High-strength high-toughness wear-resistant high-chromium cast iron and preparation method thereof

A high-chromium cast iron, high-strength and high-toughness technology, applied in the field of wear-resistant metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

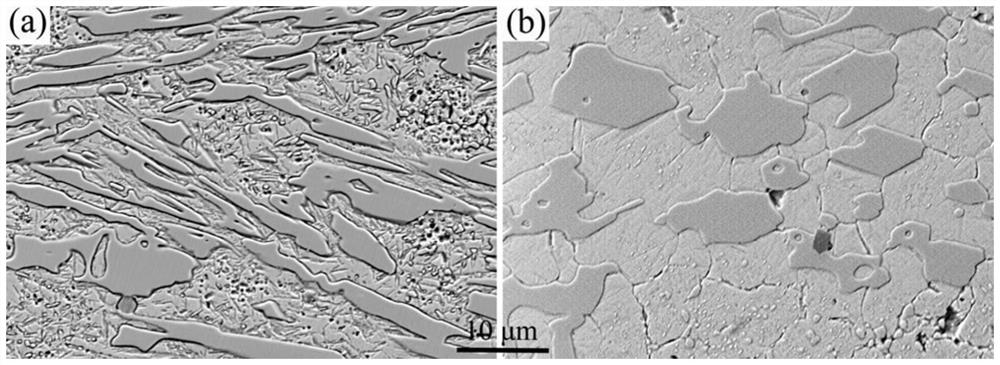

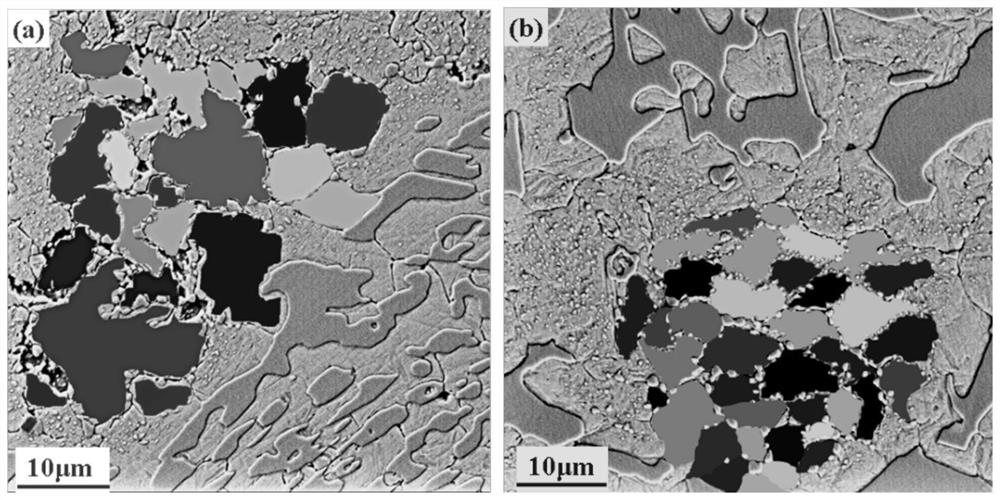

Image

Examples

Embodiment 1

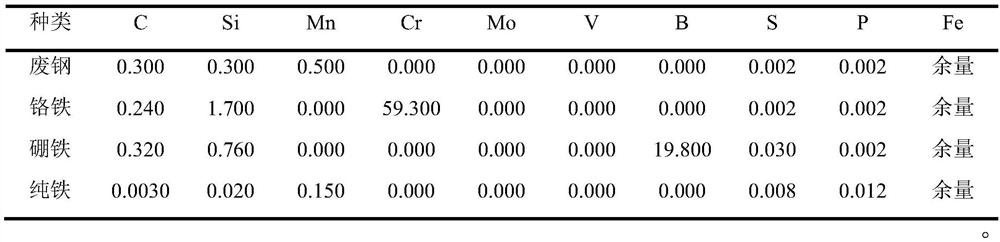

[0040] Adopt 500 kilograms of medium-frequency induction furnaces to smelt boron white cast iron of the present invention, and its manufacturing process steps are:

[0041] 1) Take scrap steel, ferrochrome and pure iron according to the mass ratio of 40%: 9%: 49.2%, mix them, fill them into the melting furnace, and heat them until they melt;

[0042] 2) Add microelement powder in the melting furnace: 0.3% Nb, 0.3% Ti, 0.3% Re for microalloying, and at the same time pass argon gas to remove impurities, the time is 25min;

[0043] 3) Bottom punching method: add 0.3% bulk ferroboron with a size less than 10mm in the furnace;

[0044] 4) Raise the temperature of the smelting furnace to 1500°C, add deoxidizer aluminum wire, and add 0.6% K / Na modifier by pouring into the bottom after the furnace charge is completely melted;

[0045]5) When the temperature of the molten steel reaches 1450°C, cast it into a casting, then keep the casting at 1000°C for 4 hours, air cool to room temper...

Embodiment 2

[0048] Adopt 500 kilograms of medium-frequency induction furnaces to smelt boron white cast iron of the present invention, and its manufacturing process steps are:

[0049] 1) Take scrap steel, ferrochromium and pure iron according to the mass ratio of 40%: 9%: 48.4%, mix them, fill them into the melting furnace, and heat them until they melt;

[0050] 2) Add microelement powder in the melting furnace: 0.4% Nb, 0.4% Ti, 0.5% Re for microalloying, and at the same time pass in argon gas to remove impurities for 30 minutes;

[0051] 3) Bottom punching method: add 0.3% bulk ferroboron with a size less than 10mm in the furnace;

[0052] 4) Raise the temperature of the smelting furnace to 1500°C, add deoxidizer aluminum wire, and add 1.0% K / Na modifier by pouring into the bottom after the furnace charge is completely melted;

[0053] 5) When the temperature of the molten steel reaches 1450°C, cast it into a casting, then keep the casting at 1000°C for 4 hours, air cool to room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| shape factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com