Confining liquid for aluminum or aluminum alloy anode oxide film, and application thereof

An anodic oxidation film and anodic oxidation technology, which is applied in the field of aluminum or aluminum alloy anodic oxidation film sealing fluid, can solve the problems of environmental pollution, affecting human health, and high energy consumption for sealing holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

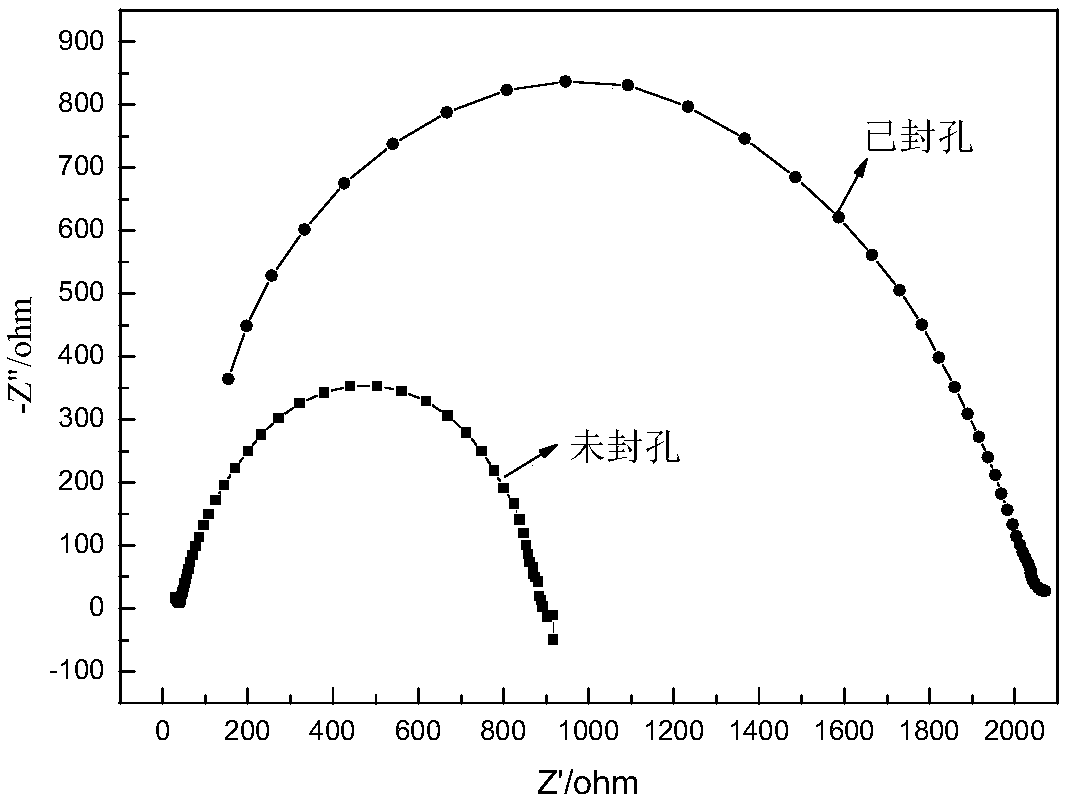

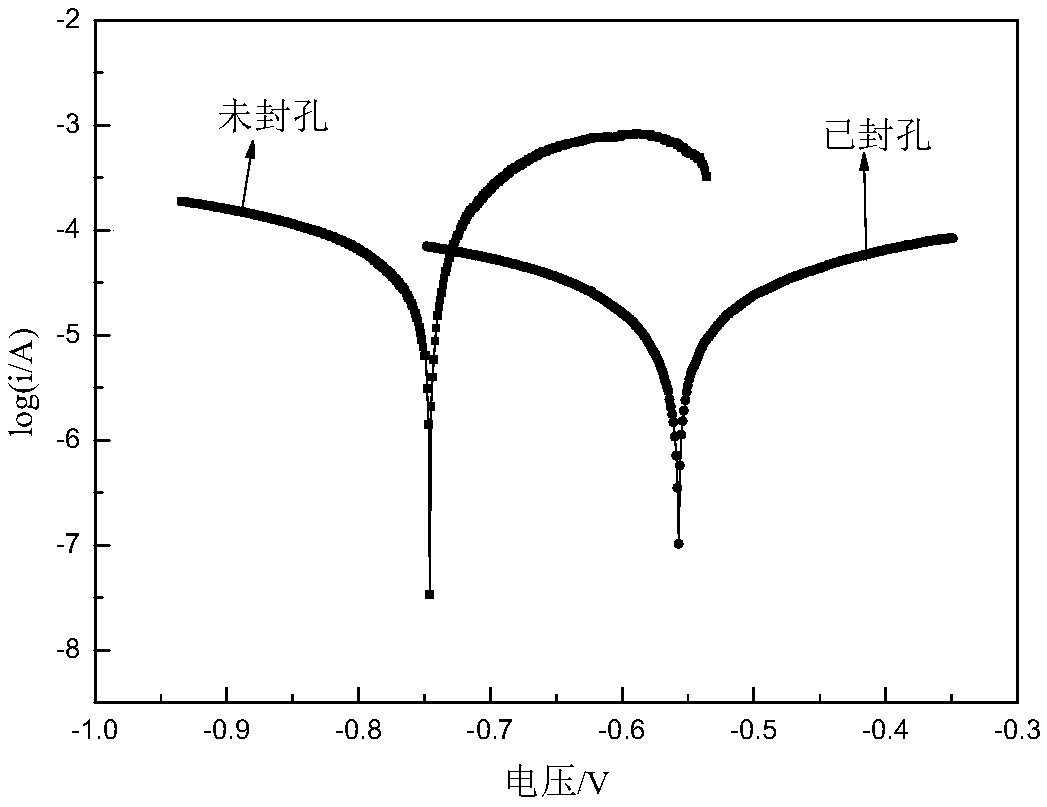

Method used

Image

Examples

Embodiment 1

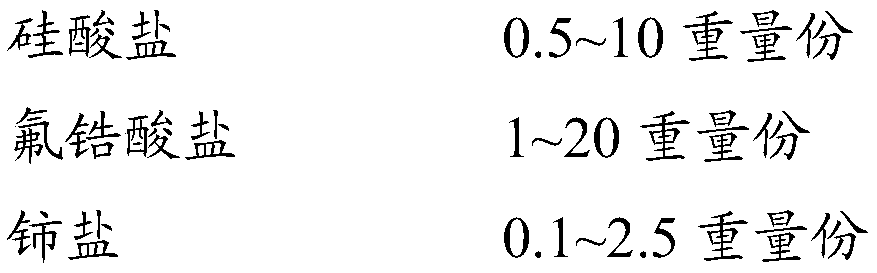

[0056] At room temperature, 2g sodium silicate, 7g ammonium fluozirconate, 0.5g cerium nitrate, 0.1g polyethylene glycol, 0.5g ethylenediaminetetraacetic acid, 2.5g mass concentration of 25% ammonia and 1000g deionized water Mixing, adjusting the pH value to 5.5 with a sulfuric acid solution with a mass fraction of 25%, to obtain a sealing solution for aluminum or aluminum alloy anodic oxidation film;

[0057] Put the aluminum alloy in the polishing solution and polish it for 3-5 minutes, take it out and rinse it with water; in a 160g / L sulfuric acid solution, set the DC voltage to 18V, perform DC anodization for 20 minutes, and wash it with water to obtain the oxidized aluminum alloy;

[0058] Under the condition of 30° C., soak the oxidized aluminum alloy in the aluminum or aluminum alloy anodized film sealing solution for 5 minutes, take it out, wash with water and dry naturally to obtain the sealed aluminum alloy.

[0059] Drop blue ink on the surface of the sealed aluminu...

Embodiment 2

[0069] At room temperature, 0.5g sodium silicate, 1g ammonium fluozirconate, 0.1g cerium nitrate, 0.01g polyethylene glycol, 0.05g ethylenediaminetetraacetic acid, 1g mass concentration of 25% ammonia and 1000g deionized water Mixing, adjusting the pH value to 4.5 with a sulfuric acid solution with a mass fraction of 25%, to obtain a sealing solution for aluminum or aluminum alloy anodic oxidation film;

[0070] Put the aluminum alloy in the polishing solution and polish it for 3-5 minutes, take it out and rinse it with water; in a 160g / L sulfuric acid solution, set the DC voltage to 18V, perform DC anodization for 20 minutes, and wash it with water to obtain the oxidized aluminum alloy;

[0071] Under the condition of 30° C., soak the oxidized aluminum alloy in the aluminum or aluminum alloy anodized film sealing solution for 5 minutes, take it out, wash with water and dry naturally to obtain the sealed aluminum alloy.

[0072] Drop blue ink on the surface of the sealed alumi...

Embodiment 3

[0075] At room temperature, mix 10g of sodium silicate, 20g of ammonium fluozirconate, 0.1g of cerium nitrate, 0.01g of polyethylene glycol, 0.05g of ethylenediaminetetraacetic acid, 1g of 25% ammonia and 1000g of deionized water , using a sulfuric acid solution with a mass fraction of 25% to adjust the pH value to 6.5 to obtain an aluminum or aluminum alloy anodic oxidation film sealing solution;

[0076] Put the aluminum alloy in the polishing solution and polish it for 3-5 minutes, take it out and rinse it with water; in a 160g / L sulfuric acid solution, set the DC voltage to 18V, perform DC anodization for 20 minutes, and wash it with water to obtain the oxidized aluminum alloy;

[0077] Under the condition of 30° C., soak the oxidized aluminum alloy in the aluminum or aluminum alloy anodized film sealing solution for 5 minutes, take it out, wash with water and dry naturally to obtain the sealed aluminum alloy.

[0078] Drop blue ink on the surface of the sealed aluminum al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com