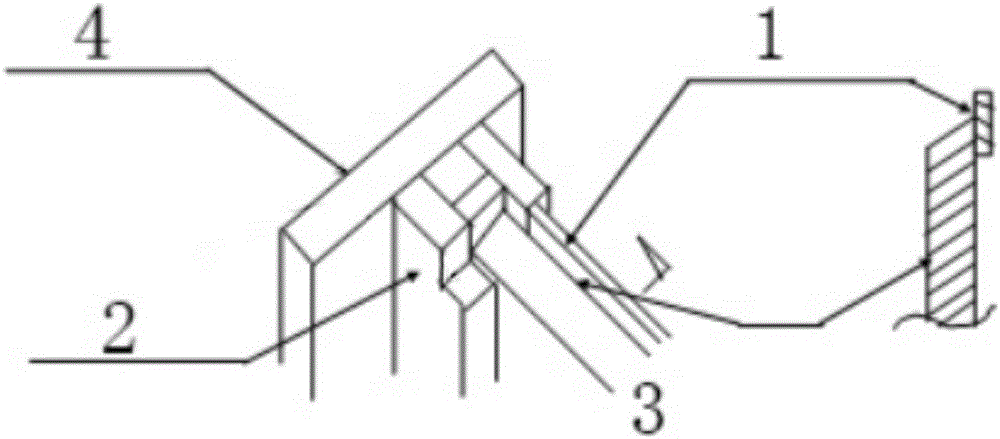

Construction process of removable special-shaped three-dimensional steel-frame structure

A technology of steel structure construction and building construction, which is applied in the direction of architecture and building construction, and can solve problems such as large construction difficulty, unsatisfactory construction speed, and construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

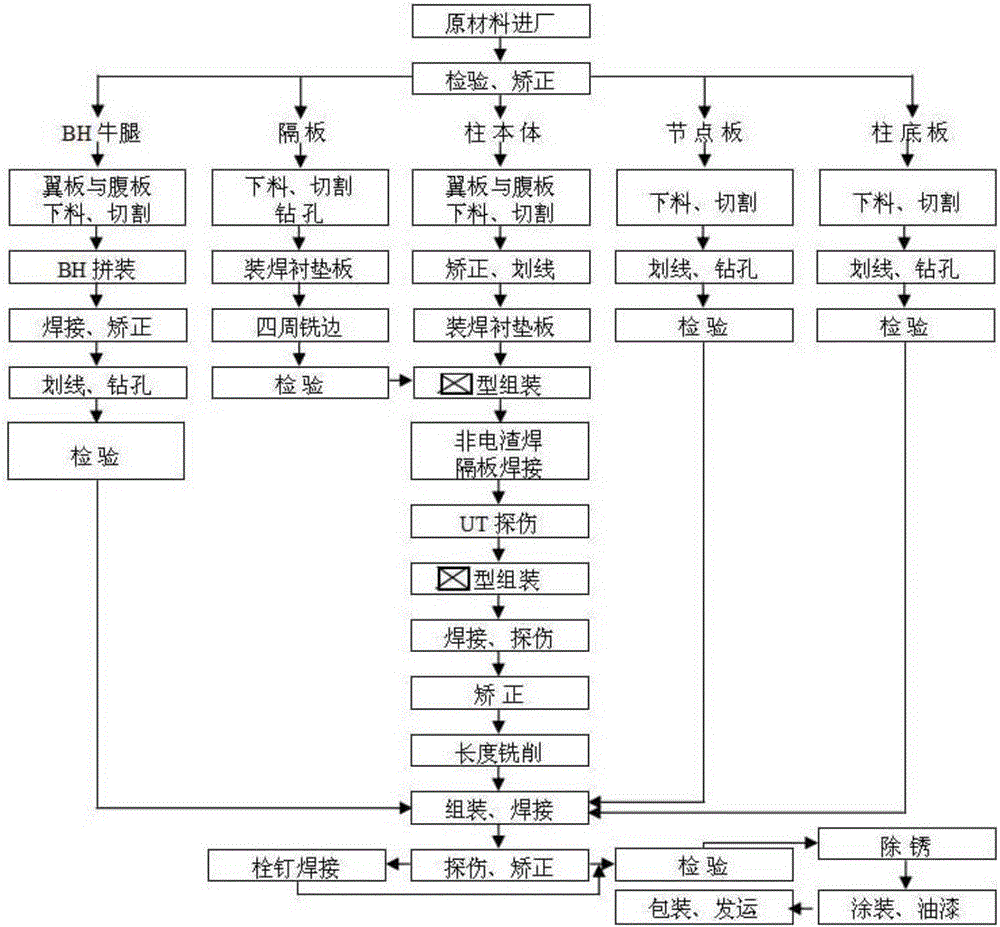

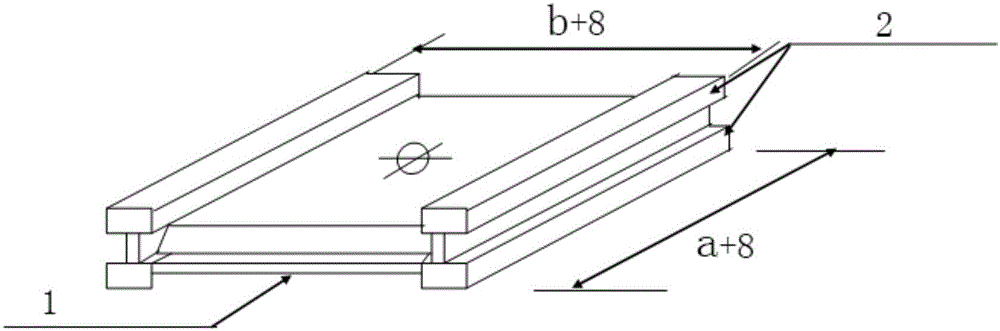

[0048] This process is only used for factory production and processing of steel structure box columns and box girders in this project.

[0049] The adaptation basis, norms and standards for the preparation of this process:

[0050] ⑴Steel structure fabrication and installation regulations (DG-TJ08-216-2007);

[0051] ⑵Building steel structure welding technical regulations (JGJ81-2002);

[0052] ⑶Code for Construction Quality Acceptance of Steel Structure Engineering (GB50205-2001);

[0053] In the process of manufacturing and welding steel structural parts, the factory's quality management regulations should be strictly followed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com