Long life distribution chute

A technology of distributing chute and chute, which is applied to the arrangement of bells and funnels, furnaces, lighting and heating equipment, etc., which can solve the problems of increasing the weight of the chute, small cross-section of the material, and damage of the liner, so as to improve the performance of impact resistance and wear resistance , prevent excessive deformation and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

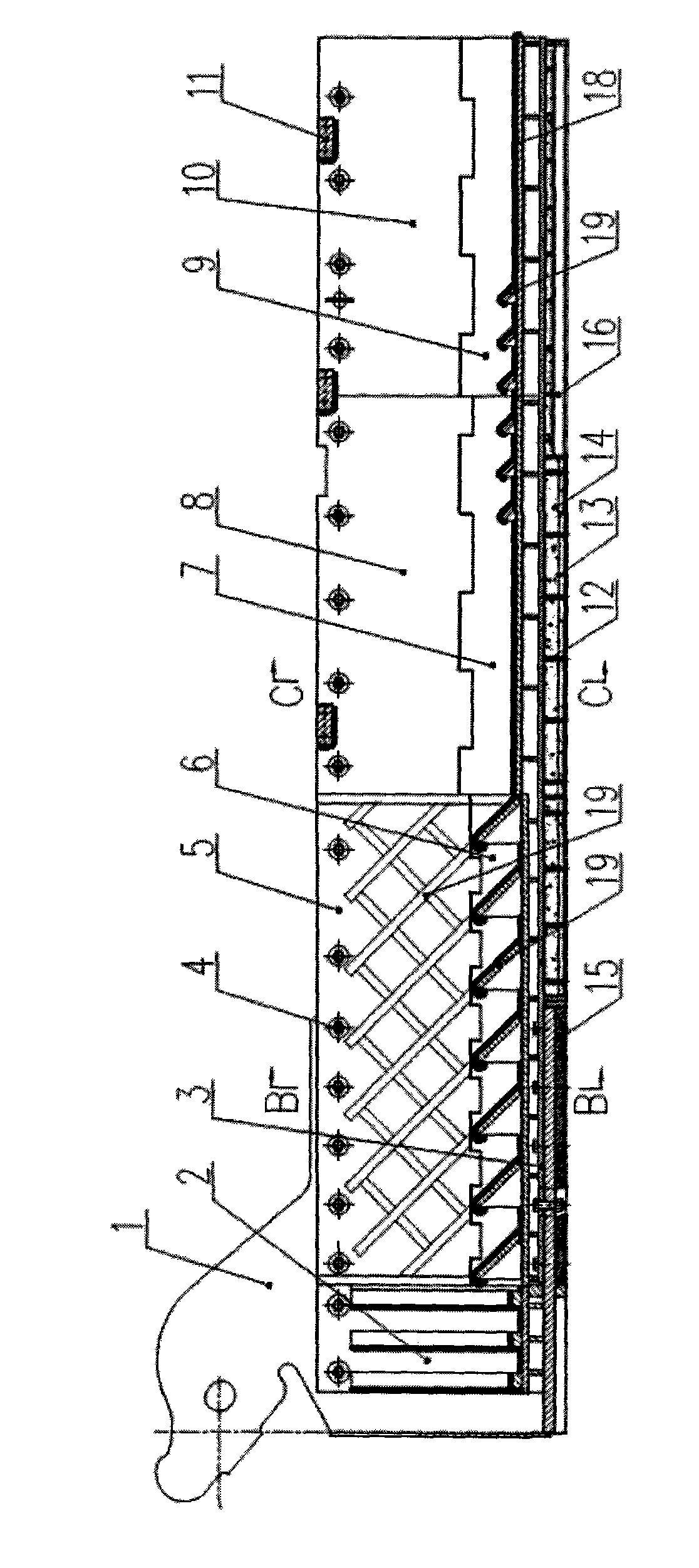

[0016] The present invention will be further described below in conjunction with accompanying drawing:

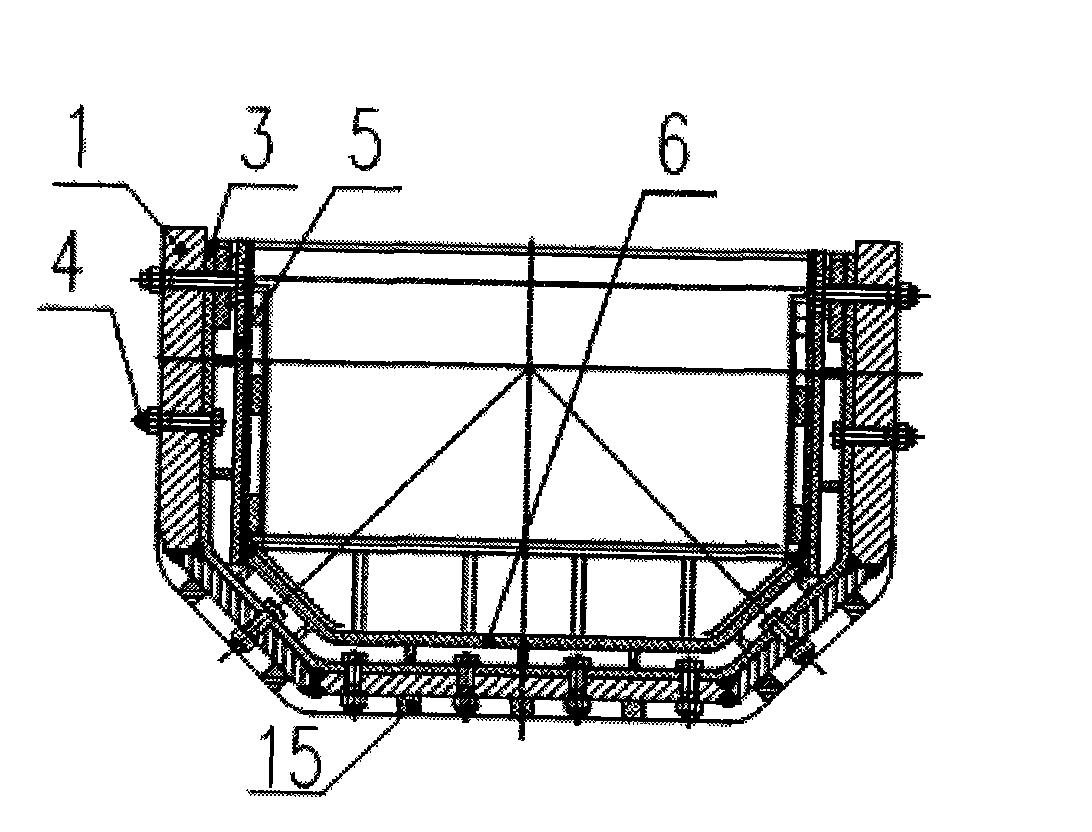

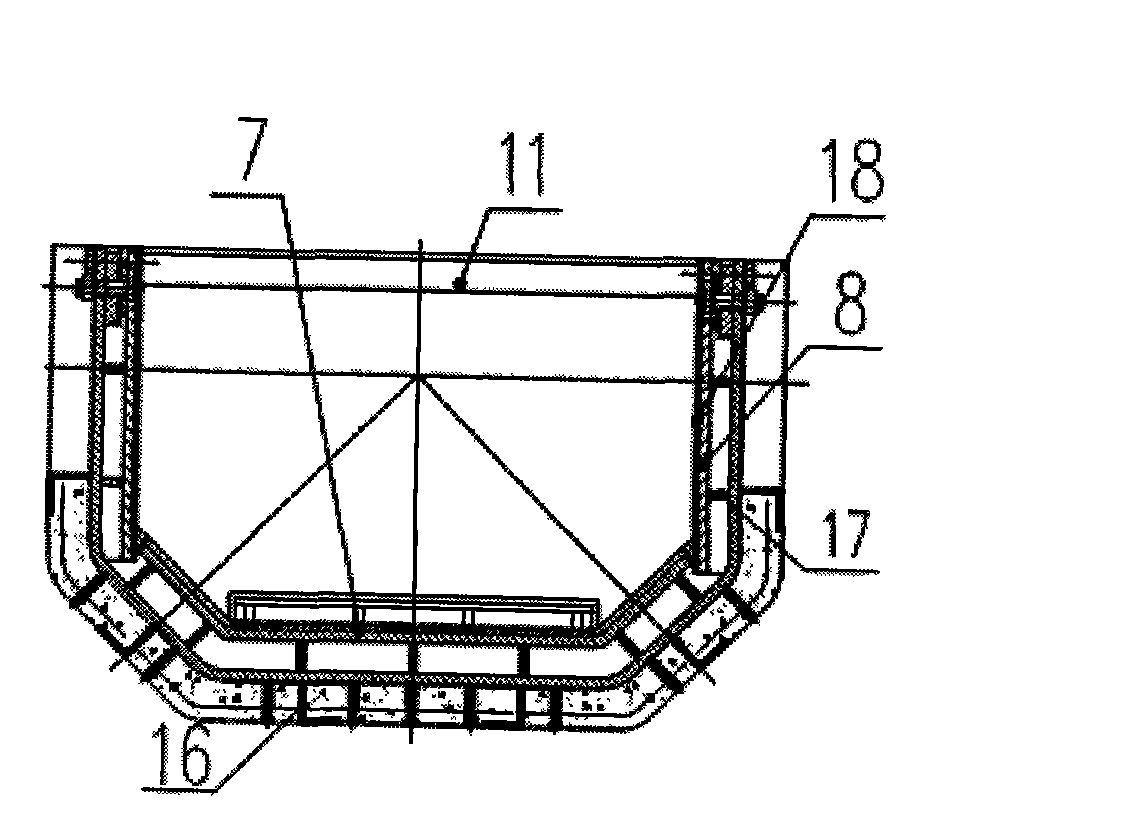

[0017] A long-life cloth chute used on the roof of a blast furnace, comprising a chute head 1, a head wear-resistant lining 2, a chute body 3, several fasteners 4, two left and right front side wear-resistant linings 5, a front Bottom wear-resistant liner 6, left and right two middle side wear-resistant liners 8, middle bottom wear-resistant liner 7, left and right tail side wear-resistant liners 10, tail bottom wear-resistant liner 9, several connecting beams 11, Some refractory material anchors 12, stainless steel wire mesh 13 and light refractory material 14 etc. for fixing refractory materials.

[0018] The chute head 1 comprises a U-shaped open hexagon welded by 5 steel plates, and each steel plate is provided with connecting bolt holes.

[0019] The head wear-resistant liner 2 is tiled on the inner surface of the hexagonal chute head 1 and connected with correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com