A kind of preparation method of magnesium alloy/hydroxyapatite composite material

A technology of hydroxyapatite and nano-hydroxyapatite, which is applied in surgical adhesives, medical science, prostheses, etc., can solve the problem of uneven composition and structure of magnesium alloy-hydroxyapatite composite materials, affecting performance uniformity, Inhomogeneous structure and other problems, to achieve the effect of facilitating exchange and transportation, good mechanical properties, and improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

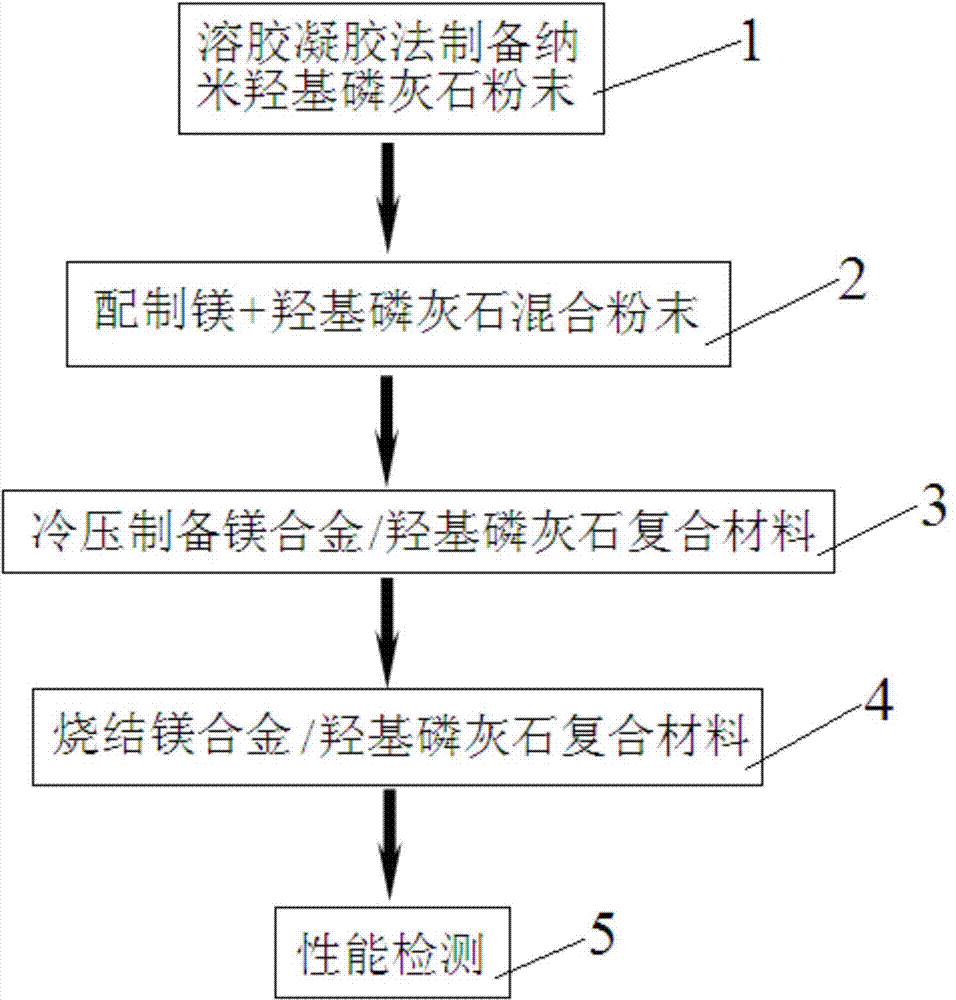

[0026] refer to figure 1 , the preparation of magnesium alloy / hydroxyapatite composite materials requires the following steps: 1. Preparation of nano-hydroxyapatite powder by sol-gel method; 2. Preparation of magnesium + hydroxyapatite powder; 3. Preparation of magnesium alloy / hydroxyapatite by cold pressing Limestone composite material; 4. Sintered magnesium alloy / hydroxyapatite composite material; 5. Performance testing. details as follows:

[0027] (1) Preparation of nano-hydroxyapatite powder: Ca(NO 3 ) 2 4H 2 O and P 2 o 5 Dissolve in ethanol solution with Ca / P (molar ratio) = 1.67, respectively prepare 1mol / L alcohol solution, P 2 o 5 Alcoholic solution was slowly added Ca(NO 3 ) 2 In the alcohol solution, heated in a water bath under the condition of slow magnetic stirring, the temperature is 60°C, and the time is about 2 hours, a colorless and transparent solution is obtained; the ammonia water is adjusted to pH = 11, and the stirring is continued; the aging t...

Embodiment 2

[0030] (1) Preparation of nano-hydroxyapatite powder: Ca(NO 3 ) 2 4H 2 O and P 2 o 5 Dissolve in ethanol solution with Ca / P (molar ratio) = 1.67, respectively prepare 1mol / L alcohol solution, P 2 o 5 Alcoholic solution was slowly added Ca(NO 3 ) 2 In the alcohol solution, heated in a water bath under the condition of slow magnetic stirring, the temperature was 60°C, and the time was about 2 hours to obtain a colorless and transparent solution; the ammonia water was adjusted to pH = 11, and the stirring was continued; standing still for aging treatment until the formation of Gel; put it in an oven, heat at 100°C until the alcohol is completely volatilized; grind the obtained white block into powder, and conduct vacuum heat treatment to crystallize at 800°C, keep it warm for 2 hours to obtain nano-hydroxyapatite powder .

[0031] (2) Preparation of magnesium alloy / hydroxyapatite composite material: in terms of mass fraction, after mixing evenly 80% magnesium powder and 2...

Embodiment 3

[0033] (1) Preparation of nano-hydroxyapatite powder: Ca(NO 3 ) 2 4H 2 O and P 2 o 5 Dissolve in ethanol solution with Ca / P (molar ratio) = 1.67, respectively prepare 1mol / L alcohol solution, P 2 o 5 Alcoholic solution was slowly added Ca(NO 3 ) 2 In the alcohol solution, heated in a water bath under the condition of slow magnetic stirring, the temperature was 60°C, and the time was about 2 hours to obtain a colorless and transparent solution; the ammonia water was adjusted to pH = 11, and the stirring was continued; standing still for aging treatment until the formation of Gel; put it in an oven, heat at 100°C until the alcohol is completely volatilized; grind the obtained white block into powder, and conduct vacuum heat treatment to crystallize at 800°C, keep it warm for 2 hours to obtain nano-hydroxyapatite powder .

[0034] (2) Preparation of magnesium alloy / hydroxyapatite composite material: in terms of mass fraction, after mixing 90% magnesium powder and 10% nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com