Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Improve impact and wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-toughness high-boron medium-chrome low-carbon wear-resisting alloy steel and preparation method thereof

The invention relates to a high-toughness high-boron medium-chrome low-carbon wear-resisting alloy steel and a preparation method thereof. The high-toughness high-boron medium-chrome low-carbon wear-resisting alloy steel comprises the following chemical components by weight percentage: 0.20-0.5% of C, 5-12% of Cr, 0.5-1.2% of Si, 3.5-5.5% of Mn, 0.3-2.8% of B, 0.3-2.1% of Cu, 0.2-0.5% of Ti, 0.05-0.25% of Ca, 0.03-0.3% of Ce, 0.02-0.18% of N, 0.05-0.3% of Nb, 0.04-0.09% of Al, 0.1-0.5% of SiMgRe, 0.04-0.13% of K, less than 0.03% of S, less than 0.04% of P and the balance of Fe and inevitable impurity elements. The preparation method comprises the following steps of: adding a copper plate, silicon iron and ferromanganese iron after steel scrap and chromium iron are melted; after the component adjustment before furnace is qualified, increasing the temperature of the melt to 1560-1620 DEG C, adding a calcium-silicon alloy and aluminum for deoxidation, and orderly adding ferrotitanium and ferroboron, melting, and then discharging; putting a composite inoculant composed of granular rare-earth magnesium alloy with granule size being less than 12mm, metal cerium, Si3N4, VN, Nb and K at the bottom of a steel ladle after baking, and performing inoculation treatment on the molten steel by a rush-into-ladle method, wherein the casting temperature of the molten steel ranges from 1400 DEG C to 1450 DEG C; preserving the heat of castings for 4-6 hours at 700-780 DEG C, and then carrying out subcritical air quenching to obtain the alloy steel.

Owner:丁家伟

Impact-resistant anti-wear agent for hydraulic concrete

The invention provides an impact-resistant and anti-wear agent for hydraulic concrete, which mainly comprises a nano material, slag, latex powder, rubber powder, a water reducing agent, fibers, an exciting agent and a defoaming agent. The impact-resistant anti-wear agent is suitable for places such as water conservancy projects, roads and airport pavements requiring high impact-resistant and anti-wear concrete, has the functions of resisting crack, reducing water, reinforcing and reducing elasticity, and excellent mixing and constructing properties. The impact-resistant and anti-wear agent has the advantages of increasing concrete impact-resistant and anti-wear properties, prolonging maintenance period and reducing maintenance cost.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE +1

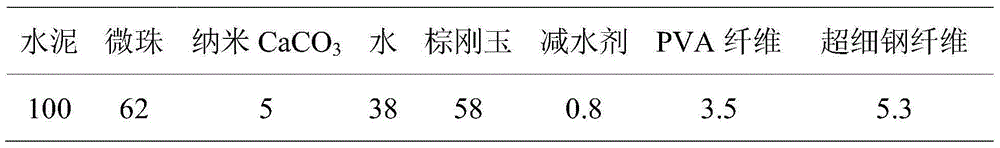

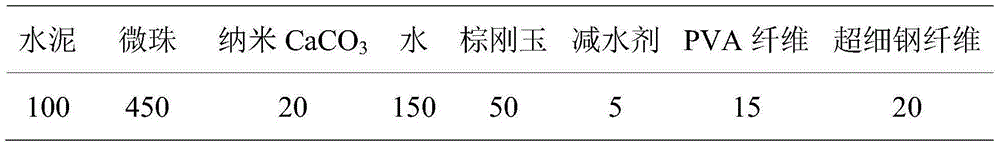

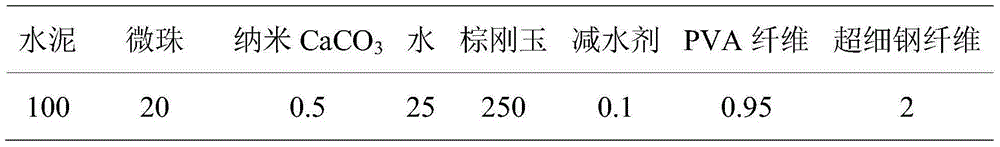

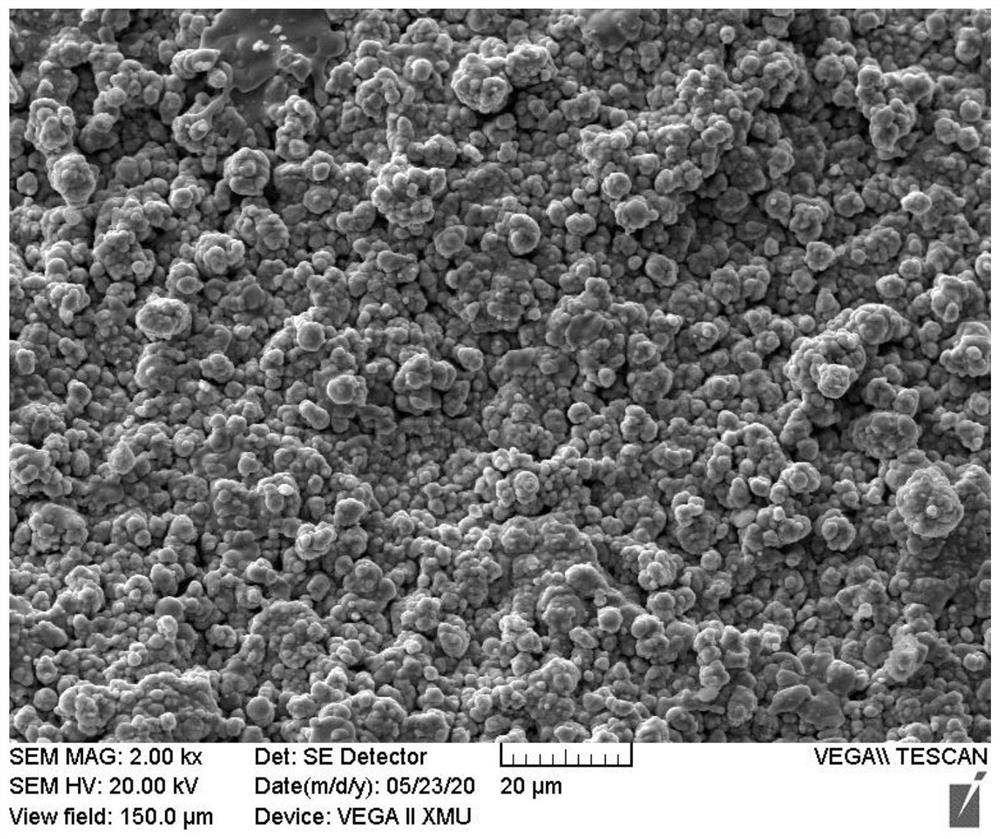

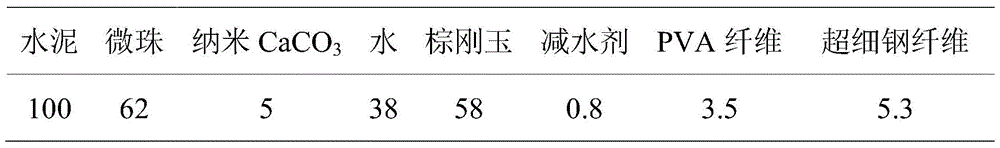

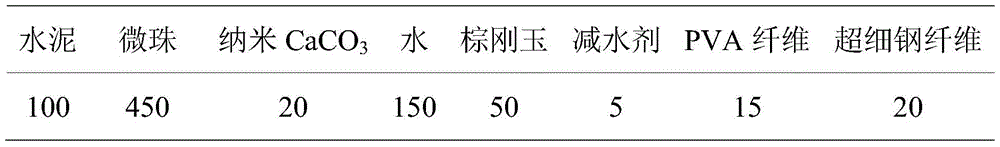

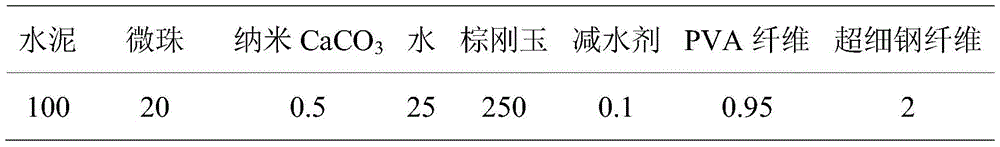

High-ductility cement-based material for repairing hydraulic outlet works, and preparation method thereof

The invention discloses a high-ductility cement-based material for repairing hydraulic outlet works, and a preparation method thereof. The material comprises, by weight, 100 parts of cement, 25-150 parts of water, 50-250 parts of brown fused alumina, 20-450 parts of microspheres, 0.5-20 parts of nano-CaCO3, 0.1-5 parts of a water reducer, 0.95-15 parts of PVA fibers and 2-20 parts of ultrafine steel fibers. The high-ductility cement-based material for repairing hydraulic outlet works has the advantages of high impact and wear strength, high bonding strength with a matrix, high ductility, similar thermal expansion coefficient with concrete, consistence with deformation of the matrix concrete, simple and convenient construction process, and wide sources of raw materials.

Owner:SOUTHEAST UNIV

Process for preparing rare earth modified carbon nanotube/polyimide composite materials

The invention relates to a method for preparation of rare earth-modified carbon nano-tube / polyimide composite, which consists of performing mat-forming treatment of modifying property to carbon nano-tube adopting rare earth modifier first, then laying the disposed carbon nano-tube into the ball grinder to mill, afterwards, mechanically blending the carbon nano-tube and the polyimide powder and controlling the percentage by weight of the carbon nano-tube to occupy 1-10 % of the mixed powder, then laying the mixed powder into the stainless steel die for press forming, finally preparing the composite by high-sintering. Thereinto, the rare earth modifier consists of rare-earth compound, alcohol, ethylene diamine tetraacetic acid, ammonii chloridum, aqua fortis and aquacare. The invention is of simple technique and low cost, is non-contamination, and the prepared composite possess good dynamic property and frictional behavior.

Owner:SHANGHAI JIAO TONG UNIV

High manganese steel containing tungsten

The invention discloses a high manganese steel which contains tungsten, and the high manganese steel contains chemical constituents in the following mass percent: C: 1.05%-1.35%, Si: 0.3%-0.9%, Mn: 11%-19%, W: 0.5%-1.5%, P<=0.070% and S<=0.045%, and the rest is Fe, furthermore, the high manganese steel also can contain a rare earth element RE, and the content of the RE is 0.01%-0.3%. The high manganese steel also can contain Cr and the content of the Cr is 1.2-2.5%. The high manganese steel which contains the tungsten of the invention is added with the elements of tungsten, rare earth element RE and chrome in particular when the content of the Mn is 16%-19%, which enables the whole high manganese steel to have the advantages of good toughness, high yield strength, high work hardening degree, better abrasive resistance and the like compared with the existing steel, and thereby the application range of the high manganese steel is enlarged. The high manganese steel of the invention is suitable for preparing fitting parts which are used in the working condition of abrasion and in particular to impact abrasion.

Owner:JINAN UNIVERSITY

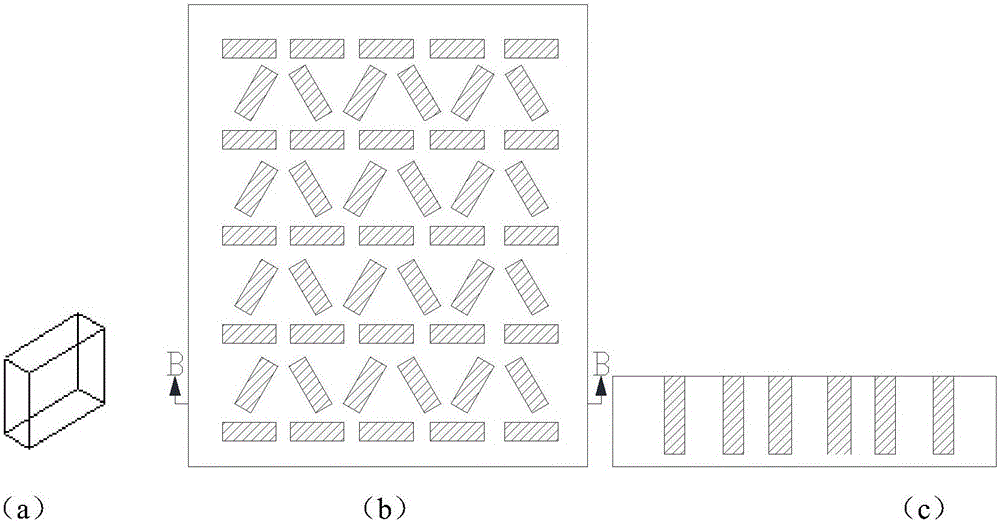

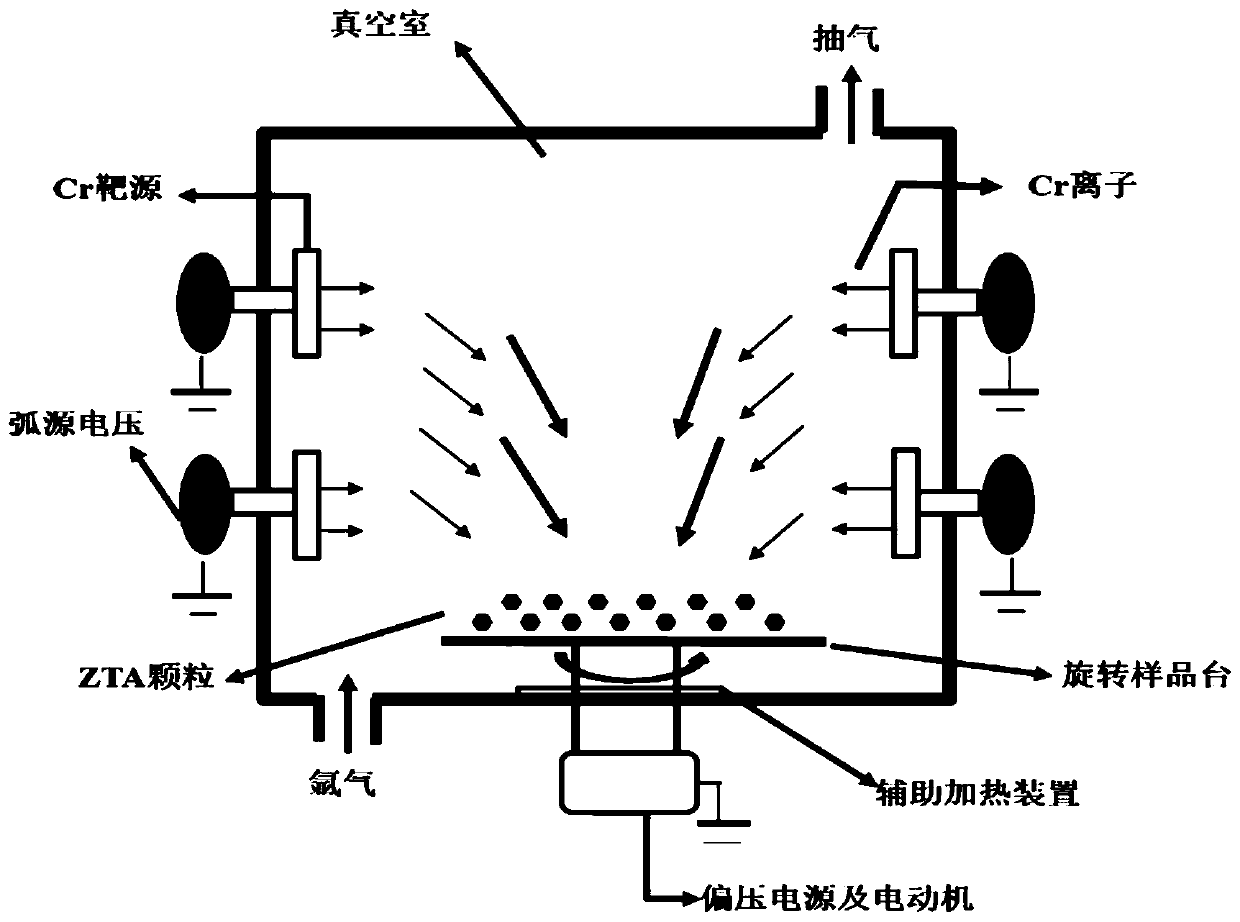

NiCrAlY high-temperature sintering ZTA particle reinforced steel-based composite material and preparation method thereof

ActiveCN111809100AImprove wettabilityEnhanced interface bindingTransportation and packagingVacuum evaporation coatingCeramic coatingAdhesive

The invention discloses a NiCrAlY high-temperature sintering ZTA particle reinforced steel-based composite material and a preparation method of the NiCrAlY high-temperature sintering ZTA particle reinforced steel-based composite material. Surface microroughening is conducted on ZTA Particles. The thermal stability of a ceramic coating is improved by adding an active element Y. The adsorption capacity of the Cr and Al on the O element can greatly improve the wettability of Ni and the ceramic particles. The interface combination is caused to be converted into metallurgical bonding by combining mechanical combining. High combining and impact strength is realized. Working condition environment in a high-load state is realized. A self-made adhesive is then added for shaping. A preform with a honeycomb structure is obtained after drying treatment. Then the honeycomb preform is subjected to heat treatment to improve the bonding strength of the honeycomb preform. The honeycomb preform is put into a sand box, molten metal is cast, and the ZTA reinforced steel-based composite material with high wear resistance is obtained after cooling. The wear-resistant composite material prepared by the technology has high impact resistance and wear resistance, and guarantees service safety under severe working conditions.

Owner:XI AN JIAOTONG UNIV +1

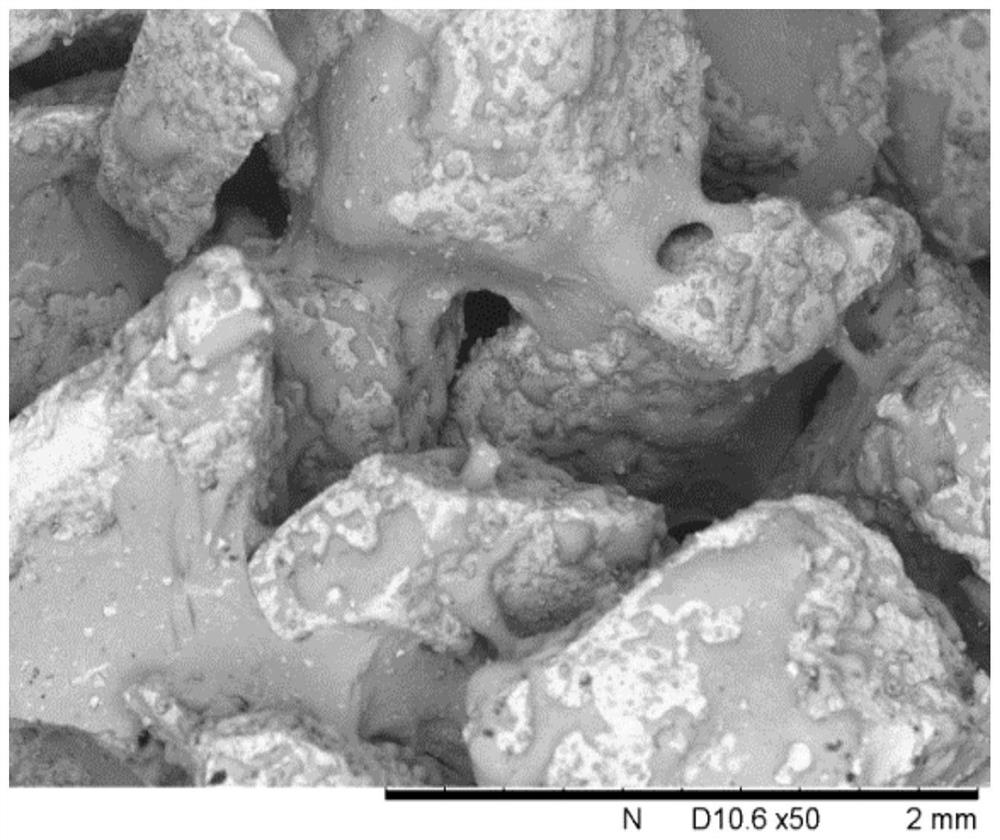

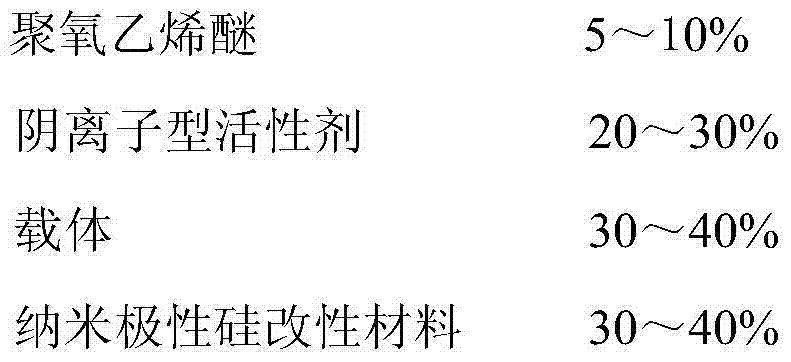

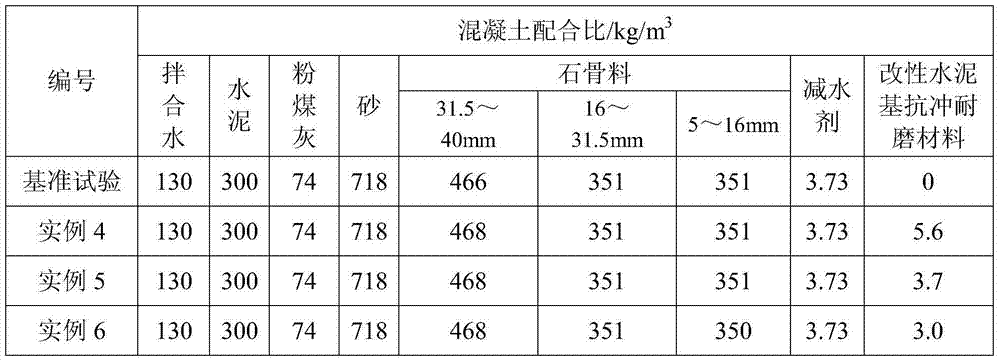

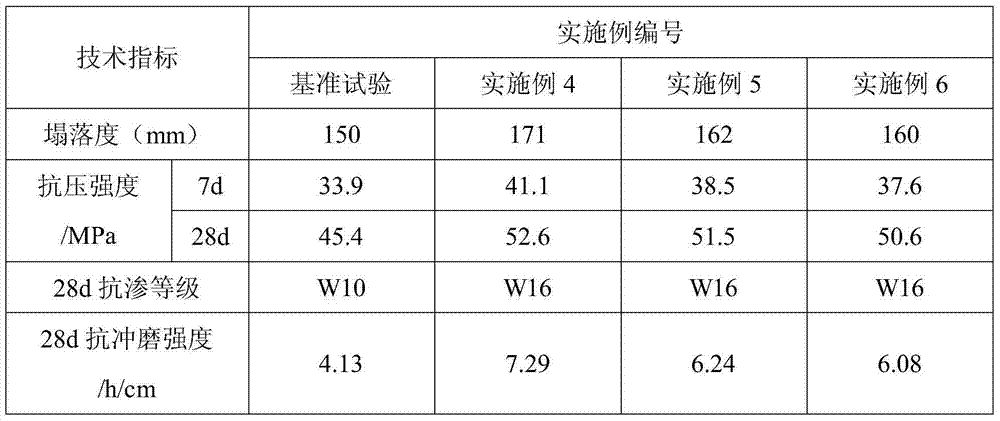

Modified cement-based antishock and wear-resistant material and preparation and application methods thereof

The invention discloses a modified cement-based antishock wear-resistant material and preparation and application methods thereof. The modified cement-based antishock wear-resistant material comprises the following components in percentage by mass: 5 to 10% of polyoxyethylene ether, 20 to 30% of anionic active agent, 30 to 40% of carrier and 30 to 40% of nanometer polar silicon modifying material. The preparation method comprises the following steps of: compositing polyoxyethylene ether and the anionic active agent onto the carrier; adding the nanometer polar silicon modifying material to the obtained composite; and homogenizing to obtain the modified cement-based antishock wear-resistant material. The application method comprises the following steps of: uniformly mixing weighed sand and aggregate; adding cement, fly ash and the modified cement-based antishock wear-resistant material; uniformly agitating; adding mixing water and a water reducing agent; and uniformly mixing to obtain concrete. The modified cement-based antishock wear-resistant material has high antishock wear-resistant performance; the preparation method is simple and mild in conditions; the process parameters are easily controlled; the yield is high; and the production cost is low.

Owner:WUHAN UNIV

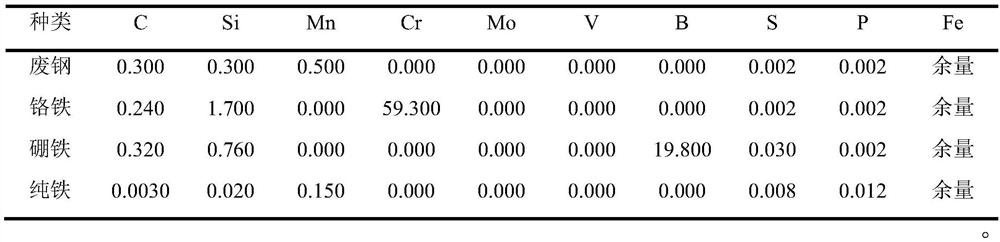

Boracic wear-resisting alloy steel and preparation method thereof

The invention discloses boracic wear-resisting alloy steel and a preparation method thereof. The boracic wear-resisting alloy steel is prepared from, by mass percent, 0.20%-0.5% of C, 2%-6% of Cr, 0.4%-1.0% of Si, 3.0%-5.0% of Mn, 0.3%-2.5% of B, 0.2%-1.2% of Cu, 0.2%-0.6% of Ti, 0.05%-0.25% of Ca, 0.03%-0.3% of ReSiMg, 0.02%-0.18% of N, 0.05%-0.3% of Nb, 0.03%-0.08% of Al, 0.04%-0.13% of K, smaller than 0.03% of S, smaller than 0.04% of P and the balance Fe. Melting is carried out through an intermediate frequency furnace until the temperature ranges from 1,560 DEG C to 1,620 DEG C, ferrovanadium, ferrotitanium, potassium oxide, a silicon-calcium-barium alloy and nitrogen containing ferrochromium which are 60 meshes to 100 meshes, BC, BN, B2O3, Si3N4, Al and ReSiMg are matched according to the mass percent and then rolled into a metal cored wire with the diameter ranging from 8 mm to 15 mm through low-carbon steel with the thickness ranging from 0.12 mm to 0.25 mm, the metal cored wire is added into smelted molten steel as a boron supplying agent for boron supplying and metamorphic inoculation treatment, and the casting temperature of the molten steel ranges from 1,400 DEG C to 1,450 DEG C; and a casting is subjected to heat preservation for 2-4 hours at the temperature ranging from 920 DEG C to 1,150 DEG C, and air cooling is carried out to room temperature. The boracic wear-resisting alloy steel is good in strength, hardness, toughness, heat fatigue resistance and wear resistance and low in production cost.

Owner:DANYANG JIAWEI WEAR RESISTANT MATERIAL TECH CO LTD

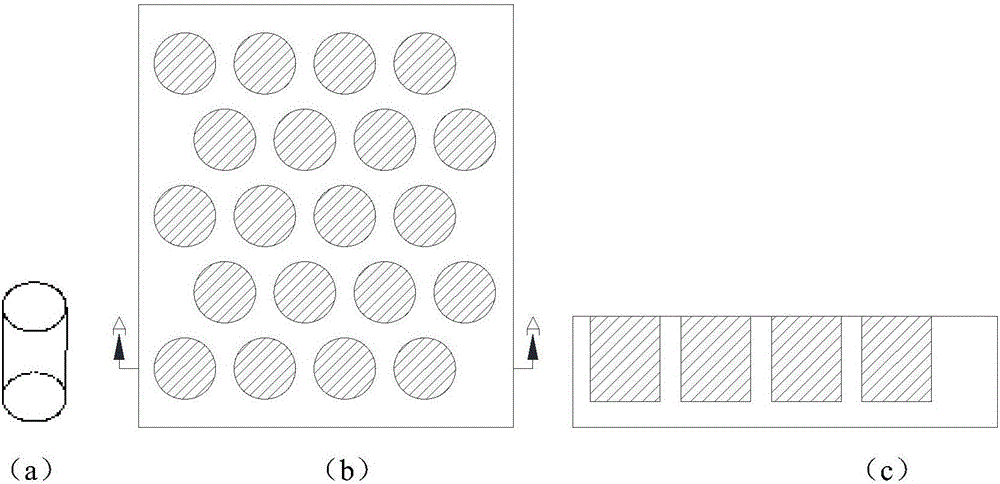

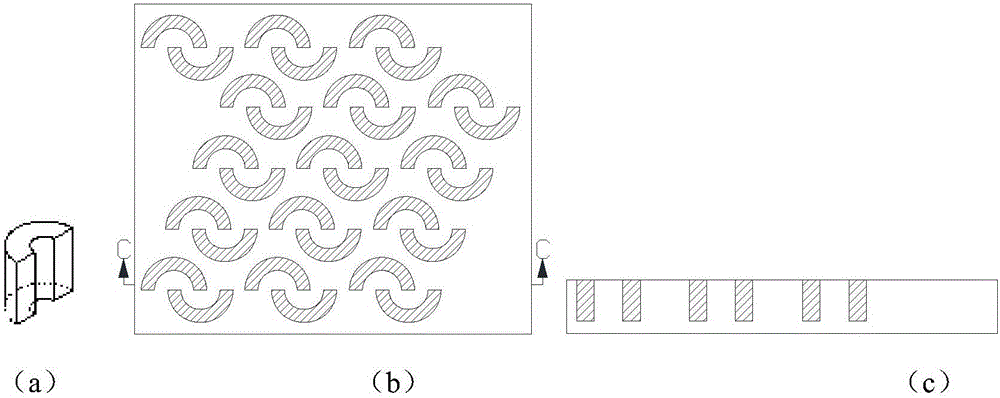

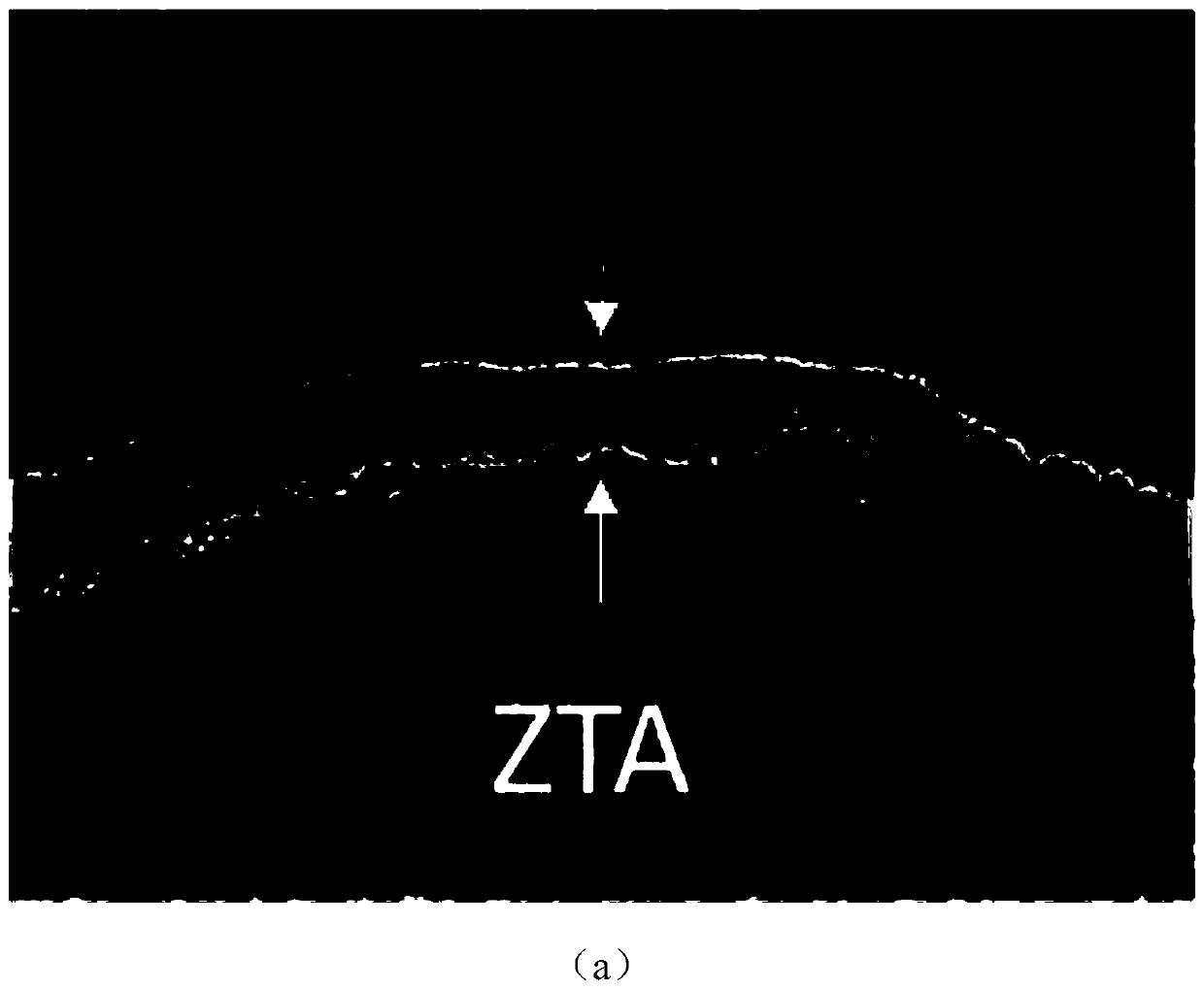

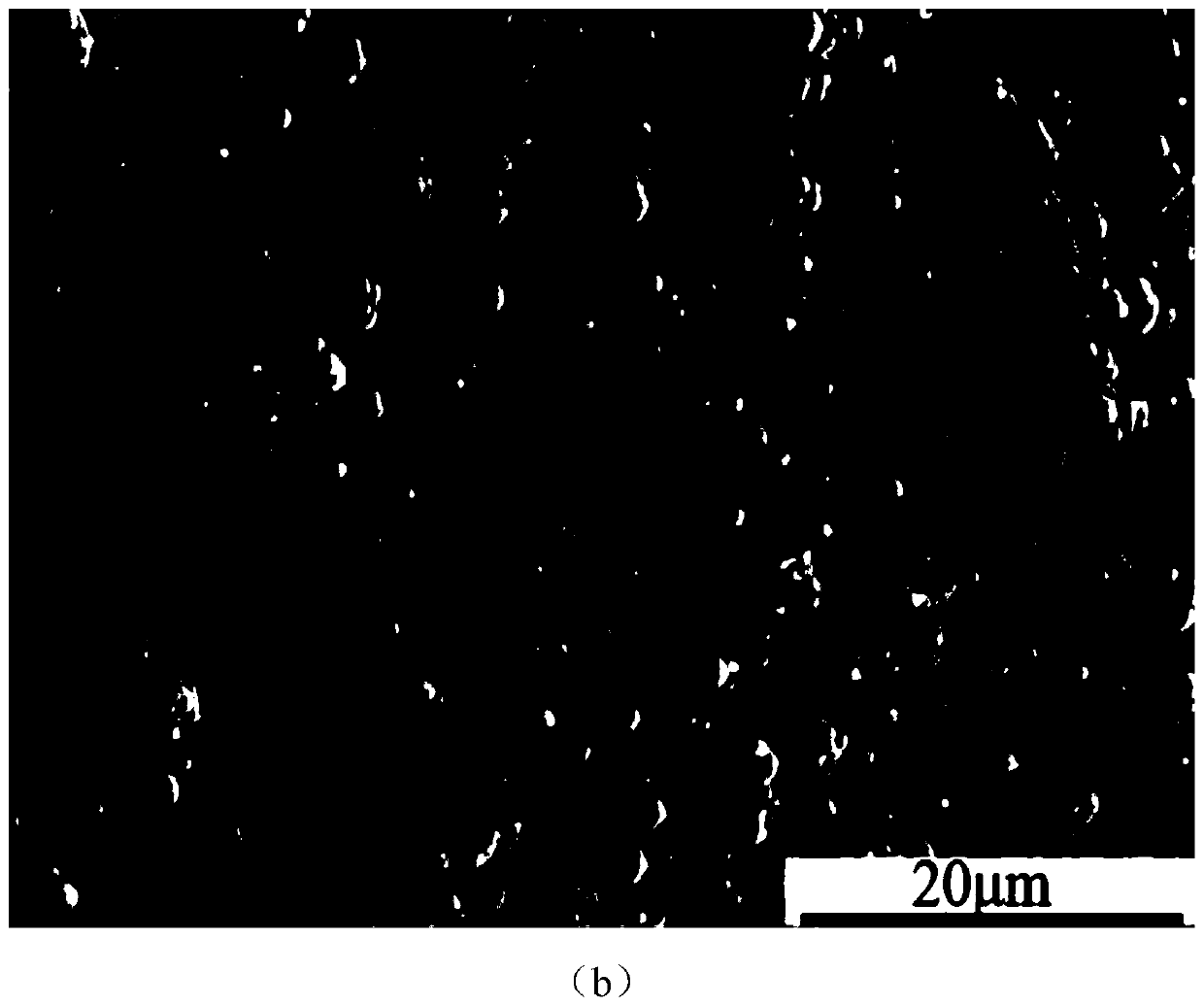

Preparation method for surface treatment ZTA particle enhanced steel-based composite grinding roller

ActiveCN110935864AEnhanced interface bindingHigh bonding strengthVacuum evaporation coatingSputtering coatingHoneycomb likeHeat treating

The invention discloses a preparation method for a surface treatment ZTA particle enhanced steel-based composite grinding roller. The surfaces of ZTA particles are subjected to micro roughening; attachment points of the ZTA particles during Cr plating are improved, the plating efficiency is improved, and the surfaces of the ZTA particles are subjected to metallization modifying by adopting a micro-arc ion plating method; then a self-made adhering agent is added for sizing, drying treatment is performed so that a prefabricated body of a honeycomb-shaped structure is obtained, and then heat treatment is performed on the honeycomb-shaped prefabricated body so that the bonding strength of the prefabricated body can be improved; and the prefabricated body is placed into a sand box for molten metal casting, and after cooling, the grinding roller with high abrasion resistance is obtained. According to the preparation method, Cr element plating is performed through physical vapor deposition sothat the bonding manner between the ZTA particles and metal can be improved, interface bonding is converted into metallurgical bonding from simple mechanical bonding, and high bonding and impacting strength is achieved. An abrasion-resistant composite material prepared through the technology of the preparation method has high impacting abrasion resisting performance, and the service safety underharsh working conditions is also guaranteed.

Owner:XI AN JIAOTONG UNIV +1

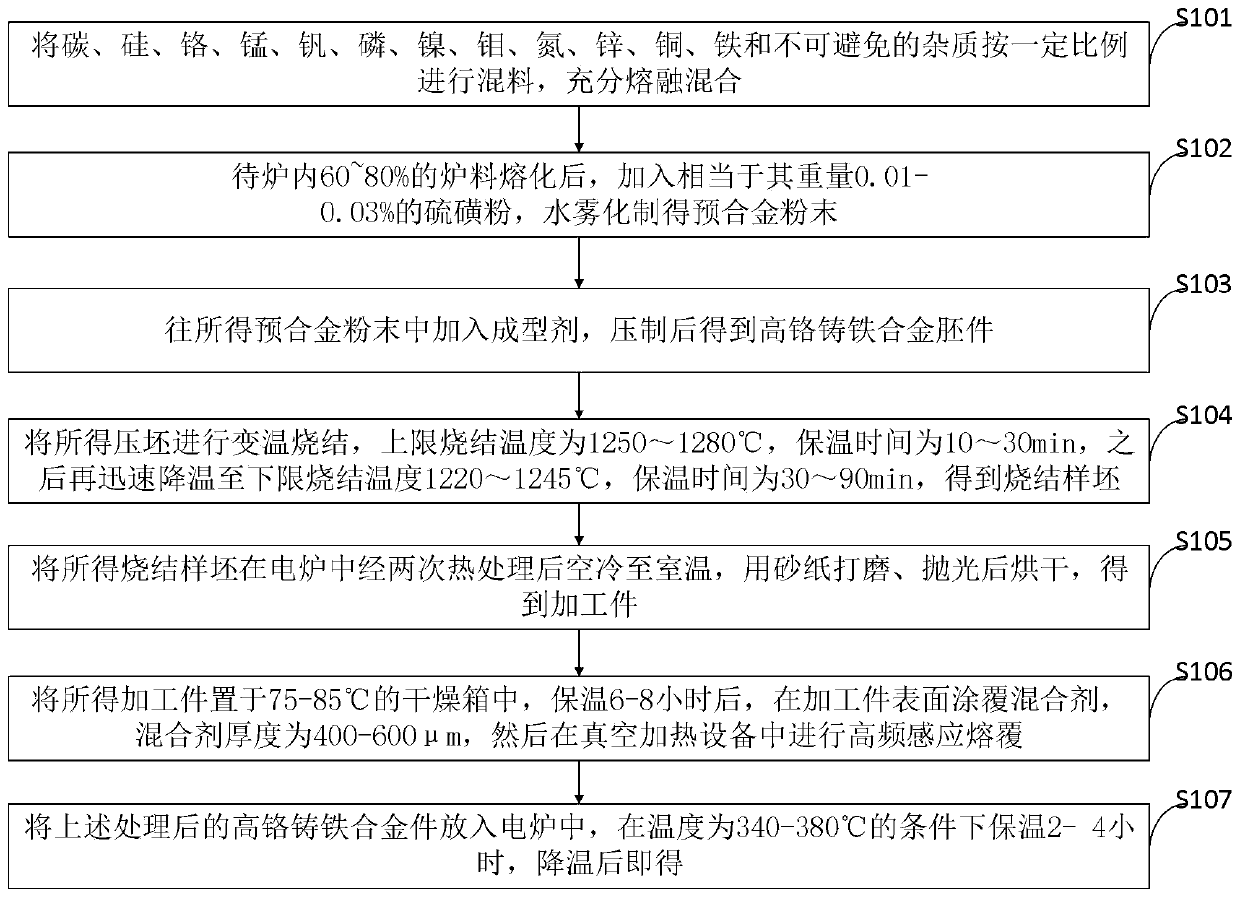

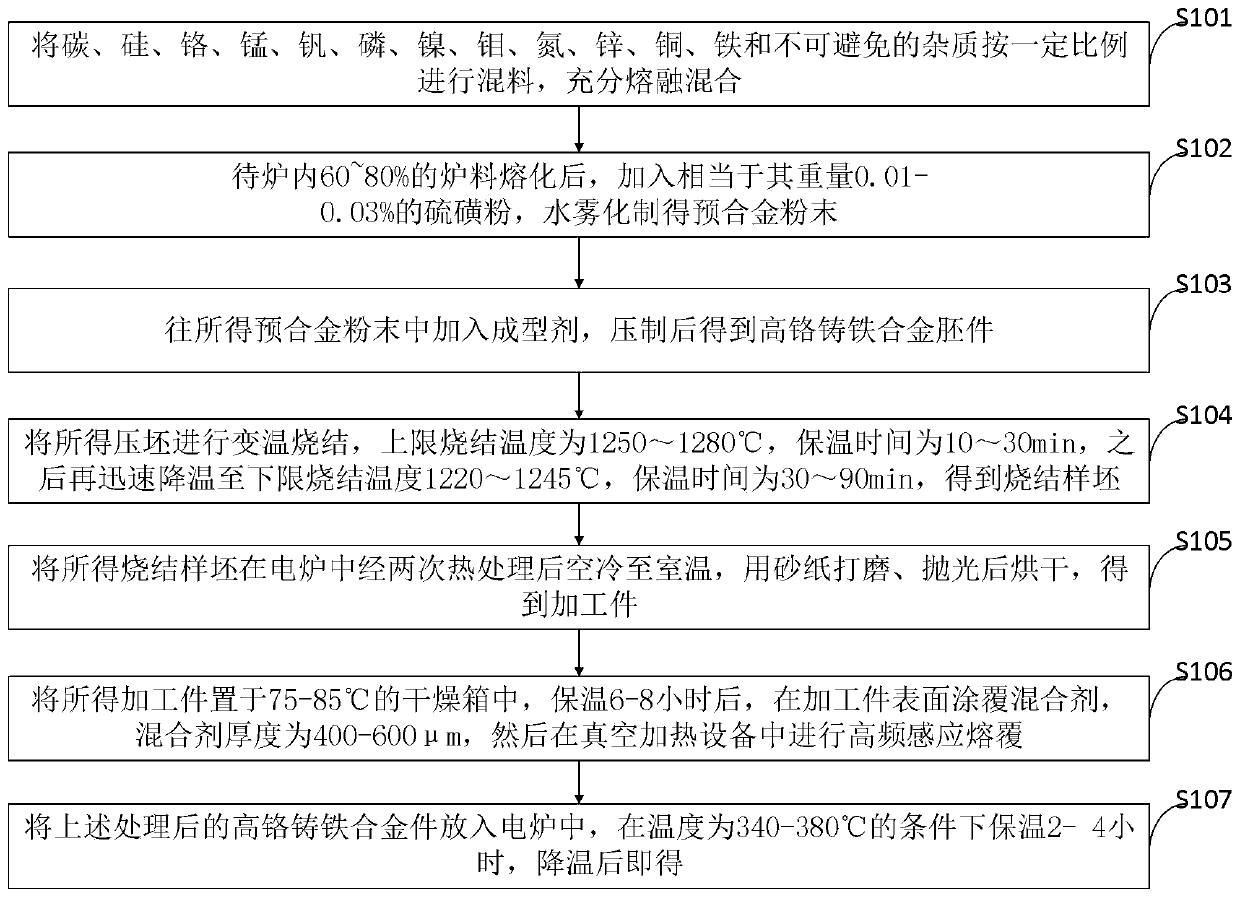

Anti-corrosion wear-resistance high chrome cast iron alloy and preparing method thereof

InactiveCN110042305AHigh hardnessImprove shock absorption capacityMetallic material coating processesAlloyShock resistance

The invention belongs to the technical field of wear-resisting metal materials, and discloses an anti-corrosion wear-resistance high chrome cast iron alloy and a preparing method thereof. The method comprises the steps of raw material preparing, atomizing mixing powder making, mould pressing blank making, variable temperature sintering, heat treatment cooling, mixture treatment, and finished product making. Through adjusting of the raw material proportion of the blank of the high chrome cast iron alloy, the corrosion resistance and impact resistance are improved, before casting, sulphur powderis used for hardening and tempering, in cooperation with the heat treatment process, the phenomenon that much carbide is precipitated from austenite is avoided, a condensation structure is fine, thegood mechanical property is achieved, the matrix structure, the graphite size, the graphite shape and graphite distribution are improved, corrosion resistance is obviously improved, and the hardness of the high chrome cast iron alloy blank can be improved; and through the mixture, the surface of the high chrome cast iron alloy is modified, the absorption impact resistance capacity of the high chrome cast iron alloy is improved while the hardness of the high chrome cast iron alloy is ensured, and accordingly the wear resistance is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

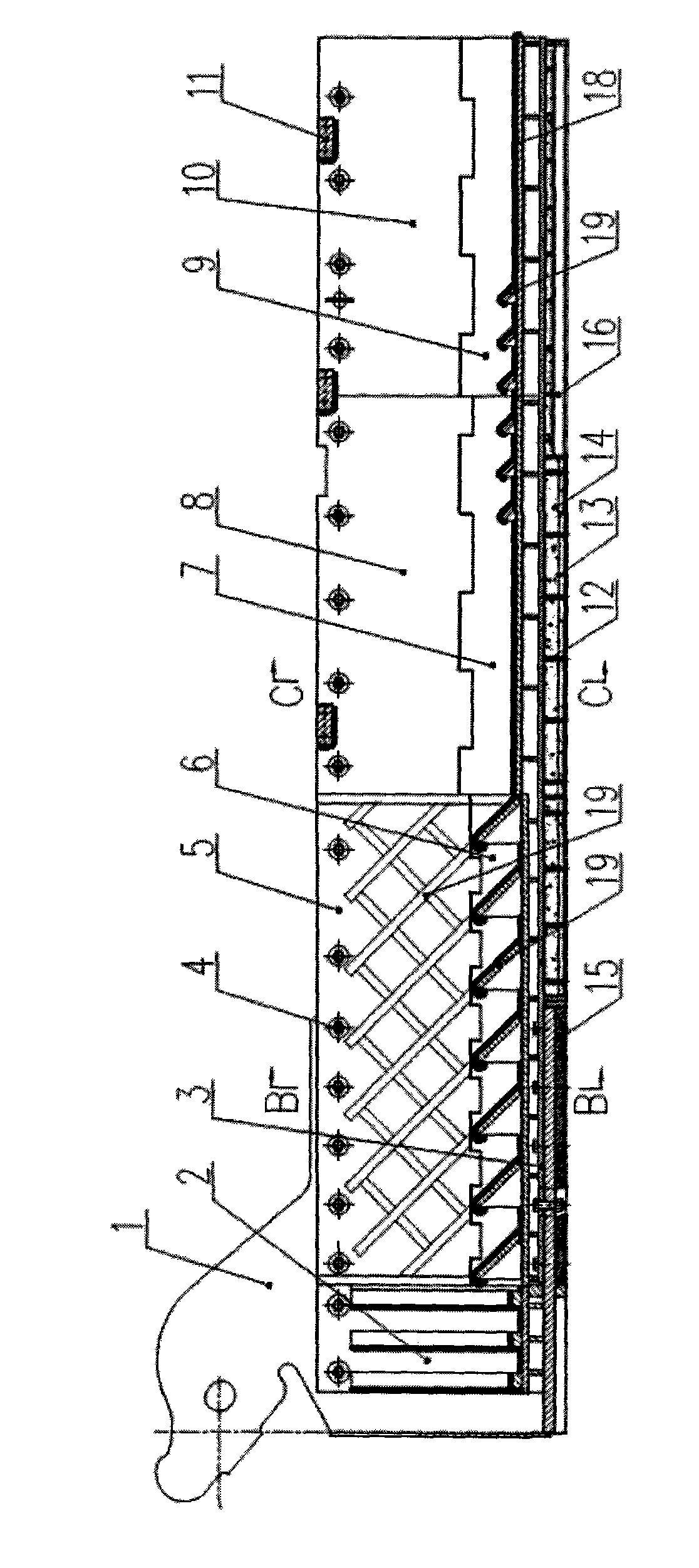

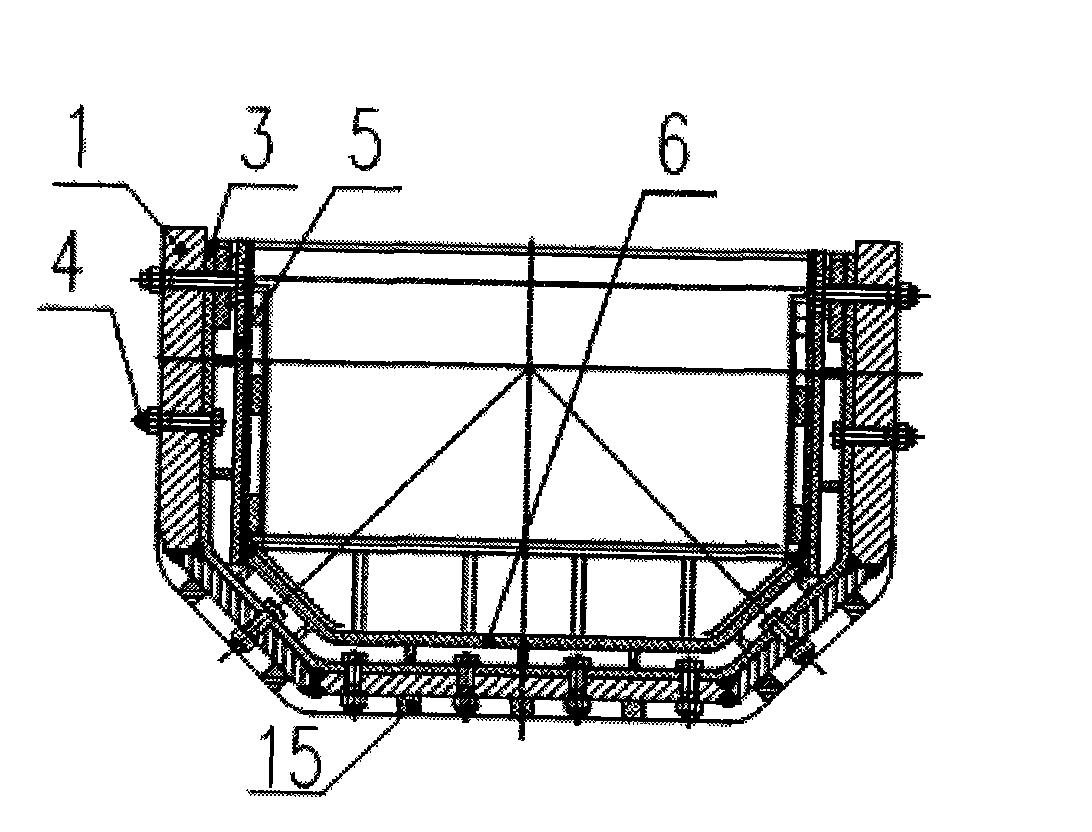

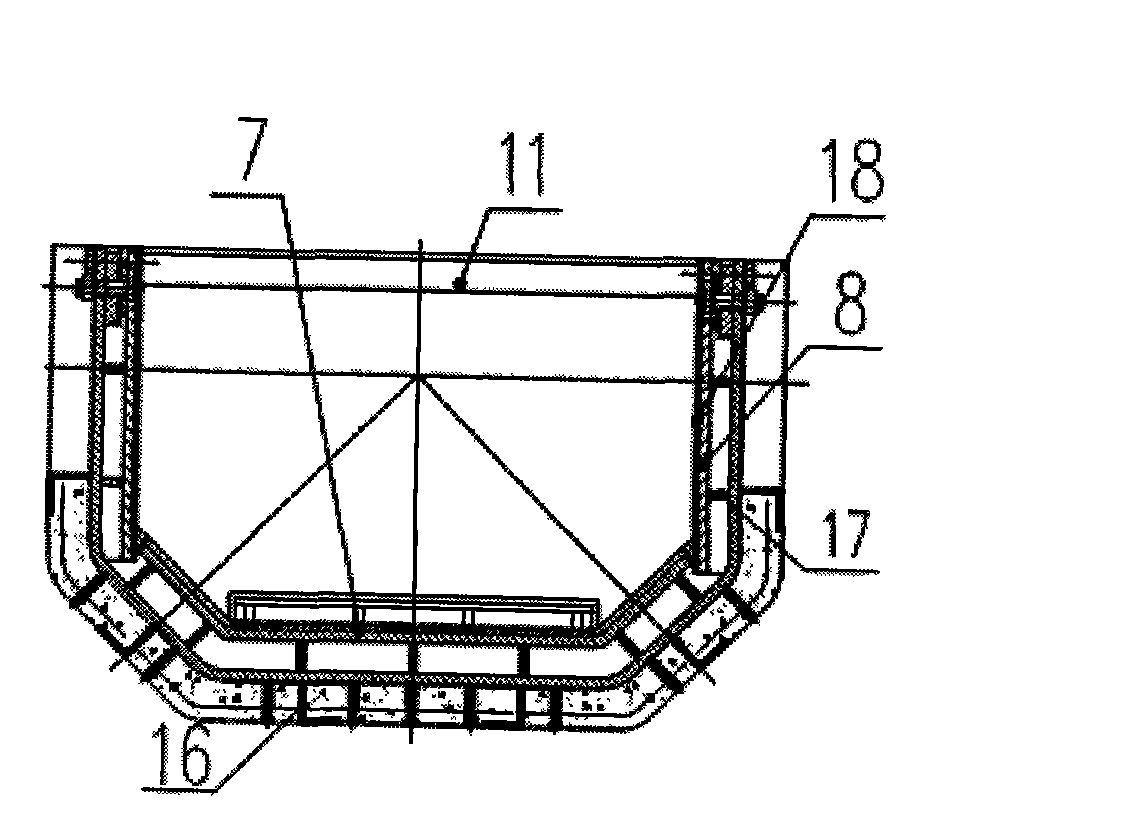

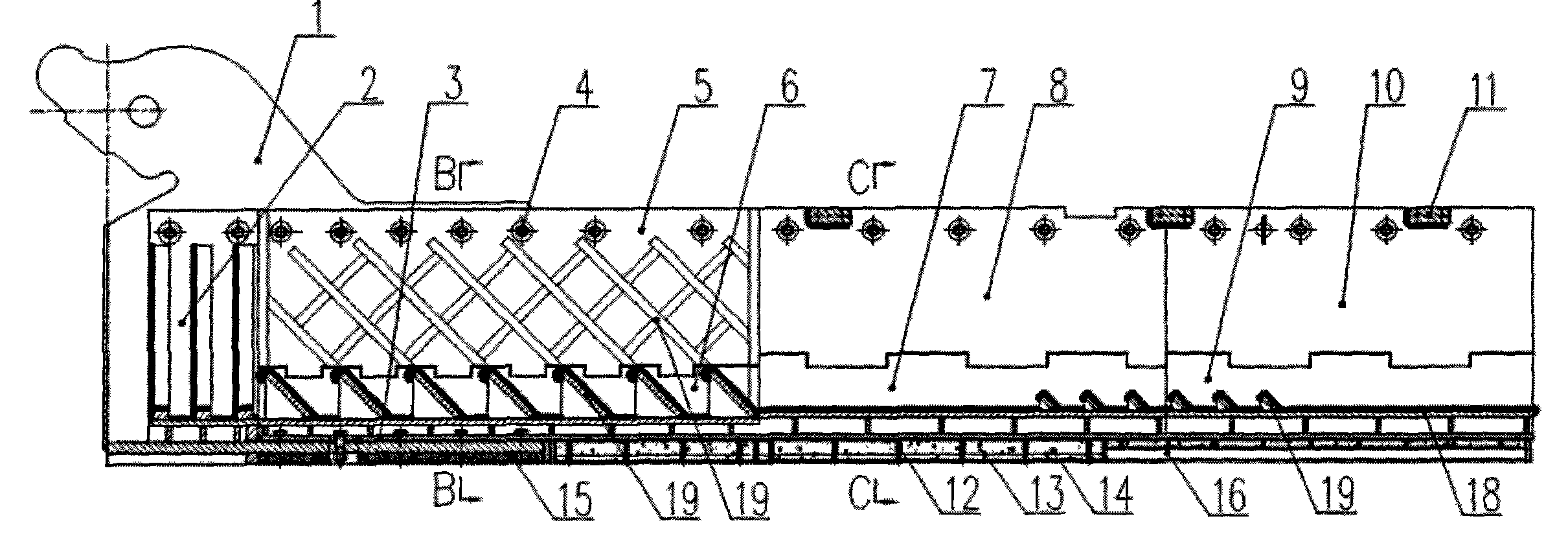

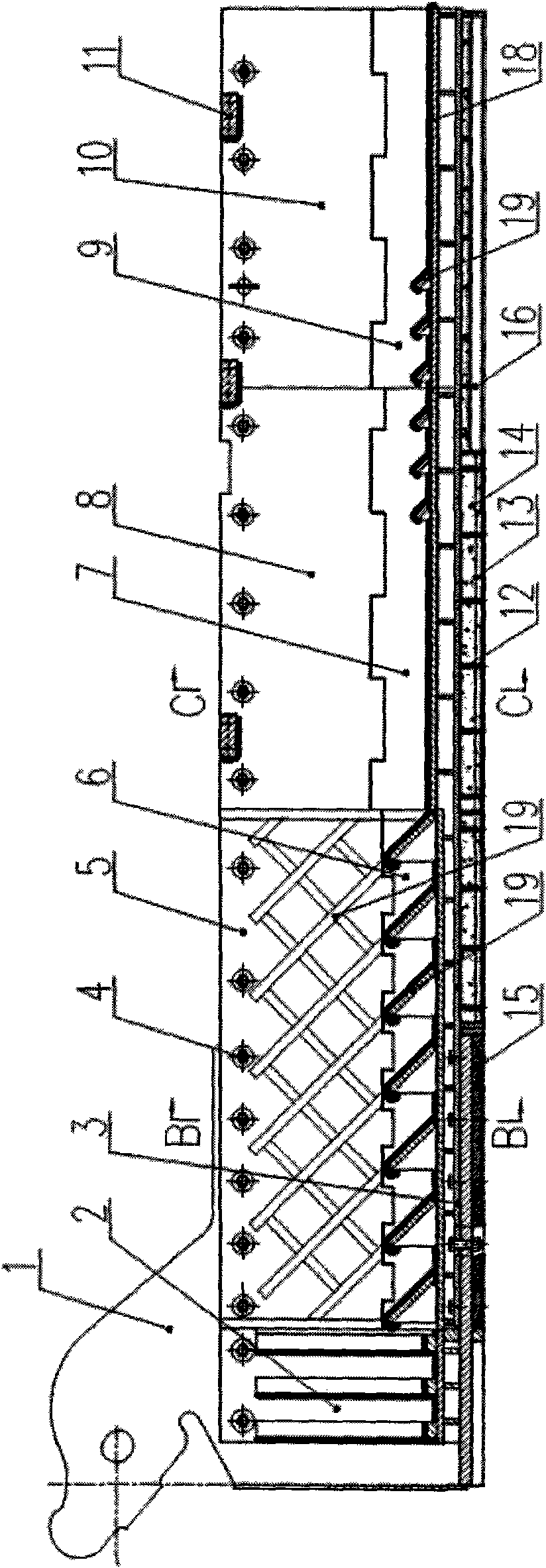

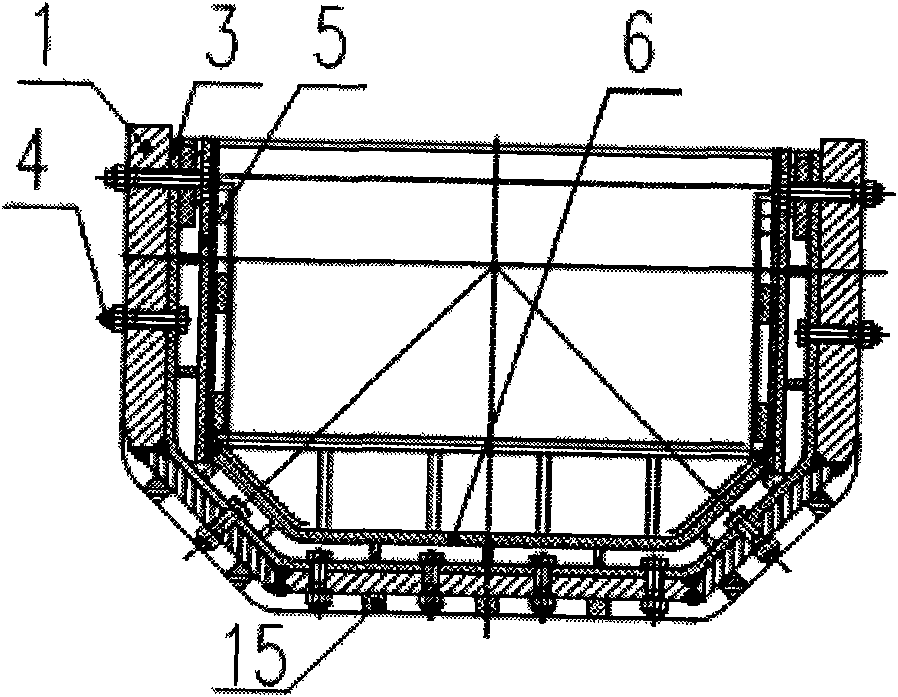

Long life distribution chute

ActiveCN101581541AReduce chute weightReduce weightBell-and-hopper arrangementCharge manipulationRefractoryLife time

The invention discloses a long life distribution chute which comprises a hexagonal chute head, a hexagonal chute body, wear-resisting liners, a lightweight refractory material, fasteners and other fittings. An abrasive material stocking plate is additionally arranged at a blanking point inside the chute and used for preventing the direct impact on the wear-resisting liners of material stream; the lightweight refractory material is coated on the outer surfaces of the middle section and the front section of the chute body, thereby reducing the weight of the chute and being capable of resisting the impact of high temperature central air flow in a furnace; and the wear-resisting liners at the side and bottom surface of the chute are movably connected by adopting concave and convex interlacing seals, thereby being capable of effectively absorbing the deformation of the wear-resisting liners. The long life distribution chute has the advantages of reasonable structure, light weight, impact abrasion resistance and long service life, and meets the requirement of blast furnace top distribution.

Owner:CISDI ENG CO LTD

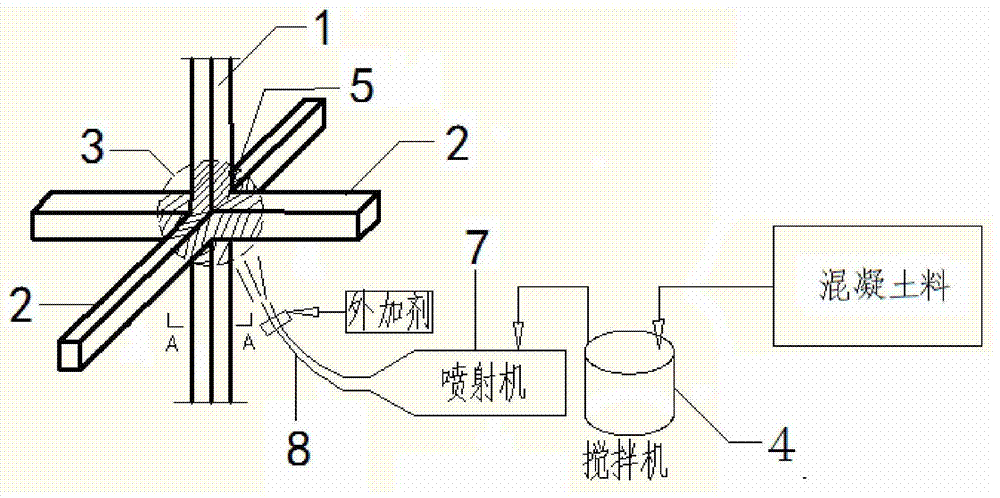

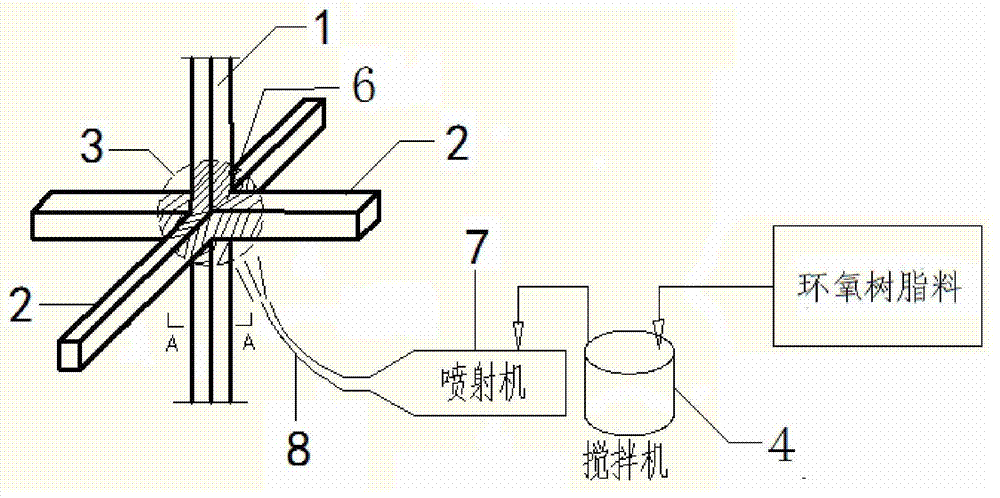

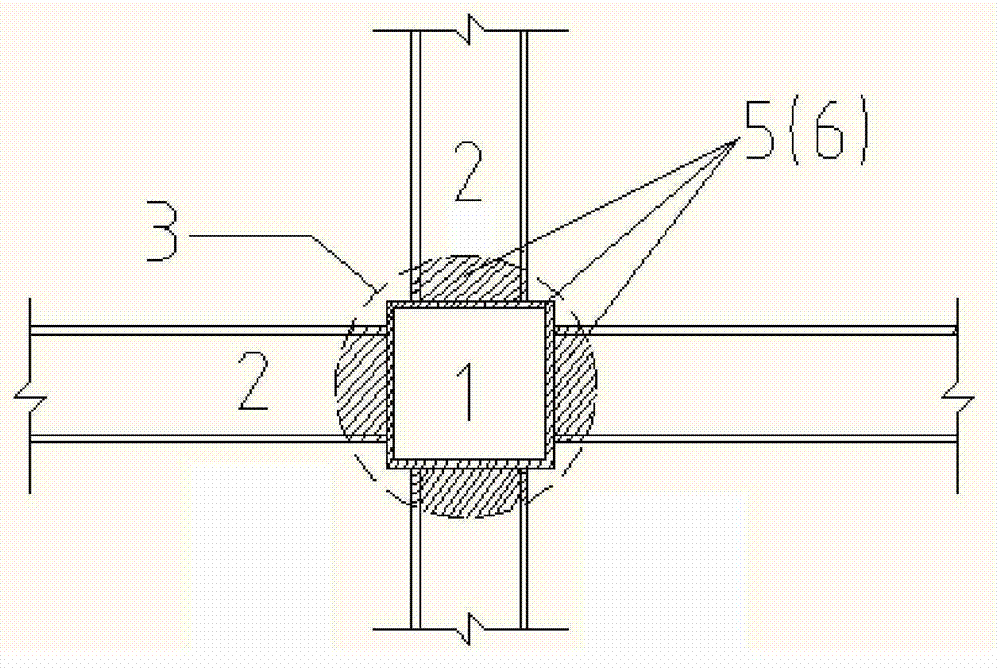

Reinforcing method of concrete structure beam column nodes

The invention relates to a reinforcing method of concrete structure beam column nodes, in particular to a method aiming at reinforcing beam column nodes in which both space structure and stress are complex. The reinforcing method of the concrete structure beam column nodes comprises the following steps: chopped fiber, concrete and water are mixed and stirred into a mixture and accelerator is added on a nozzle of an injection machine and injected to the beam column nodes. Alternatively, the reinforcing method of the concrete structure beam column nodes can comprise the following steps: chopped fiber reinforce plastic (FRP) fiber, epoxy resin and additive are mixed and stirred into a mixture and the mixture is injected to the beam column nodes by the injection machine to reinforce the nodes. The reinforcing method of the concrete structure beam column nodes can reinforce the beam column nodes which is complex in space structure without being affected by shape and scale of construction elements; intensity of an injection layer is high, and toughness is good; rebound rate of dry materials in the construction process is low, construction time is greatly shortened, loss of the dry materials is reduced, and environment is not polluted; no external template is needed to arrange in construction, anchorage and erecting reinforcement fabric is not needed, massive materials are saved, a template arranging procedure is removed, and construction is convenient, simple and rapid. The reinforcing method of the concrete structure beam column nodes can be applied not only to reinforcing beam column nodes but also to rapid repairing after an earthquake.

Owner:BEIJING JIAOTONG UNIV

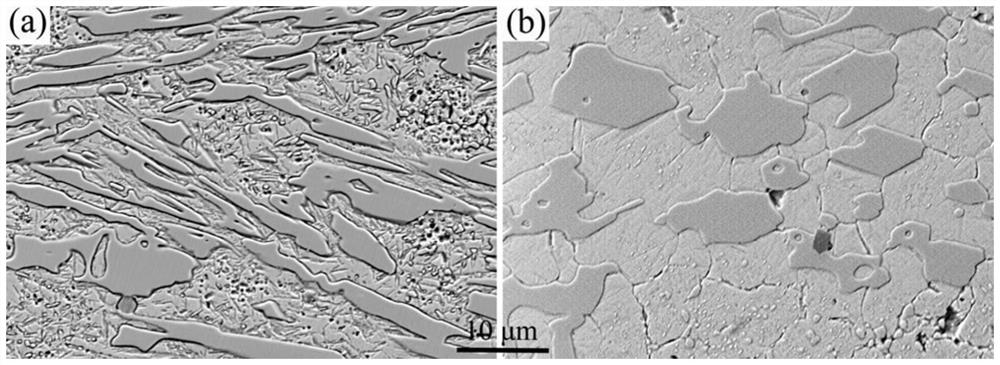

High-tenacity boron-containing high-chromium abrasion-resistant alloy and preparation method thereof

InactiveCN105316589AAddition amount deviation fluctuation is smallHigh yieldFerrochromeMaterials science

The invention discloses a high-tenacity boron-containing high-chromium abrasion-resistant alloy and a preparation method thereof. The high-tenacity boron-containing high-chromium abrasion-resistant alloy comprises, by mass, 0.20%-0.6% of C, 15%-20% of Cr, 0.5%-1.10% of Si, 3.5%-6.0% of Mn, 0.4%-2.3% of B, 0.4%-1.5% of Cu, 0.3%-1.2% of Ti, 0.10%-1.0% of V, 0.05%-0.3% of Nb, 0.05%-0.10% of Al, 0.10%-0.25% of Ca, 0.05%-0.2% of Y, 0.05%-0.3% of Ce, 0.04%-0.20% of N, 0.05%-0.15% of K, 0-0.03% of S, 0-0.04% P, and the balance Fe. Scrap steel and ferrochromium are smelted to the temperature of 1560 DEG C to 1620 DEG C by using an intermediate frequency furnace, after ferrovanadium, ferrotitanium, potassium oxide, silicon-calcium-barium alloy, ferrochromium containing nitrogen, Al, BC, BN, B2O3, Si3N4, Ce and Y in 60 meshes to 100 meshes are proportioned together according to the mass percent, the mixture is rolled into metal cored wires of which the diameters range from 8 mm to 15 mm through the adoption of low-carbon steel of which the thickness ranges from 0.12 mm to 0.25 mm, the metal cored wires serving as a boron supplying agent are added into smelted molten steel, then boron is added, and modifying inoculation is conducted. The molten steel pouring temperature is 1400 DEG C to 1450 DEG C, heat preservation is conducted on a casting for 2 h to 4 h at the temperature of 920 DEG C to 1150 DEG C, and then the casting is subjected to air cooling to the room temperature. The high-tenacity boron-containing high-chromium abrasion-resistant alloy has the advantages of being good in strength, hardness, tenacity, thermal-fatigue resistance and abrasion resistance and low in production cost.

Owner:DANYANG JIAWEI WEAR RESISTANT MATERIAL TECH CO LTD

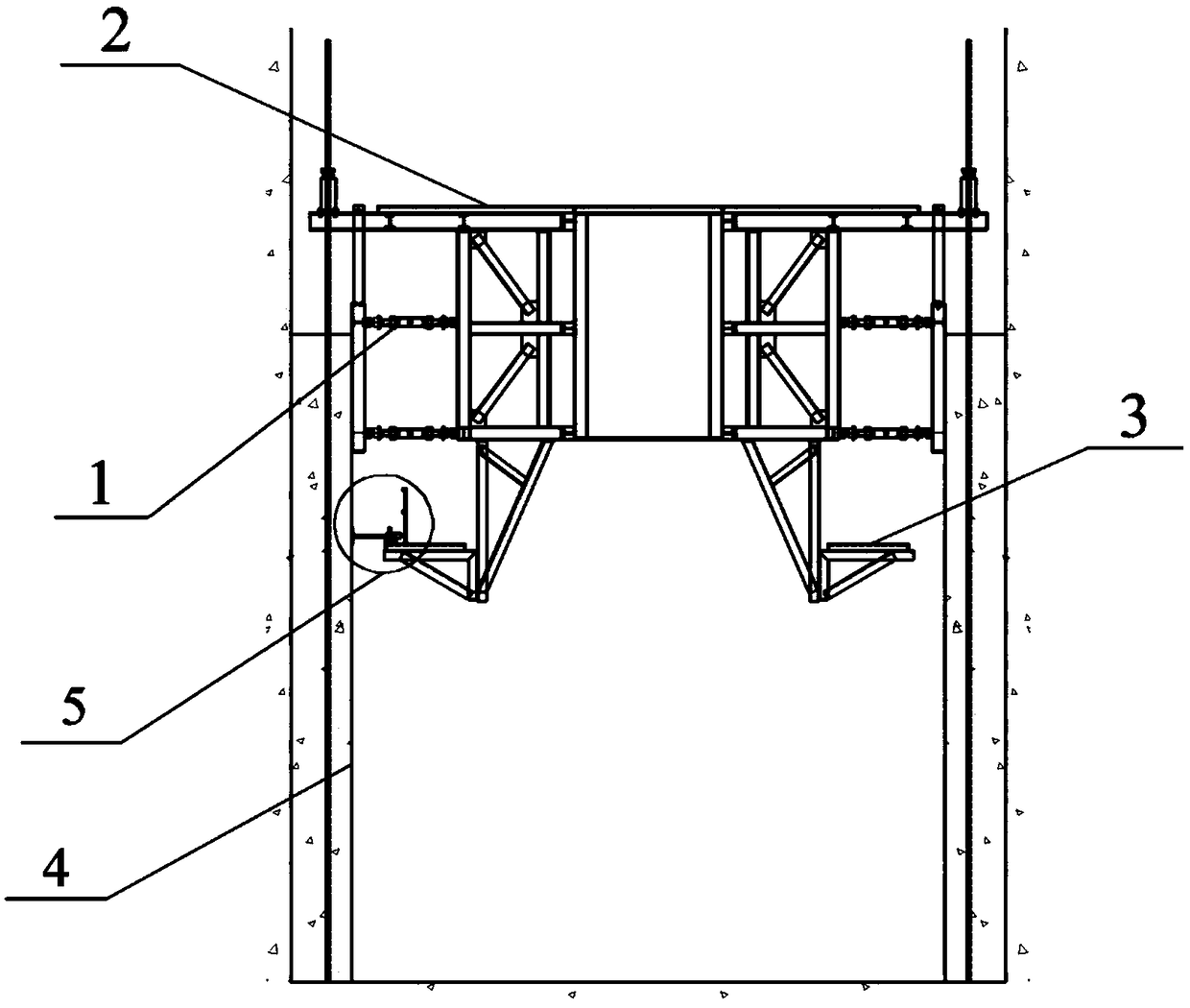

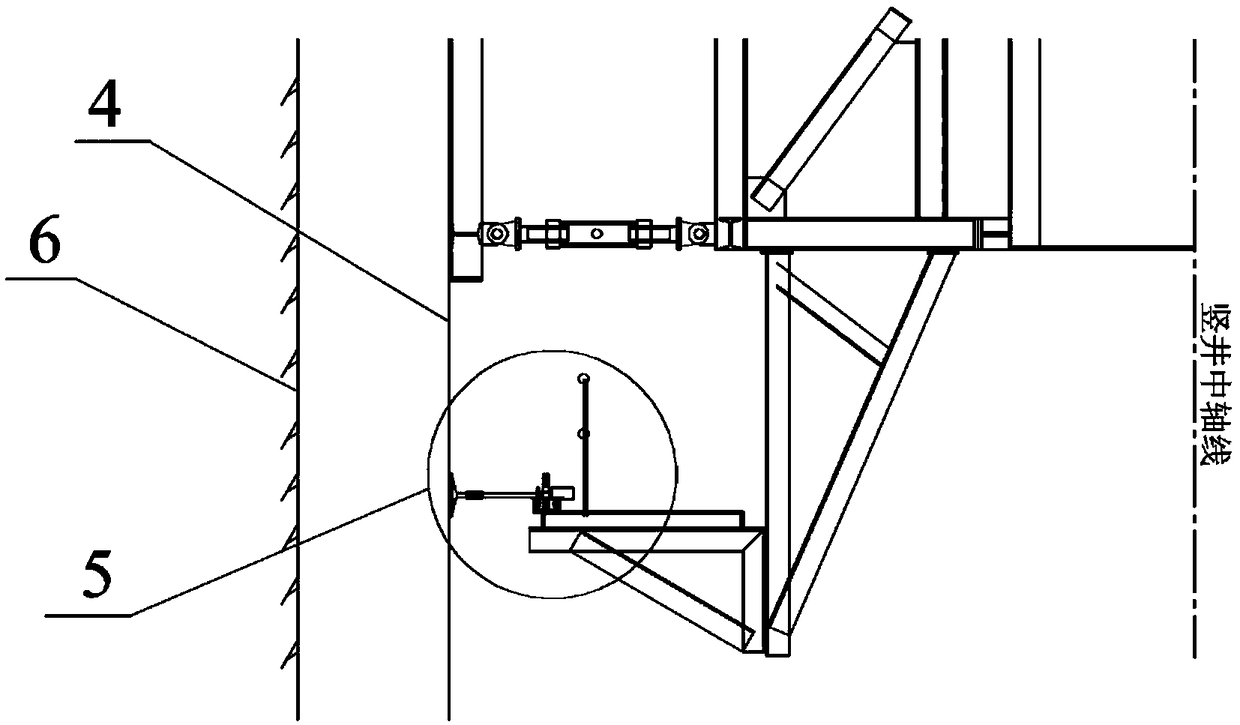

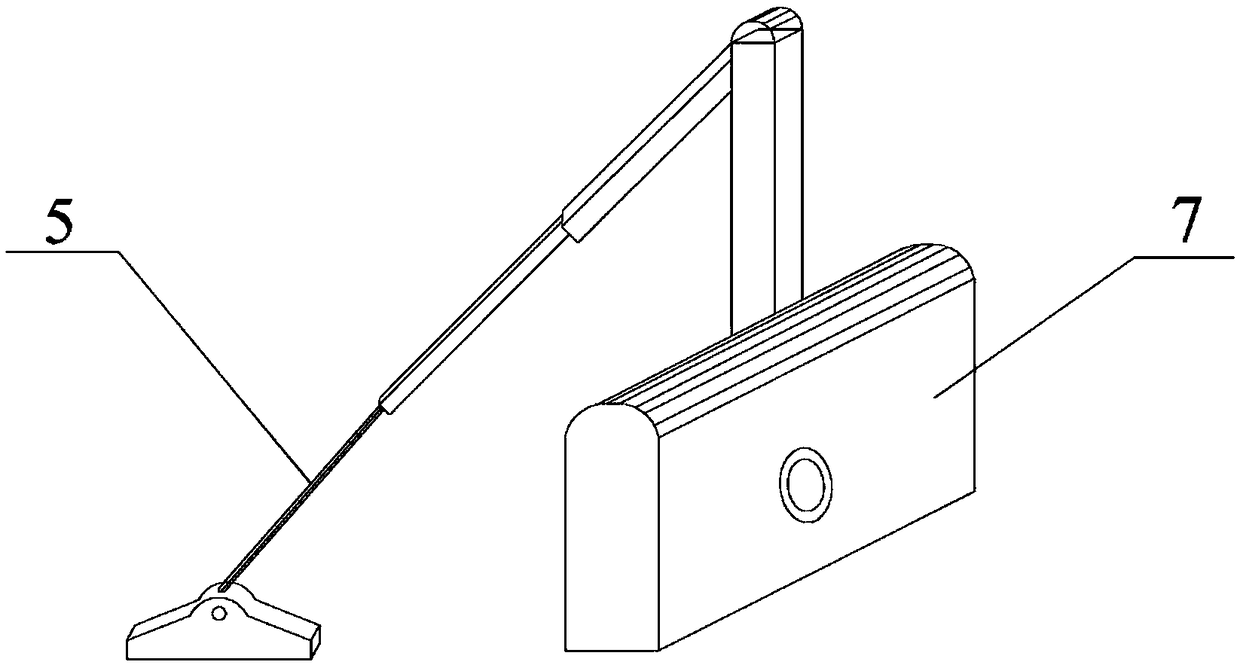

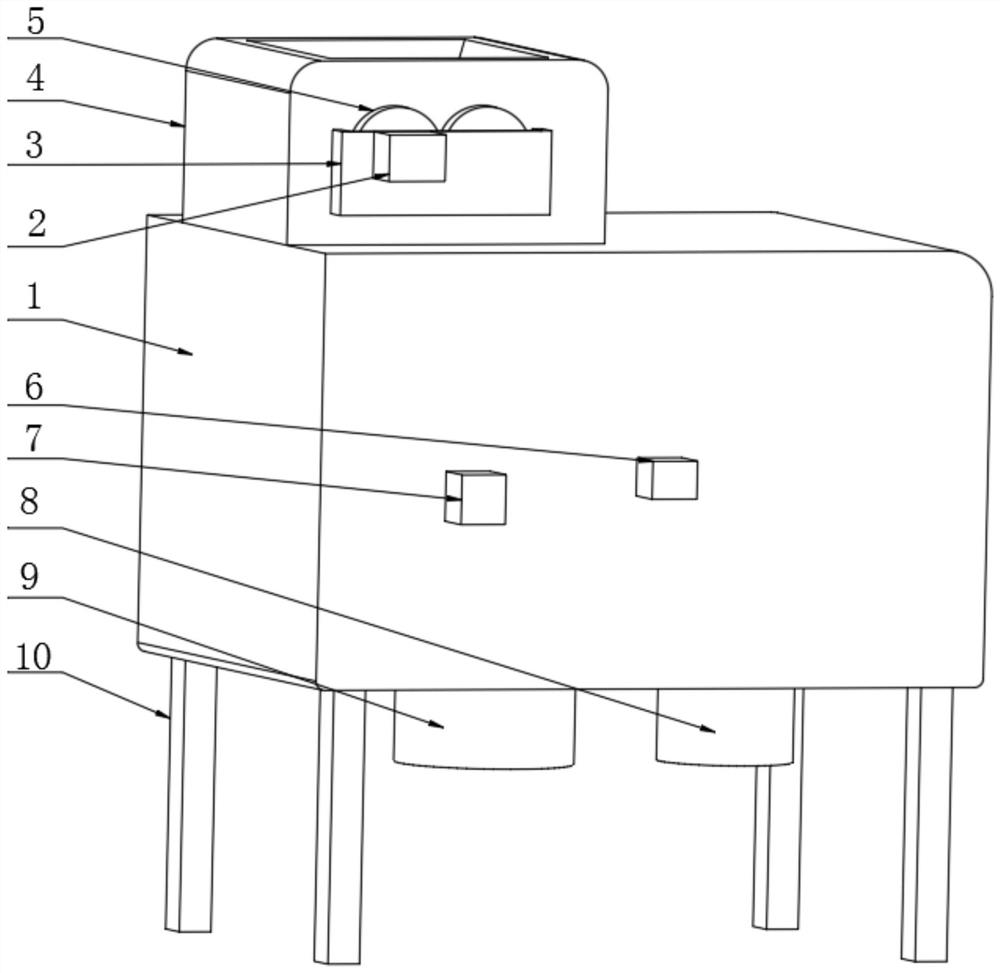

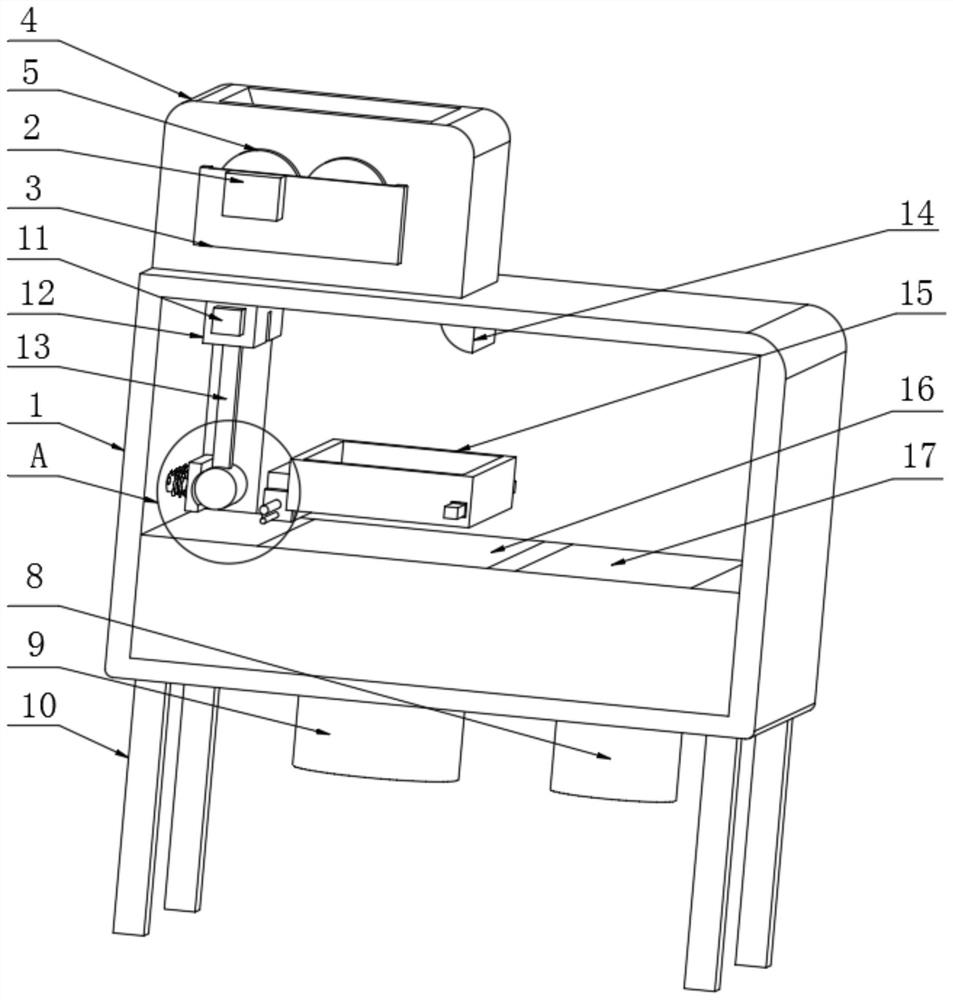

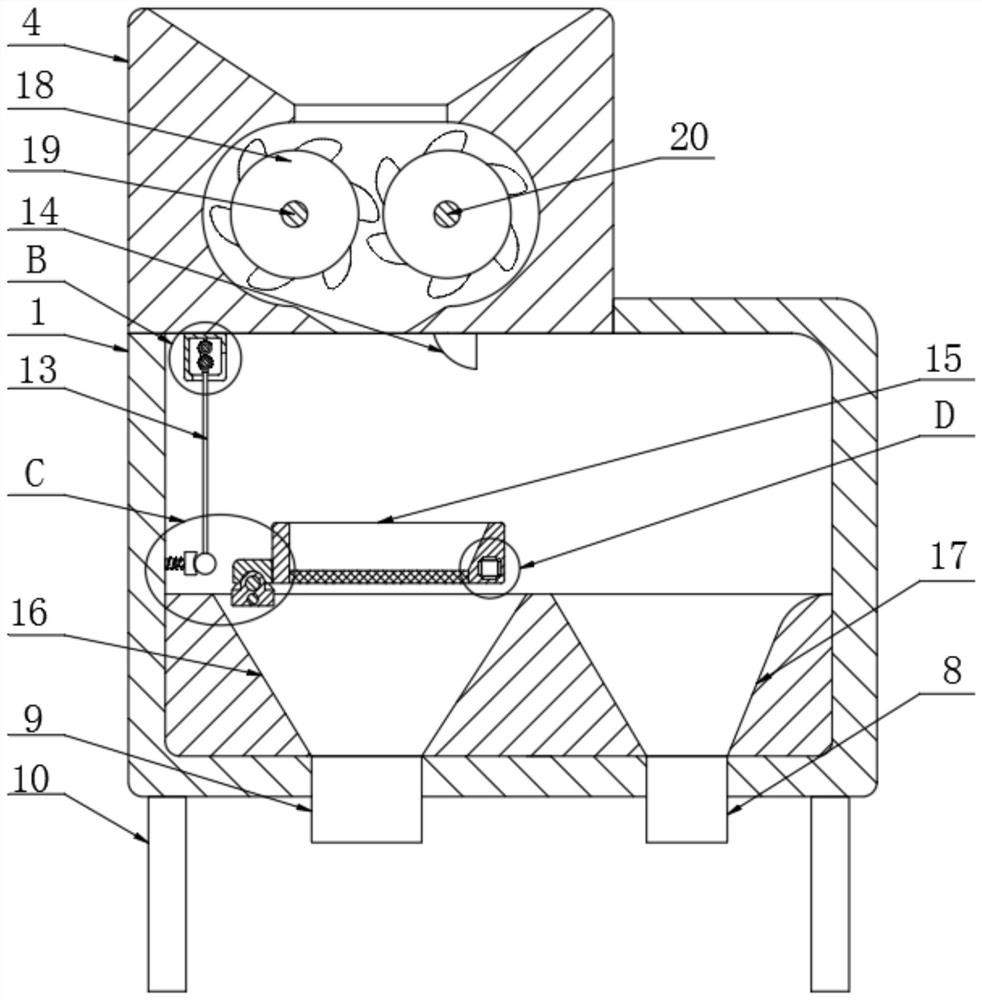

Vertical shaft slip form concrete calendaring device and calendaring method

PendingCN109026013AMeet the surface calendering construction requirementsRealize mechanized operationShaft liningBuilding construction

Owner:SINOHYDRO BUREAU 5

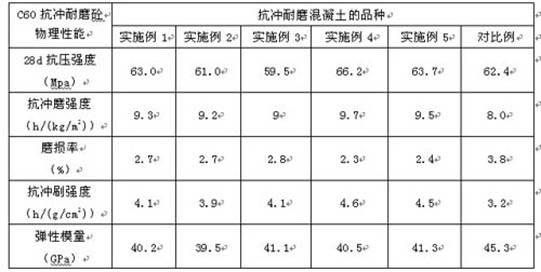

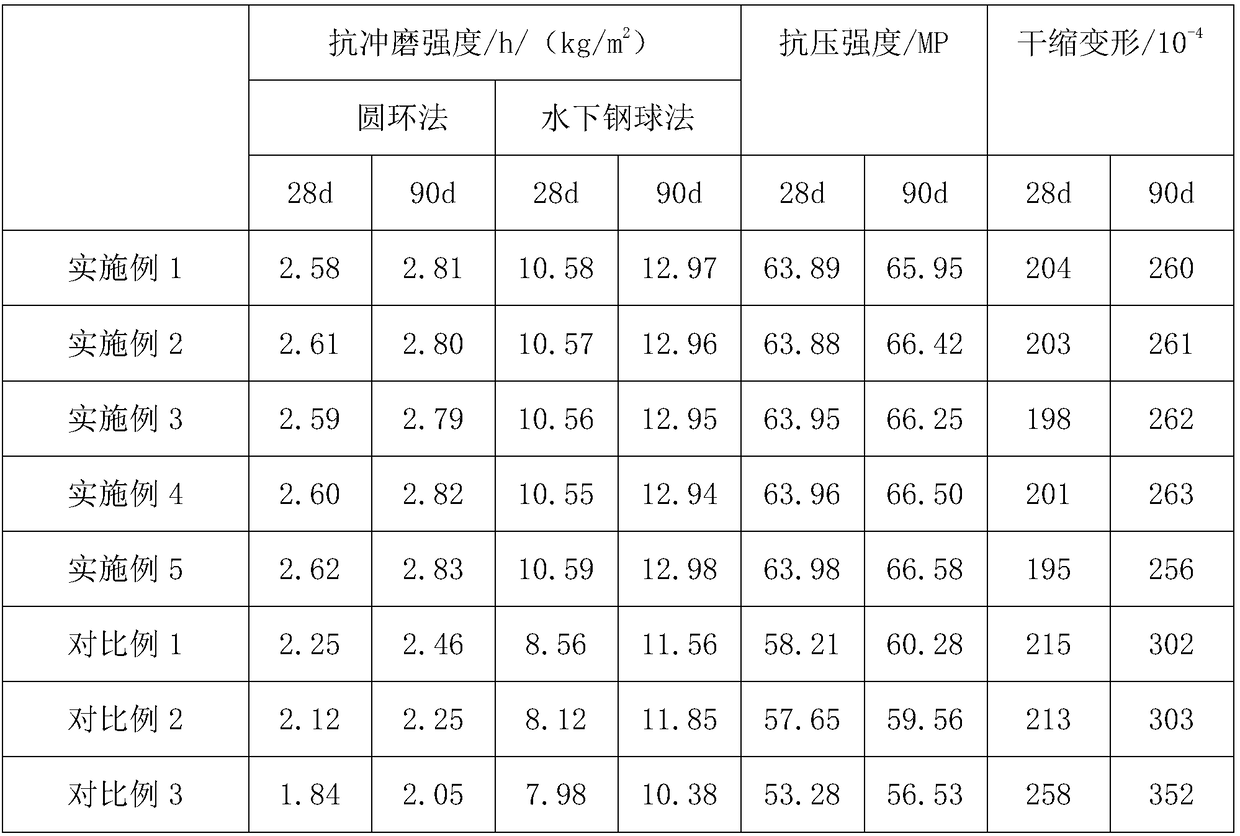

Impact-resistant abrasion-resistance concrete for hydraulic engineering and preparation method of impact-resistant abrasion-resistance concrete for hydraulic engineering

InactiveCN108529973AMeet construction needsImprove impact and wear resistanceGlass fiberActivated carbon

The invention discloses impact-resistant abrasion-resistance concrete for hydraulic engineering. The concrete is prepared from, by weight, 20-30 parts of modified glass fibers, 15-25 parts of modifiedbamboo activated carbon powder, 70-80 parts of ordinary Portland cement, 30-40 parts of aggregates, 50-60 parts of deionized water and 5-10 parts of a water reducing agent. The invention further discloses a preparation method of the impact-resistant abrasion-resistance concrete for hydraulic engineering. The preparation method includes steps: (1) modified glass fiber preparation; (2) modified bamboo activated carbon powder preparation; (3) mixing. On the basis that ordinary Portland cement is used as a concrete raw material currently, modified glass fibers and modified bamboo activated carbonpowder are added, and accordingly impact resistance and abrasion resistance of concrete are greatly improved; in addition, glass fibers and the bamboo activated carbon powder are extensive in source,energy saving, environmental friendliness, suitableness for large-scale production and high reliability are realized, and construction requirements of hydraulic engineering are met.

Owner:河南正海实业有限公司 +18

Long life distribution chute

ActiveCN101581541BReduce chute weightReduce weightBell-and-hopper arrangementCharge manipulationRefractoryMaterials science

Owner:CISDI ENG CO LTD

Variable-temperature sintering technology for high-chromium cast iron

ActiveCN109249019AHigh hardnessImprove impact toughnessTransportation and packagingMetal-working apparatusLower limitTemperature control

The invention provides a variable-temperature sintering technology for high-chromium cast iron, and belongs to the field of the metal material powder metallurgy. The technology comprises the followingsteps: (1) atomizing and powdering; (2) mould-pressing and blank-making: adding a forming agent to pre-alloy powder, after pressing, to obtain a pressed blank; (3) variable-temperature sintering: performing the variable-temperature sintering on the pressed blank, wherein an upper limit sintering temperature is 1250-1280 DEG C, and heat-preserving time is 10-30 min, after that, rapidly cooling toa lower limit sintering temperature of 1220-1245 DEG C, wherein the heat-preserving time is 30-90 min, to obtain a sintering sample blank; and (4) temperature control cooling: performing the temperature control cooling on the sintering sample blank, furnace-cooling later or immediately air-cooling in a room temperature. The technology is capable of, through processes of pre-alloy atomizing and powdering, mould-pressing and blank-making, variable-temperature sintering, and temperature control cooling, greatly shortening preparation time, reducing operation difficulty, after acquiring a carbidewhich is simple in morphology, small in size and uniform in distribution, greatly improving bending strength of an alloy as well as enabling impact toughness of the high-chromium cast iron to be improved, and greatly improving shock-resisting and wear-resisting properties of the high-chromium cast iron alloy.

Owner:HUNAN UNIV

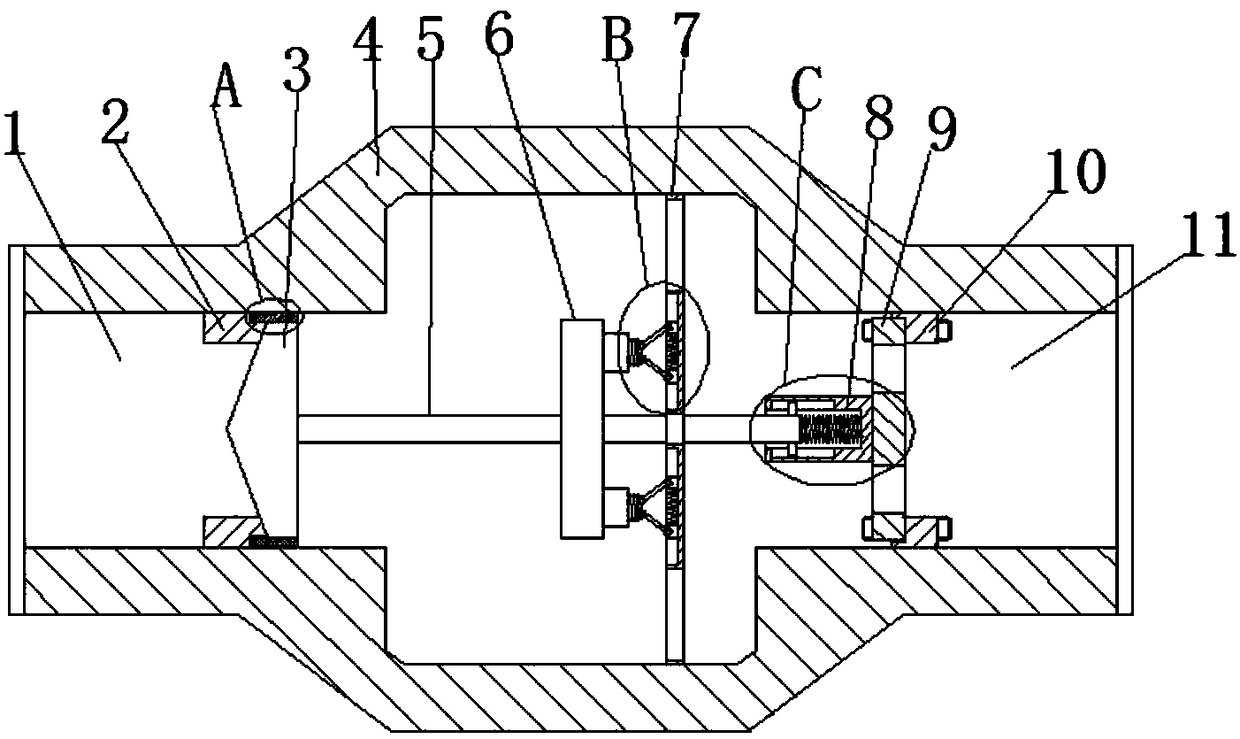

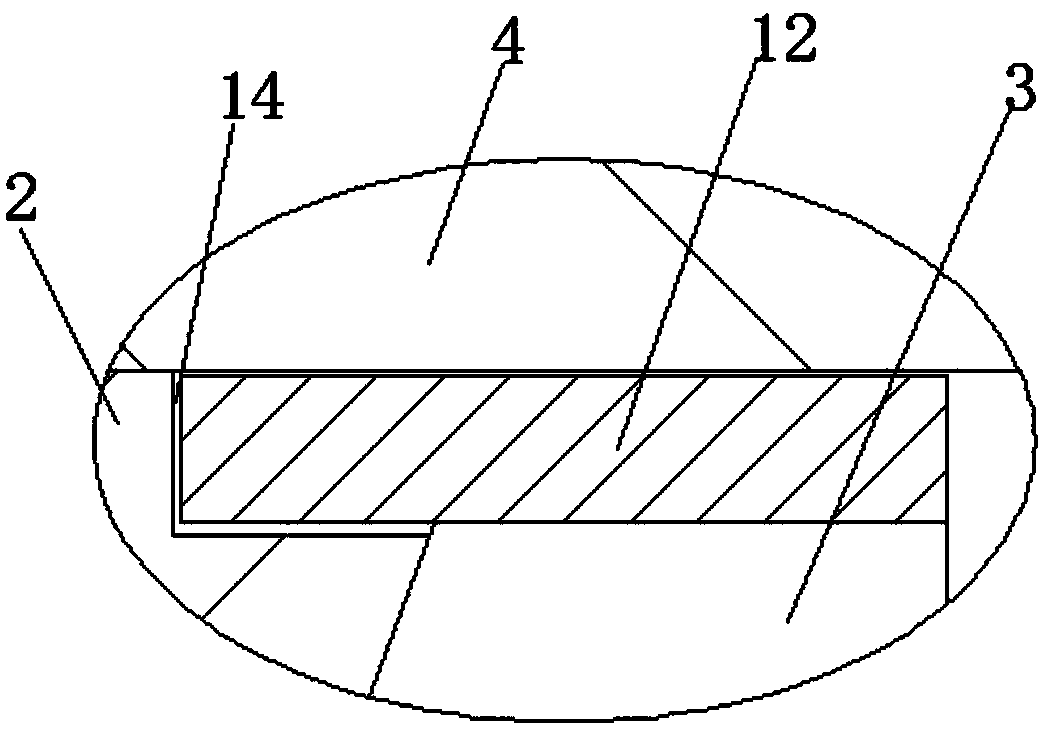

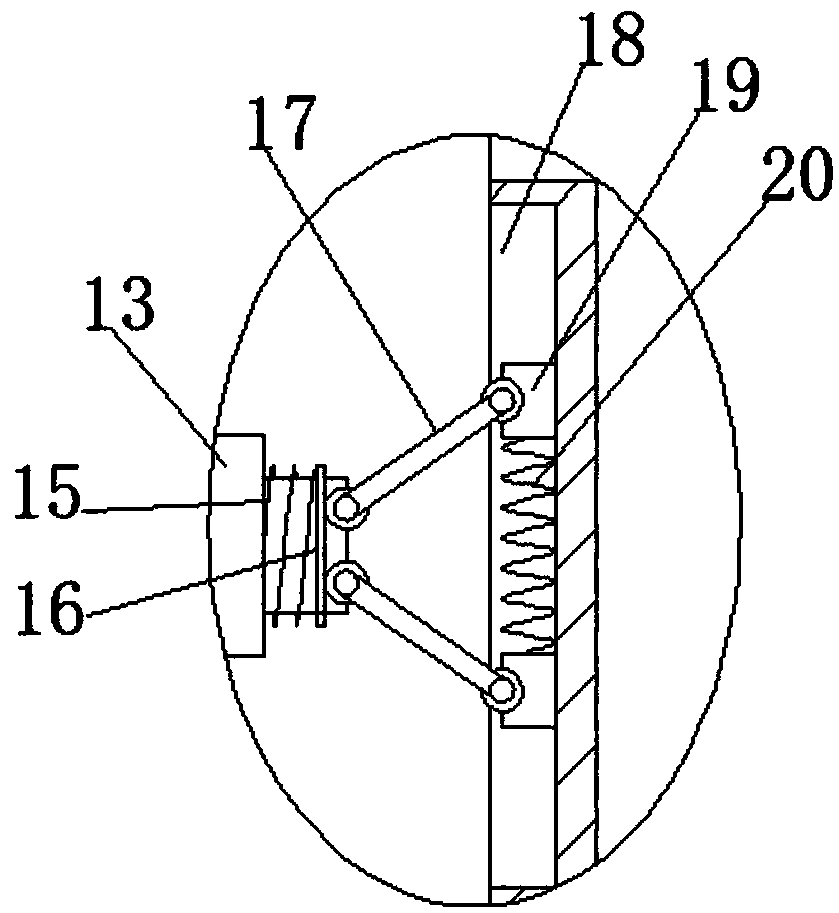

Non-return valve with high impact resistance and wear resistance

InactiveCN108343764AImprove impact and wear resistanceImprove impact resistanceCheck valvesHigh resistanceShock resistance

The invention discloses a non-return valve with high impact resistance and wear resistance. The non-return valve comprises a valve body which is of a hollow structure, wherein a water inlet is formedin the side wall of one side of the valve body; a first baffle ring is arranged on the inner wall of the water inlet; a movable rod which is transversely arranged is arranged in the valve rod; a baffle plate is arranged on the side wall of one side of the movable rod; one side, away from the movable rod, of the baffle plate abuts against the side wall of the first baffle ring; a water outlet is formed in one side, away from the water inlet, of the valve body; a second baffle ring is arranged on the inner wall of the water outlet; a first fixed block which is vertically arranged is arranged onthe side wall of one side of the second baffle ring; the first fixed block is in fastening connection with the second baffle ring through a bolt; a plurality of first through holes are formed in the side wall of one side of the first fixed block in a surrounding mode; and a sleeve rod which is transversely arranged is arranged on the side wall of the center of the first fixed block. The non-returnvalve with high impact resistance and wear resistance is relatively high in impact resistance and wear resistance, and can prolong the service life.

Owner:范科晨

High-toughness impact-resistant and wear-resistant repairing material

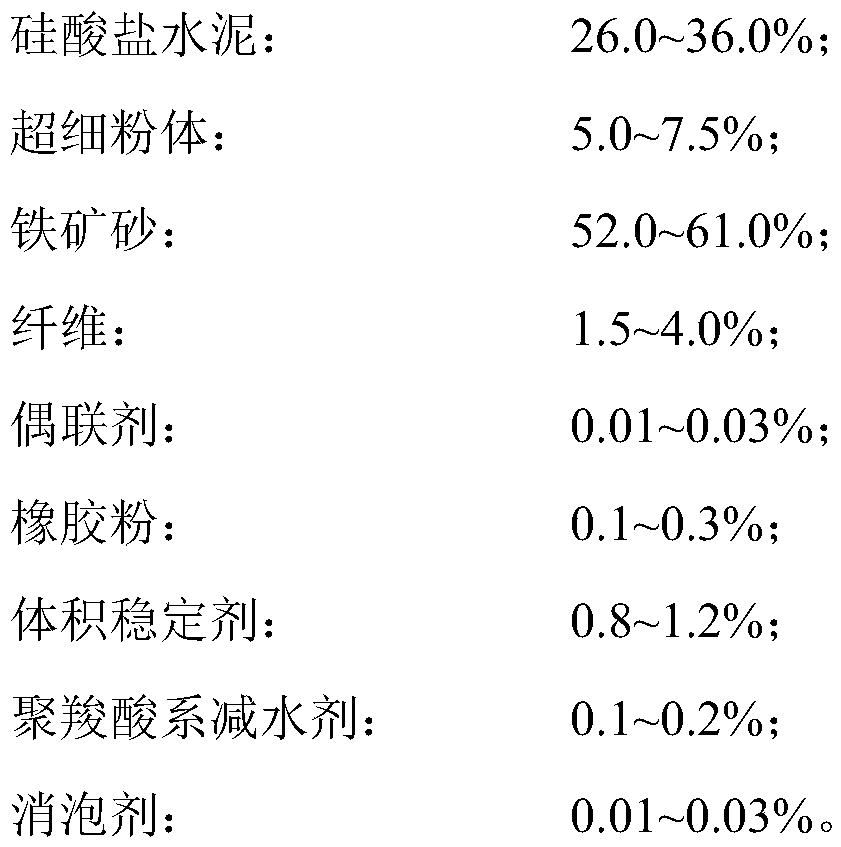

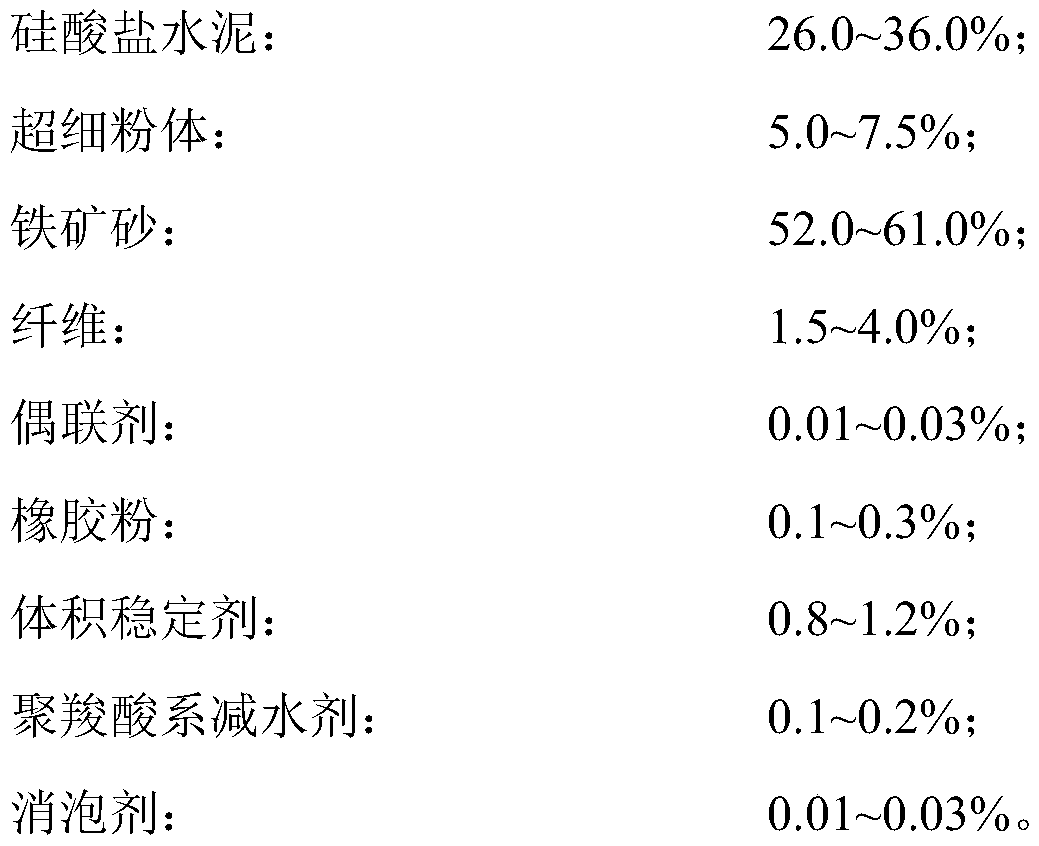

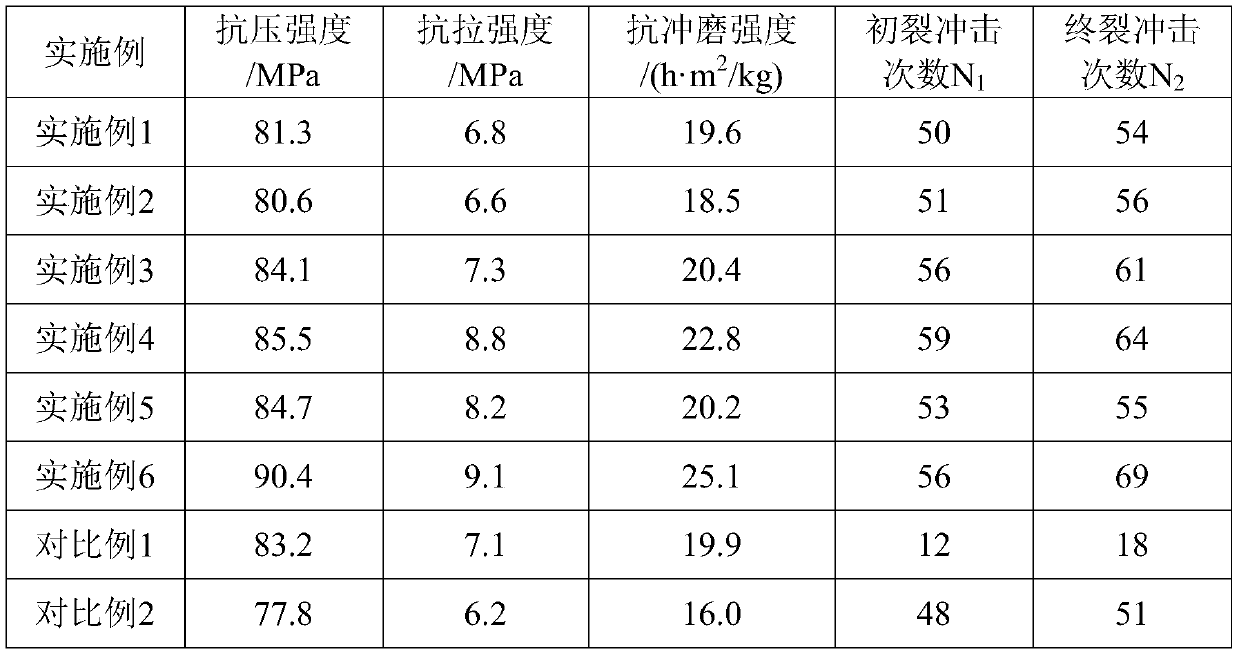

The invention provides a high-toughness impact-resistant and wear-resistant repairing material which is mainly prepared from 26.0 to 36.0 percent of portland cement, 5.0 to 7.5 percent of ultrafine powder, 52.0 to 61.0 percent of iron ore, 1.5 to 4.0 percent of fiber, 0.01 to 0.03 percent of a coupling agent, 0.1 to 0.3 percent of rubber powder, 0.8 to 1.2 percent of a volume stabilizer, 0.1 to 0.2 percent of a polycarboxylate water reducing agent, 0.01 to 0.03 percent of a defoaming agent and the like. The high-toughness impact-resistant and wear-resistant repairing material provided by the invention has the advantages of low price, convenient construction, high impact toughness, high impact strength, high bonding strength, low shrinkage and high crack resistance, has a linear expansion coefficient close to that of concrete, cannot fall off from a base material, and can replace organic materials such as epoxy resin mortar and the like.

Owner:安徽瑞和新材料有限公司 +1

A special reinforcing agent for ready-mixed permeable concrete and its preparation method

ActiveCN108751784BPrevent shrinkage fractureReduce stress crackingStructural engineeringPervious concrete

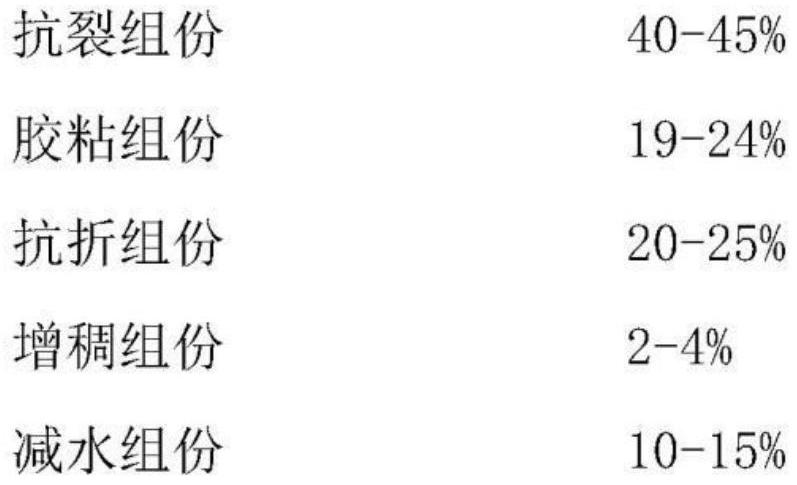

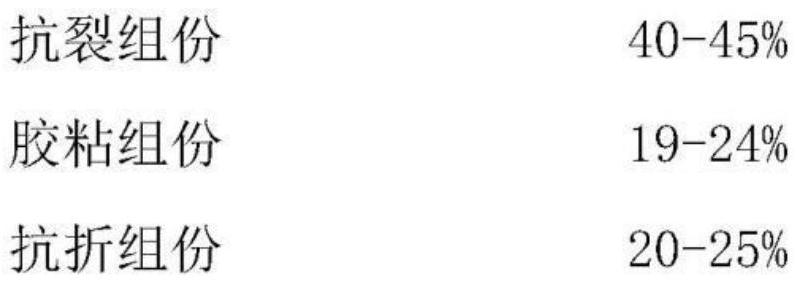

The invention provides a special reinforcing agent for ready-mixed pervious concrete and a preparation method thereof. The special reinforcing agent for the ready-mixed pervious concrete includes thefollowing raw materials by mass: 40-45% of anti-cracking component, 20-25% of flexural component, 2%-4% of thickening component, 19-24% of adhesive component and 10-15% of water reduction component. The dosage of the special reinforcing agent in the pervious concrete is 2-3% of the mass of a cementing material. The reinforcing agent can not only effectively prevent the late shrinkage of the pervious concrete and reduce the stress cracking, but also significantly improve the flexural resistance and the frost resistance of the pervious concrete, ensures the mechanical property and the durabilityof pervious concrete pavements, and enhances the water retention and the slump retention of the previous concrete to meet the construction requirements of the ready-mixed concrete. The reinforcing agent is beneficial to prepare the premixed medium and high strength pervious concrete.

Owner:WUHAN YUANJIN BUILDING MATERIALS TECH CO LTD

Composite facing material

ActiveCN107175854ASolve the technical problems of impact resistance and wear resistanceGuaranteed softnessSynthetic resin layered productsRubber layered productsElastomerPolyolefin

The invention discloses a composite facing material, comprising a wear-resistant layer, a base layer and a bonding layer sequentially from top to bottom; the wear-resistant layer and the base layer are formed by co-extrusion; the base layer is pasted to the bonding layer through hot melt glue; the wear-resistant layer is made from, by weight, 40-70% of EPDM (ethylene propylene diene monomer), 25-60% of PP (polypropylene), 1-3% of a peroxide, and 1-3% of a crosslinking modifier; the base layer is formed by adding a foaming agent and crosslinking agent DCP to POE (polyolefin elastomer) and micro-foaming; the bonding layer is of fabric. The wear-resistant polyolefin elastomer is combined to the foamed POE material, and therefore, wear resistance and impact resistance are imparted to the surface, and the base layer is imparted softness.

Owner:百晟新材料有限公司

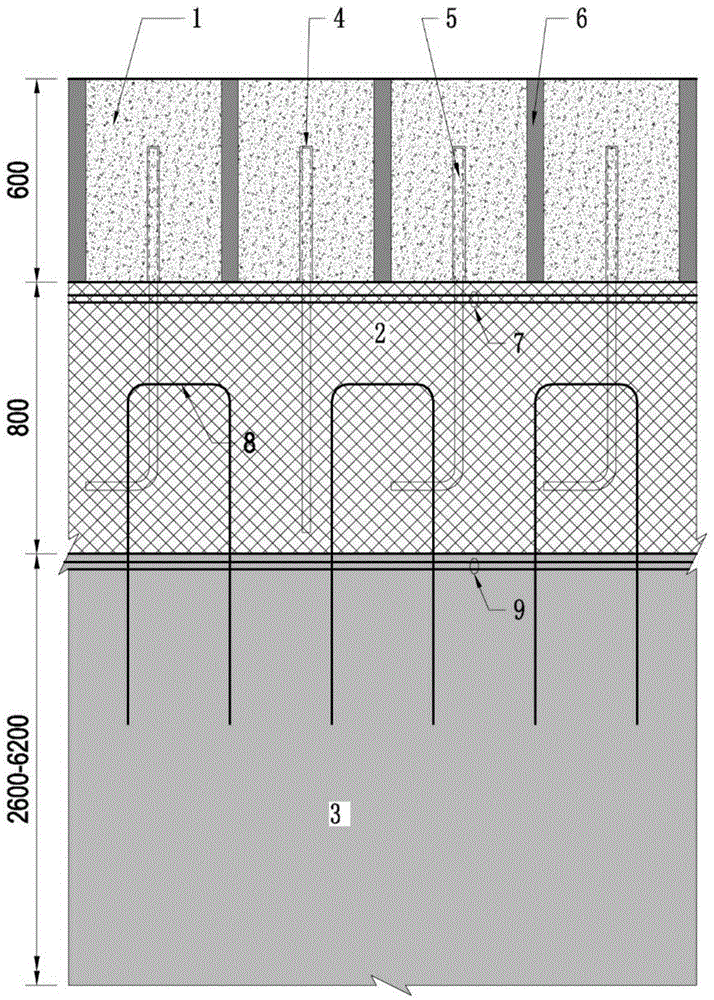

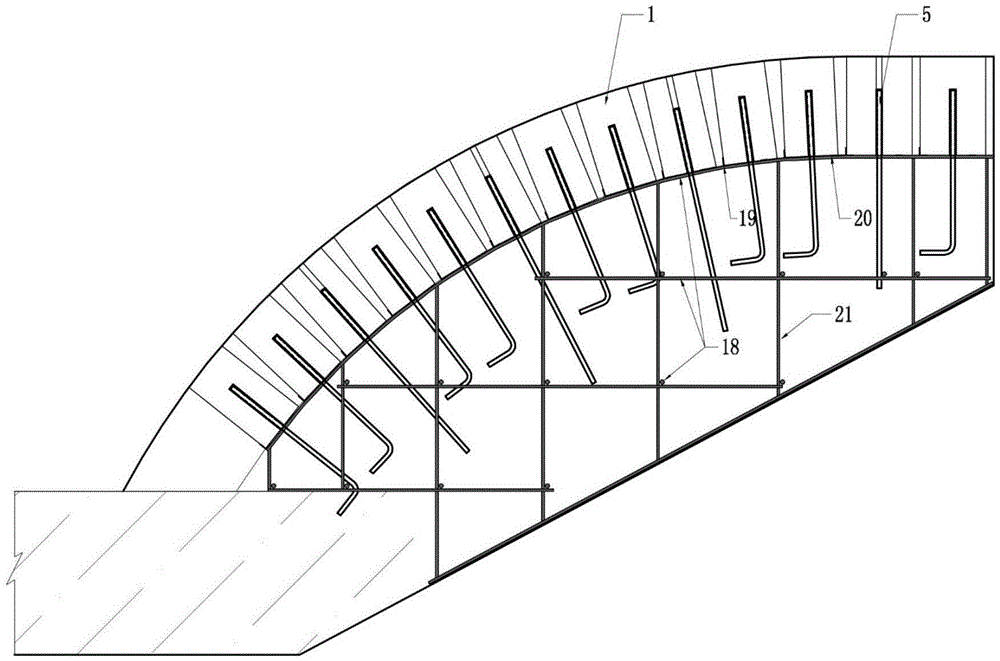

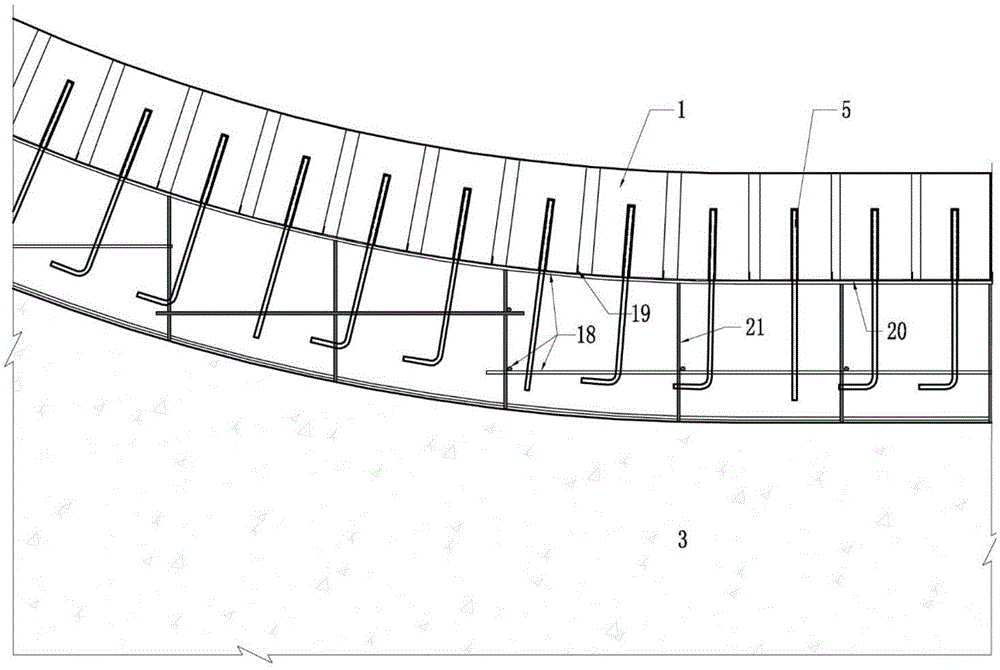

Protection structure of high-speed overflowing surface and construction method thereof

ActiveCN104929084AConvenience for contour controlIncrease anchoring forceBarrages/weirsSurface layerStructure of the Earth

The invention discloses a protection structure of a high-speed overflowing surface and a construction method thereof. The structure comprises granites on a protection surface layer, secondary concrete on a middle transition layer and primary concrete on a base layer, wherein primary structural concrete reinforcements are arranged on the top surface of the primary concrete; secondary concrete surface layer reinforcements are arranged on the top surface of the secondary concrete; the primary concrete and the secondary concrete are connected through U-shaped ribs; the secondary concrete and the granites are connected through elbow anchor ribs or straight anchor ribs; and multiple granites are arranged in sequence to form an array, and are filled with gap concrete to be fixedly connected. The structure is novel in design idea, safe, reliable and convenient to operate, and greatly improves the scour resistance and the wear resistance of spillways. The structure is suitable for medium-high dam spillway engineering under bad river bed geological conditions.

Owner:中国葛洲坝集团第三工程有限公司

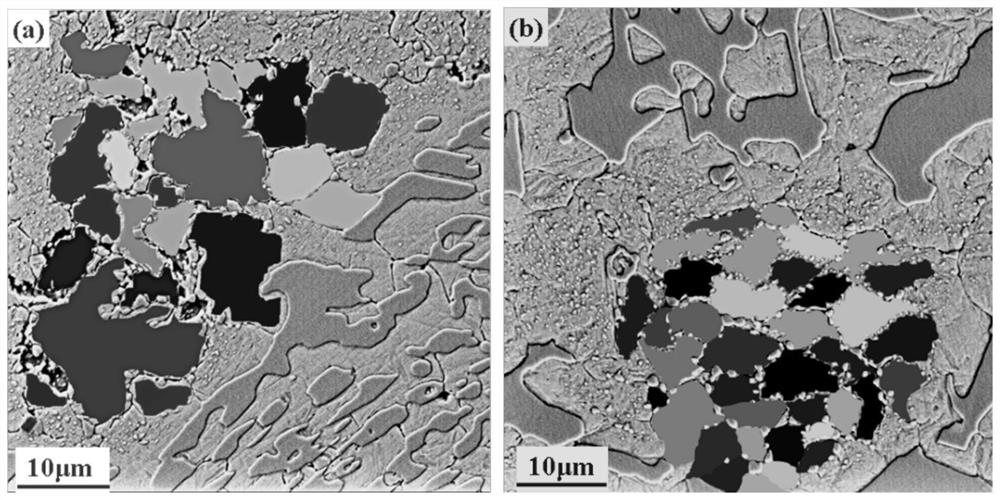

High-strength high-toughness wear-resistant high-chromium cast iron and preparation method thereof

InactiveCN113444964AEvenly distributedUniform and fine grain distributionProcess efficiency improvementMetallic materialsCarbide

The invention belongs to the technical field of wear-resistant metal materials, and particularly relates to high-strength high-toughness wear-resistant high-chromium cast iron and a preparation method thereof. The cast iron comprises the following chemical components in percentage by weight: 2.5 to 3.5 percent of C, 0.5 to 1.0 percent of Si, 15 to 18 percent of Cr, 0.4 to 0.6 percent of B, 0.3 to 0.5 percent of Nb, 0.3 to 0.5 percent of Ti, 0.6 to 1 percent of K / Na, 0.3 to 0.5 percent of Re and the balance of Fe. By adding effective alloy elements and carrying out modification treatment, the high-chromium cast iron provided by the invention can refine a matrix structure, improves the form and distribution of corresponding carbides to improve the strength and toughness of the high-chromium cast iron, and can improve the wear resistance of the high-chromium cast iron. The macrohardness of the cast iron provided by the invention is as high as 63 HRC to 66 HRC, and the impact toughness of the cast iron is as high as 13.5 J / cm<2> to17.5 J / cm<2>.

Owner:JINAN UNIVERSITY

Surface treatment technology of sliding bearing for lead pig cold granulator

InactiveCN106929782AImprove surface wear resistanceDimensionally stableLiquid surface applicatorsCoatingsBiological activationQuenching

The invention discloses a surface treatment technology of a sliding bearing for a lead pig cold granulator. The technology comprises the steps of firstly, cleaning, secondly, pre-assembling, fourthly, pickling activation, fifthly, radiation treatment, sixthly, quenching, seventhly, tempering and eighthly, powder coating. Through the synergistic effect of whole procedure treatment, the impact-resisting wear property of the treated bearing is greatly improved, the technology is applied to a shear device of the lead pig cold granulator, the precision and the thickness of the section are greatly improved, the thickness is uniform, no knife connecting phenomenon exists, the shearing effect is better, the sectioning efficiency is high, meanwhile, energy consumption is reduced, and the service life of the shearing device is prolonged by three to four times.

Owner:蚌埠市华鼎机械科技有限公司

A high-ductility cement-based material for repairing hydraulic drainage structures and its preparation method

The invention discloses a high-ductility cement-based material for repairing hydraulic outlet works, and a preparation method thereof. The material comprises, by weight, 100 parts of cement, 25-150 parts of water, 50-250 parts of brown fused alumina, 20-450 parts of microspheres, 0.5-20 parts of nano-CaCO3, 0.1-5 parts of a water reducer, 0.95-15 parts of PVA fibers and 2-20 parts of ultrafine steel fibers. The high-ductility cement-based material for repairing hydraulic outlet works has the advantages of high impact and wear strength, high bonding strength with a matrix, high ductility, similar thermal expansion coefficient with concrete, consistence with deformation of the matrix concrete, simple and convenient construction process, and wide sources of raw materials.

Owner:SOUTHEAST UNIV

Impact-resistant and wear-resistant concrete for rapid road repair and preparation process thereof

PendingCN113321461AImprove work performanceGood construction performanceCarboxylic acidProcess engineering

The invention discloses impact-resistant and wear-resistant concrete for rapid road repair and a preparation process thereof, wherein the technical scheme comprises that the impact-resistant and wear-resistant concrete comprises 150-210 parts of water, 230-290 parts of cement, 70-90 parts of fly ash, 20-60 parts of silica fume, 80-120 parts of medium sand, 70-110 parts of aggregate, 20-40 parts of propylene fibers, 10-30 parts of an expanding agent, 3-10 parts of an impact-resistant and wear-resistant agent, 5-15 parts of a polycarboxylic acid high-performance water reducing agent and 7-13 parts of a retarder. The preparation method comprises the following specific preparation steps: S1, aggregate processing; S2, mixing and stirring; and S3, adding an additive. The concrete has the beneficial effects that the impact-resistant and wear-resistant agent can improve the compressive strength and the impact-resistant and wear-resistant strength of the concrete, the wear rate is reduced due to the addition of the fly ash, the concrete has good construction performance and high impact-resistant and wear-resistant strength after hardening, and the volume dosage of the polypropylene fiber is increased, so that the concrete poured on a road is rapidly solidified and the road is repaired, and the road can be quickly put into use.

Owner:广东大禹水利建设有限公司 +1

A composite veneer material

ActiveCN107175854BSolve the technical problems of impact resistance and wear resistanceGuaranteed softnessSynthetic resin layered productsRubber layered productsElastomerPolyolefin

The invention discloses a composite facing material, comprising a wear-resistant layer, a base layer and a bonding layer sequentially from top to bottom; the wear-resistant layer and the base layer are formed by co-extrusion; the base layer is pasted to the bonding layer through hot melt glue; the wear-resistant layer is made from, by weight, 40-70% of EPDM (ethylene propylene diene monomer), 25-60% of PP (polypropylene), 1-3% of a peroxide, and 1-3% of a crosslinking modifier; the base layer is formed by adding a foaming agent and crosslinking agent DCP to POE (polyolefin elastomer) and micro-foaming; the bonding layer is of fabric. The wear-resistant polyolefin elastomer is combined to the foamed POE material, and therefore, wear resistance and impact resistance are imparted to the surface, and the base layer is imparted softness.

Owner:百晟新材料有限公司

Process for preparing rare earth modified carbon nanotube/polyimide composite materials

The invention relates to a method for preparation of rare earth-modified carbon nano-tube / polyimide composite, which consists of performing mat-forming treatment of modifying property to carbon nano-tube adopting rare earth modifier first, then laying the disposed carbon nano-tube into the ball grinder to mill, afterwards, mechanically blending the carbon nano-tube and the polyimide powder and controlling the percentage by weight of the carbon nano-tube to occupy 1-10 % of the mixed powder, then laying the mixed powder into the stainless steel die for press forming, finally preparing the composite by high-sintering. Thereinto, the rare earth modifier consists of rare-earth compound, alcohol, ethylene diamine tetraacetic acid, ammonii chloridum, aqua fortis and aquacare. The invention is of simple technique and low cost, is non-contamination, and the prepared composite possess good dynamic property and frictional behavior.

Owner:SHANGHAI JIAOTONG UNIV

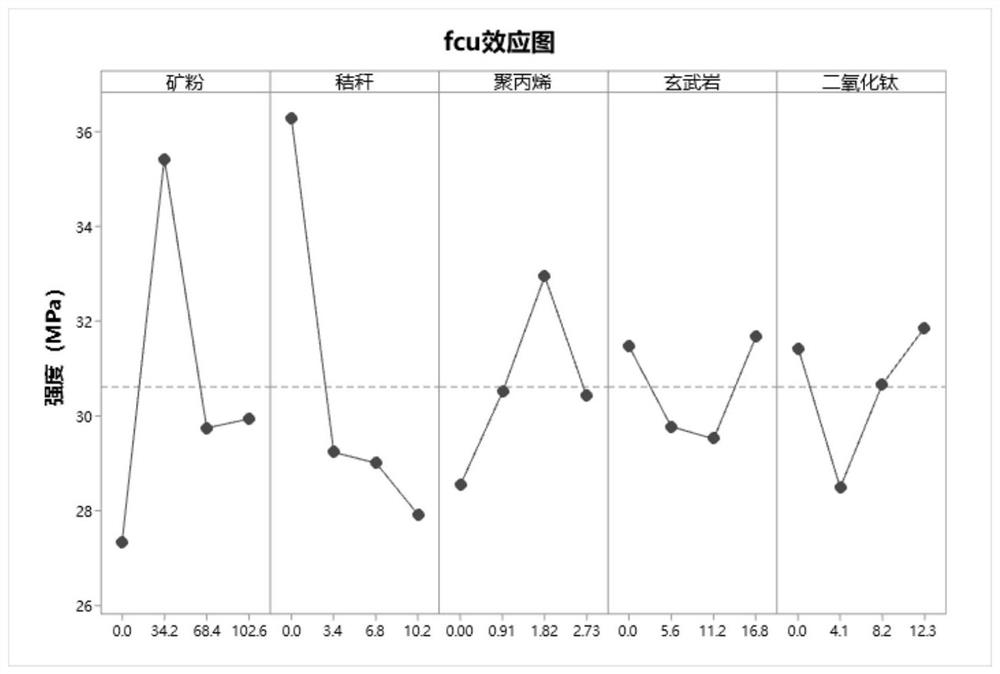

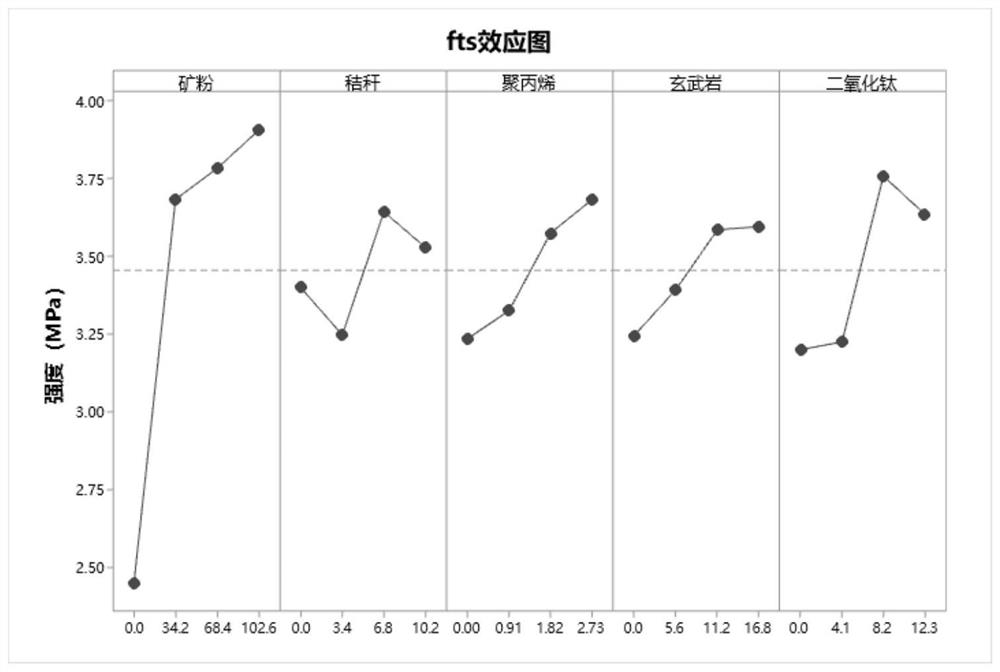

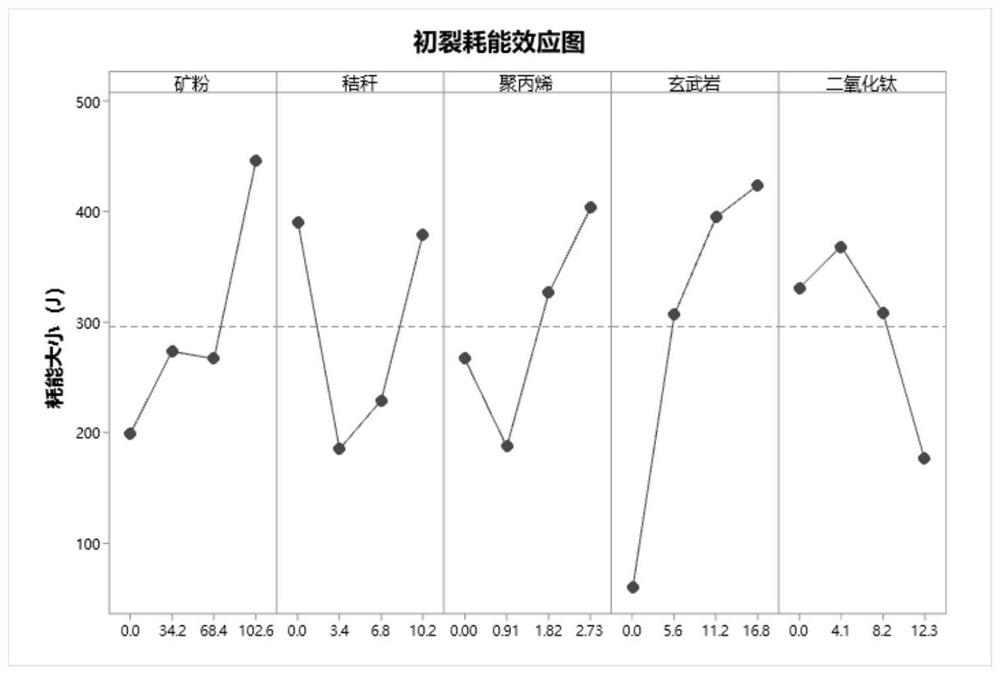

Preparation method of antibacterial high-performance fiber concrete

The invention provides a preparation method of antibacterial high-performance fiber concrete. The preparation method comprises the following steps: step 1, performing material cutting; step 2, carrying out material crushing; step 3, pretreating straw fiber ; step 4, carrying out modification treatment on the straw fiber; step 5, preparing modified polypropylene fiber; step 6, carrying out material preparation; step 7, mixing all the prepared materials; step 8, mixing nano-TiO2, a water reducer and water; step 9, uniformly pouring white uniform liquid into a stirrer, and conducting stirring for 60-90 s to form a hybrid fiber concrete mixture; step 10, carrying out a slump test on the hybrid fiber concrete mixture, and adding the hybrid fiber concrete mixture into a concrete mold; and step 11, putting the mold into a standard curing room with a temperature of 20 + / - 2 DEG C and a relative humidity of 95% or more, and conducting curing for 28 days. The tensile strength, brittleness, impact resistance, wear resistance and other properties of the prepared fiber concrete are obviously improved. Meanwhile, the obvious technical effects of resisting bacteria, being not prone to cracking and the like can be achieved, the service life of the concrete is prolonged, and the human settlement environment, health and safety are improved.

Owner:SOUTHWEST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com