Rare earth high-entropy alloy material with high saturation magnetization and preparation method thereof

A magnetization, high-entropy alloy technology, applied in magnetic materials, magnetic objects, electrical components, etc., can solve problems such as unfavorable high saturation magnetization, and achieve the effects of low equipment cost, simple preparation method, and simple sample matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method of a GdTbHoEr high saturation magnetization material, comprising the following steps:

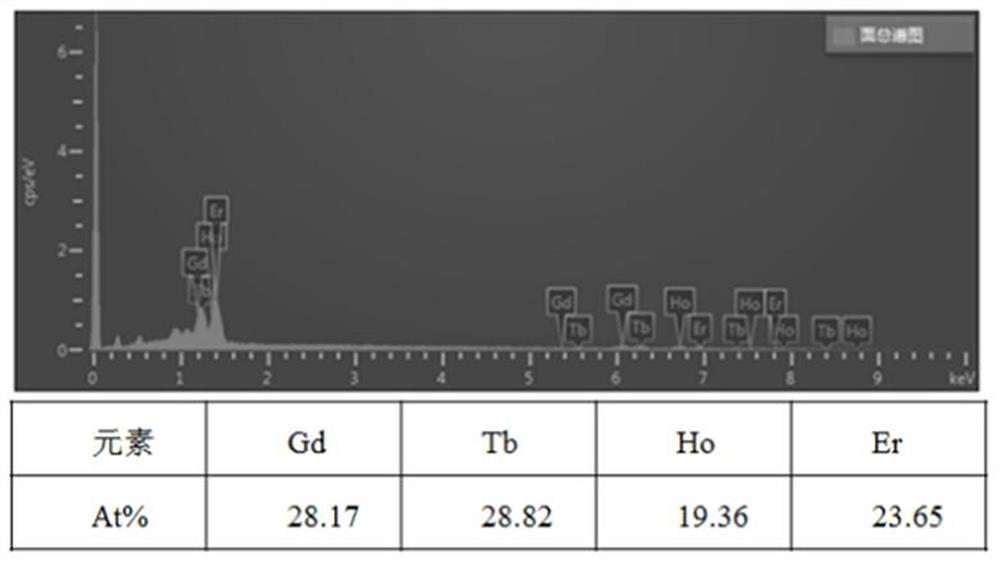

[0049] According to the chemical formula of GdTbHoEr, the raw materials Gd, Tb, Ho and Er were weighed, and the prepared samples were prepared into high-entropy alloy GdTbHoEr by vacuum arc melting.

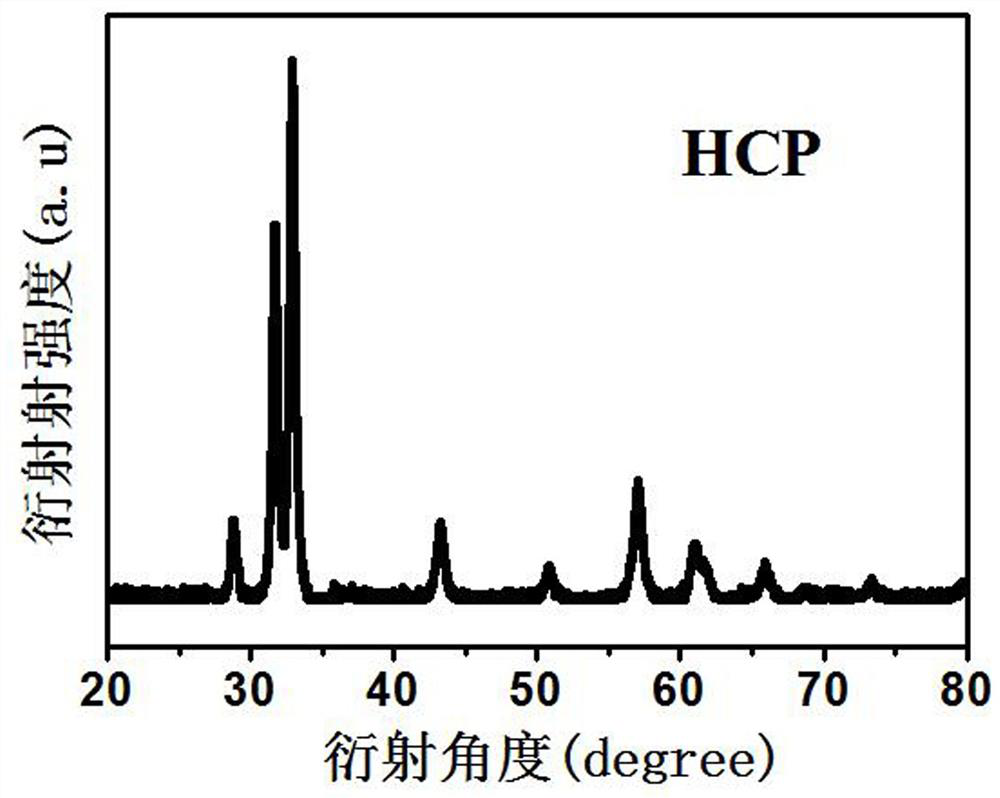

[0050] In order to detect the composition structure of the sample, an X-ray diffraction test was carried out, and the test results are as follows: figure 1 As shown, the GdTbHoEr material has a hexagonal close-packed single-phase crystal structure.

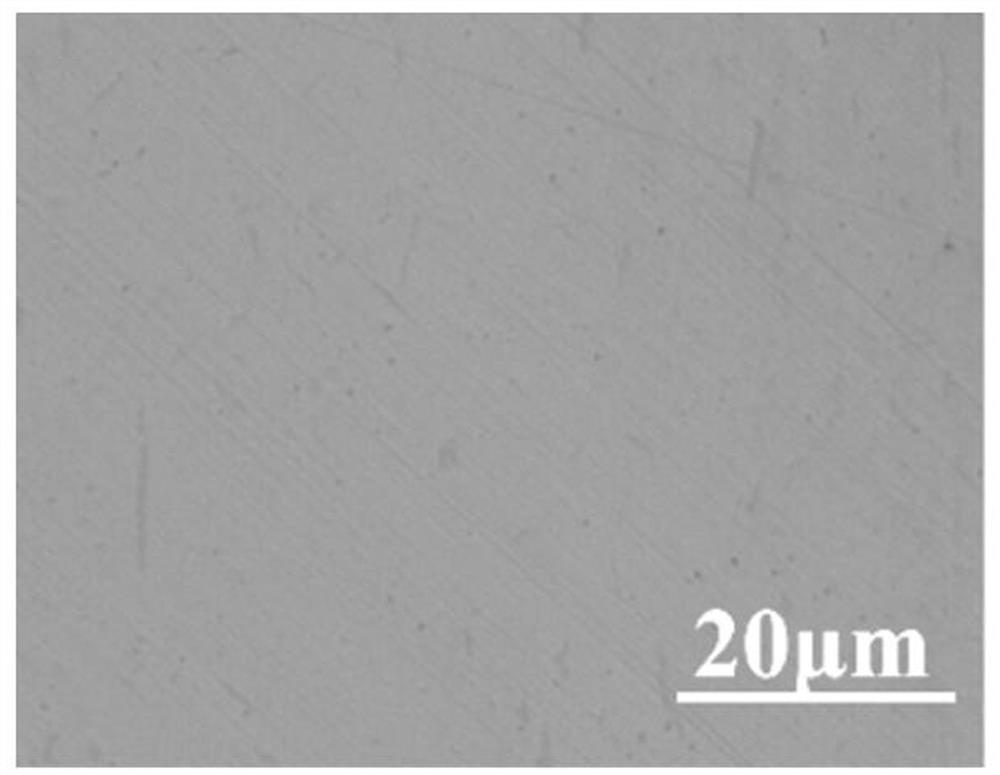

[0051] In order to verify that the sample has a single-phase structure, a metallographic test is carried out. The specific method is to grind out the metallographic phase after slicing the sample, and observe the metallographic phase with a scanning electron microscope (SEM). The test results are as follows figure 2 As shown, the SEM picture shows that there is only one phase structure in the sample.

[0052] In orde...

Embodiment 2

[0071] A preparation method of a GdTbHoEr material with high saturation magnetization, the unexplained steps are the same as those in Example 1, except that La element is added on the basis of GdTbHoEr.

[0072] The magnetic properties of the resulting GdTbHoErLa, as Figure 14 As shown, the saturation magnetization at 7K is 189.8 emu / g, and the coercive force is 1473 Oe.

[0073] The magnetization of the resulting GdTbHoErLa varies with temperature as Figure 16 As shown, the magnetic transition temperature is about 127K.

Embodiment 3

[0075] A preparation method of a GdTbHoEr material with high saturation magnetization, the unexplained steps are the same as those in Example 1, except that two elements La and Y are added to GdTbHoEr.

[0076] The magnetic properties of the resulting GdTbHoErLaY, as Figure 15 As shown, the saturation magnetization at 7K is 176.1 emu / g, and the coercive force is 1706 Oe.

[0077] The magnetization of the resulting GdTbHoErLaY varies with temperature as Figure 17 As shown, the magnetic transition temperature is about 120K.

[0078] By contrasting Example 1, Example 2 and 3, the following conclusions can be obtained:

[0079] 1. Adding La and Y to the high-entropy alloy GdTbHoEr as the matrix can control the magnetic transition temperature of the alloy in the range of 190K to 120K;

[0080] 2. Adding La and Y to the high-entropy alloy GdTbHoEr as the matrix can control the coercive force of the alloy in the range of 600 Oe to 1706 Oe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com