Impact-resistant abrasion-resistance concrete for hydraulic engineering and preparation method of impact-resistant abrasion-resistance concrete for hydraulic engineering

A technology for hydraulic engineering and concrete, applied in the field of concrete, can solve the problems of poor impact and wear resistance of concrete, and achieve the effects of increasing impact and wear resistance, high reliability and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

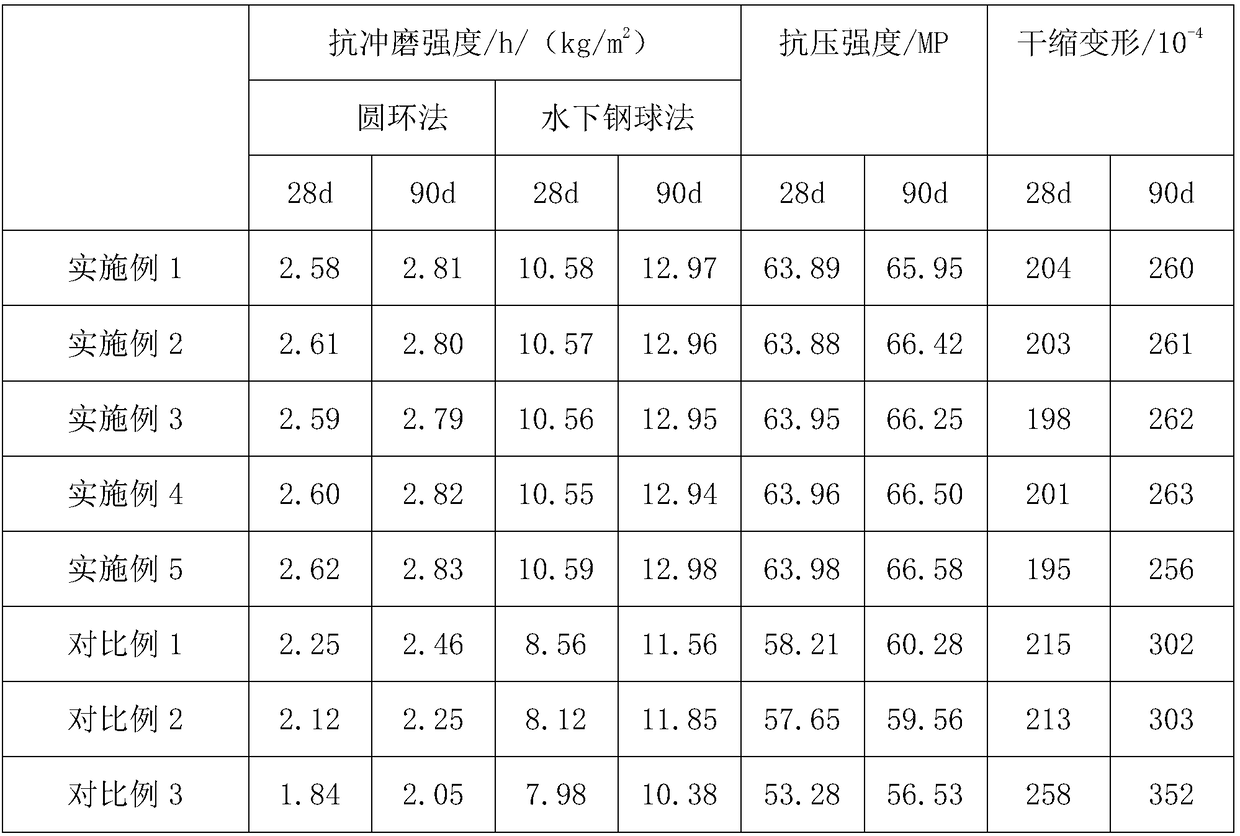

Examples

Embodiment 1

[0022] In Example 1 of the present invention, a kind of impact-resistant and wear-resistant concrete for water conservancy projects, the concrete is made of the following raw materials in parts by weight: 20 parts of modified glass fiber, 15 parts of modified bamboo activated carbon powder, ordinary silicic acid 70 parts of salt cement, 30 parts of aggregate, 50 parts of deionized water, and 5 parts of water reducing agent.

[0023] The preparation method of above-mentioned concrete comprises the steps:

[0024] (1), preparation of modified glass fiber: mercaptoethanol and deionized water are mixed into a mercaptoethanol solution whose mass concentration is 5%, and polyethylene glycol monomethyl ether and absolute ethanol are mixed into a 15% mass concentration Polyethylene glycol monomethyl ether solution, then put the glass fiber into the mercaptoethanol solution, raise the temperature to 75°C under the protection of nitrogen, and heat and stir at this temperature for 40min,...

Embodiment 2

[0028] In Example 2 of the present invention, a water conservancy project uses an impact-resistant and wear-resistant concrete, and the concrete is made of the following raw materials in parts by weight: 30 parts of modified glass fibers, 25 parts of modified bamboo activated carbon powder, ordinary silicic acid 80 parts of salt cement, 40 parts of aggregate, 60 parts of deionized water, and 10 parts of water reducing agent.

[0029] The preparation method of above-mentioned concrete comprises the steps:

[0030] (1), preparation of modified glass fiber: mercaptoethanol and deionized water are mixed into a mercaptoethanol solution whose mass concentration is 10%, and polyethylene glycol monomethyl ether and absolute ethanol are mixed into a 25% mass concentration Polyethylene glycol monomethyl ether solution, then put the glass fiber into the mercaptoethanol solution, raise the temperature to 85°C under the protection of nitrogen, and heat and stir at this temperature for 50mi...

Embodiment 3

[0034] In Example 3 of the present invention, a kind of impact-resistant and wear-resistant concrete for water conservancy projects, the concrete is made of the following raw materials in parts by weight: 22 parts of modified glass fibers, 17 parts of modified bamboo activated carbon powder, ordinary silicic acid 72 parts of salt cement, 32 parts of aggregate, 52 parts of deionized water, and 6 parts of water reducer.

[0035] The preparation method of above-mentioned concrete comprises the steps:

[0036] (1), preparation of modified glass fiber: mercaptoethanol and deionized water are mixed into a mercaptoethanol solution whose mass concentration is 7.5%, and polyethylene glycol monomethyl ether and absolute ethanol are mixed into a 20% mass concentration Polyethylene glycol monomethyl ether solution, then put the glass fiber into the mercaptoethanol solution, raise the temperature to 80°C under the protection of nitrogen, and heat and stir at this temperature for 45min, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com