Modified cement-based antishock and wear-resistant material and preparation and application methods thereof

A wear-resistant material, cement-based technology, applied in the field of concrete admixtures, can solve the problems of increased production costs, limited wear resistance, high price, etc., to improve impact and wear resistance, improve impact and abrasion resistance, and be easy to use The effect of transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

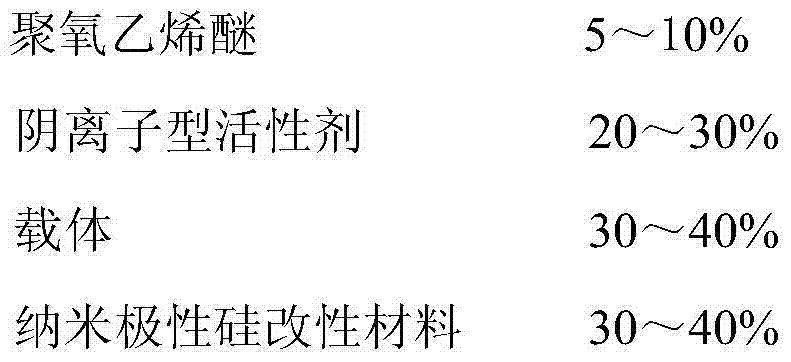

Embodiment 1

[0025] The modified cement-based anti-impact and wear-resistant material is made of the following components: 10% polyoxyethylene ether, 25% anionic active agent, 35% carrier, and 30% nano-polar silicon modified material. Among them, the mass average molecular weight of polyoxyethylene ether is 3500, the anionic active agent substance is sodium dodecylbenzenesulfonate, the carrier is 230 mesh mordenite, and the nano-polar silicon modified material is nano-scale silicon dioxide modified material ( Specific surface area S≥600m 2 / g).

[0026] Pour the polyoxyethylene ether and anionic active agent in the mass percentage into a reaction kettle filled with distilled water. After heating to 80°C, pour the carrier into it, stir for 10 minutes, cool to 30°C-40°C, and add after drying The nano-polar silicon modified material in the mass percentage was homogenized for 30 minutes to obtain a modified cement-based impact-resistant and wear-resistant material.

Embodiment 2

[0028] The modified cement-based anti-impact and wear-resistant material is made of the following components: 8% polyoxyethylene ether, 27% anionic active agent, 30% carrier, and 35% nano-polar silicon modified material. Among them, the mass average molecular weight of polyoxyethylene ether is 4000, the anionic active agent substance is sodium alkyl polyoxyethylene ether carboxylate, the carrier is clinoptilolite of 250 mesh, and the nano-polar silicon modified material is nano-scale silicon dioxide modified Material (specific surface area S≥600m 2 / g),.

[0029] Pour the polyoxyethylene ether and anionic active agent in the mass percentage into a reaction kettle filled with distilled water. After heating to 80°C, pour the carrier into it, stir for 10 minutes, cool to 30°C-40°C, and add after drying The nano-polar silicon modified material in the mass percentage was homogenized for 30 minutes to obtain a modified cement-based impact-resistant and wear-resistant material.

Embodiment 3

[0031] The modified cement-based anti-impact and wear-resistant material is made of the following components: 5% polyoxyethylene ether, 25% anionic active agent, 30% carrier, and 40% nano-polar silicon modified material. Among them, the mass average molecular weight of polyoxyethylene ether is 4500, the anionic active agent substance is naphthalenesulfonic acid formaldehyde condensation polymer, the carrier is 280 mesh mordenite, and the nano-polar silicon modified material is nano-scale silicon dioxide modified material (specific surface area S≥600m 2 / g).

[0032] Pour the polyoxyethylene ether and anionic active agent in the mass percentage into a reaction kettle filled with distilled water. After heating to 80°C, pour the carrier into it, stir for 10 minutes, cool to 30°C-40°C, and add after drying The nano-polar silicon modified material in the mass percentage was homogenized for 30 minutes to obtain a modified cement-based impact-resistant and wear-resistant material. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com