Coating capable of improving surface corrosion resistance and biocompatibility of medical magnesium and magnesium alloy and preparing method of coating

A biocompatible, magnesium alloy technology, used in coatings, electrolytic coatings, medical science, etc., can solve the problems of inappropriate phosphating methods and poor degradability, and achieve tight arrangement, increased self-corrosion potential, and corrosion resistance. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a coating for improving the corrosion resistance and biocompatibility of medical magnesium and magnesium alloys, comprising the following steps:

[0030] (1) Pretreatment of the base material: Cut the Mg-Zn-Ca alloy to be treated into a rectangular block of 25mm×10mm×4mm, use it as the base material, and use 100#, 200#, 400#, 600# and 800# #Metallographic sandpaper mechanically polish the surface in turn, and perform ultrasonic cleaning (frequency 40kHz) for 10 minutes in a mixed solution of absolute ethanol / acetone with a volume ratio of 1:1 to remove surface stains, and then air dry naturally after taking it out;

[0031] (2) Configure the electrolyte: mix Ca(NO 3 ) 2 4H 2 O, Zn(NO 3 ) 2 ·6H 2 O, NH 4 h 2 PO 4 and NaNO 3 Dissolved in water to prepare electrolyte, and the concentration of each component in the electrolyte is: Ca(NO 3 ) 2 4H 2 O40mmol / L, Zn(NO 3 ) 2 ·6H 2 O2mmol / L, NH 4 h 2 PO 4 28mmol / L, NaNO 3 0.1mol / L;

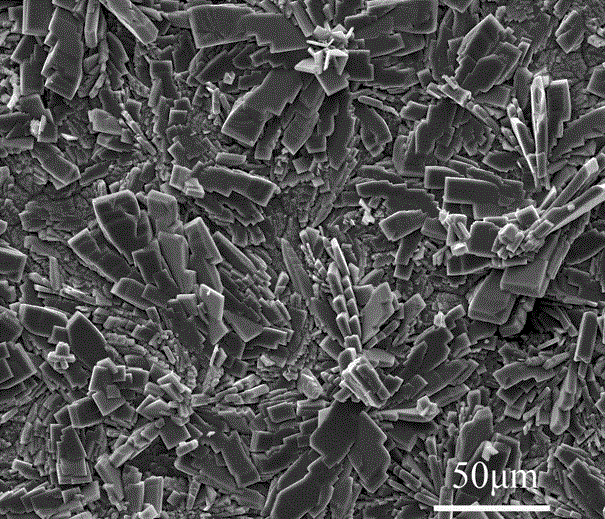

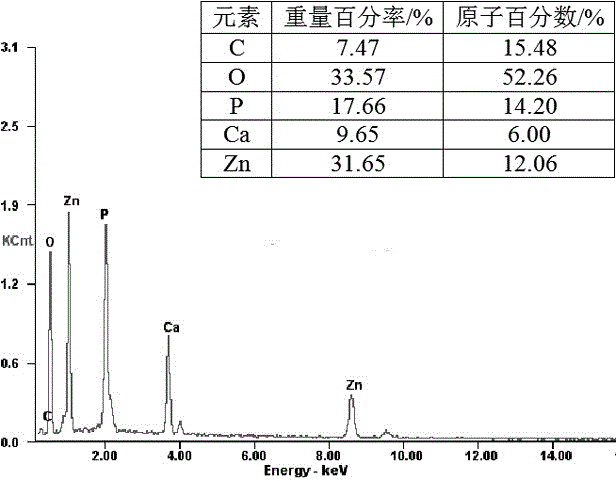

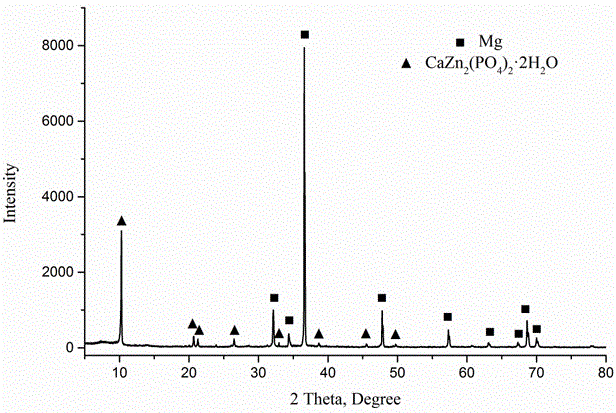

[00...

Embodiment 2

[0038] A method for preparing a coating for improving the corrosion resistance and biocompatibility of medical magnesium and magnesium alloys, comprising the following steps:

[0039] (1) Pretreatment of the base material: Cut the Mg-Zn-Y-Nd alloy to be treated into a rectangular block of 25mm×10mm×4mm, use it as the base material, use 100#, 200#, 400#, 600# Mechanically polish the surface with 800# metallographic sandpaper in sequence, and perform ultrasonic cleaning (frequency 40kHz) for 10 minutes in a mixed solution of absolute ethanol / acetone with a volume ratio of 1:1 to remove surface stains, and then air dry naturally after taking it out;

[0040] (2) Configure the electrolyte: mix Ca(NO 3 ) 2 , Zn(H 2 PO 4 ) 2 2H 2 O, NaH 2 PO 4 and NaNO 3 Dissolved in water to prepare electrolyte, and the concentration of each component in the electrolyte is: anhydrous Ca(NO 3 ) 2 30mmol / L, Zn(H 2 PO 4 ) 2 2H 2 O0.8mmol / L, NaH 2 PO 4 15mmol / L, NaNO 3 0.1mol / L;

[00...

Embodiment 3

[0045] A method for preparing a coating for improving the corrosion resistance and biocompatibility of medical magnesium and magnesium alloys, comprising the following steps:

[0046] (1) Pretreatment of the substrate material: Cut the AZ31 alloy to be processed into a rectangular block of 25mm×10mm×4mm, use it as the substrate material, and use 100#, 200#, 400#, 600# and 800# metallographic sandpaper The surface is mechanically polished in turn, and ultrasonically cleaned (frequency 40kHz) for 10 minutes in a mixed solution of absolute ethanol / acetone with a volume ratio of 1:1 to remove surface stains, and then air-dried naturally after taking it out;

[0047] (2) Configure the electrolyte: mix Ca(NO 3 ) 2 4H 2 O, Zn(NO 3 ) 2 ·6H 2 O, NaH 2 PO 4 and NaNO 3 Dissolved in water to prepare electrolyte, and the concentration of each component in the electrolyte is: Ca(NO 3 ) 2 4H 2 O50mmol / L, Zn(NO 3 ) 2 ·6H 2 O8mmol / L, NaH 2 PO 4 27mmol / L, NaNO 3 0.5mol / L.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com