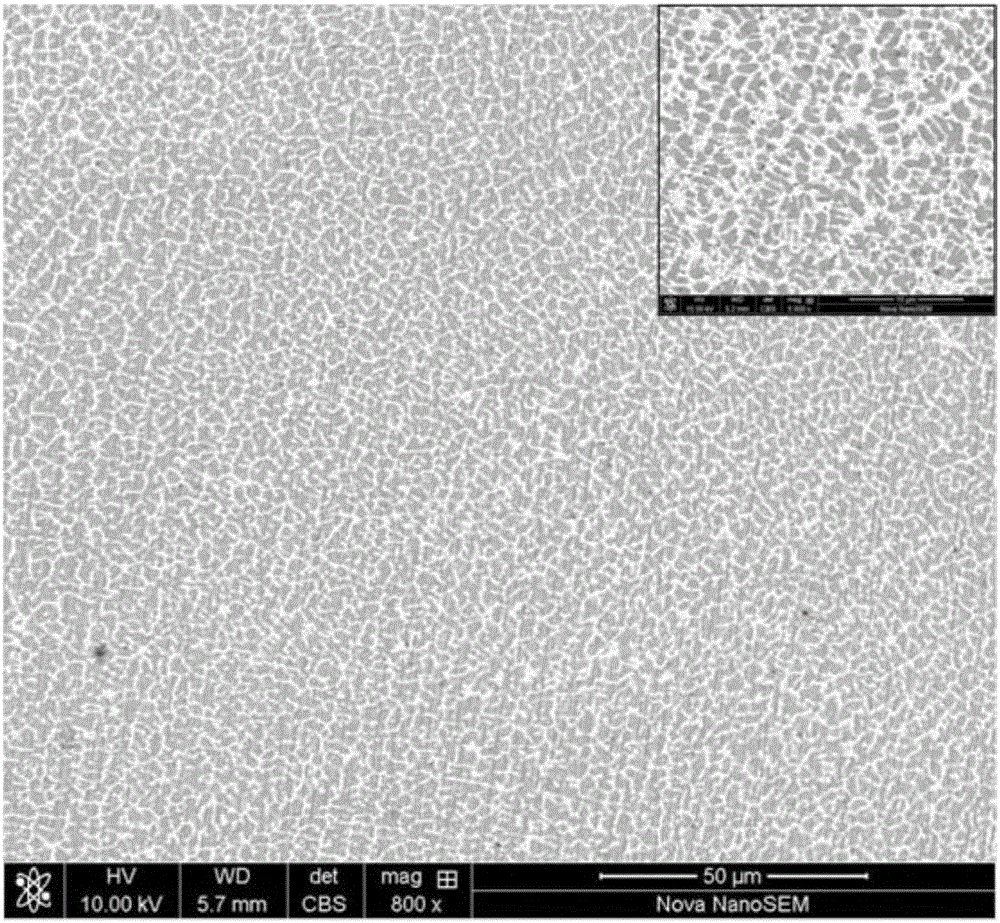

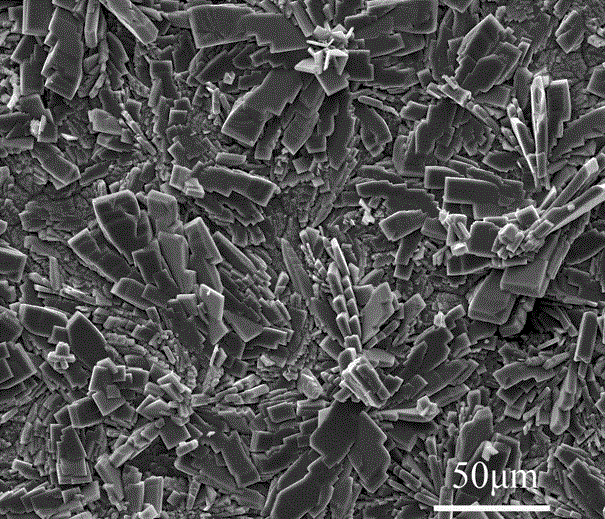

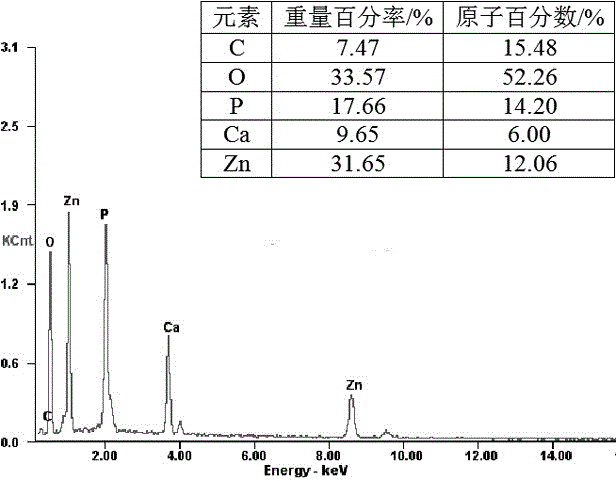

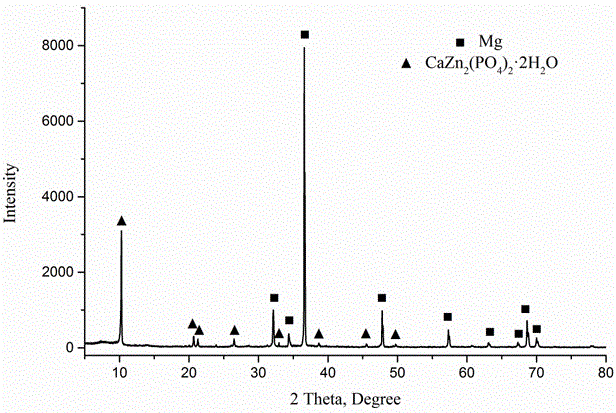

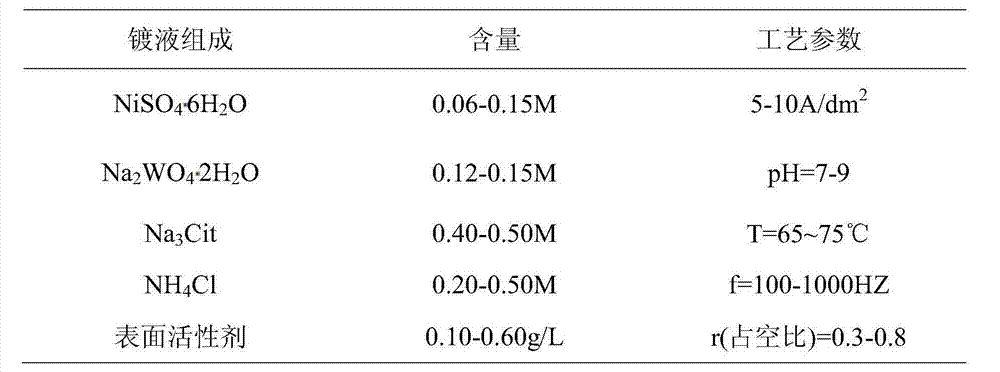

Coating capable of improving surface corrosion resistance and biocompatibility of medical magnesium and magnesium alloy and preparing method of coating

ActiveCN105603484AClosely arrangedIncreased self-corrosion potentialElectrolytic coatingsTissue regenerationBiocompatibility TestingChemical measurement

The invention provides a coating capable of improving the surface corrosion resistance and biocompatibility of medical magnesium and magnesium alloy and a preparing method of the coating. An electrolyte is composed of an aqueous solution containing Zn2+ salt, Ca2+ salt, H2PO4- salt and NaNO3. The zinc-calcium-phosphate-containing coating good in coverage is prepared on the surfaces of magnesium and magnesium alloy with the electrolyte through an electrochemical deposition method. The coating belongs to non-stoichiometric CaZn2(PO4)2.2H2O coatings, and has the significant advantages that degradation can be achieved while the corrosion resistance of a magnesium matrix is improved, and the degradability of the matrix cannot be changed by the coating. Meanwhile, Zn2+ can be released in the degrading process of the coating, differentiation of osteoblast can be promoted, the activity of osteoclast can be restrained, and thus the biocompatibility of the matrix is also improved. Thus, the coating has good application prospects when applied to magnesium alloy bone implanting medical instruments.

Owner:ZHENGZHOU UNIV

Nickel-tungsten multi-walled carbon nanotube (MWCNT) composite plating solution, plated film and preparation method thereof

InactiveCN104726924AImprove mechanical propertiesEffective dispersionElectrolytic coatingsPulse electroplatingComposite plate

The invention discloses a nickel-tungsten multi-walled carbon nanotube (MWCNT) composite plating solution, a plated film and a preparation method thereof. According to the plating solution, MWCNTs (Multi-Walled Carbon Nano-Tubes) which have good mechanical properties and can be effectively dispersed are introduced into the plating solution and are effectively deposited and dispersed in a Ni-W matrix during electroplating. A Ni-W-MWCNTs composite plated film is successfully prepared on a carbon steel base body by a pulse electroplating codeposition method. The nanotubes are dispersed in the Ni-W matrix, so that the coefficient of friction of the plated film is lowered. The competitive relation between crystal nucleation and growth is effectively changed during codeposition, so that the structure of the plated film is improved, a deposited film layer can become more uniform and denser, intercrystalline corrosion is weakened, the diffusion path of a corrosive medium is prolonged, the self-corrosion potential is increased, local corrosion is effectively inhibited, the stability of a passivation film is improved, and thus, the corrosion resistance of the composite plated film is improved.

Owner:SOUTHWEST PETROLEUM UNIV

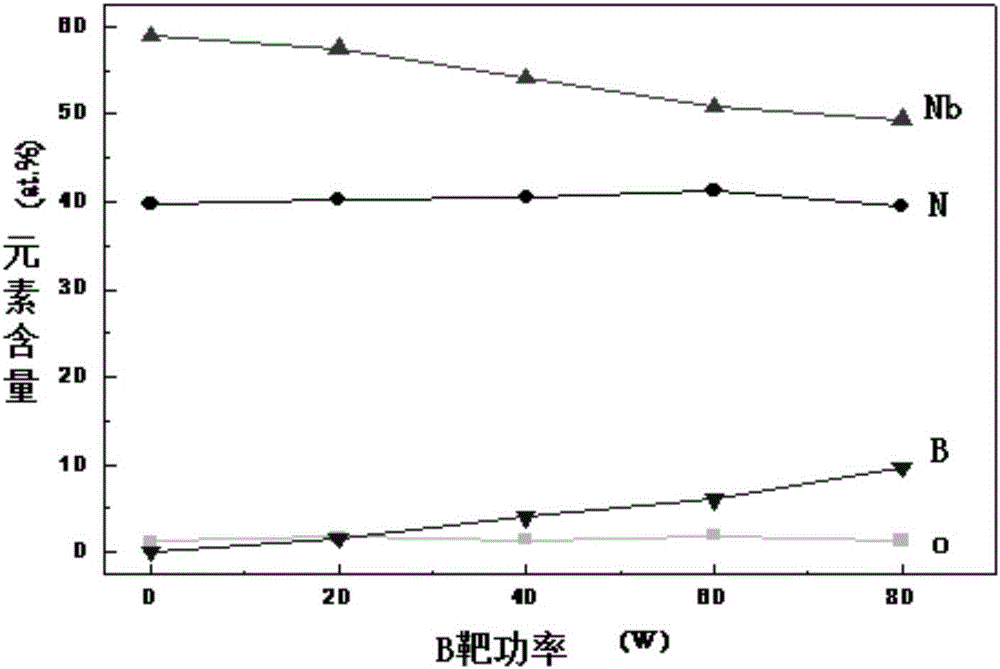

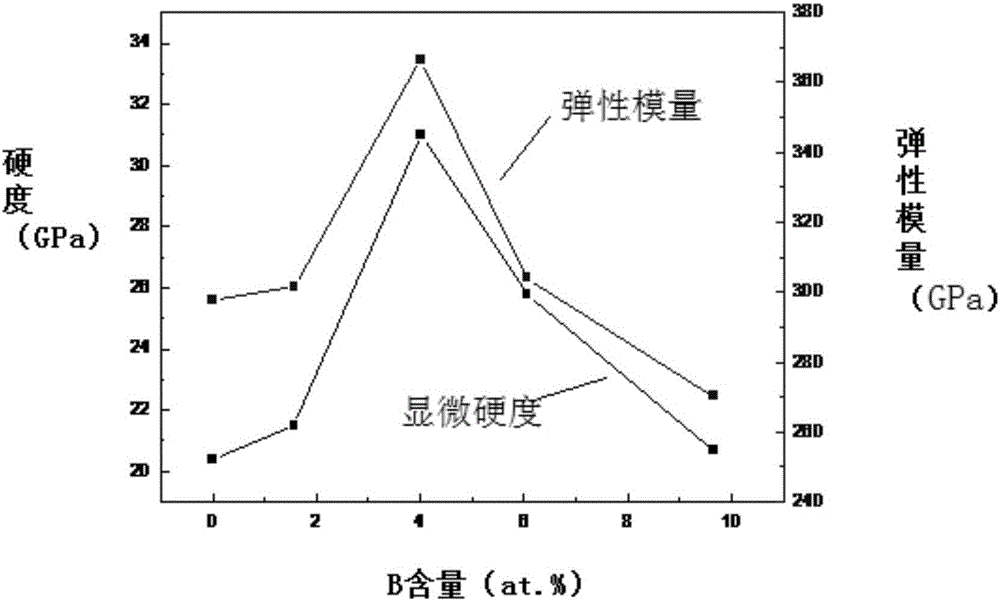

NbBN composite coating and preparation method thereof

InactiveCN106191771AIncreased microhardnessHigh elastic modulusVacuum evaporation coatingSputtering coatingRadio frequencyCemented carbide

The invention discloses a NbBN composite coating and a preparation method thereof. The NbBN composite coating is prepared by sputtering on a cemented carbide or ceramic substrate at a room temperature according to a double-target confocal radio-frequency reactive magnetron sputtering method, is 1.5 to 2.5 [mu]m thick, and comprises 0 to 9.65 at.% of the B component, 49.43 to 58.92 at.% of the Nb component, 39.8 to 41.2 at.% of the N component, and the balance of O. According to the NbBN composite coating and the preparation method, the mechanical properties, the corrosion resistance and the wear resistance of a NbN coating are further improved; and the NbBN composite coating is a protective coating with excellent overall properties, so as to be applied to the fields of high speed, dry cutting, corrosion protection and the like more widely.

Owner:JIANGSU UNIV OF SCI & TECH

High-weather-fastness aluminum alloy and preparing method thereof

ActiveCN107739929AImprove corrosion resistanceGood weather resistanceMetallic material coating processesRare-earth elementHeat treated

The invention discloses a high-weather-fastness aluminum alloy and a preparing method thereof, and belongs to the technical field of high-performance aluminum alloy materials. According to the high-weather-fastness aluminum alloy and the preparing method, rare-earth powder formed by Y2O3, La2O3 and CeO2 is added into the aluminum alloy, and a heat treatment process under the specific condition isused in cooperation, so that the decay resistance of the aluminum alloy is improved obviously; meanwhile, after activating treatment is carried out, the surface of the aluminum alloy is coated with acoating containing rare-earth salt, and therefore the coating tightly combined with the surface of the aluminum alloy in a mutual embedded manner rather than only coated on the surface of the aluminumalloy; and in addition, as the coating contains rare earth elements, the weather fastness of the aluminum alloy is further improved.

Owner:XIHUA UNIV

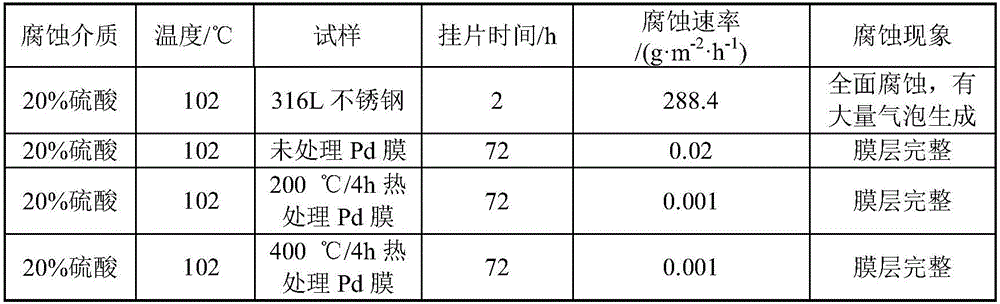

Method for improving corrosion resisting performance of palladium film on surface of stainless steel and palladium film

InactiveCN106757236AImprove corrosion resistanceIncreased self-corrosion potentialTime rangePalladium

The invention relates to a method for improving corrosion resisting performance of a palladium film on the surface of stainless steel and the palladium film. The method comprises the steps that after the palladium film is plated to the surface of the stainless steel, the palladium film on the surface of the stainless steel is subjected to heat treatment in the inert gas atmosphere or vacuum environment; and according to technological parameters, the temperature ranges from 200 DEG C to 600 DEG C, and time ranges from 1h to 4 h. According to the method for improving corrosion resisting performance of the palladium film on the surface of stainless steel and the palladium film, the self-corrosion potential of the palladium film on the surface of the stainless steel in an inoxidizability medium is further improved, and the corrosion resisting performance is further improved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Method for preparing hydrotalcite coating on magnesium alloy surface by combining acid pretreatment and steam method

PendingCN113564590ADense surfaceIncrease phase densityMetallic material coating processesOXALIC ACID DIHYDRATEHydrotalcite

The invention discloses a method for preparing a hydrotalcite coating on the surface of a magnesium alloy by combining acid pretreatment and a steam method, and mainly solves the technical problem that the corrosion resistance of a hydrotalcite coating in the prior art is not ideal. The method comprises the following steps: (1) pretreating the surface of a magnesium alloy matrix; (2) carrying out acid pretreatment on the pretreated magnesium alloy matrix; and (3) preparing the hydrotalcite coating on the surface of the magnesium alloy matrix subjected to acid pretreatment through an in-situ steam method, wherein an acid solution adopted in acid pretreatment is an organic weak acid solution, and the organic weak acid is at least one of oxalic acid, an acetic acid solution or citric acid. The hydrotalcite coating obtained by the invention has the characteristics of compact structure, strong adhesive force, good corrosion resistance and long service life.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com