Method for improving corrosion resistance of magnesium alloy by adopting nitrogen doped graphene quantum dot coating

A technology of graphene quantum dots and magnesium alloys, applied in metal material coating process, electrolytic inorganic material coating, etc., can solve the problems of poor anti-corrosion effect on the surface of magnesium alloys, and achieve simple operation steps and equipment requirements, easy to implement , Improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Preprocessing, the steps are as follows:

[0019] The AZ31 magnesium alloy was ground with sandpaper, polished, ultrasonically cleaned, rinsed with distilled water, and ultrasonically cleaned with absolute ethanol for 10 minutes.

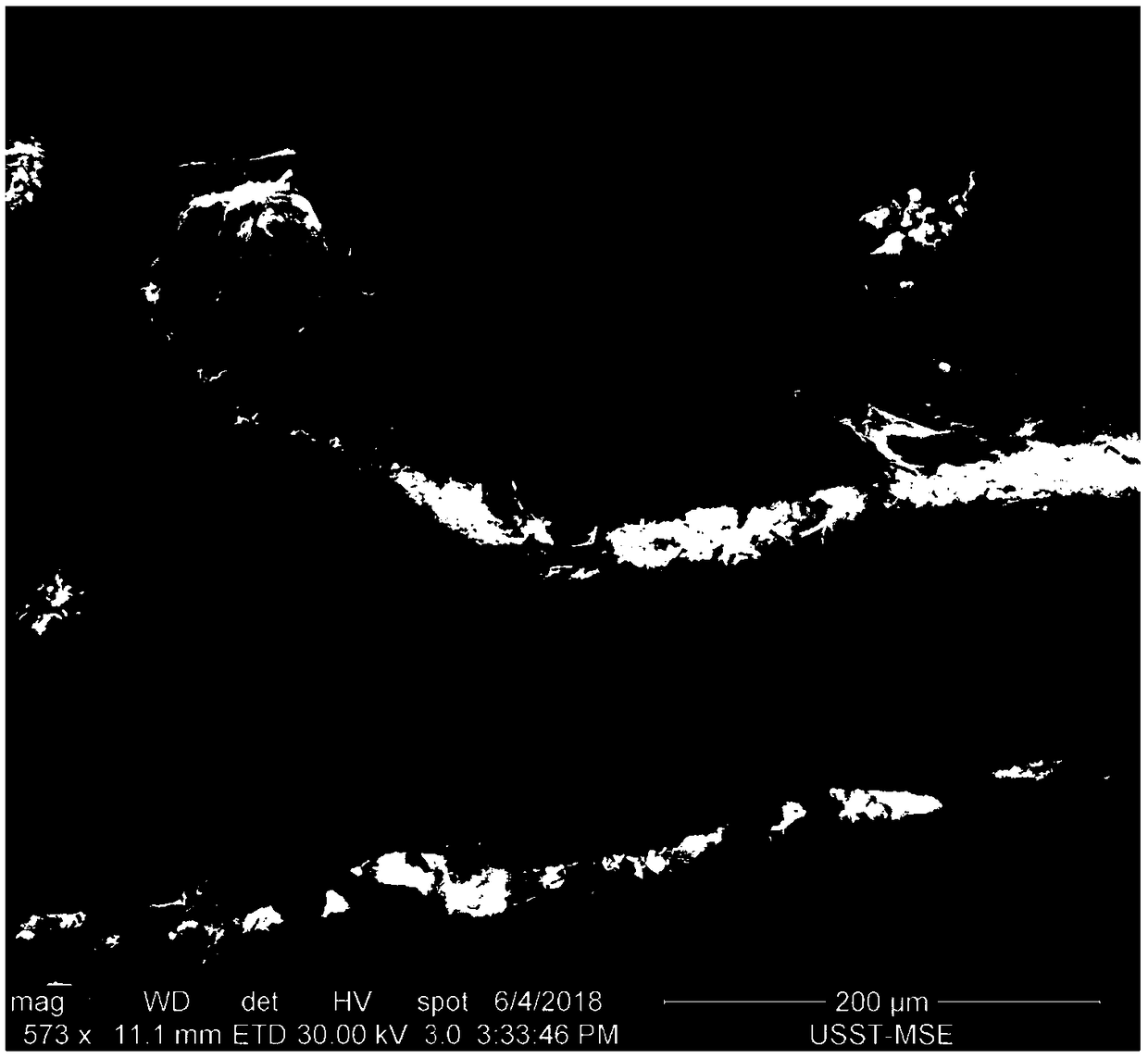

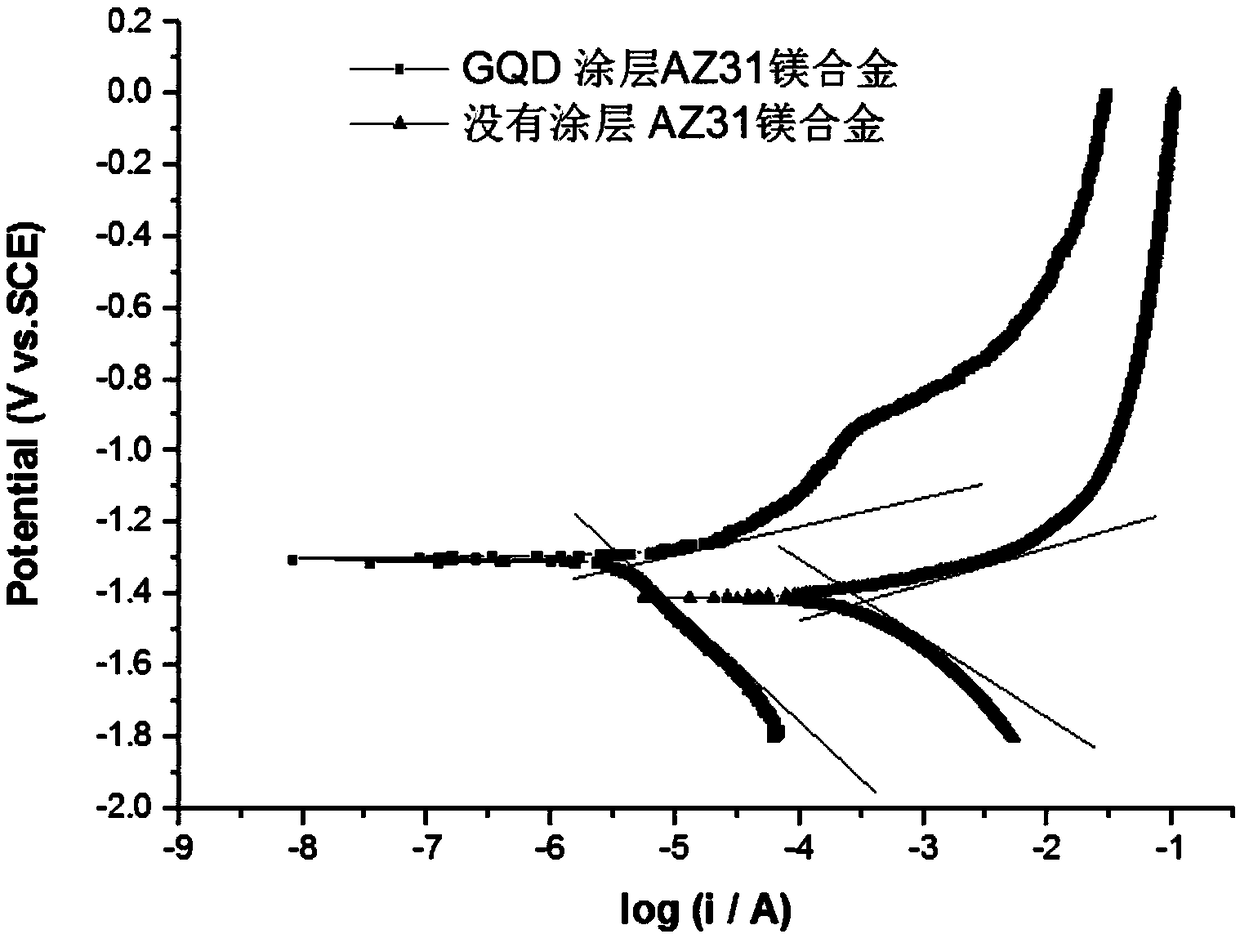

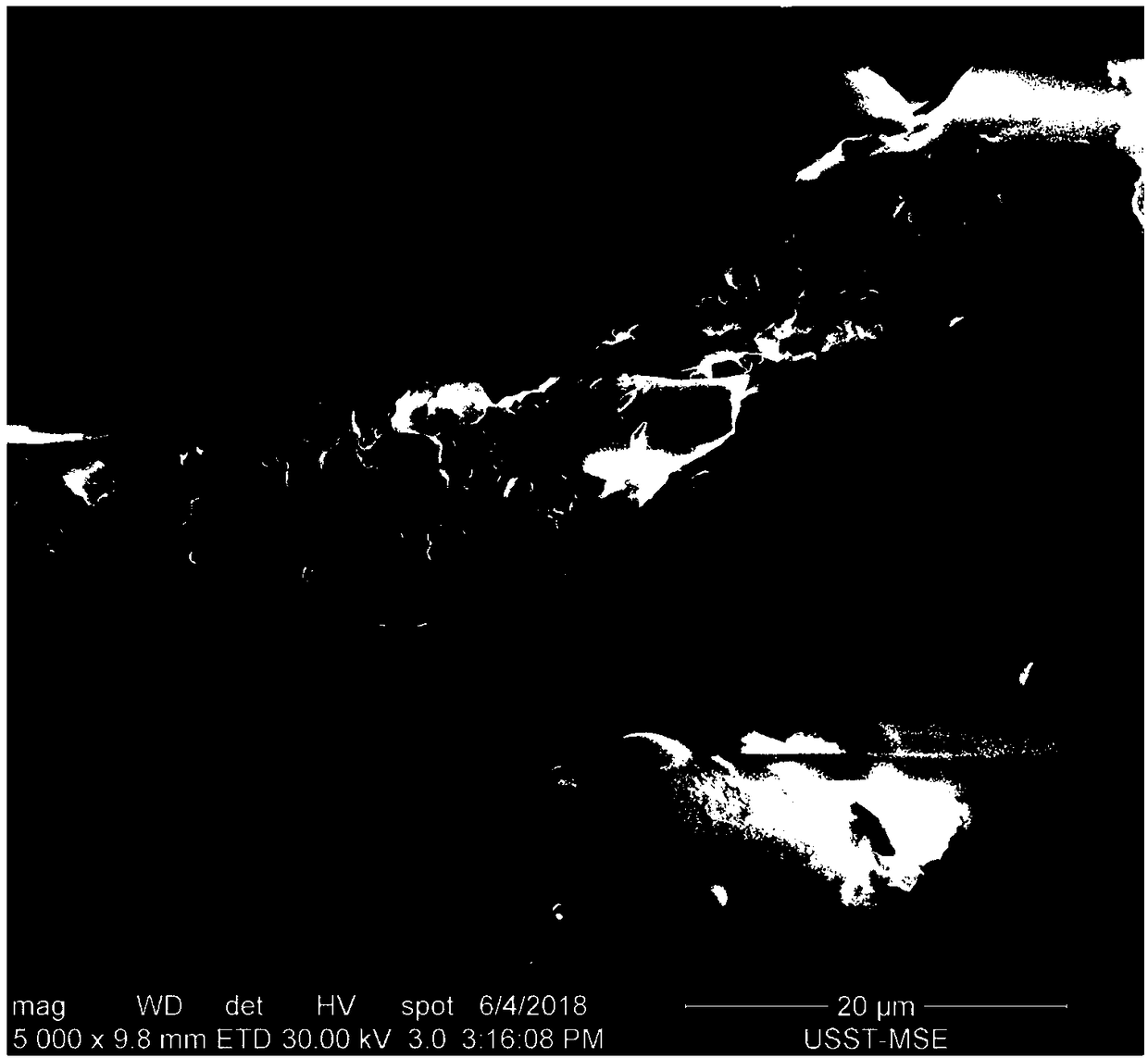

[0020] 2) Electrodeposition of nitrogen-doped graphene quantum dot coating:

[0021] A CHI860D electrochemical workstation was used to assemble a three-electrode system, the AZ31 magnesium alloy pretreated in step 1) was used as the working electrode, the platinum electrode was used as the auxiliary electrode, and the saturated calomel electrode was used as the reference electrode. Take 100ml of 10mg / mL nitrogen-doped graphene quantum dot solution, carry out ultrasonic dispersion for 30 minutes and use it as electrolyte solution. Select the constant current method, the current is 0.26A, and the electrodeposition time is 10 minutes. After electrochemical deposition, the AZ31 magnesium alloy was taken out and placed in a space to dry for 1...

Embodiment 2

[0026] 1) Preprocessing, the steps are as follows:

[0027] The sample material used in Example 2 was AZ31 magnesium alloy, which was ground, polished, and ultrasonically cleaned with 2000# sandpaper, then rinsed with distilled water, and ultrasonically cleaned with absolute ethanol for 15 minutes.

[0028] 2) Electrodeposition of nitrogen-doped graphene quantum dot coating:

[0029] Use the CHI860D electrochemical workstation to assemble a three-electrode system. The AZ31 magnesium alloy pretreated in step 1) is used as the working electrode, the platinum electrode is used as the auxiliary electrode, and the saturated calomel electrode is used as the reference electrode. Take 10 mg / mL nitrogen-doped 100ml of graphene quantum dot solution was used as electrolyte solution after ultrasonic dispersion for 30 minutes. Select the constant current method, the current is 0.20A, and the electrodeposition time is 8 minutes. After electrochemical deposition, the AZ31 magnesium alloy w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com