Corrosion resistant film prepared by magnesium alloy surface hydrothermal method and preparation technology thereof

A technology of magnesium alloy and surface water, which is applied in the coating process of metal materials, etc., to achieve the effects of easy control of process parameters, rapid film formation and strong affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Select the magnesium alloy material: AZ31 magnesium alloy bar, as cast, and then cut it into 25mm×25mm×5mm samples, which are successively polished, tap water cleaning, alkali cleaning, water washing, pickling, water cleaning, hot air drying, and preservation Steps for preprocessing;

[0061] The treatment solution selected in this embodiment is the NaOH of 40g / L, the LiCl of 240g / L, and the filling degree is 50%;

[0062] Put the cleaned magnesium alloy sample into a hydrothermal reaction kettle with a polytetrafluoroethylene liner, then inject the above-mentioned treatment liquid into the reaction kettle, seal the reaction kettle, and place the reaction kettle at a temperature of 120°C. In the drying oven, after keeping warm for 2h, 4h, and 6h, take out the reaction kettle, put it in cold water to cool, open the reaction kettle, take out the sample, wash it with distilled water and dry it, and measure its corrosion potential and corrosion current density respectively....

Embodiment 2

[0066] The difference from Example 1 is:

[0067] The treatment liquid is 40g / L NaOH, 120g / L LiCl, and the filling degree is 70%;

[0068] Put the cleaned magnesium alloy sample into a hydrothermal reaction kettle with a polytetrafluoroethylene inner liner, then inject the above-mentioned treatment liquid into the reaction kettle, seal the reaction kettle, and place the reaction kettle at a temperature of 120°C, In a drying oven at 140°C and 160°C, keep warm for 4 hours; take out the reaction kettle, put it in cold water to cool, open the reaction kettle, take out the sample, wash it with distilled water and dry it, and measure its corrosion potential and corrosion current density respectively. The results are shown in the table 2.

[0069] Table 2

[0070]

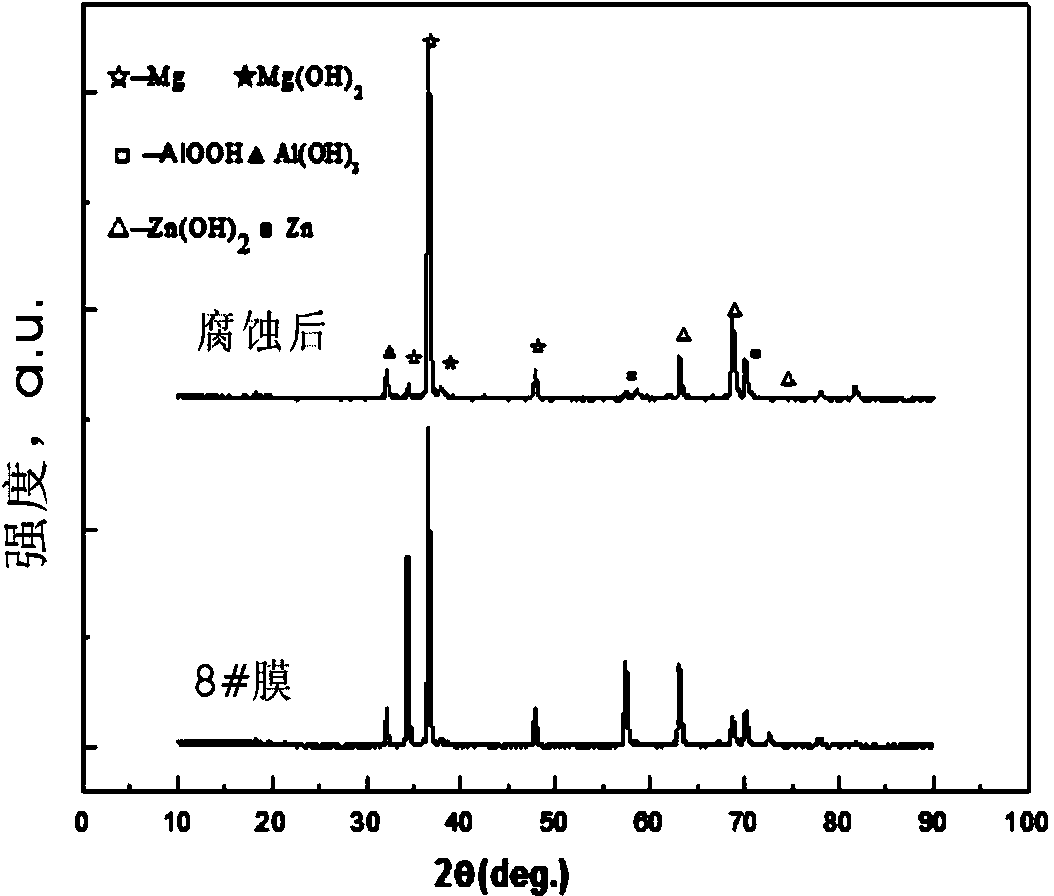

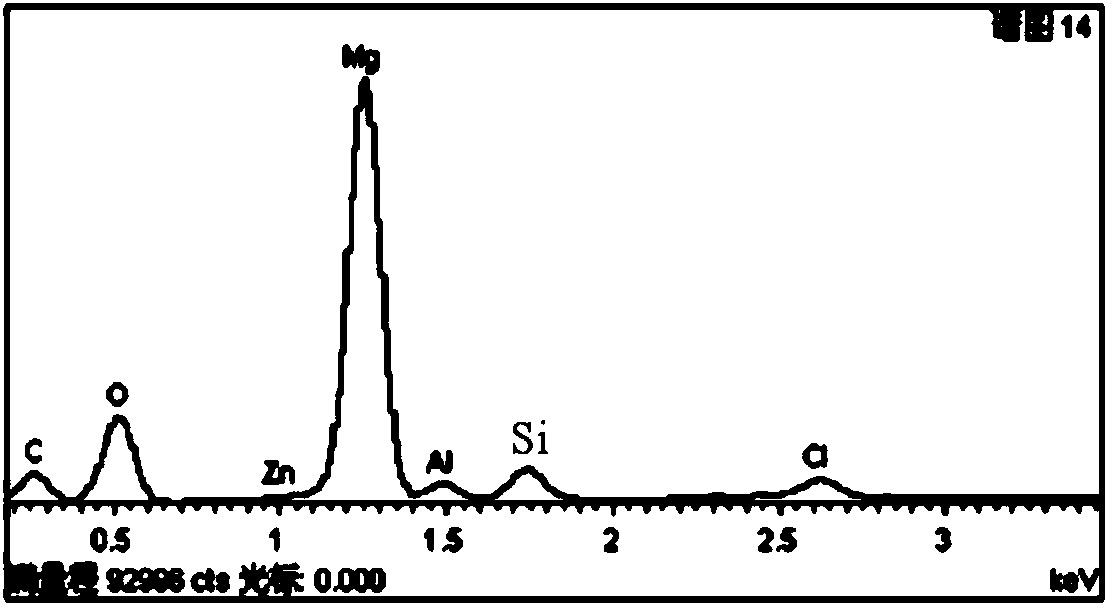

[0071] The XRD diagrams before and after corrosion of this embodiment are as follows figure 1 , indicating that the composition of the membrane contains Mg(OH) 2 , Al(OH) 3 and Zn(OH) 2 .

[0072] The SEM topogr...

Embodiment 3

[0074] The difference from Example 1 is:

[0075] The treatment liquid is 40g / L NaOH and 0g / L LiCl, 40g / L NaOH and 60g / L LiCl, 40g / L NaOH and 120g / L LiCl, and the filling degree is 70%;

[0076] Put the cleaned magnesium alloy sample into a hydrothermal reaction kettle with a polytetrafluoroethylene inner liner, then inject the above-mentioned treatment liquid into the reaction kettle, and seal the reaction kettle. Place the reaction kettle in a drying oven at 160°C and keep it warm for 4 hours; take out the reaction kettle, put it in cold water to cool, open the reaction kettle, take out the sample, wash it with distilled water and dry it, and measure its corrosion potential and corrosion current density respectively. as shown in Table 3.

[0077] table 3

[0078]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com