Preparation method of magnesium alloy/hydroxyapatite composite

A hydroxyapatite and nano-hydroxyapatite technology, which is applied in surgical adhesives, medical science, prostheses, etc., can solve the problem of uneven composition of magnesium alloy-hydroxyapatite composite materials, affecting performance uniformity, It is easy to produce cracks and other problems, and achieves the effect of being beneficial to exchange transportation, good mechanical properties, and accelerated healing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

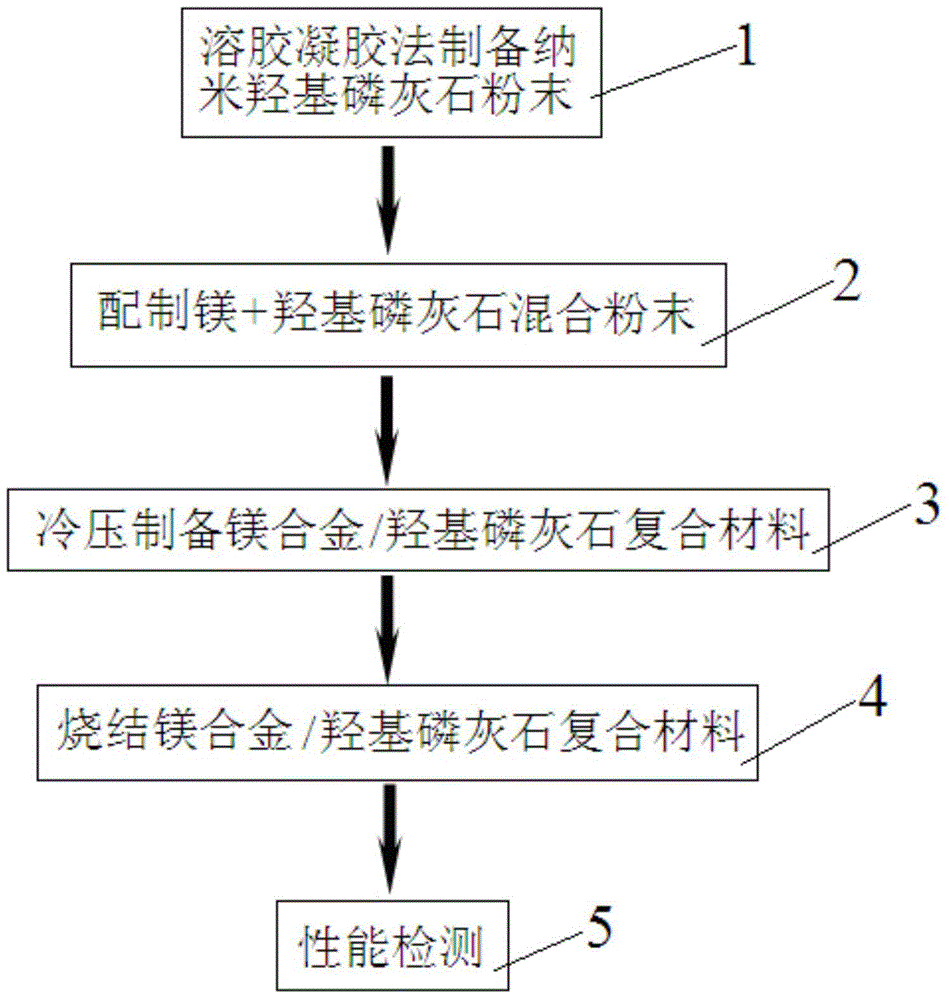

[0026] refer to figure 1 , the preparation of magnesium alloy / hydroxyapatite composite materials requires the following steps: 1. Preparation of nano-hydroxyapatite powder by sol-gel method; 2. Preparation of magnesium + hydroxyapatite powder; 3. Preparation of magnesium alloy / hydroxyapatite by cold pressing Limestone composite material; 4. Sintered magnesium alloy / hydroxyapatite composite material; 5. Performance testing. details as follows:

[0027] (1) Preparation of nano-hydroxyapatite powder: Ca(NO 3 ) 2 4H 2 O and P 2 o 5 Dissolve in ethanol solution with Ca / P (molar ratio) = 1.67, respectively prepare 1mol / L alcohol solution, P 2 o 5 Alcoholic solution was slowly added Ca(NO 3 ) 2 In the alcohol solution, heated in a water bath under the condition of slow magnetic stirring, the temperature is 60°C, and the time is about 2 hours, a colorless and transparent solution is obtained; the ammonia water is adjusted to pH = 11, and the stirring is continued; the aging t...

Embodiment 2

[0030] (1) Preparation of nano-hydroxyapatite powder: Ca(NO 3 ) 2 4H 2 O and P 2 o 5 Dissolve in ethanol solution with Ca / P (molar ratio) = 1.67, respectively prepare 1mol / L alcohol solution, P 2 o 5 Alcoholic solution was slowly added Ca(NO 3 ) 2 In the alcohol solution, heated in a water bath under the condition of slow magnetic stirring, the temperature was 60°C, and the time was about 2 hours to obtain a colorless and transparent solution; the ammonia water was adjusted to pH = 11, and the stirring was continued; standing still for aging treatment until the formation of Gel; put it in an oven, heat at 100°C until the alcohol is completely volatilized; grind the obtained white block into powder, and conduct vacuum heat treatment to crystallize at 800°C, keep it warm for 2 hours to obtain nano-hydroxyapatite powder .

[0031] (2) Preparation of magnesium alloy / hydroxyapatite composite material: in terms of mass fraction, after mixing evenly 80% magnesium powder and 2...

Embodiment 3

[0033] (1) Preparation of nano-hydroxyapatite powder: Ca(NO 3 ) 2 4H 2 O and P 2 o 5 Dissolve in ethanol solution with Ca / P (molar ratio) = 1.67, respectively prepare 1mol / L alcohol solution, P 2 o 5 Alcoholic solution was slowly added Ca(NO 3 ) 2 In the alcohol solution, heated in a water bath under the condition of slow magnetic stirring, the temperature was 60°C, and the time was about 2 hours to obtain a colorless and transparent solution; the ammonia water was adjusted to pH = 11, and the stirring was continued; standing still for aging treatment until the formation of Gel; put it in an oven, heat at 100°C until the alcohol is completely volatilized; grind the obtained white block into powder, and conduct vacuum heat treatment to crystallize at 800°C, keep it warm for 2 hours to obtain nano-hydroxyapatite powder .

[0034] (2) Preparation of magnesium alloy / hydroxyapatite composite material: in terms of mass fraction, after mixing 90% magnesium powder and 10% nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com