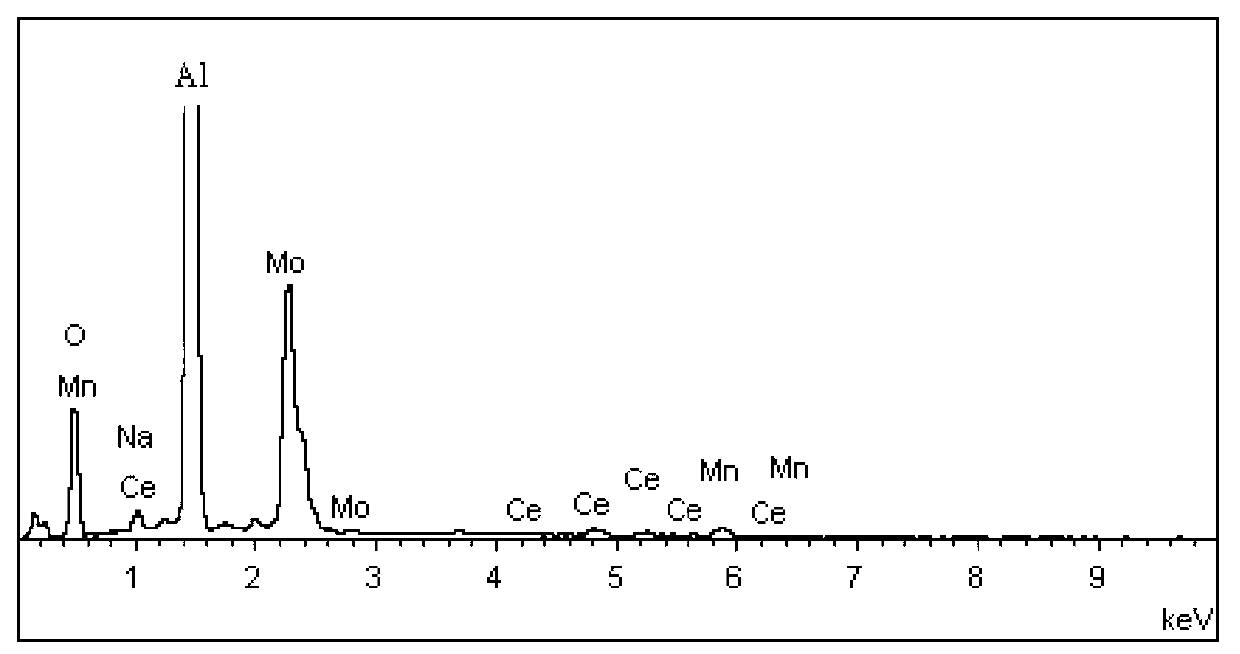

Method for preparing cerium-manganese/molybdenum multi-element composite conversion coating on surface of aluminum alloy

An aluminum alloy surface, multi-component composite technology, applied in the direction of metal material coating process, etc., can solve the problems of insufficient corrosion resistance of the film layer and insufficient stability of the passivation solution, and achieve simple composition, good bonding force, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] In this embodiment, the method for preparing a cerium-manganese / molybdenum multi-component composite conversion film on the surface of an aluminum alloy includes the following steps:

[0062] (1) Sample preparation: online cutting from 6063 aluminum alloy profiles (thickness 4mm), cut out 40×40mm samples, punch holes in the corners of each sample, and use SiC water sandpaper to polish the aluminum alloy surface to 1500#, rinse it with deionized water, dry it with a hair dryer, and hang it with a thin wire at the hole;

[0063] (2) Pre-treatment activation: put the aluminum alloy in industrial acid at 30°C for surface degreasing, soak for 3 minutes, wash the surface of the alloy with deionized water, then place it in mixed acid at 30°C for 1 minute, and then use deionized Rinse with water and dry with a hair dryer for later use. The composition of industrial acid is 100g / L sulfuric acid + 20mL / L phosphoric acid + 0.3g / LOP-10 + 6mL / L hydrofluoric acid, and the compositio...

Embodiment 2

[0076] In this embodiment, the method for preparing a cerium-manganese / molybdenum multi-component composite conversion film on the surface of an aluminum alloy includes the following steps:

[0077] (1) Sample preparation: online cutting from 6063 aluminum alloy profiles (thickness 4mm), cut out 40×40mm samples, punch holes in the corners of each sample, and use SiC water sandpaper to polish the aluminum alloy surface to 1500#, rinse it with deionized water, dry it with a hair dryer, and hang it with a thin wire at the hole;

[0078] (2) Pre-treatment activation: put the aluminum alloy in industrial acid at 20°C for surface degreasing, soak for 8 minutes, wash the surface of the alloy with deionized water, then place it in a mixed acid at 20°C for 3 minutes, and then use deionized Rinse with water and dry with a hair dryer for later use. Every liter of industrial acid contains 60g of sulfuric acid, 10mL of phosphoric acid, 0.1g of OP-10 and 1mL of hydrofluoric acid; the mixed...

Embodiment 3

[0084]In this embodiment, the method for preparing a cerium-manganese / molybdenum multi-component composite conversion film on the surface of an aluminum alloy includes the following steps:

[0085] (1) Sample preparation: online cutting from 6063 aluminum alloy profiles (thickness 4mm), cut out 40×40mm samples, punch holes in the corners of each sample, and use SiC water sandpaper to polish the aluminum alloy surface to 1500#, rinse it with deionized water, dry it with a hair dryer, and hang it with a thin wire at the hole;

[0086] (2) Pre-treatment activation: put the aluminum alloy in industrial acid at 35°C for surface degreasing, soak for 1 min, wash the surface of the alloy with deionized water, then place it in mixed acid at 35°C for 0.5 min, and then use Rinse with ionized water and dry with a hair dryer for later use. Every liter of industrial acid contains 200g of sulfuric acid, 30mL of phosphoric acid, 1.0g of OP-10 and 12mL of hydrofluoric acid; the mixed acid con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Self-corrosion current density | aaaaa | aaaaa |

| Self-corrosion current density | aaaaa | aaaaa |

| Self-corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com