Preparation method of antibacterial high-performance fiber concrete

A high-performance fiber and concrete technology, applied in the field of building materials preparation, can solve the problems of low tensile strength, loss of function of buildings, and high brittleness, and achieve the effect of improving performance and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

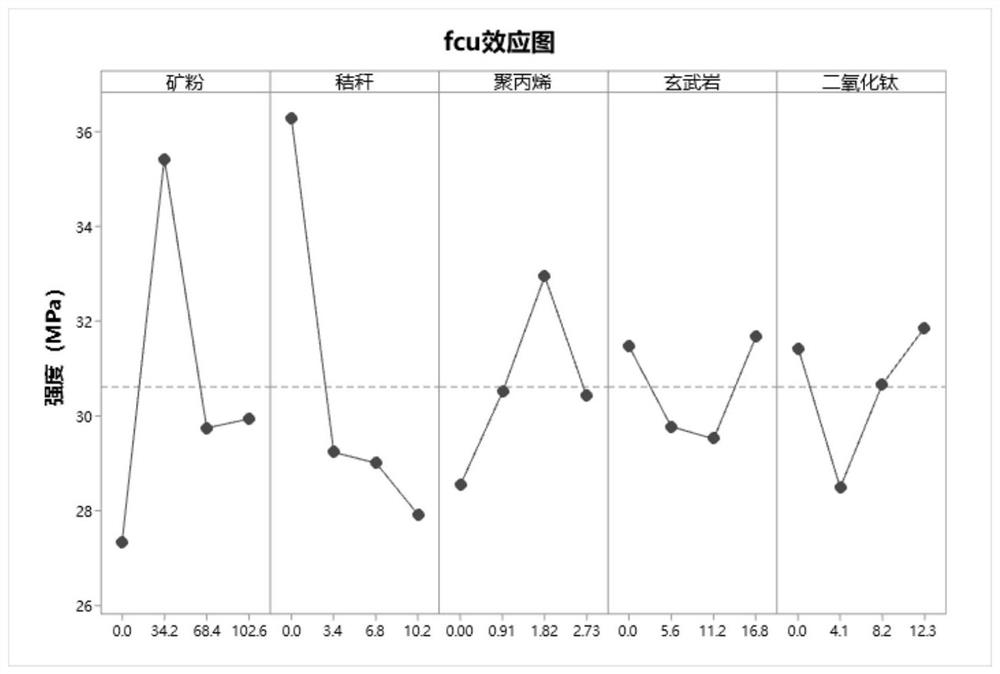

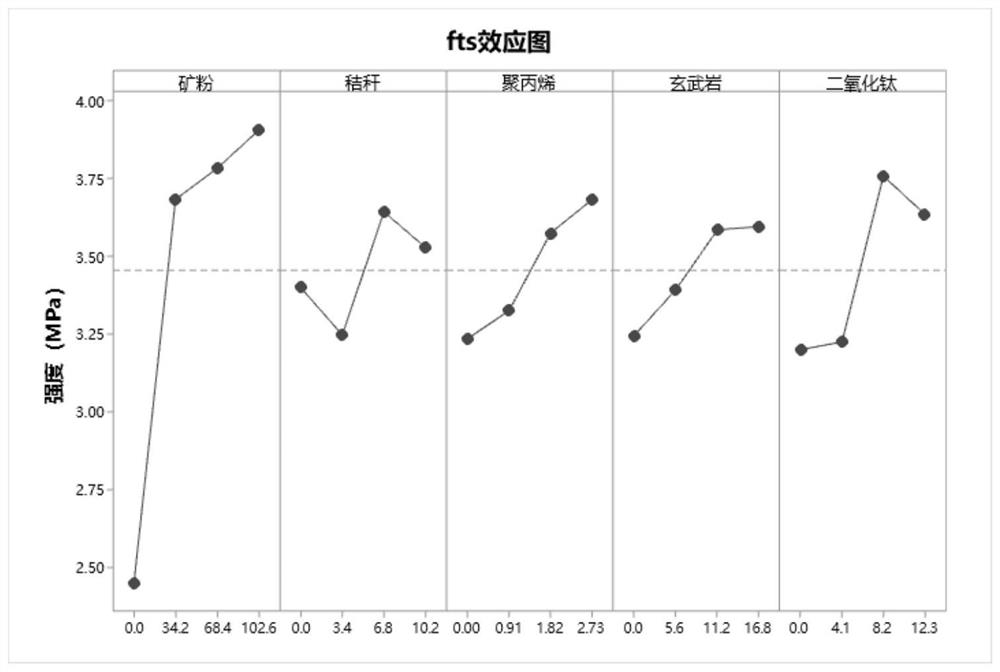

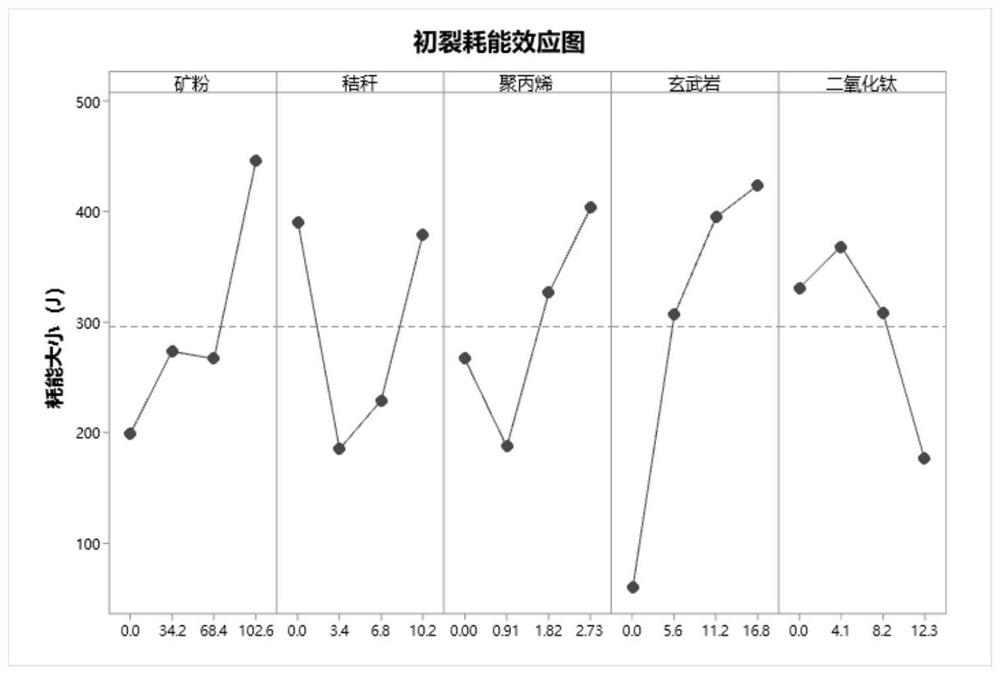

[0028] like Figure 1 to Figure 7 Shown, present embodiment discloses a kind of preparation method of high-performance fiber concrete with antibacterial property, it comprises the following steps:

[0029] Step 1, cutting materials, cutting the rice stalks recycled in the farmland into 30-50mm long straw knots.

[0030] Step 2, scrapping, the straw joints are smashed to form straw fibers with a pulverizer.

[0031] Step 3, straw fiber pretreatment, the straw fiber of step 2 and the NaOH solution that mass fraction is 1% are mixed in the constant temperature water bath pot and soaked, wherein, the mass ratio of straw fiber and NaOH solution is 1:10, constant temperature water bath pot Set the temperature to 80°C, then continuously stir with a magnetic stirrer for 30 min, and control the rotational speed of the magnetic stirrer to 300 r / min.

[0032] In this step of this embodiment, the surface of the rice straw stalk is uneven, with many thorny structures attached thereto. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com