420MPa-grade weather-resistant bridge steel and production method thereof

A production method and bridge steel technology, applied in the field of weather-resistant steel production, can solve the problems of high alloy cost, high equipment capacity requirements, and the inability to stably produce 420MPa-level weather-resistant bridge steel in industrialized batches, so as to increase supply and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

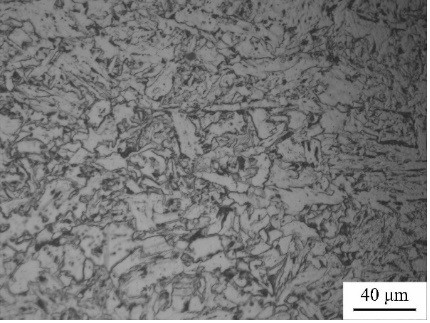

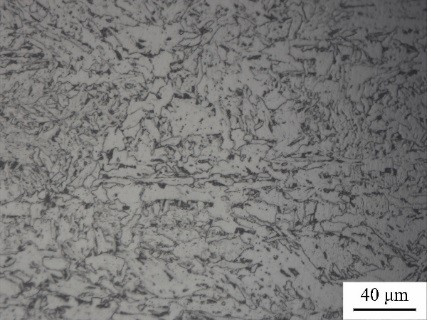

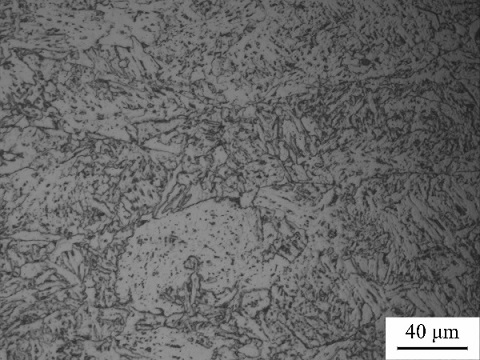

[0050] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

[0051] The chemical compositions and mass percentages of the weather-resistant bridge steels of Examples 1-10 of the present invention and Comparative Examples 1-5 are shown in Table 1, and the balance is Fe and unavoidable impurities.

[0052] The production method of the 420MPa grade weather-resistant bridge steel of the present invention is specifically as follows.

[0053] (1) Steel billet preparation. Raw materials are prepared according to the design requirements of the weathering steel composition in Table 1, and the billet is obtained through the process of smelting molten iron-LF refining-RH refining-continuous casting. Among them, the LF refining process adopts white slag operation, the white slag retention time is ≥ 10min, and the total refining time is guaranteed to be ≥ 30min. The chemical composition of molten steel is contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com