Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Improve effective thermal conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

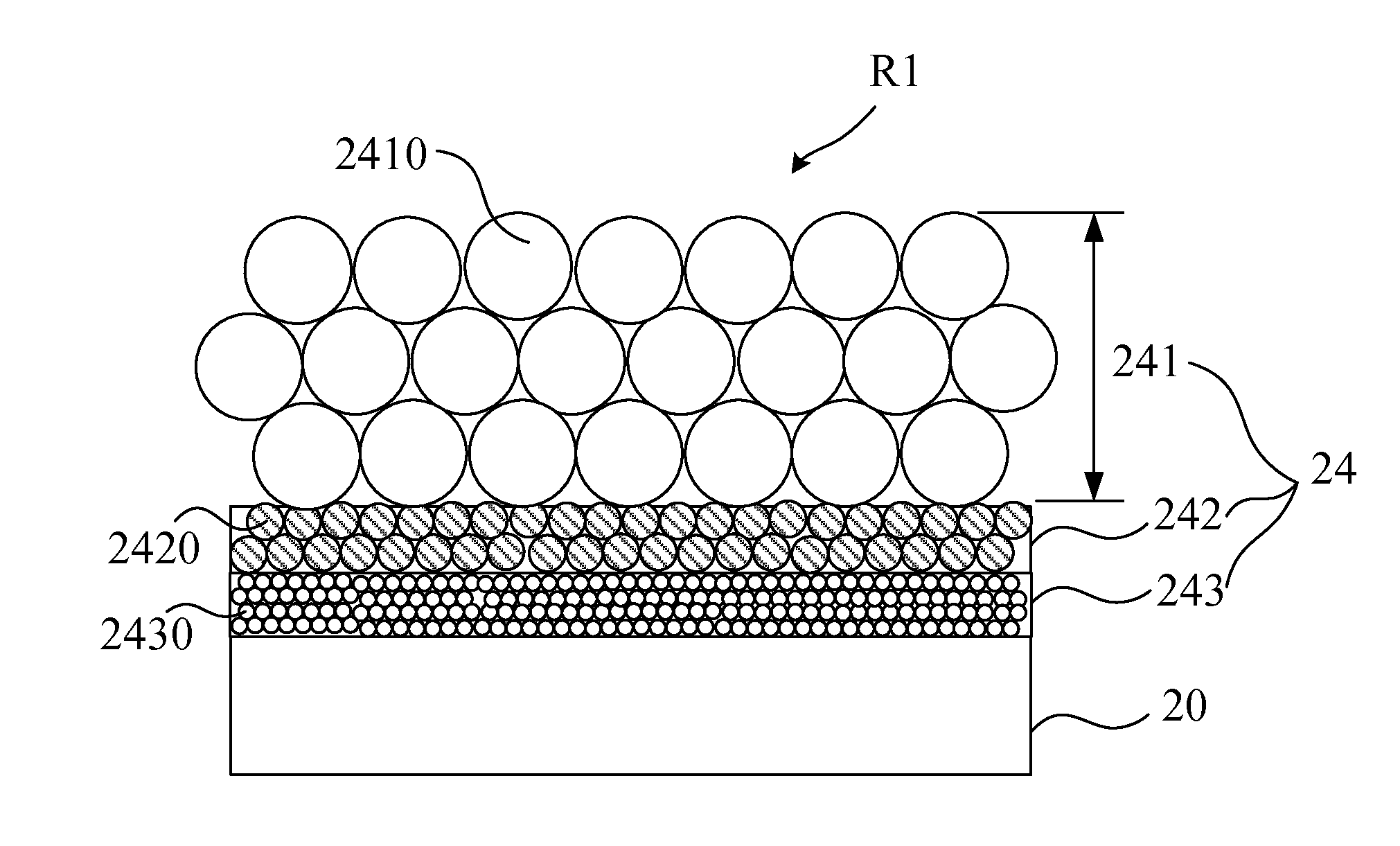

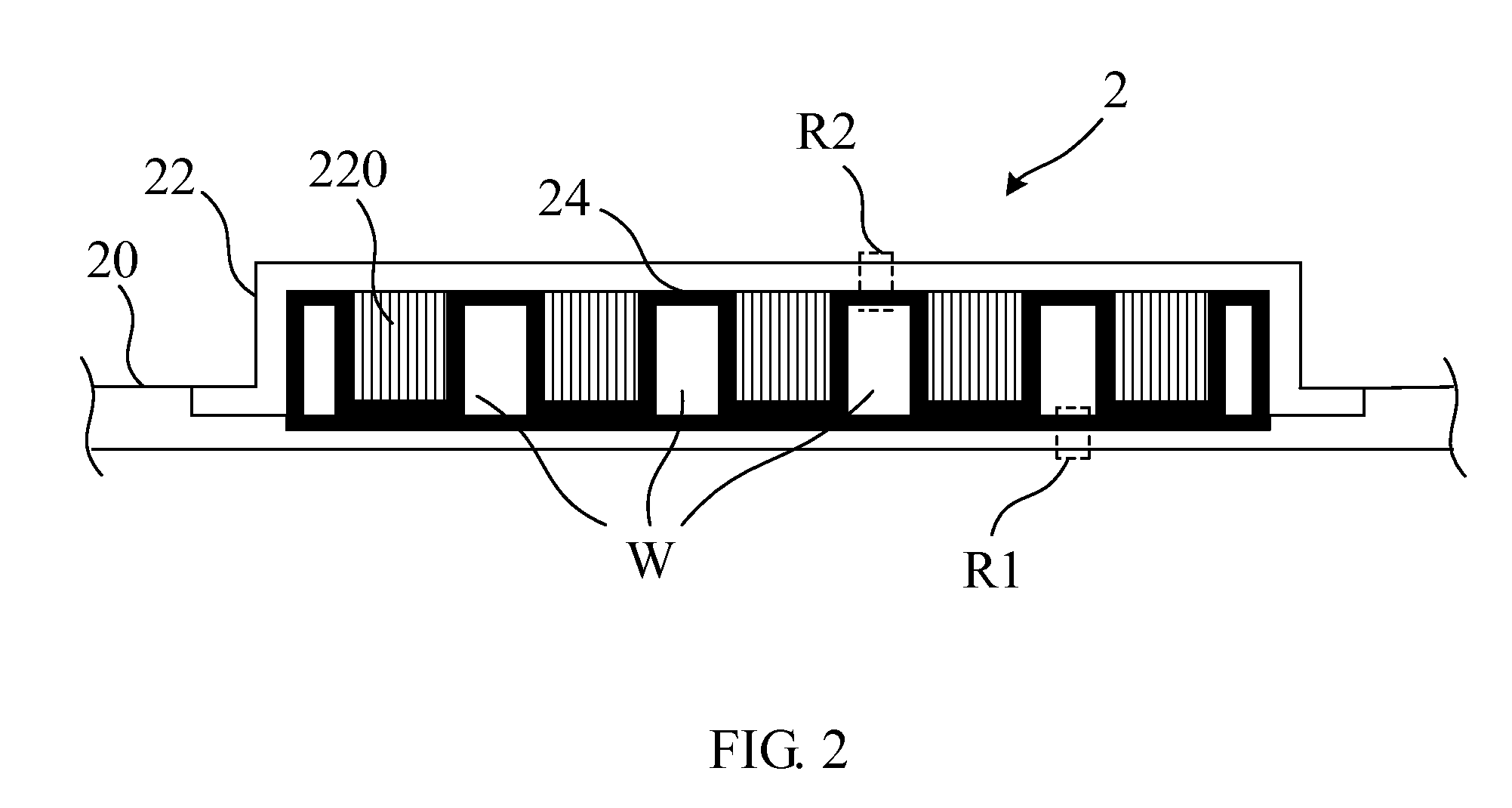

Vapor chamber and method for manufacturing the same

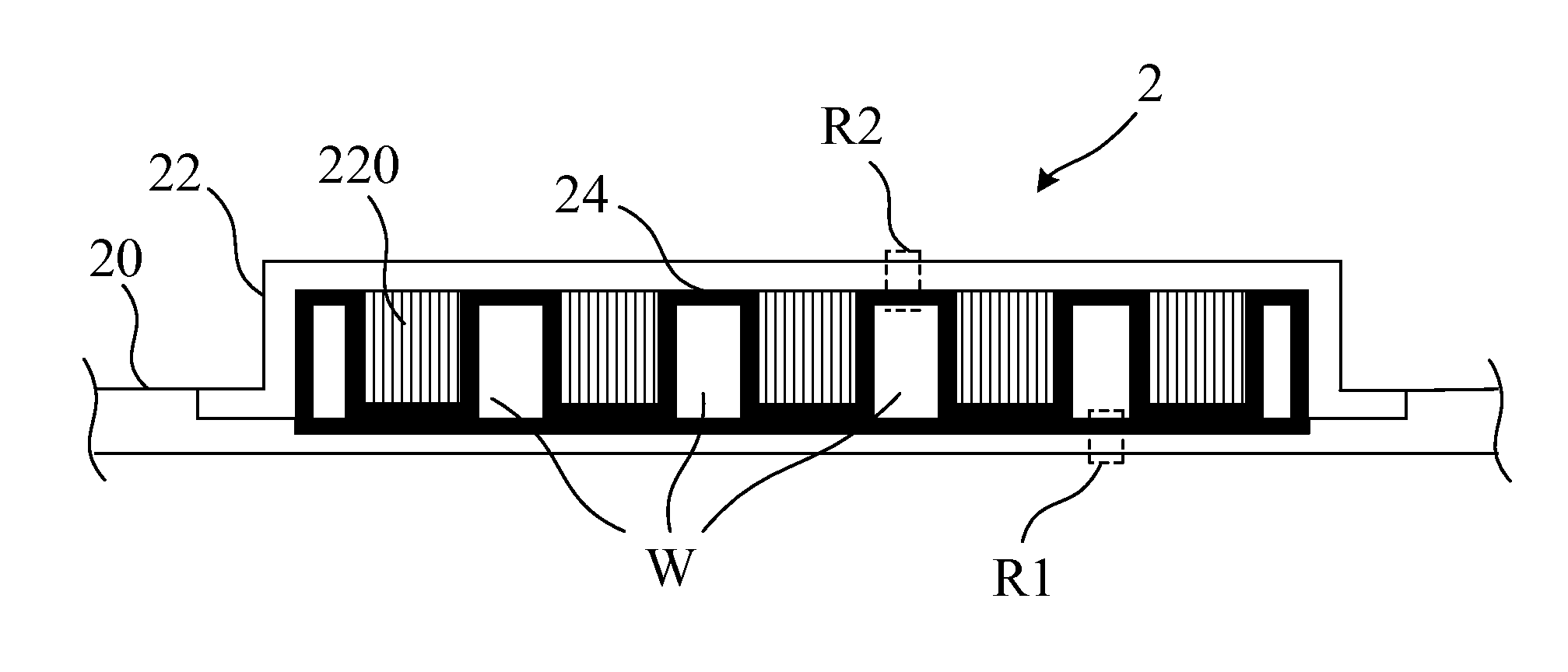

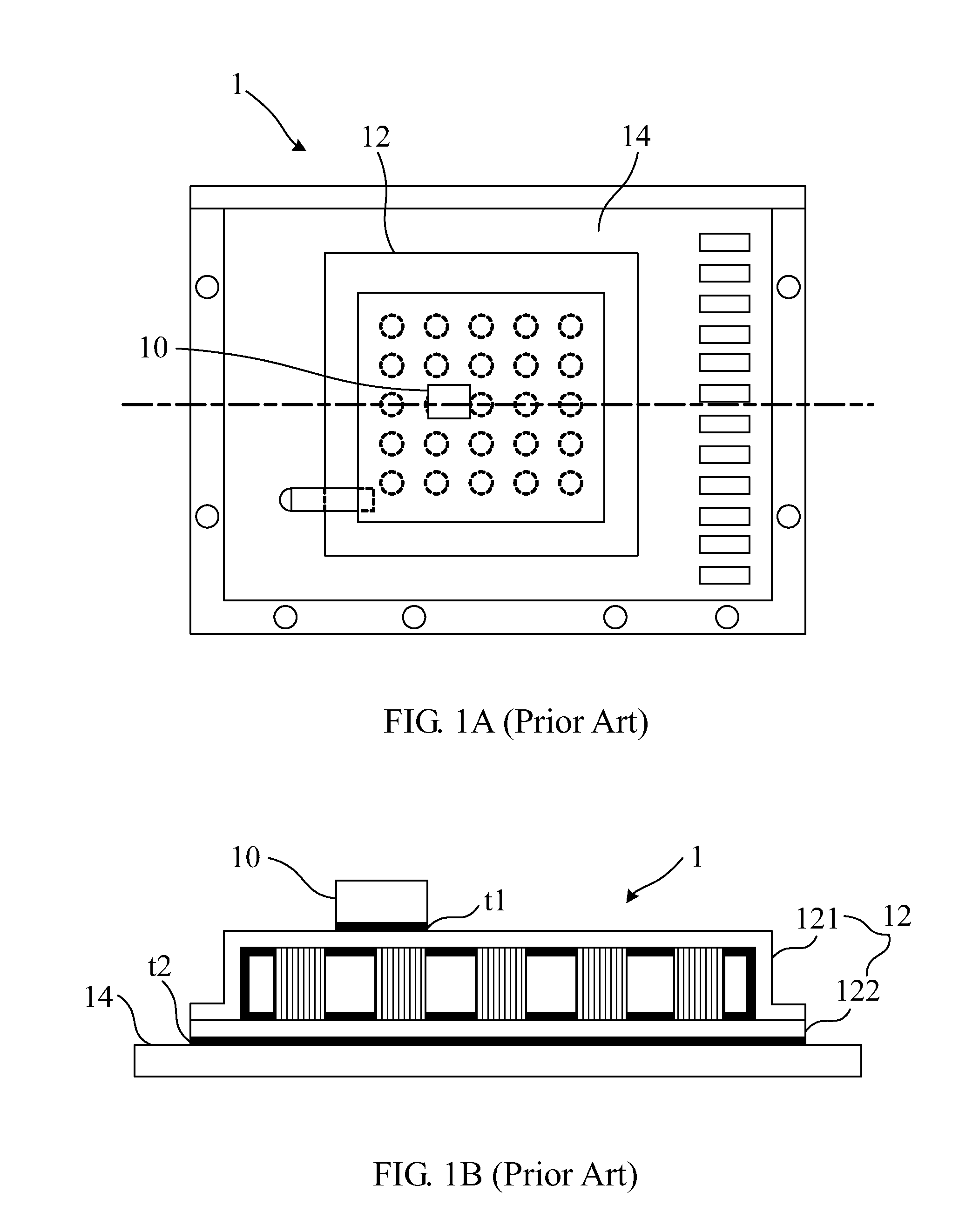

ActiveUS20110174474A1Low thermal conductivityImprove effective thermal conductivitySafety devices for heat exchange apparatusSemiconductor/solid-state device detailsWorking fluidEngineering

This invention discloses a vapor chamber and a method for manufacturing the same. The vapor chamber is used in an electronic device. The electronic device includes a metal casing. The vapor chamber includes an upper cover, a working fluid, a waterproof layer, and a wick structure layer. The upper cover is disposed on inner walls of the metal casing to define a containing space. The working fluid is filled into the containing space. The waterproof layer is formed on inner walls of the containing space. The wick structure layer is formed on the waterproof layer.

Owner:PEGATRON

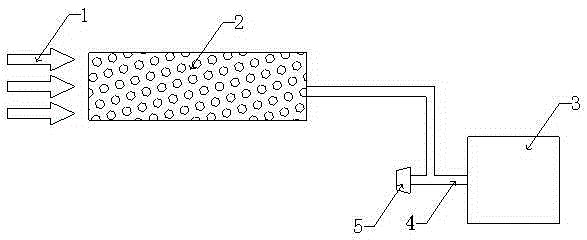

Method and apparatus for absorbing thermal energy

ActiveUS20080099187A1Improve thermal efficiencyHigh effective thermal conductivityHeat storage plantsHeat exchange apparatusThermal energyThermal energy storage

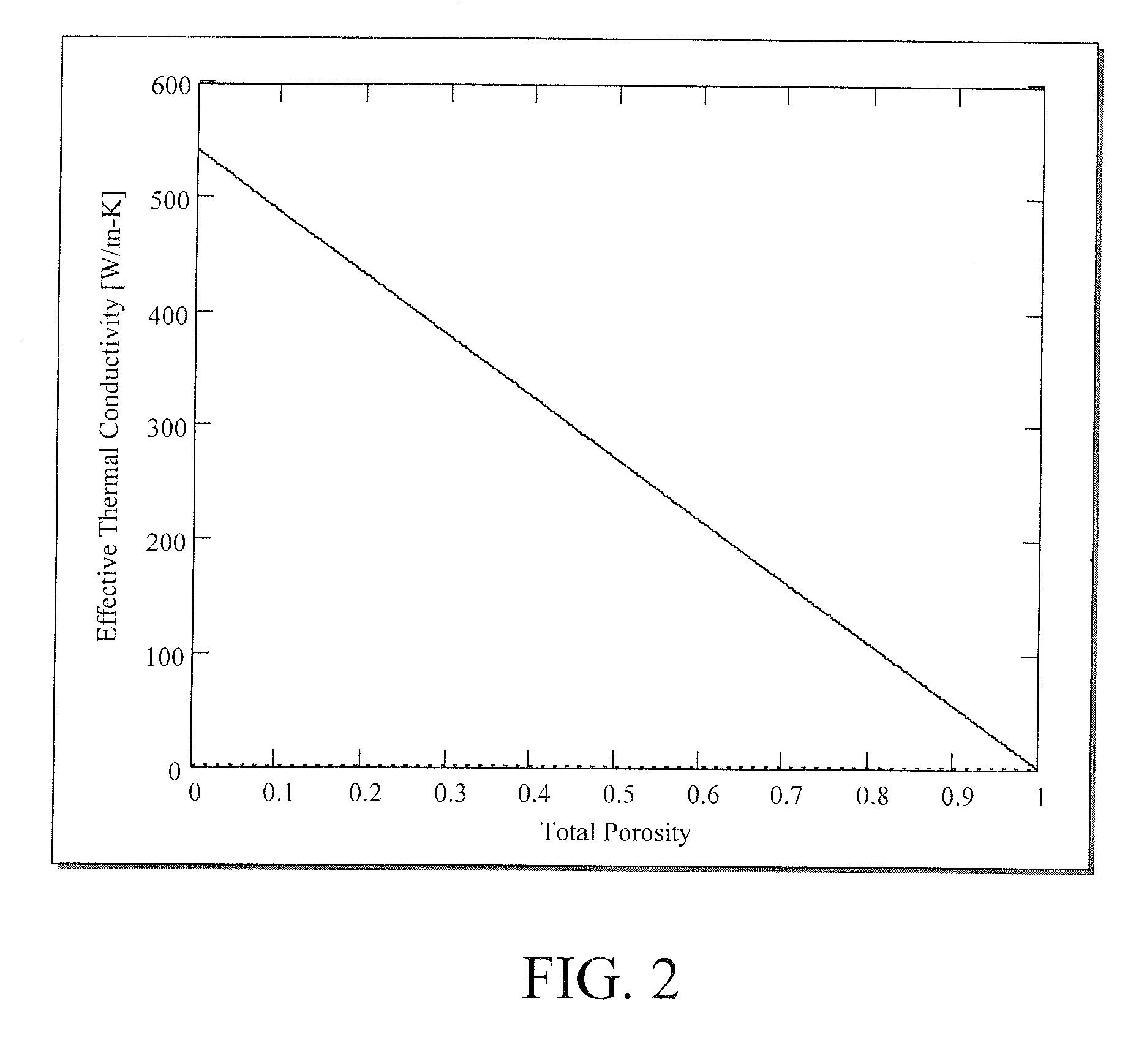

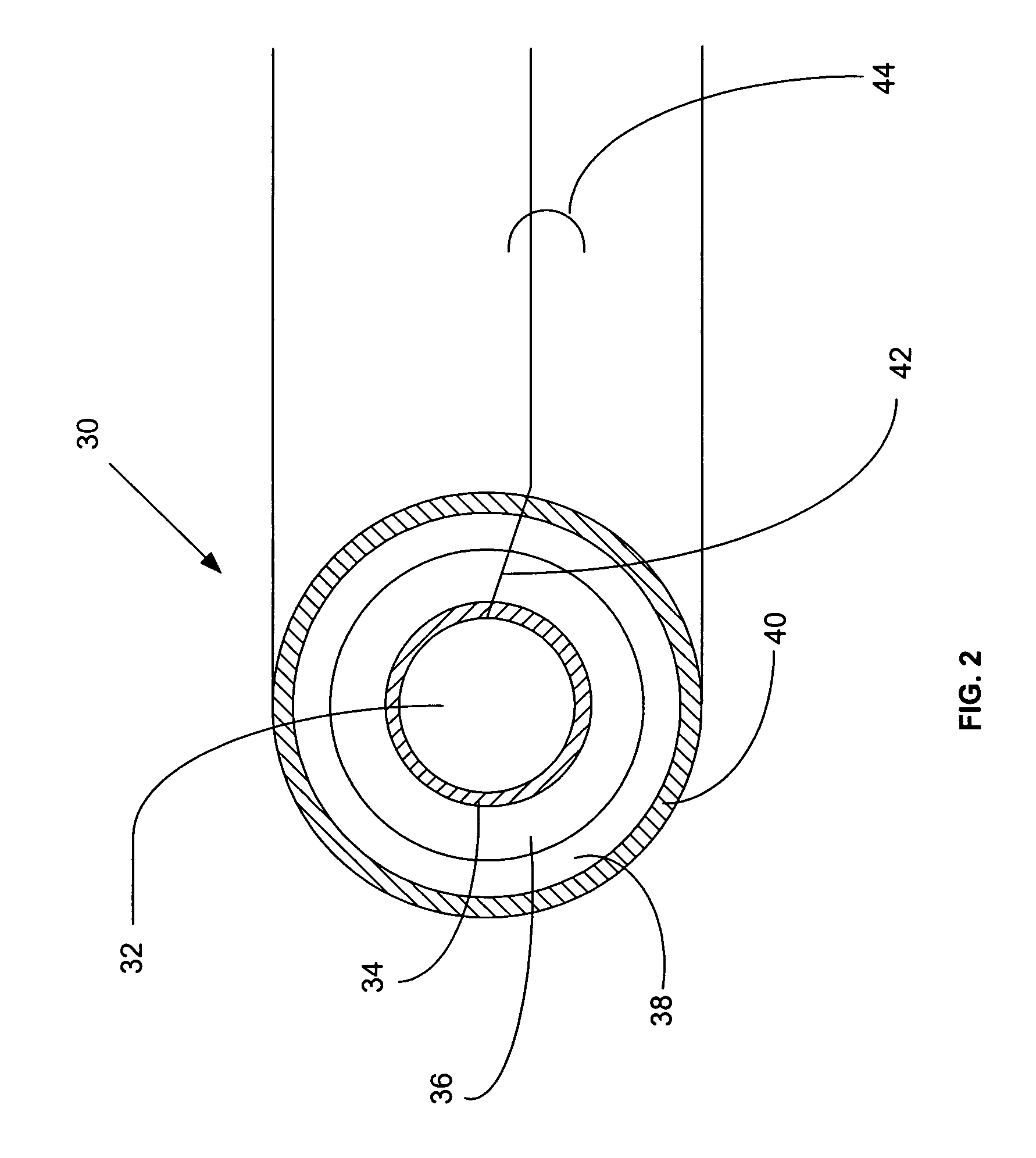

The subject invention pertains to a method and apparatus for storing thermal energy. The subject thermal energy storage apparatus can function as a heat absorber in a cooling system. A cooling system can incorporate a cooling cycle that utilizes thermal energy storage and has two coolant loops. The primary cooling loop acquires the waste heat from a heat source, such as an electronic device, by heat transfer to the primary coolant via, for example, a sensible heat process (where sensible heat is heat absorbed or transmitted by a substance during a change in temperature which is not accompanied by a change of state) or by evaporating the primary coolant through a latent heat phase change process. The waste heat absorbed by the primary coolant is transferred to the host material of the heat absorber. The subject invention uses a high thermal conductivity host material to house a lower thermal conductivity phase change material, in order to achieve a thermal energy absorber that has a high effective thermal conductivity. In a specific embodiment, the high thermal conductivity host material has have voids within the structure that can be filled by the phase change material. The increased surface area of phase change material in thermal contact with the host material per volume of phase change material allows the thermal energy to be stored or released quickly, because of the enhanced effective thermal conductivity.

Owner:RINI TECH

Thermal blanket including a radiation layer

InactiveUS20050208851A1Reduce performanceIncrease thermal resistivityThermal insulationSynthetic resin layered productsThermal radiationThermal management system

A thermal management system utilizing a composite thermal radiation barrier comprising alternating layers of a carbon cloth insulating layer and a silica-based organic cloth to reduce the temperatures experienced by the insulating layer.

Owner:HALE NICHOLAS

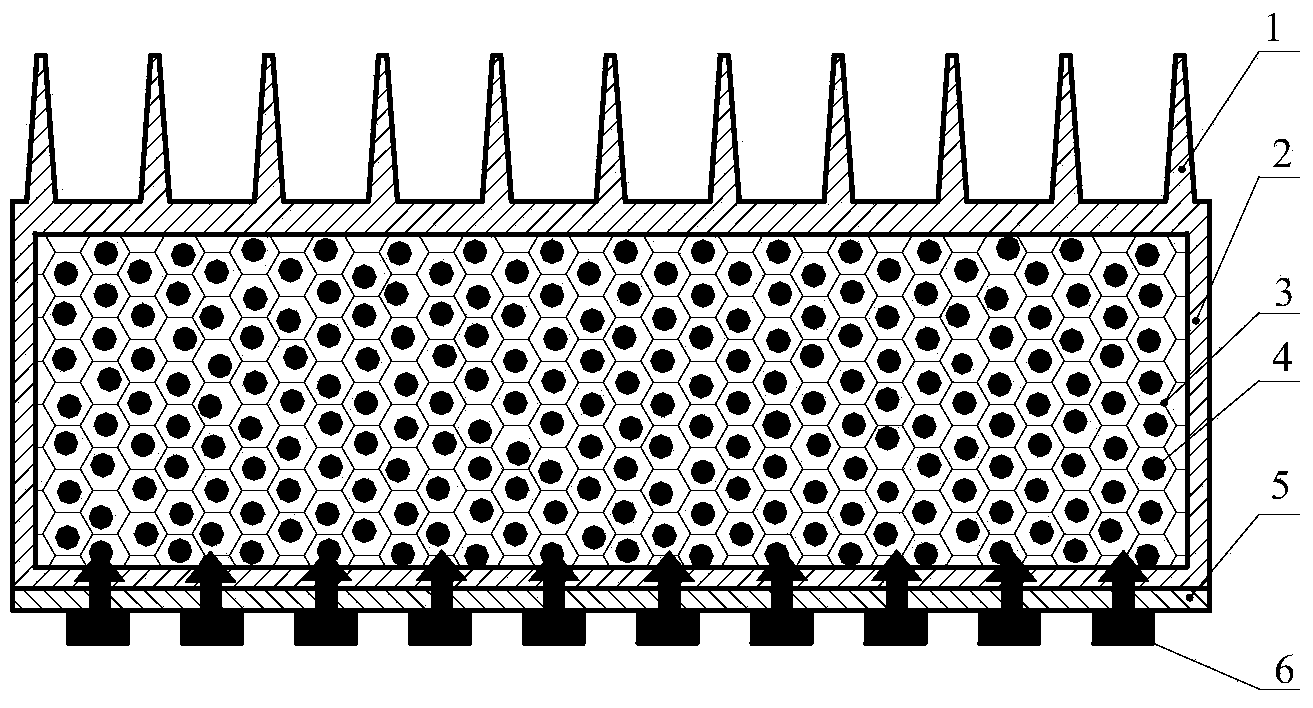

High-power LED multi-hole phase-changing heat sink structure

InactiveCN104241513AReduce dependenceImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesExternal energyWorking temperature

A high-power LED multi-hole phase-changing heat sink structure comprises a radiator inner cavity. A plurality of radiator fins are arranged on the top face of the radiator inner cavity. A metal multi-hole structure is arranged in the radiator inner cavity in a sintering mode. Holes of the metal multi-hole structure are filled with phase-changing materials. An LED electronic chip is arranged on the bottom face of the radiator inner cavity. The melting point of the phase-changing materials is lower than the normal working temperature of the LED electronic chip. The response speed of phase-changing latent heat storing can be increased, the weight and the cost of an LED radiating structure are lowered, a part of heat emitted by the chip during LED working is dissipated in a natural-convection mode, a large part is stored by latent heat absorbed during a phase-changing material melting process, meanwhile, the temperature of the LED chip is controlled through the melting point of the phase-changing materials, and radiating performance is improved. The high-power LED multi-hole phase-changing heat sink structure has the advantages of being simple in structure, light in weight, small in size, good in adjusting performance, good in radiating effect, long in service life, free from external energy loss and environment pollution and the like.

Owner:XI AN JIAOTONG UNIV

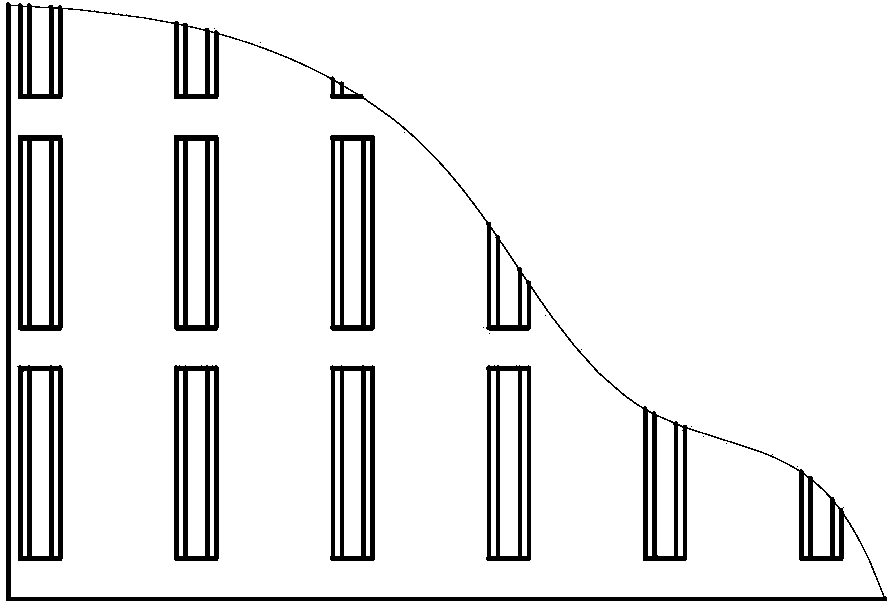

High average-power microwave window with high thermal conductivity dielectric strips

InactiveUS6118358AImprove effective thermal conductivityImprove thermal conductivityWaveguidesKlystronPolycrystalline diamond

A high average-power microwave window is provided whose thermal conductivity has been enhanced to enable it to transmit higher average RF power levels than conventional windows of the same size. Such a window is suitable for use with high-average power RF sources such as klystrons and magnetrons. The window comprises a ceramic substrate, typically a low-loss ceramic such as alumina or quartz, to which narrow strips of a high thermal conductivity material have been bonded. One such high thermal conductivity material is synthetic polycrystalline diamond, which can be bonded to the surface of a dielectric substrate using a high-temperature cement or can be directly deposited on the surface by a process such as chemical vapor deposition (CVD). High-purity alumina, a commonly-used material for high-power RF windows, has a thermal conductivity of 26.4 W / mx DEG C., while synthetic diamond has a thermal conductivity of 1000 W / mx DEG C., 2.6 times that of copper and 38 times that of alumina. The novel feature is the use of high thermal conductivity strips to increase the effective thermal conductivity of a microwave window by providing low-resistance paths by which heat can be extracted from the window, resulting in a significant increase in the window's power-handling capacity.

Owner:CROUCH DAVID D

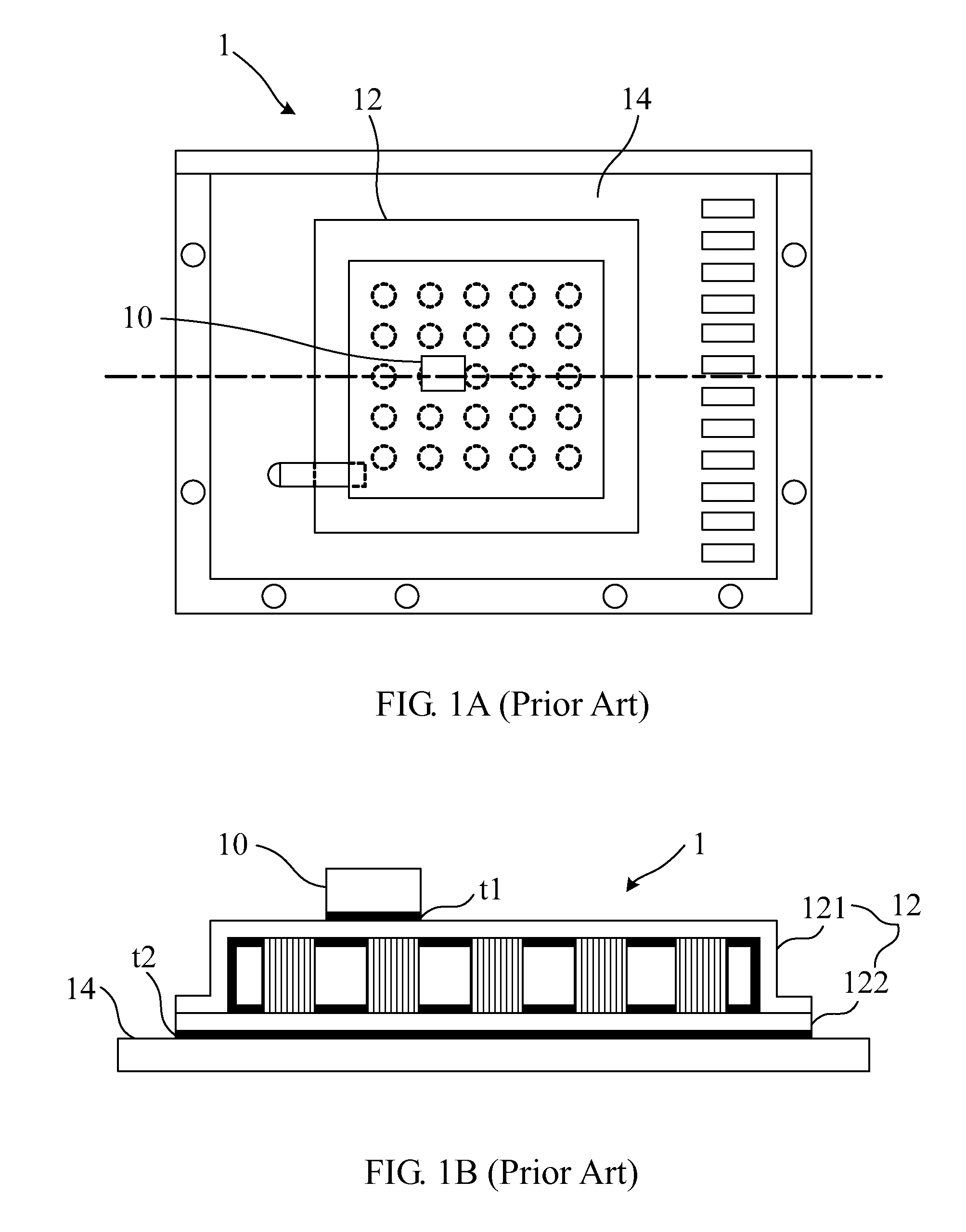

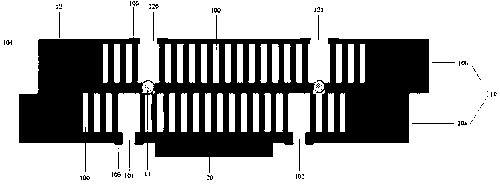

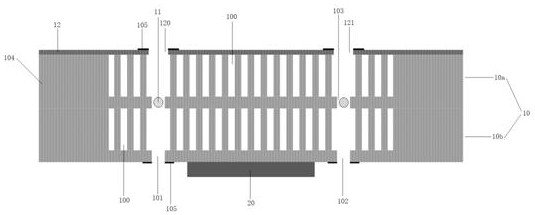

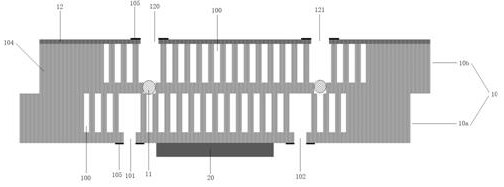

Micro-channel heat dissipation structure, manufacturing method and electronic device

ActiveCN110364501AImprove effective thermal conductivityMeet cooling needsSemiconductor/solid-state device detailsSolid-state devicesEngineeringNegative thermal expansion

The invention provides a micro-channel heat dissipation structure. The structure comprises at least two heat dissipation units which are stacked in sequence; each heat dissipation unit is provided with a heat dissipation channel; at least one inlet and at least one outlet, communicating with the heat dissipation channels, are formed in the heat dissipation units in contact with a chip; at least two circulation channels are formed in the other heat dissipation units, so that the heat dissipation channels in the adjacent heat dissipation units are connected; the structure also comprises negativethermal expansion bodies; each circulation channel is filled with the corresponding negative thermal expansion body; and the negative thermal expansion bodies are used for connecting or disconnectingthe heat dissipation channels of the adjacent heat dissipation units. The conduction or non-conduction of the adjacent heat dissipation units is controlled by the expansion or contraction of the negative thermal expansion bodies. Thus, the effective heat conduction coefficient of the heat dissipation structure can be improved on the whole, and the heat dissipation requirements of a high-power chip are met. The invention further provides a manufacturing method of the micro-channel heat dissipation structure and an electronic device with the micro-channel heat dissipation structure.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Vapor chamber and method for manufacturing the same

ActiveUS8671570B2Low thermal conductivityLow costDigital data processing detailsSafety devices for heat exchange apparatusMetallic enclosureWorking fluid

The vapor chamber is used in an electronic device. The electronic device includes a metal casing. The vapor chamber includes an upper cover, a working fluid, a waterproof layer, and a wick structure layer. The upper cover is disposed on inner walls of the metal casing to define a containing space. The working fluid is filled into the containing space. The waterproof layer is formed on inner walls of the containing space. The wick structure layer is formed on the waterproof layer.

Owner:PEGATRON

Preparation method of boron nitride-silicon rubber composite material

InactiveCN102717454AImprove effective thermal conductivityHigh thermal conductivitySelf weightBoron nitride

The invention provides a preparation method of a boron nitride-silicon rubber composite material. The preparation method is characterized by adding a certain amount of a filling material into silicon rubber in batches, fully stirring in vacuum, pouring the mixture into a stainless steel mold of which upper and lower surfaces are insulatedly isolated by a rubber sheet having a certain thickness, connecting the upper surface and the lower surface of the stainless steel mold respectively to a positive pole and a negative pole of a high-voltage direct-current power supply, and carrying out curing at a temperature of 70 to 90 DEG C for 10 to 60 minutes. In the above technical scheme, the high-voltage direct-current power supply can be replaced by an alternating current power supply so that better effects are obtained. Through use of an applied electric field, effective heat conductivity of the whole system can be improved. An alternating electric field is superior to a direct-current electric field in orientation of filling material particles. Under the action of an electric field, a high-heat conductivity crystal plane of boron nitride is oriented along a direction of the electric field so that heat conductivity in a parallel electric field direction is greatly improved by more than 1.5 times. Electric field-assistant curing preparation of a composite heat-conducting material can effectively improve heat conductivity, reduce a use amount of the filling material, save a cost and reduce self-weight of the composite heat-conducting material.

Owner:WUJIANG LANGKE CHEM FIBER

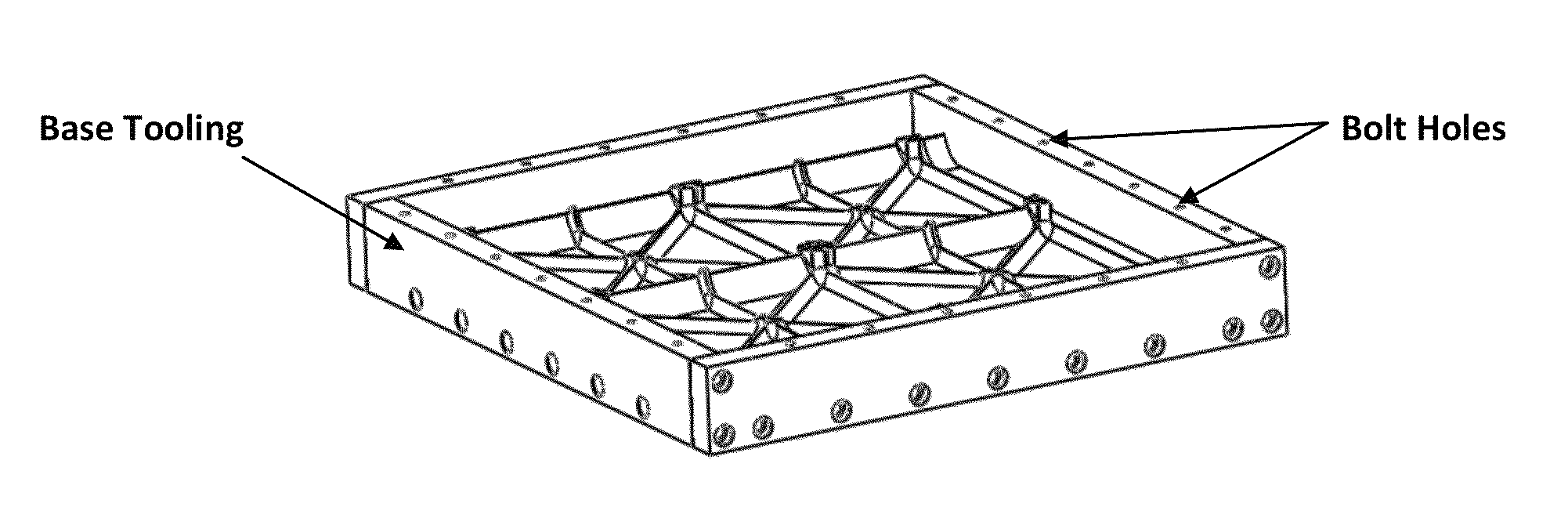

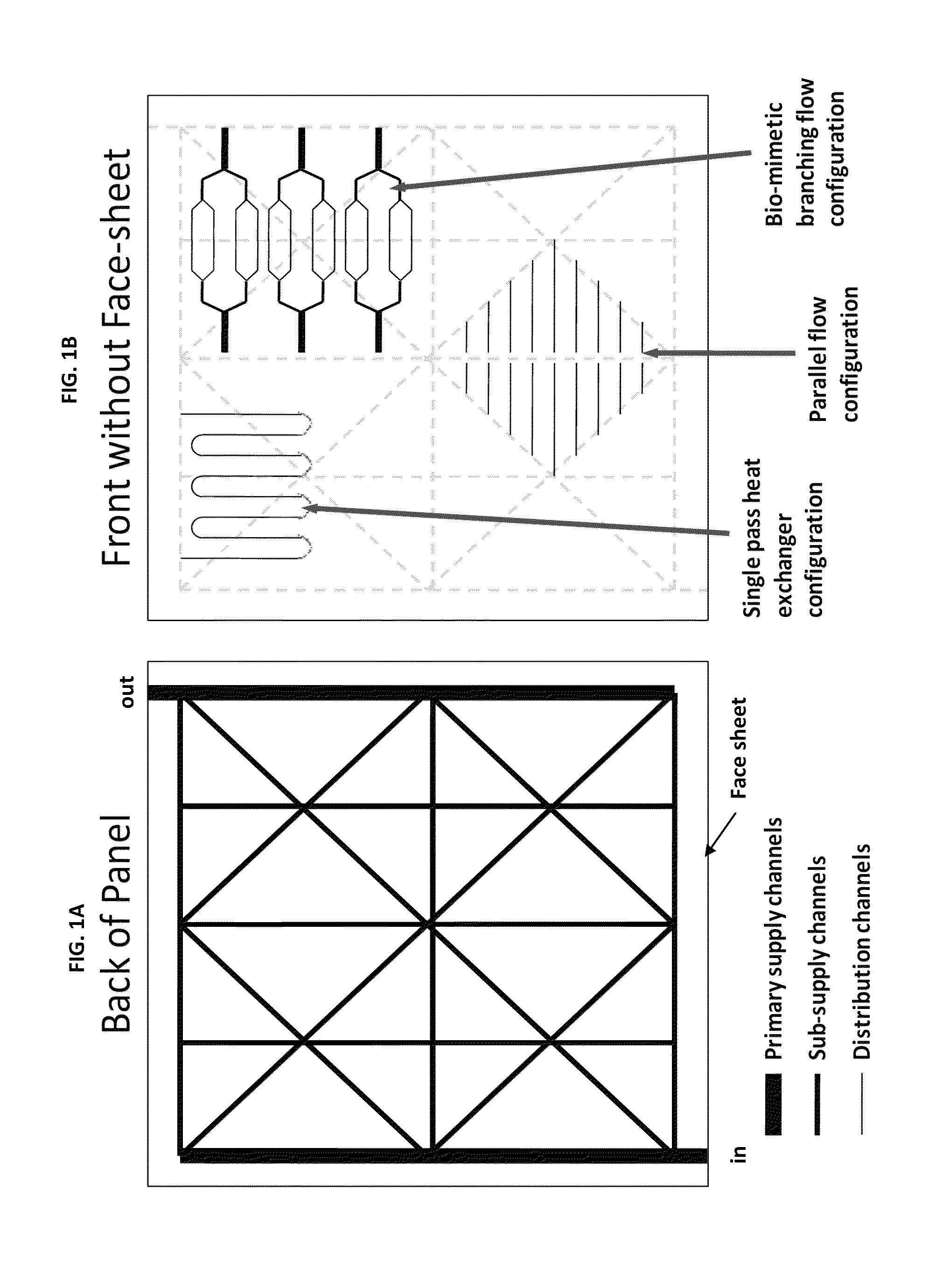

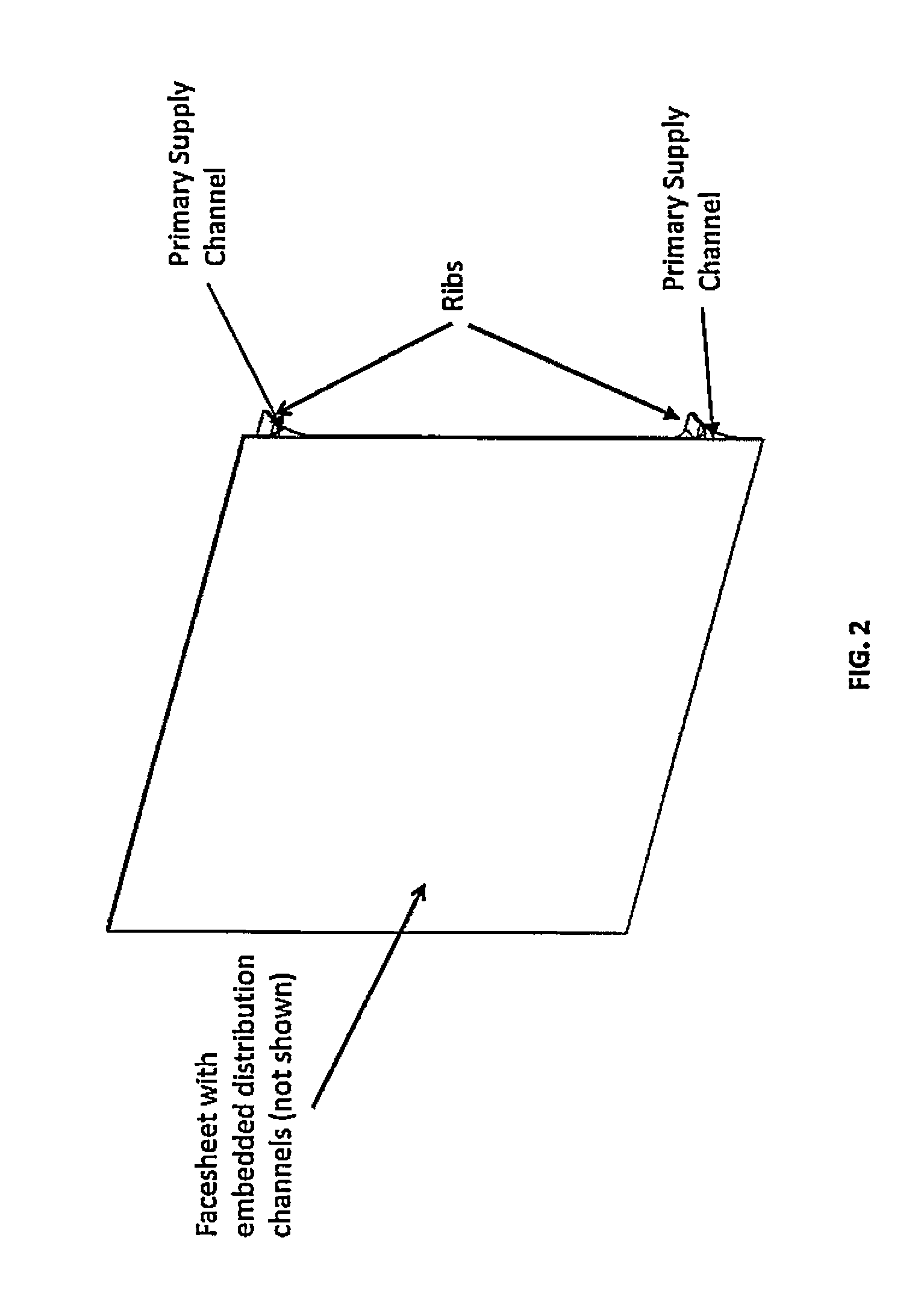

Method for fabricating composite grid-stiffened structures with integrated fluid channels

ActiveUS8657984B1Good physical propertiesPromotes self-healingLayered productsHeat exhanger conduitsEngineeringHigh pressure

A method for fabricating a grid-stiffened panel which incorporates a network of fluid channels and passageways into the ribs and face sheet is described. The method is comprised of a base tooling assembly, an expansion tooling assembly, a composite prepreg, plugs, a face sheet and a network of valves and pumps, wherein the prepreg is draped over said expansion tooling and assembled with the base tooling assembly to form a rib structure. Channel plugs are placed therein such that gaps between adjacent expansion tooling blocks are filled, and the entire rib structure assembly is autoclaved. The face sheet may be comprised of a plurality of layers, whereby channels are machined into the lower layer(s). The upper layer(s) are bonded to the lower layer(s) to seal the channels, and said face sheet is bonded to the rib structure.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Refrigerant dryer

ActiveUS20110061409A2Improve relationshipImprove energy efficiencyHeat storage plantsCompression machines with non-reversible cycleFreeze-dryingEngineering

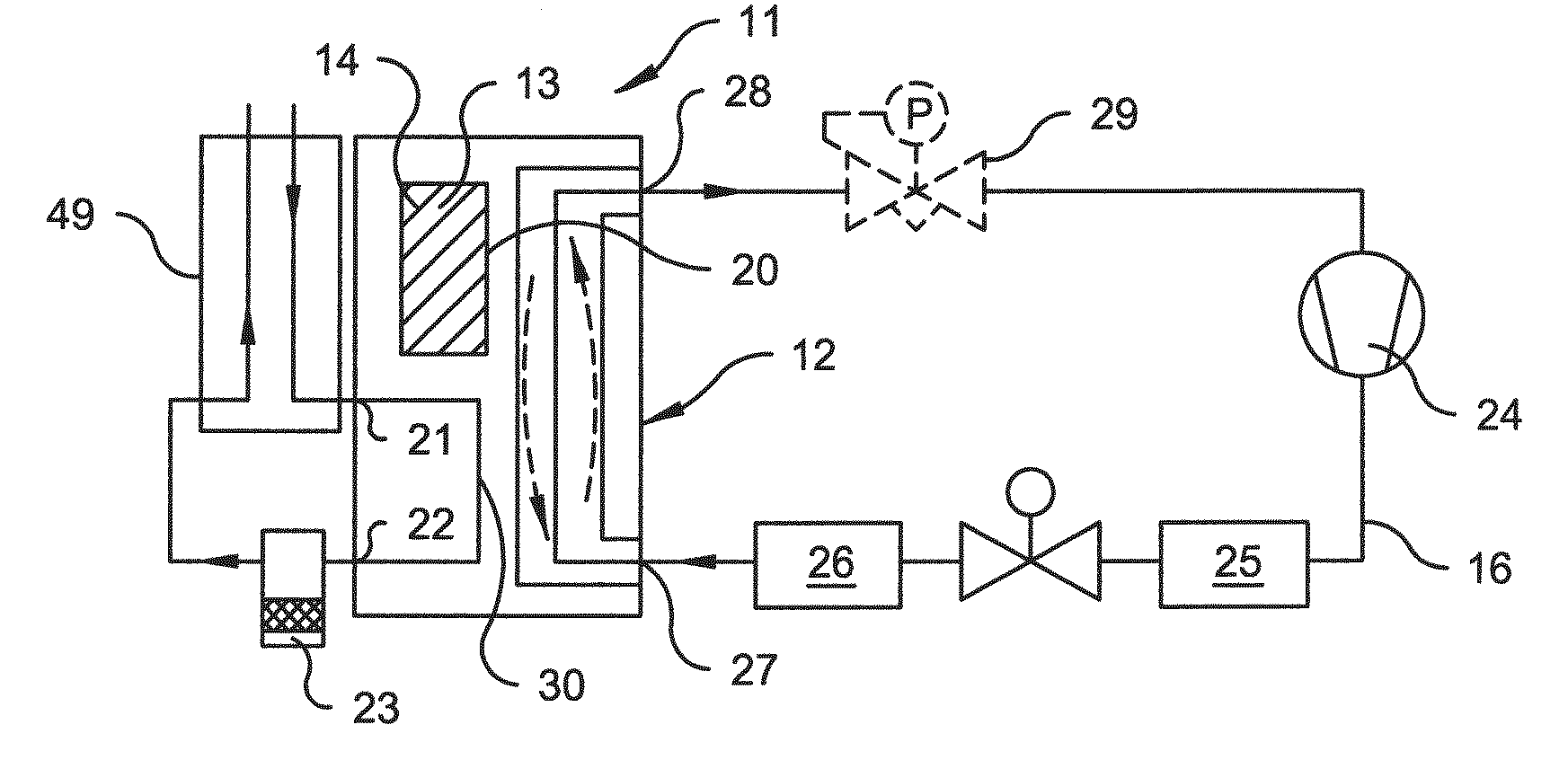

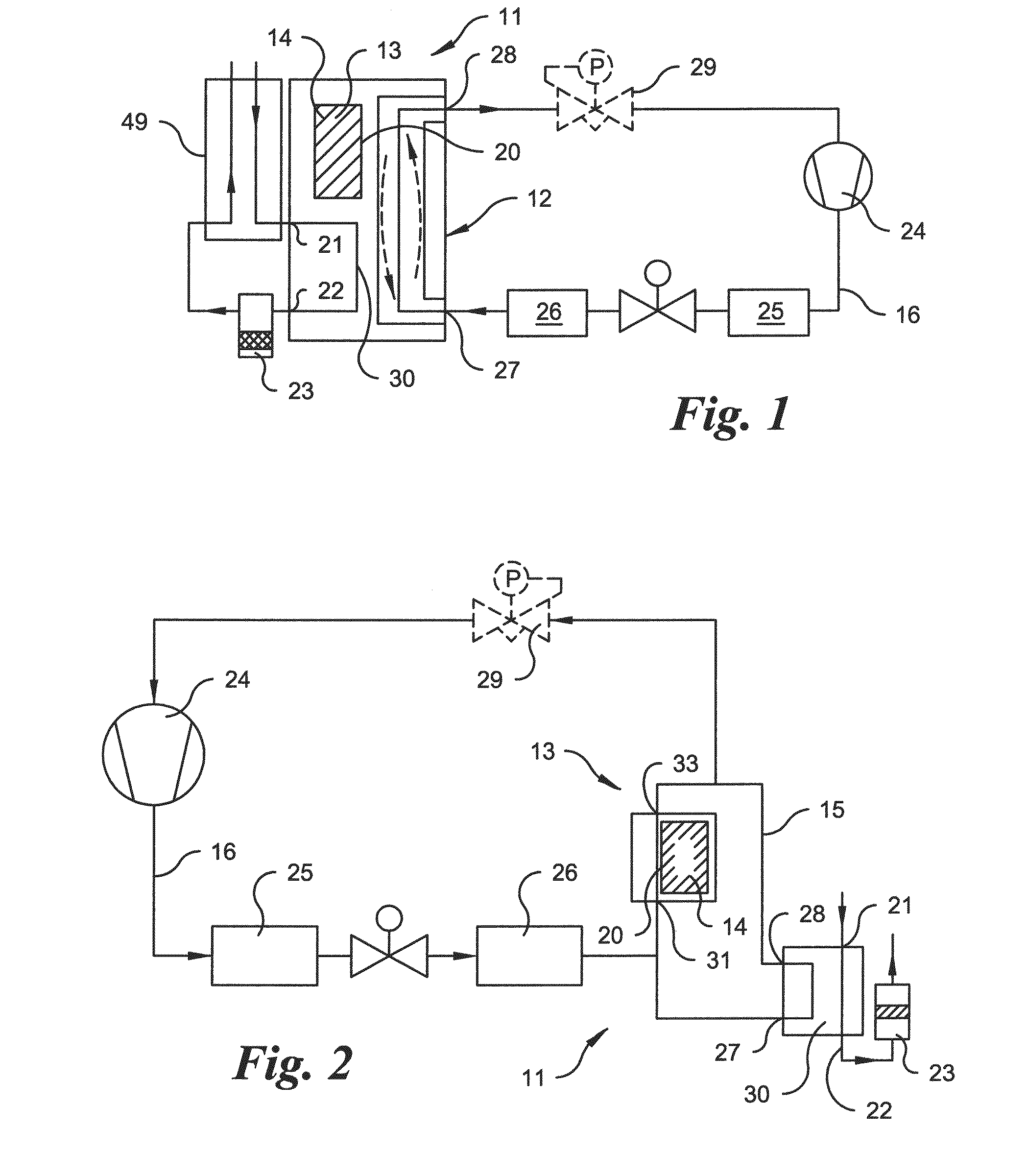

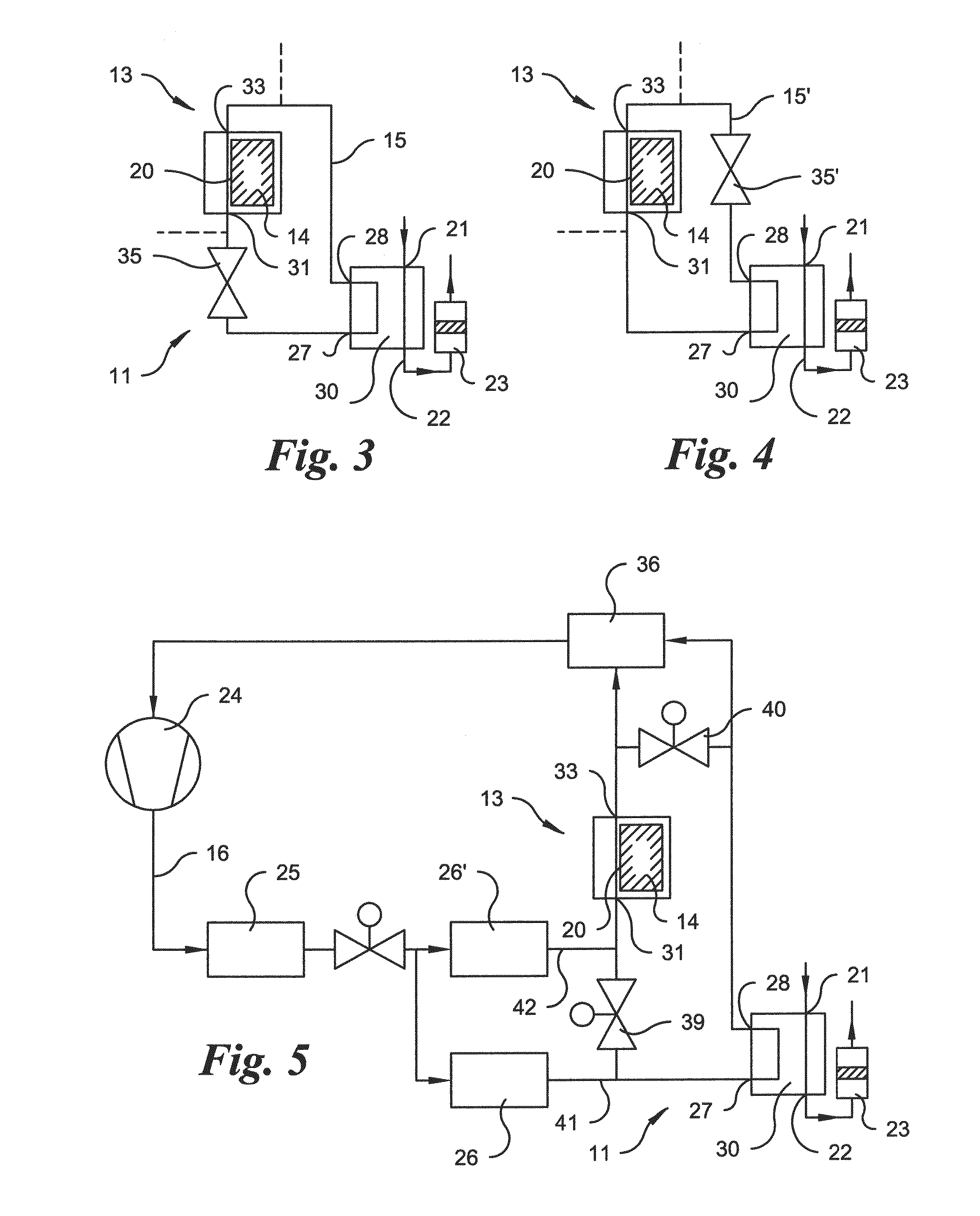

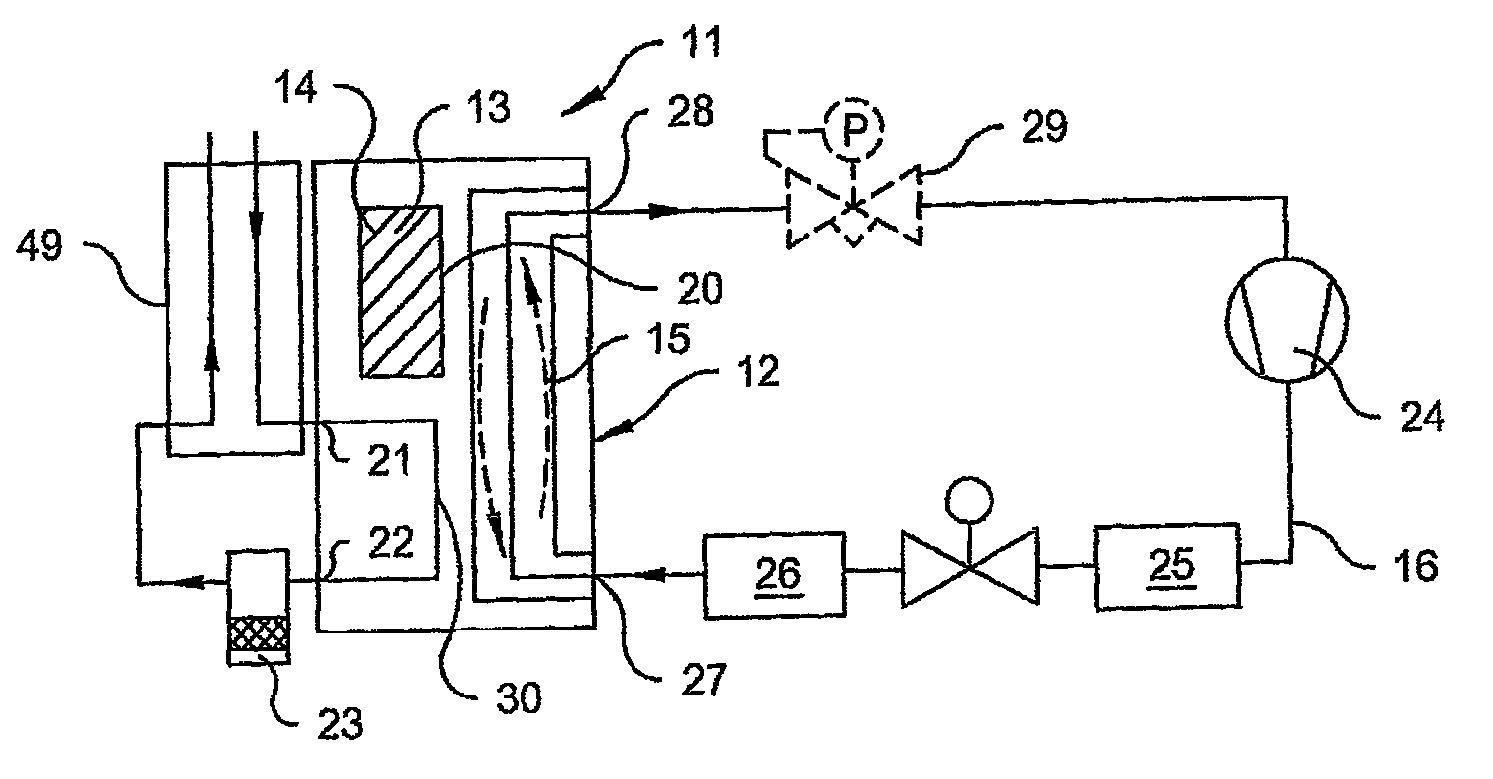

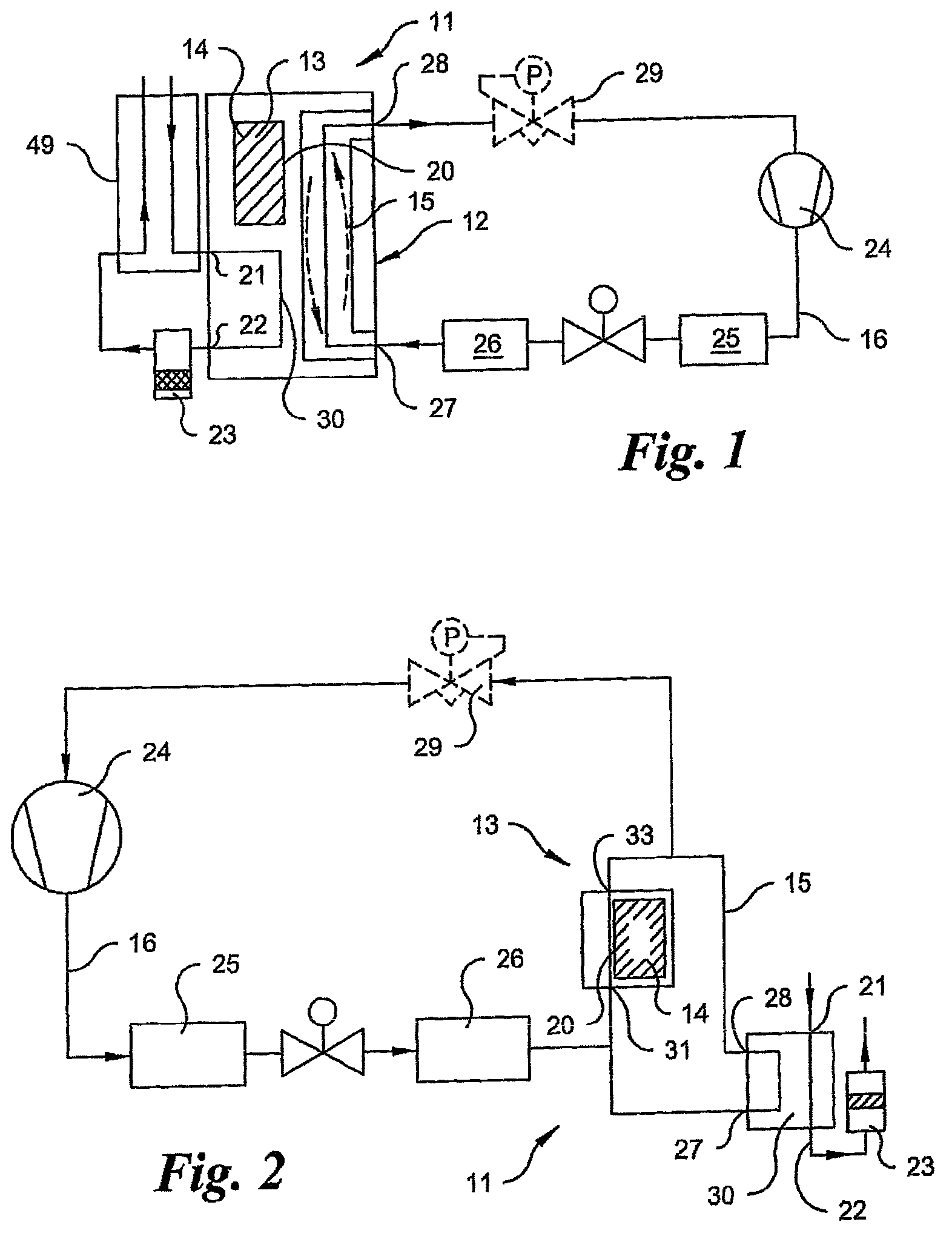

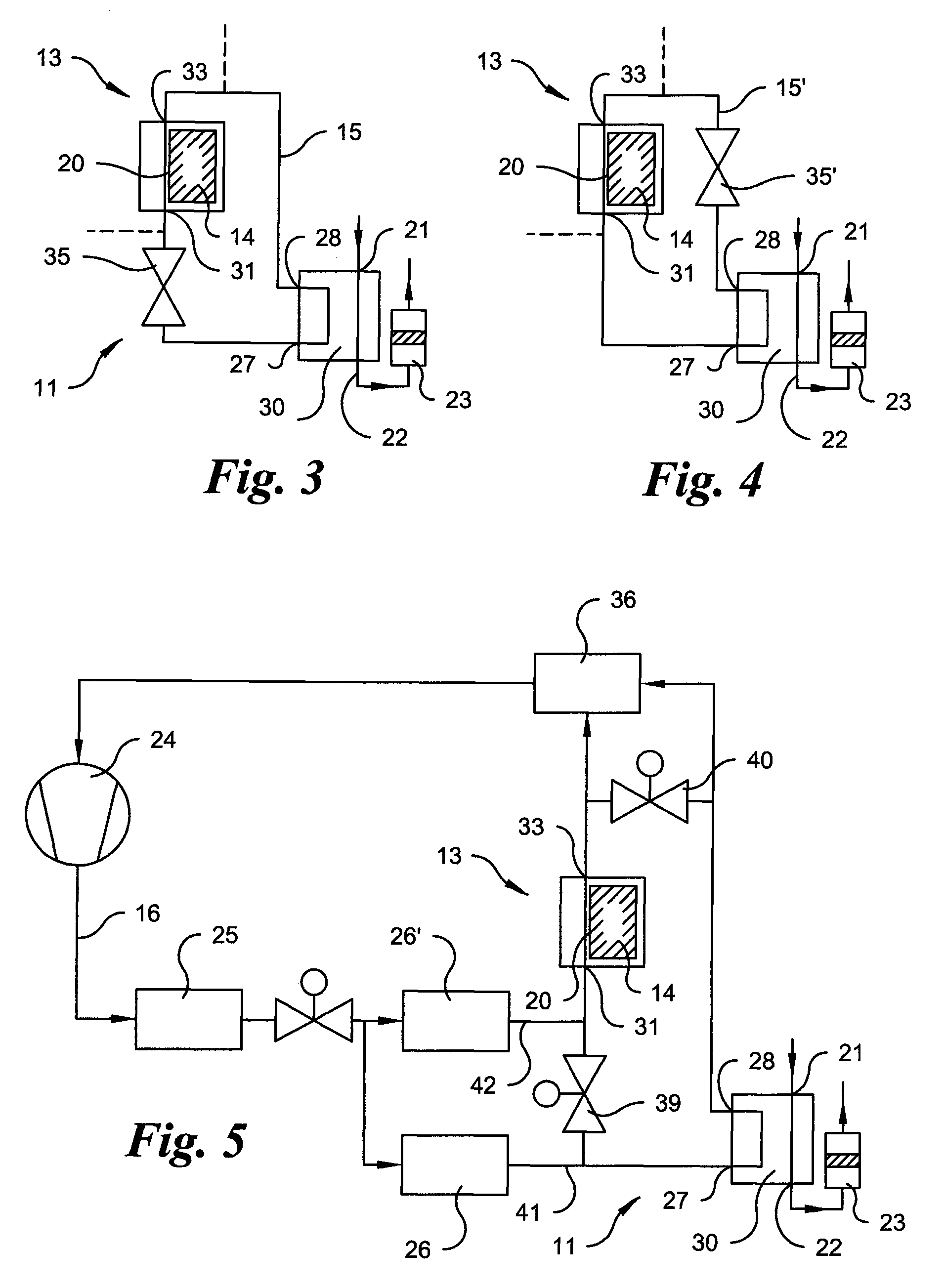

A refrigerant dryer, in particular a compressed air refrigerant dryer, is provided for drying a gaseous fluid while cooling the gaseous fluid using a refrigerant. The dryer includes a pressure fluid-refrigerant agent-heat exchanger (30) in which a cooling of the gaseous fluid takes place directly or indirectly by a refrigerant conveyed in a primary loop (16), one or more refrigerant compressor / compressors (24) for operating the primary loop, and a cold accumulator (13) with an accumulator-side heat exchanger (20) which couples an accumulator discharge fluid to a cold accumulator medium (14). The pressure fluid-refrigerant agent-heat exchanger (30) and the cold accumulator (13) are fluidically connected or can be brought into fluidic connection via a discharge loop (15) for an accumulator discharge fluid. The cold accumulator (13) is arranged, relative to gravity, above the pressure fluid-refrigerant agent-heat exchanger (30), in such a manner that the heated accumulator discharge fluid is conveyed through the discharge loop (15) for cooling in the cold accumulator (13), is cooled there, and subsequently re-conveyed to the pressure fluid-refrigerant agent-heat exchanger (30).

Owner:KAESER KOMPRESSOREN SE

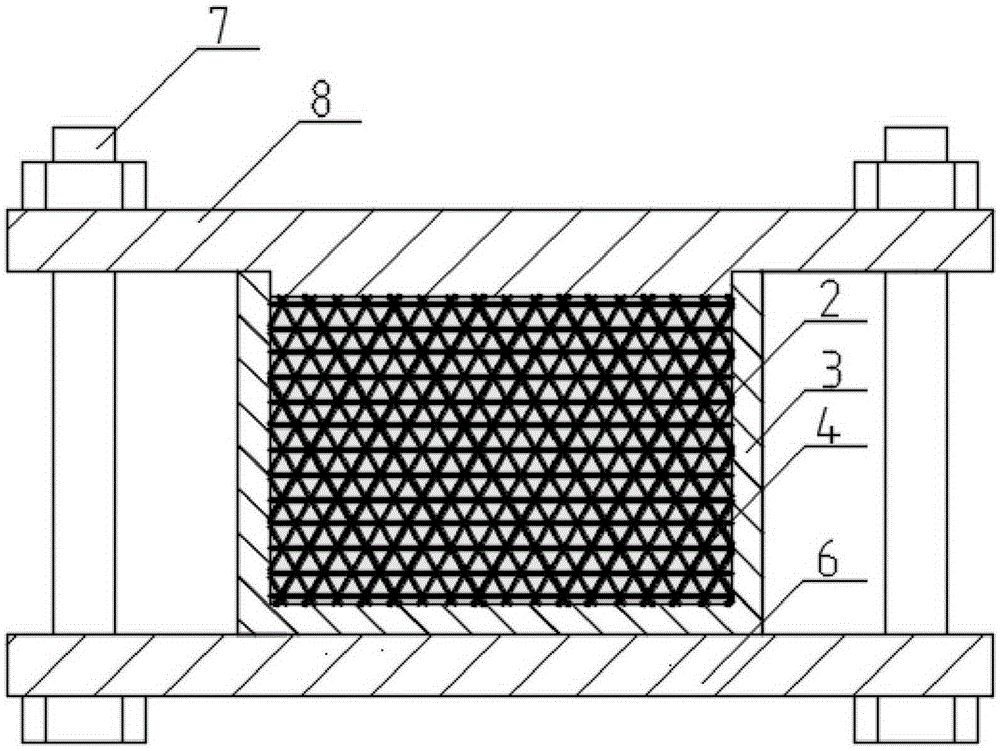

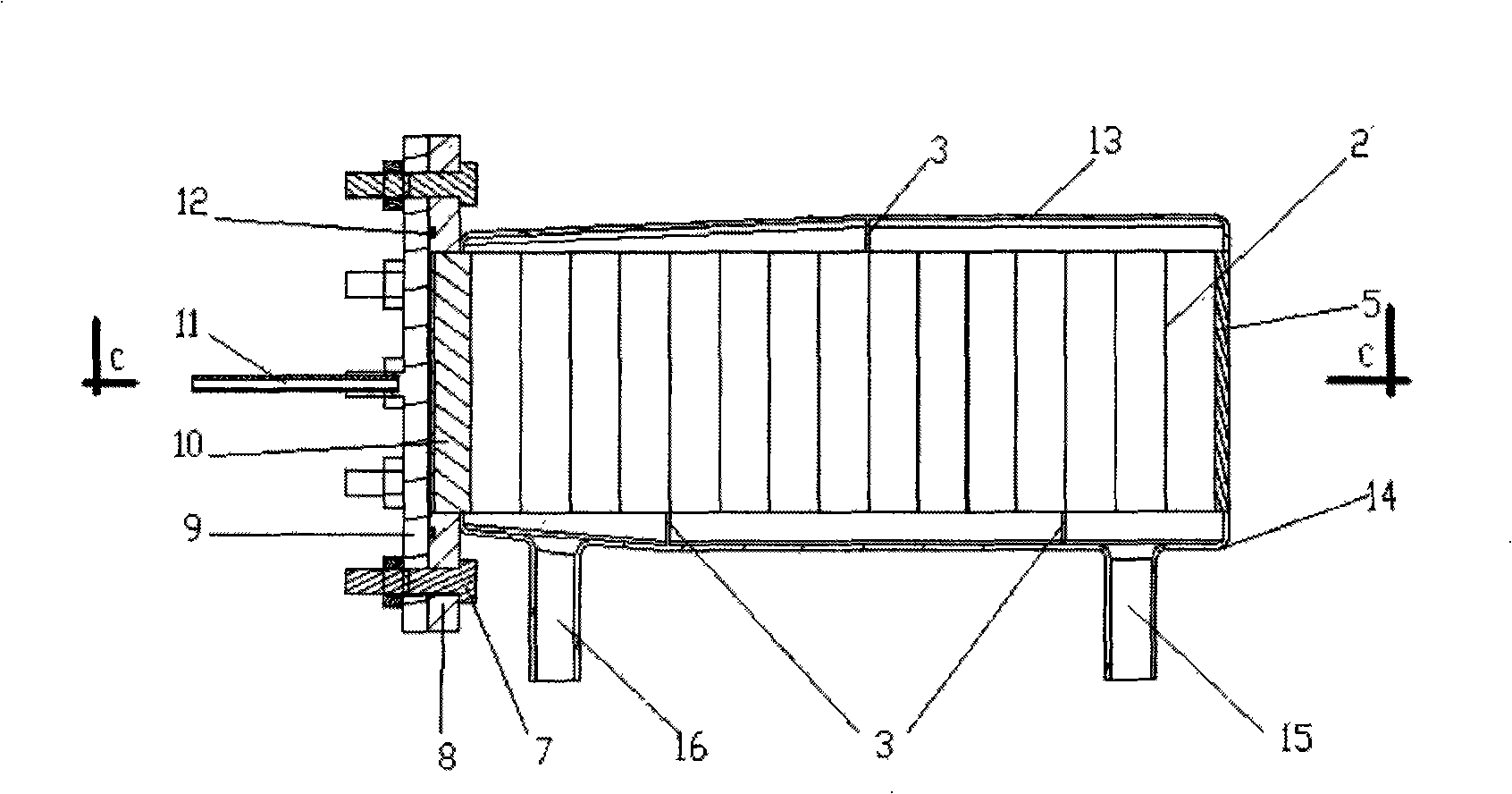

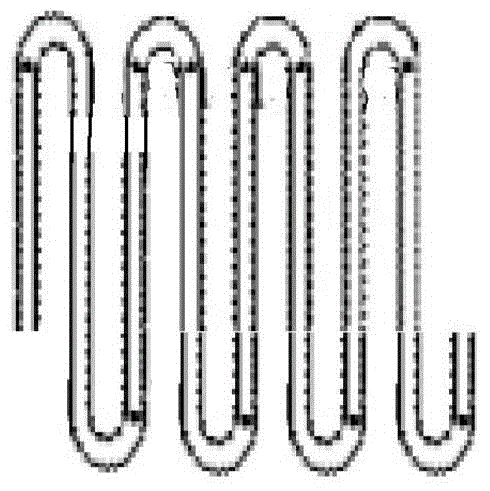

Efficient three-medium phase change coupled cold-accumulating and heat-exchanging device

InactiveCN102080906AImprove effective thermal conductivityReduce heat transfer resistanceDomestic cooling apparatusTubular elementsEngineeringPhase change

The invention relates to a heat exchange technology with a cold accumulation function and discloses an efficient three-medium phase change coupled cold-accumulating and heat-exchanging device which comprises an inner tube of a bidirectional fin, a housing tube with an outer straight rib, an upper end plate and a lower end plate. The efficient three-medium phase change coupled cold-accumulating and heat-exchanging device is characterized in that the inner side of the inner tube of the bidirectional fin is provided with an inner ripple fin, the outer side of the inner tube is provided with a plurality of axial straight fins; the outer side of the housing tube is provided with a plurality of axial straight fins used for exchanging heat with a cold carrying fluid of a cold utilizing system; the axial straight fins at the outer side of the inner tube are in soldering connection with the inner wall of the housing tube; and a low-temperature solid-liquid phase change material is filled in a multi-channel interlayer cavity formed between the inner tube and the housing tube. The invention provides a cold-accumulating and heat-exchanging device which stores and regulates low-temperature cold released by low-temperature liquefied liquid in a gas liquefying rewarming process by adopting the phase change latent heat of the low-temperature solid-liquid phase change material, and the cold-accumulating and heat-exchanging device has a function of storing and regulating low-temperature cold, can ensure the continuity and the stability of supplying the cold by using a cold utilizing system,and is a key device of the low-temperature liquefied gas cold recycling technology.

Owner:XI AN JIAOTONG UNIV

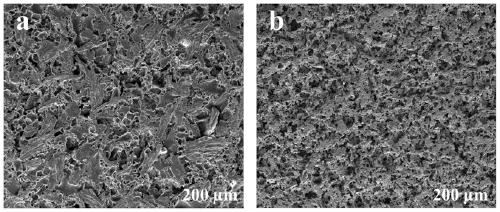

Composite phase change material heat sink of metal fiber porous skeleton and manufacturing method thereof

ActiveCN105296898ALatent heat of phase changeImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesPorosityMetal fiber

The invention discloses a composite phase change material heat sink of a metal fiber porous skeleton. The heat sink comprises a metal fiber porous skeleton, a phase change material, a heat sink basal body and a cooling fin, wherein a cavity is formed in the heat sink basal body; an opening is formed in the top surface of the heat sink basal body; the metal fiber porous skeleton is sintered by metal fibers filled in the cavity; the porosity range is 75-98%; the metal fiber porous skeleton and the heat sink basal body are sintered as a whole; the phase change material is filled in holes in the metal fiber porous skeleton by a vacuum heating filling mode; the filling rate is 95-100%; and the cooling fin is sealed in an upper opening of the heat sink basal body, and is welded with the heat sink basal body as a whole. The invention further discloses a preparation method of the composite phase change material heat sink of the metal fiber porous skeleton. The heat sink is simple in manufacturing process, suitable for large-batch manufacturing and low in cost; and the metal fiber porous skeleton is embedded in the phase change material, so that the heat conducting capacity of the phase change material in the heat sink is enhanced.

Owner:SOUTH CHINA UNIV OF TECH

Refrigerant dryer

ActiveUS8857207B2Improve relationshipImprove energy efficiencyHeat storage plantsCompression machines with non-reversible cycleRefrigerantMechanics

A refrigerant dryer, in particular a compressed air refrigerant dryer, is provided for drying a gaseous fluid while cooling the gaseous fluid using a refrigerant. The dryer includes a pressure fluid-refrigerant agent-heat exchanger (30) in which a cooling of the gaseous fluid takes place directly or indirectly by a refrigerant conveyed in a primary loop (16), one or more refrigerant compressor / compressors (24) for operating the primary loop, and a cold accumulator (13) with an accumulator-side heat exchanger (20) which couples an accumulator discharge fluid to a cold accumulator medium (14). The pressure fluid-refrigerant agent-heat exchanger (30) and the cold accumulator (13) are fluidically connected or can be brought into fluidic connection via a discharge loop (15) for an accumulator discharge fluid. The cold accumulator (13) is arranged, relative to gravity, above the pressure fluid-refrigerant agent-heat exchanger (30), in such a manner that the heated accumulator discharge fluid is conveyed through the discharge loop (15) for cooling in the cold accumulator (13), is cooled there, and subsequently re-conveyed to the pressure fluid-refrigerant agent-heat exchanger (30).

Owner:KAESER KOMPRESSOREN SE

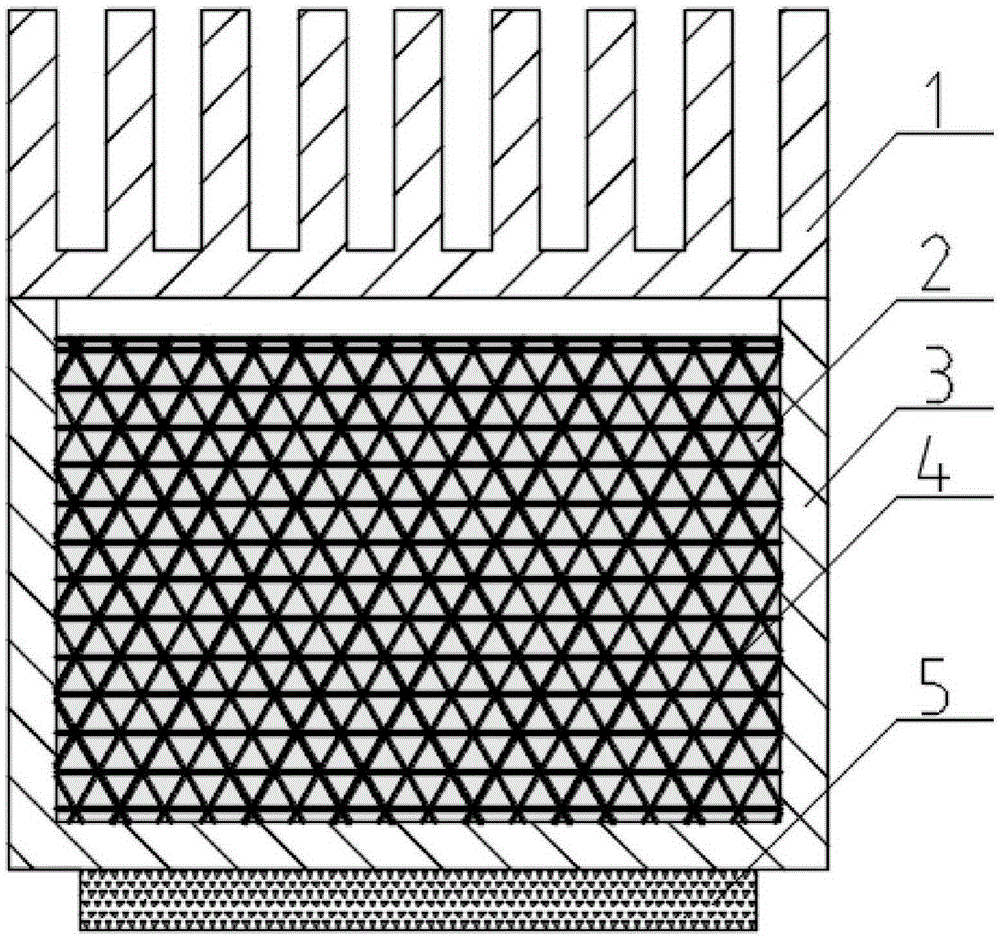

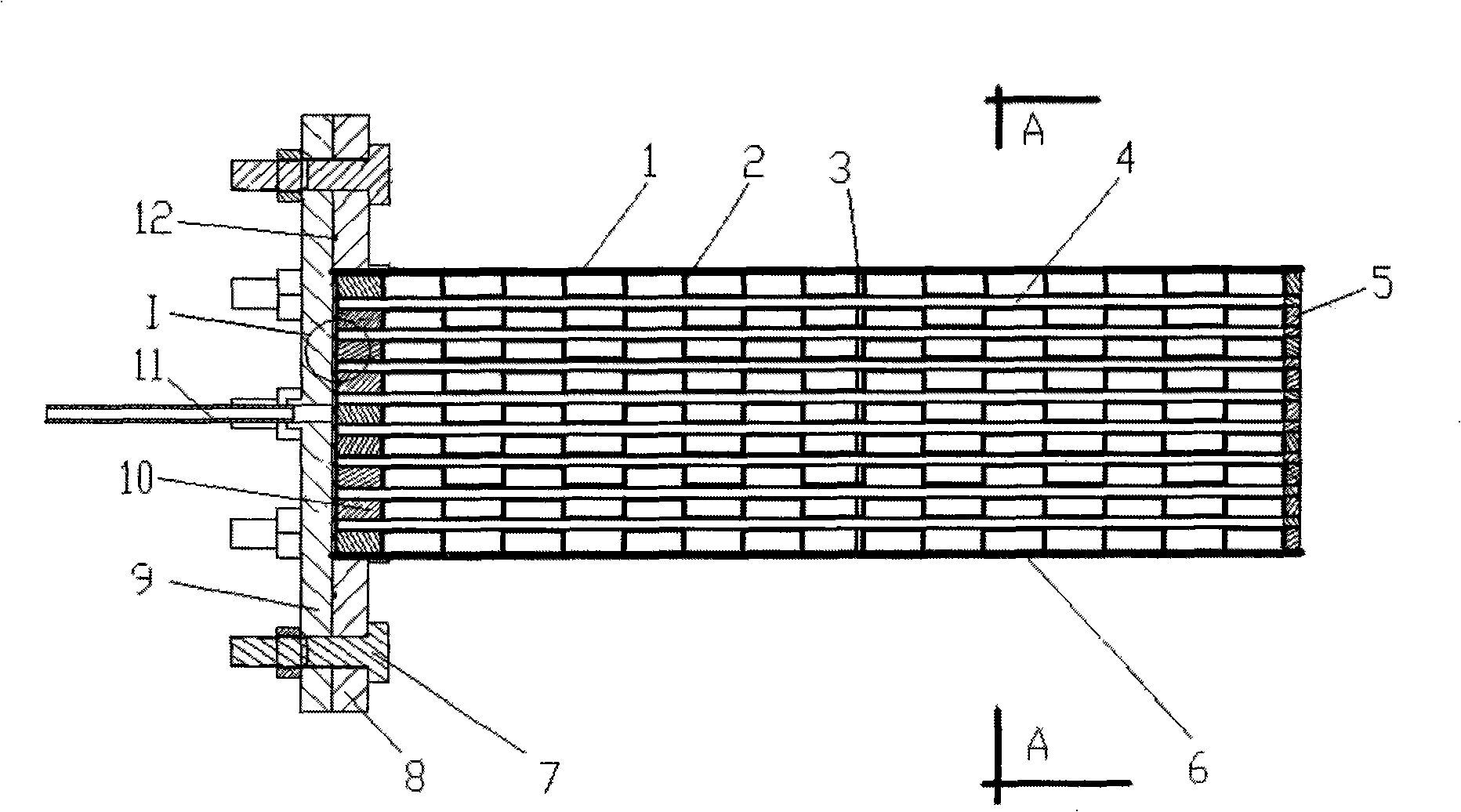

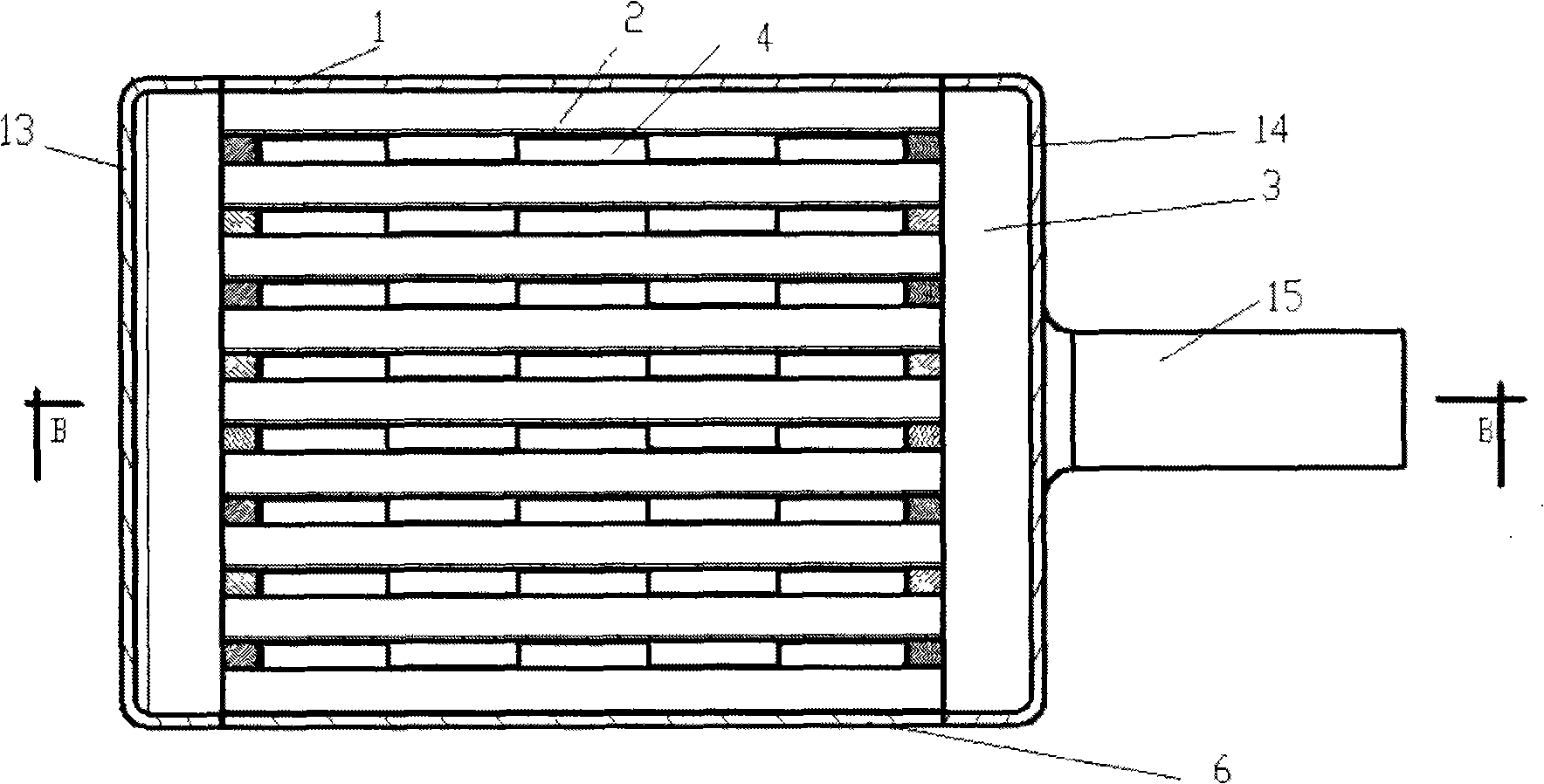

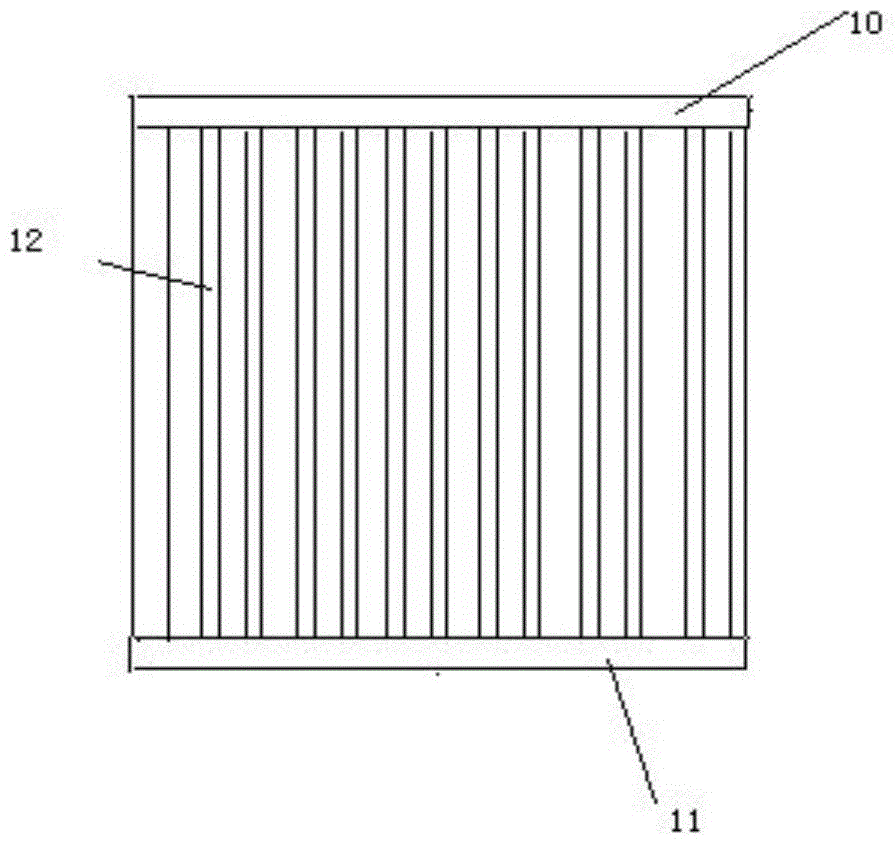

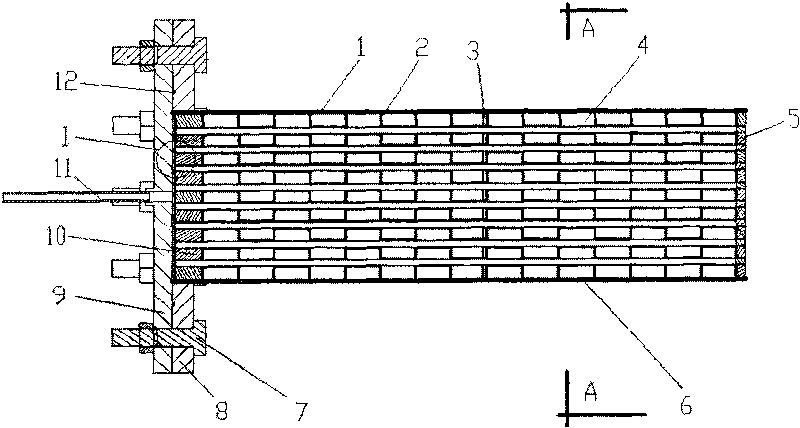

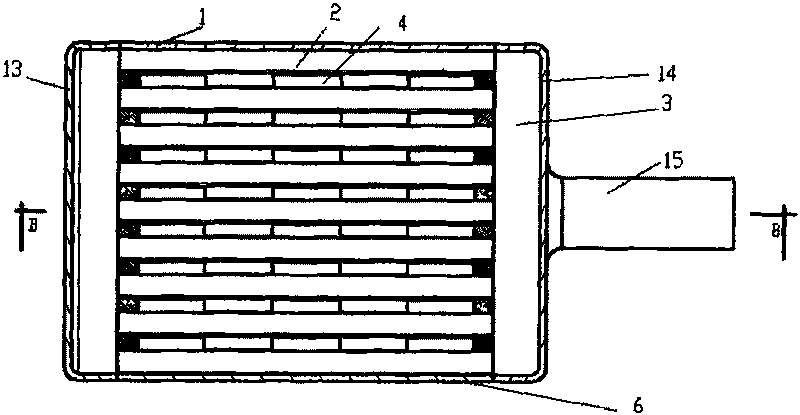

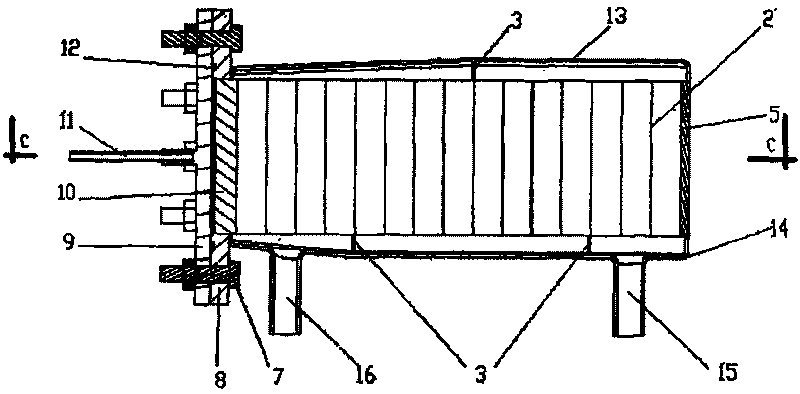

Metal hydrides plate-fin heat exchanger

InactiveCN101307994AIncrease the heat exchange areaImprove effective thermal conductivityStationary plate conduit assembliesThermal conductivityMillipore Filters

Disclosed is a metal hydride plate-fin heat exchanger, which belongs to the industrial heat exchange and energy saving technique field. The invention comprises: an upper cover plate, a fluid path flat tine fin, a spacer plate, reaction bed units, a fluid path tail sealing tape, a lower cover plate, a bolt component, a through hole flanged disc, a blind plate flanged disc, a fluid path head sealing tape, a hydrogen pipe, a fluorine rubber flange gasket, a rear enclosing cover, a front enclosing cover, a liquid inlet, a liquid outlet, a filter sheet gasket and a millipore filter sheet. Each reaction bed unit includes an upper cover plate, a unit tail sealing tape, a unit lateral sealing tape, a lower cover plate and a unit serrate fin. Each reaction bed unit has an open end and is welded with a serrate fin in the inside, thereby the heat exchange area and the effective thermal conductivity are greatly increased, and the intensity of a heat exchange unit can also be ensured under the condition of increasing the heat capacity of the heat exchange unit indistinctively. In addition, filtration and sealing difficulties of metal hydrides are greatly reduced by adopting the structure that all the reaction bed units are connected and fixed on the through hole flanged disc in parallel, meanwhile, the mass transfer capability of hydrogen will not be reduced.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing zeolite molecular sieve single finned tube for sintering shell type adsorbent bed

InactiveCN101274266AIncrease filling volumeImprove effective thermal conductivityOther chemical processesAbsorbers/adsorbersMolecular sieveSorbent

The invention relates to a fin adsorption single tube which disposably and integrally sinters zeolite molecular sieves with low temperature on a fin pipe and leads the zeolite molecular sieves to be solidified and formed, and realizes the combination of sintering of composite adsorbent and solidification of the composite adsorbent and the fin pipe wall. The fin adsorption single tube of the invention replaces light pipe sintering with the fin pipe, improves the filling quantity of the adsorbent on the unit length pipe wall and increases the heat exchanging area; the adsorbent adopted by the invention has high thermal conducting coefficient, has small resistance of the contact with the metal wall surface and fast mass transfer speed, thus improving the heat transmission and mass transfer performance of an adsorption bed, increasing the adsorption circulation quantity, and shortening the circulation time.

Owner:EAST CHINA UNIV OF SCI & TECH

Graphene carbon nanotube composite high-thermal-conductivity film and preparation method thereof

InactiveCN111908452AImprove thermal conductivityImprove conductivitySemiconductor/solid-state device detailsSolid-state devicesGraphene nanoplateletNanotube

The invention discloses a preparation method of a graphene / carbon nanotube composite heat-conducting film, which mainly comprises the following steps: preparing graphene oxide (GO) nanosheet powder byan improved hummers method, reducing the GO, growing carbon nanotubes by a catalytic chemical vapor deposition method, carrying out high-pressure homogeneous mixing on reduced graphene oxide (rGO) and carbon nanotubes (CNTs), adding an adhesive for coating the film, performing drying film forming, and calendering the film. The preparation process of the graphene / carbon nanotube composite high-thermal-conductivity film is simple, the film thickness is controllable, the in-plane thermal conductivity is up to 1900 w / k.m at 323k, and the thermal conductivity in the vertical direction is 76 w / k.m.

Owner:深圳市展旺新材料科技有限公司

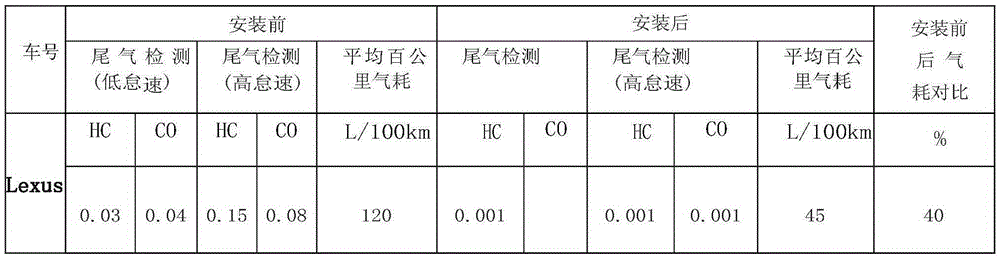

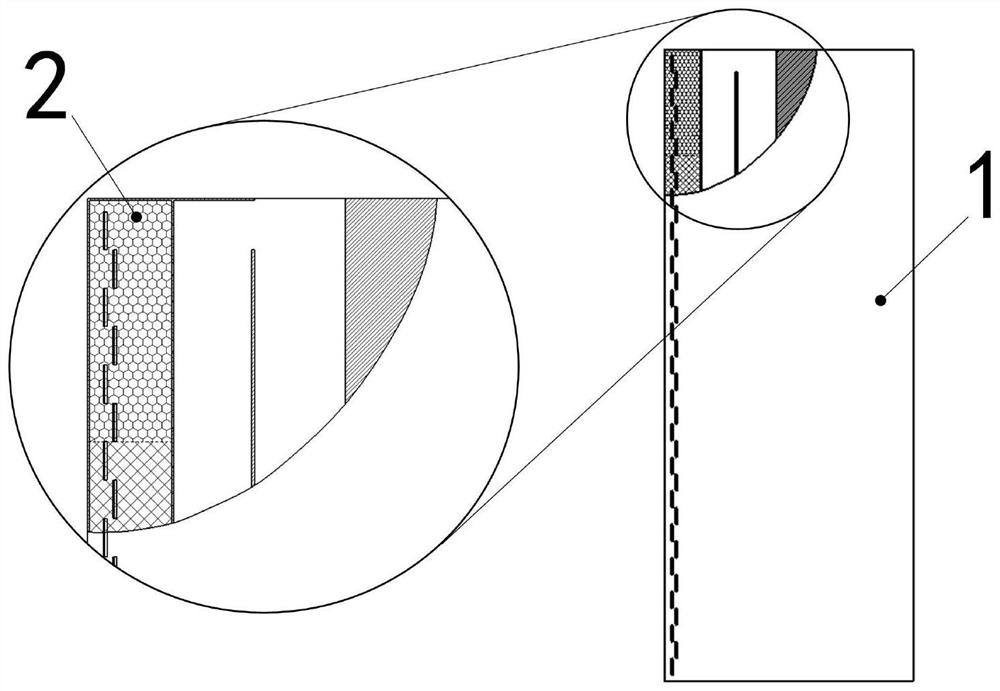

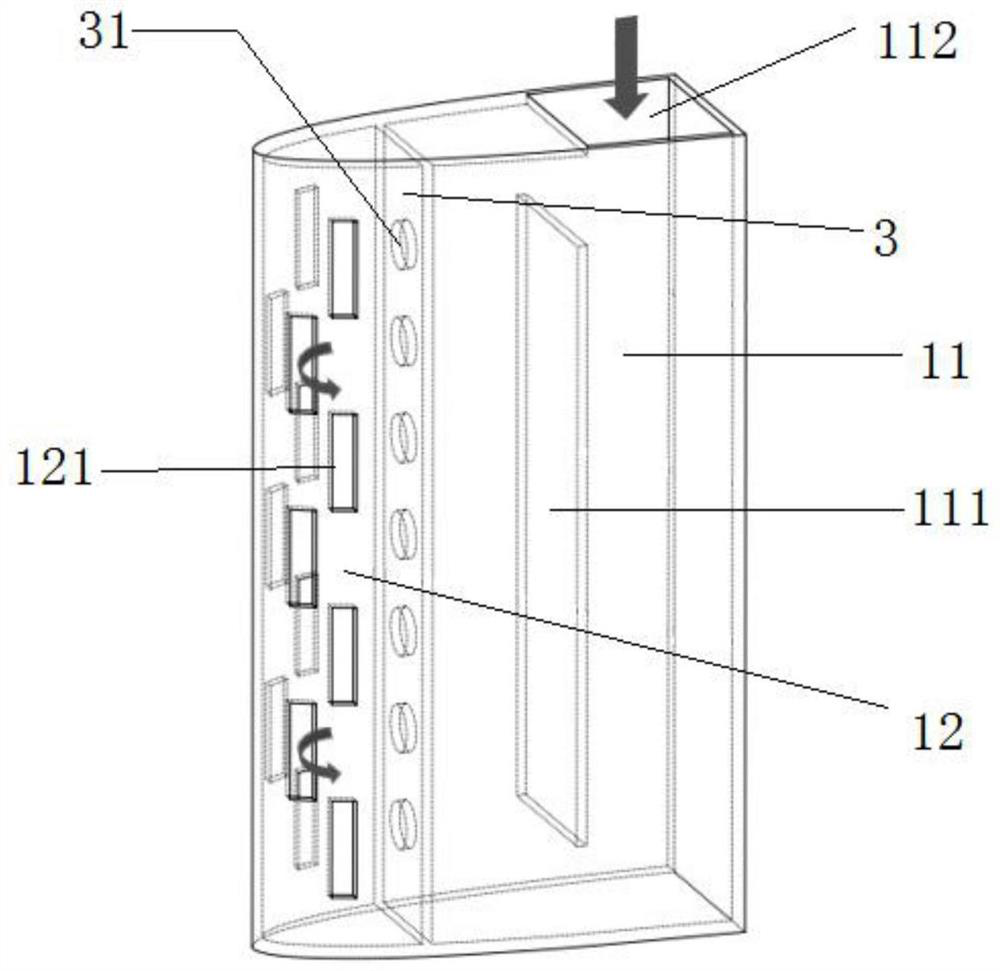

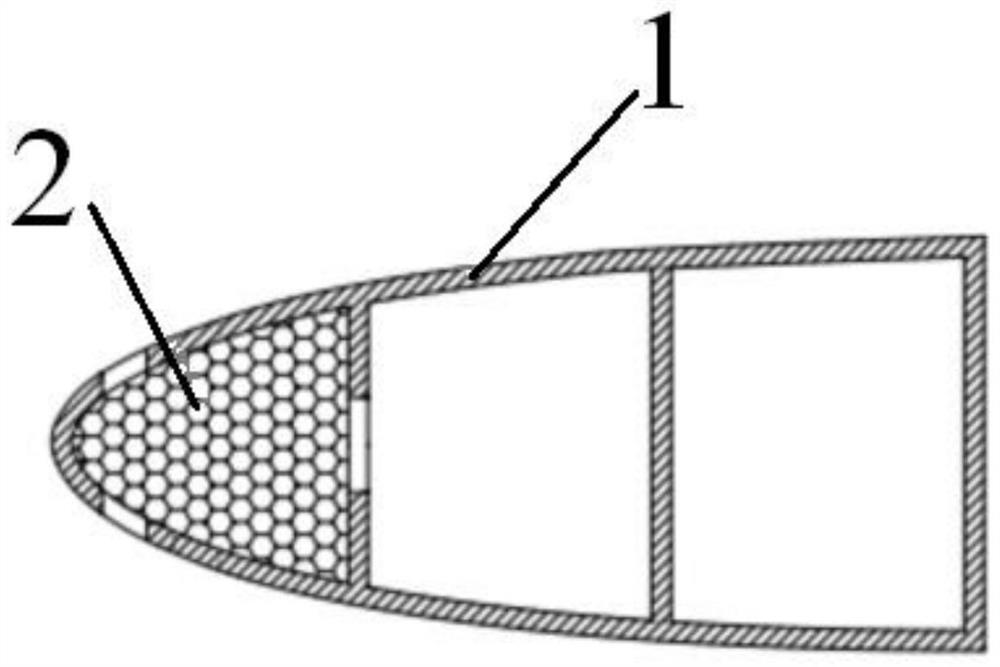

Method of improving automobile power by using honeycomb ceramics and achieving zero exhaust

InactiveCN105298691AImproved combustion patternImprove performanceInternal combustion piston enginesCombustion-air/fuel-air treatmentHoneycombCatalytic combustion

The invention discloses a method for improving automobile power by using honeycomb ceramics and achieving zero exhaust. A honeycomb ceramic catalytic converter with a plurality of open holes is placed on front of a gas inlet of an automobile engine; the honeycomb ceramic catalytic converter is provided with a catalytic device; the catalytic device is provided with a catalyst used for catalyzing combustion. Through the method, exhaust equipment is not required to eliminate harmful substances of CO and NOx; the purposes of improving the automobile power, saving oil and reducing emission can also be achieved; the oil consumption is reduced by 40%; the using performance and level of the automobile can also be improved; and the safety coefficient is improved.

Owner:HON YEE TONG

Anti-icing structure suitable for aero-engine supporting plate and wing

ActiveCN112682174AReduce the temperatureReduce trafficDe-icing equipmentsGas turbine plantsAviationThermodynamics

The invention discloses an anti-icing structure suitable for an aero-engine flow rectifing supporting plate and a wing. The anti-icing structure comprises an anti-icing part, a partition plate is arranged in the anti-icing part and divides the inner space of the anti-icing part into an air inlet cavity and an impact cavity, a jet hole is formed in the partition plate, the air inlet cavity and the impact cavity communicates through the jet hole, and convection-impact heat exchange of heat flow between the air inlet cavity and the impact cavity is formed; a flow dividing plate is vertically arranged in the air inlet cavity, an air inlet is formed in the top of the air inlet cavity on the right side of the flow dividing plate, and gaps are reserved between the two ends of the flow dividing plate and the top face and the bottom face of the anti-icing part to form a heat flow forward conveying channel; and a plurality of layers of porous medium fillers are laid in the impact cavity in the unfolding direction, and air outlet slits are formed in the surface of the impact cavity. Heat flow distribution away from the far end and the near end of a heat source can be regulated and controlled, non-uniform protection of the far end and the near end of a traditional heat exchange structure is reduced, the heat exchange effect of hot air flow and the front edge of a part can be enhanced, and hot air condition requirements needed by a conventional hot air anti-icing method are reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

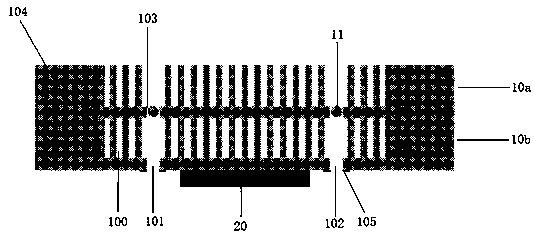

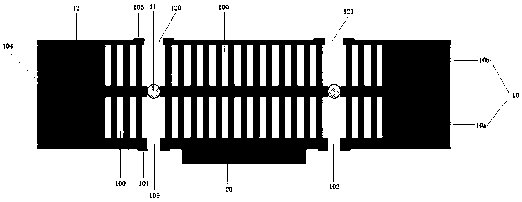

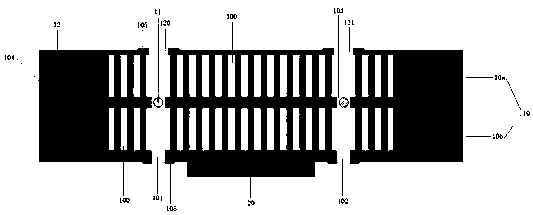

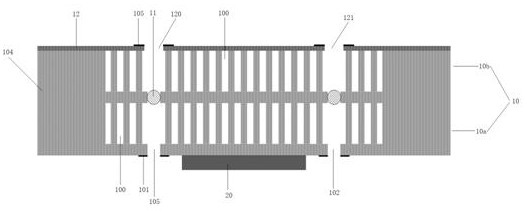

Forced convection micro-channel heat dissipation structure and manufacturing method thereof, and electronic device

ActiveCN110335854AImprove effective thermal conductivityMeet cooling needsSemiconductor/solid-state device detailsSolid-state devicesForced convectionComputer engineering

The invention provides a forced convection micro-channel heat dissipation structure. The forced convection micro-channel heat dissipation structure comprises: at least two heat dissipation units whichare sequentially stacked; a plurality of heat dissipation channels, wherein the heat dissipation channels are arranged on each heat dissipation unit; at least one inlet and at least one outlet, wherein the at least one inlet and the at least one outlet are opened on the heat dissipation units being in contact with a chip; at least two circulation channels which are arranged on other heat dissipation units not in direct contact with the chip so as to communicate the heat dissipation channels on the adjacent heat dissipation units; at least two negative thermal expansion bodies, wherein one negative thermal expansion body is correspondingly filled in one circulation channel and is used for conducting or not conducting the heat dissipation channels of the adjacent heat dissipation units; anda cover plate covering the heat dissipation unit on the top layer, wherein at least one air inlet and at least one air outlet are formed in the cover plate, and the at least one air inlet and the atleast one air outlet communicate with the heat dissipation channel on the heat dissipation unit on the top layer. The invention also provides a manufacturing method of the heat dissipation structure and an electronic device applying the heat dissipation structure.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

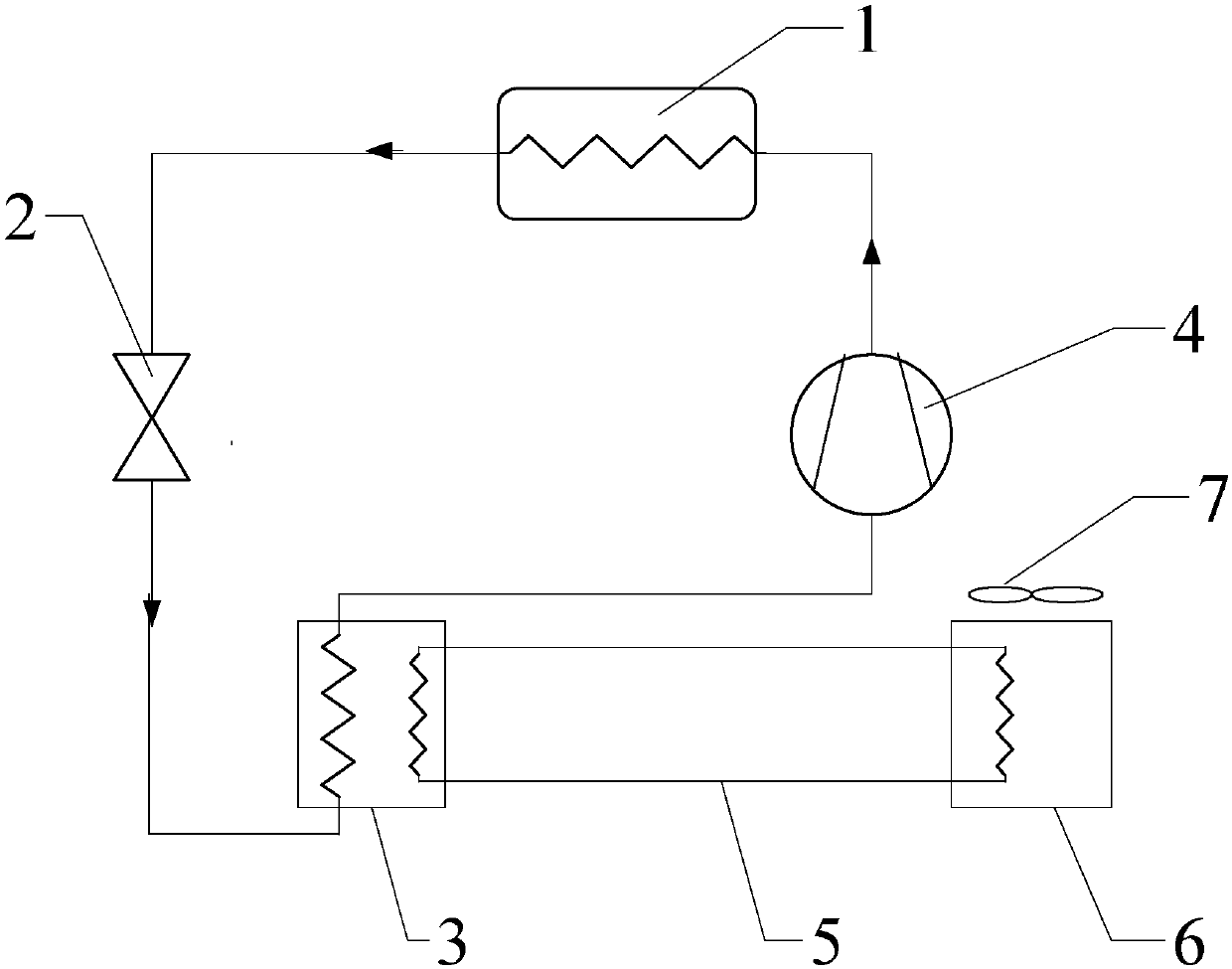

Safe and environment-friendly automobile air conditioning system

PendingCN107650619ASimple structureIncrease or decrease freelyAir-treating devicesVehicle heating/cooling devicesIntermediate heat exchangerAutomobile air conditioning

The invention discloses a safe and environment-friendly automobile air conditioning system. The safe and environment-friendly automobile air conditioning system is composed of a cooler, an expansion valve, an intermediate heat exchanger, a compressor, a secondary refrigerant pipeline, a cabin heat exchanger and a fan. An outlet of the compressor is connected with an air inlet of the intermediate heat exchanger through the cooler and the expansion valve. An air outlet of the intermediate heat exchanger is connected with an inlet of the compressor. A secondary refrigerant pipe in the intermediate heat exchanger is connected with a secondary refrigerant pipe of the cabin heat exchanger through the secondary refrigerant pipeline. The air conditioning system is filled with a working medium of CO2 or R1234yf, and the refrigerant pipeline is filled with a nano fluid secondary refrigerant. The safe and environment-friendly automobile air conditioning system can separate the refrigerant from acabin, and the nano fluid secondary refrigerant is only led into the heat exchanger in an automobile for heat exchanging with air of the cabin. During refrigerant leaking, a refrigerant is directly leaked into the environment and cannot cause damage to people in the automobile. Therefore, the system has the advantages of safety and environmental protection.

Owner:TIANJIN UNIV OF COMMERCE

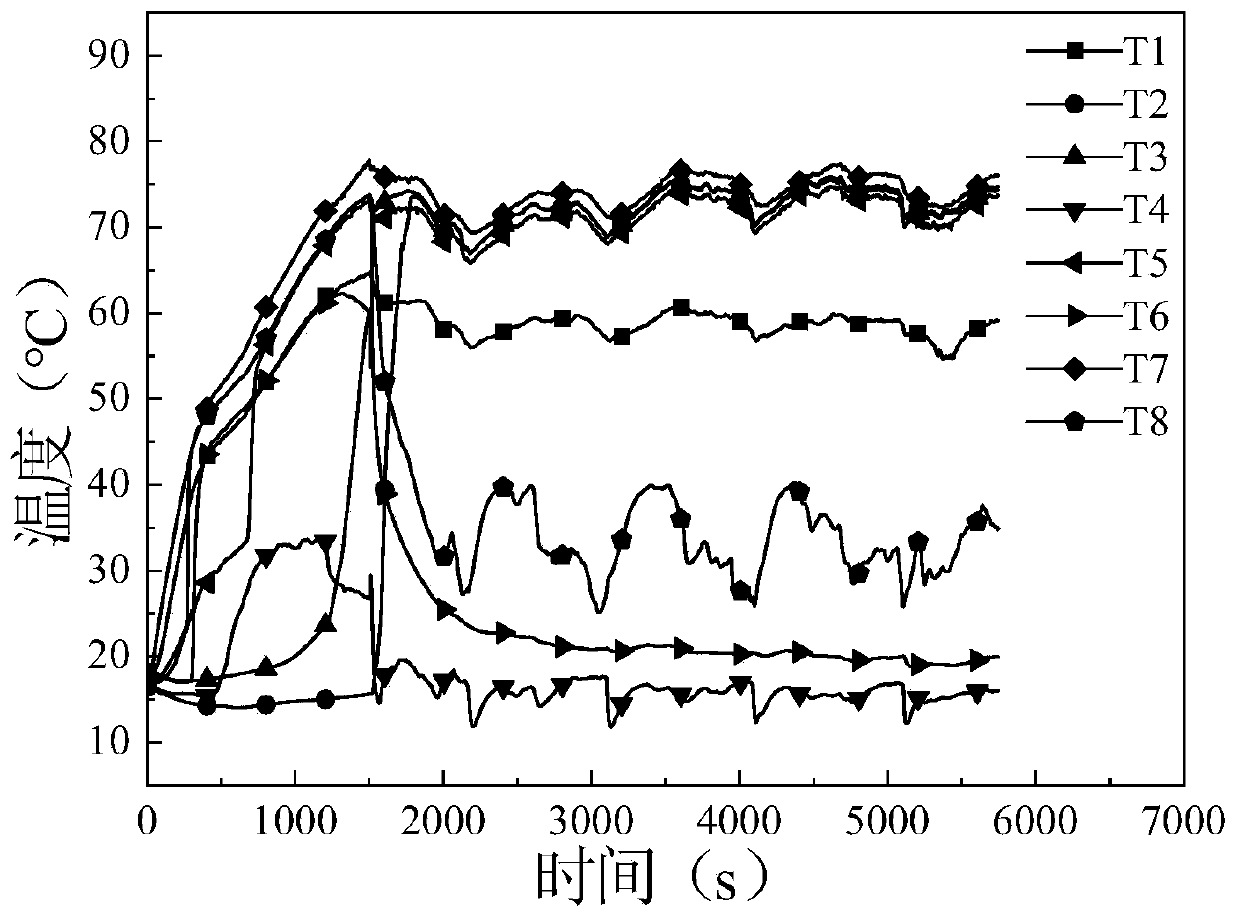

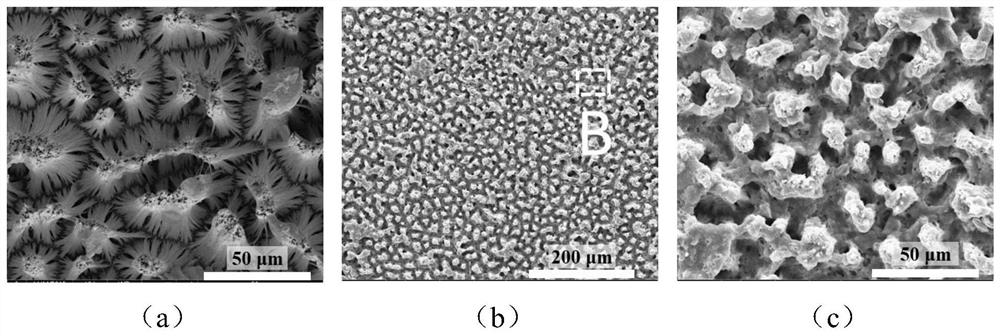

Porous copper-wood fiber/polystyrene double-layer composite capillary core for loop heat pipe and preparation method thereof

ActiveCN111189346AReduced back heat conductionImprove thermal conductivityIndirect heat exchangersFiberPolystyrene

The invention discloses a porous copper-wood fiber / polystyrene double-layer composite capillary core for a loop heat pipe and a preparation method thereof. The preparation method of the porous copper-wood fiber / polystyrene double-layer composite capillary core comprises the following steps that sodium chloride or anhydrous sodium carbonate are taken to grind, sieving is carried out to obtain a pore forming agent with the particle size of 50 to 75 microns, drying for later use is carried out; polystyrene, wood fibers and the pore forming agent are mixed, tabletting is carried out, a porous woodfiber / polystyrene composite material capillary core is obtained through sintering and washing; an electrolytic copper powder and the pore forming agent are mixed, tabletting is carried out, and a porous copper-wood fiber / polystyrene double-layer composite capillary core is obtained through sintering and washing; and the porous wood fiber / polystyrene composite material capillary core and the porous copper-wood fiber / polystyrene double-layer composite capillary core are superimposed and composite,a porous copper core is close to the evaporation end of the loop heat pipe, and the porous composite material capillary core is close to a compensation chamber of the loop heat pipe. According to the porous copper-wood fiber / polystyrene double-layer composite capillary core for the loop heat pipe and the preparation method thereof, the double-layer composite capillary core is applied to the loop heat pipe, internal heat and mass transfer can be enhanced, gradient heat resistance can be formed in the radial direction, back heat leakage is reduced, the operating temperature of the loop heat pipe is effectively reduced, a phase change interface is stabilized, and therefore the operating performance of the loop heat pipe is improved.

Owner:CHINA UNIV OF MINING & TECH

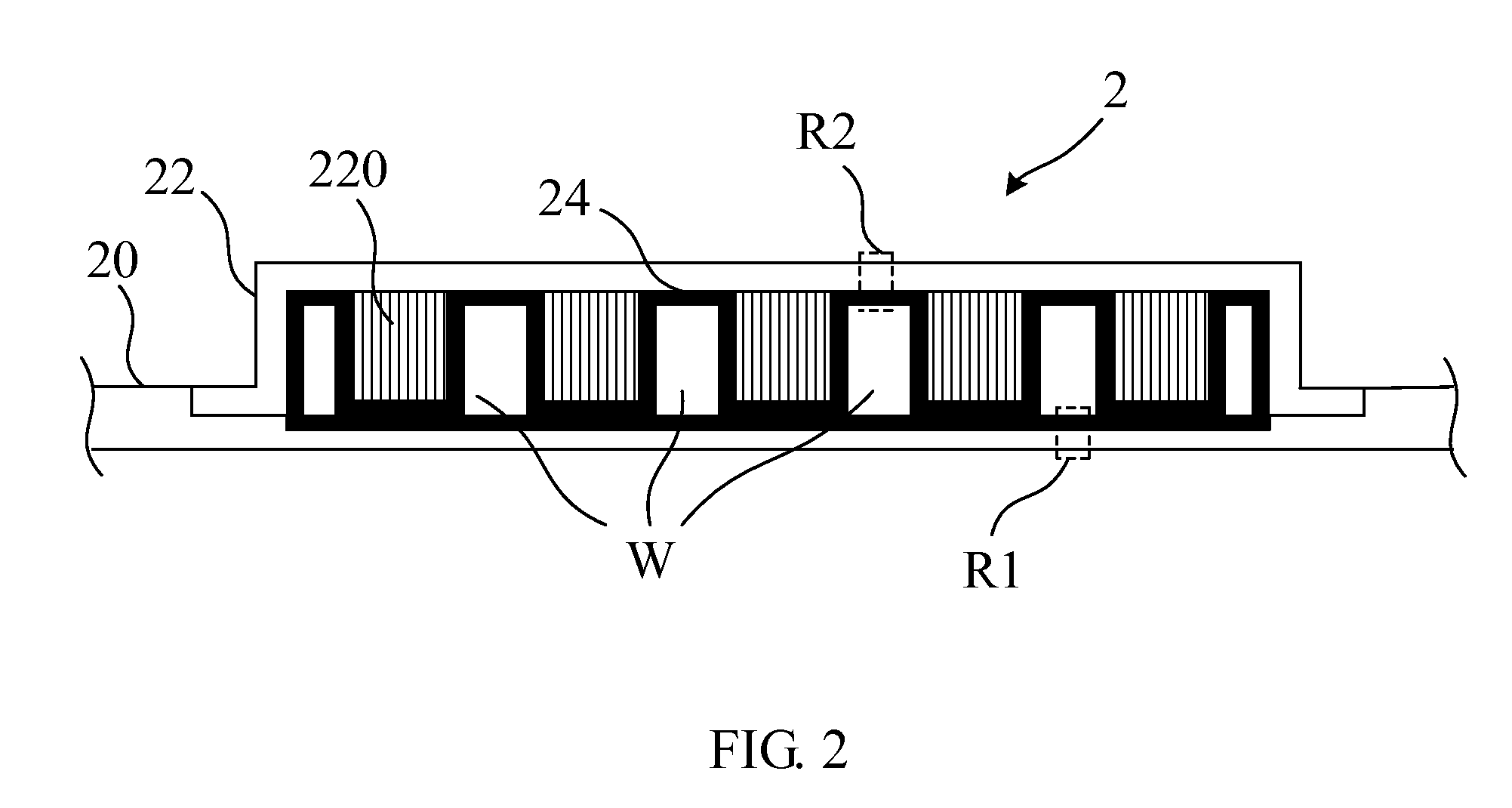

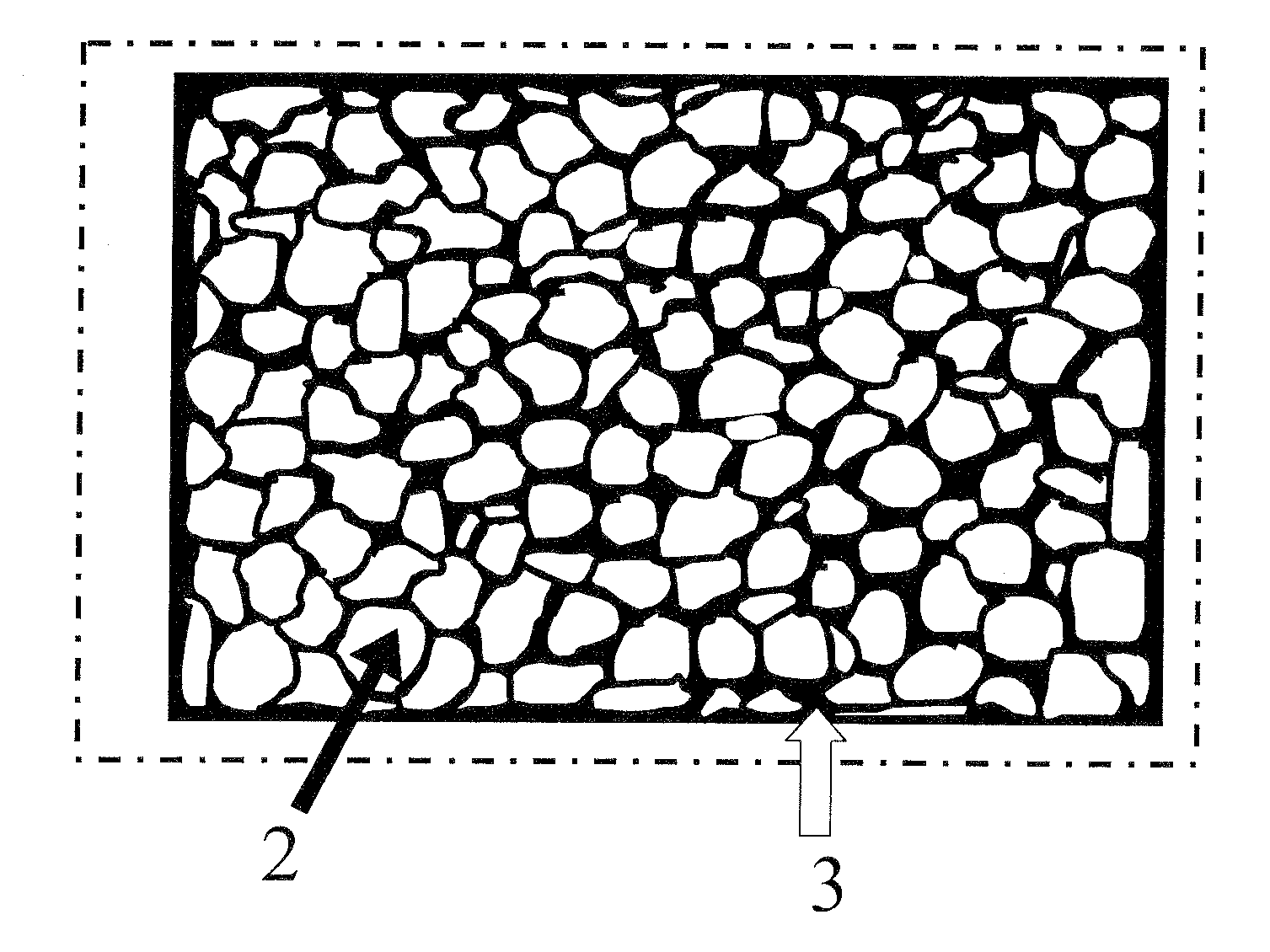

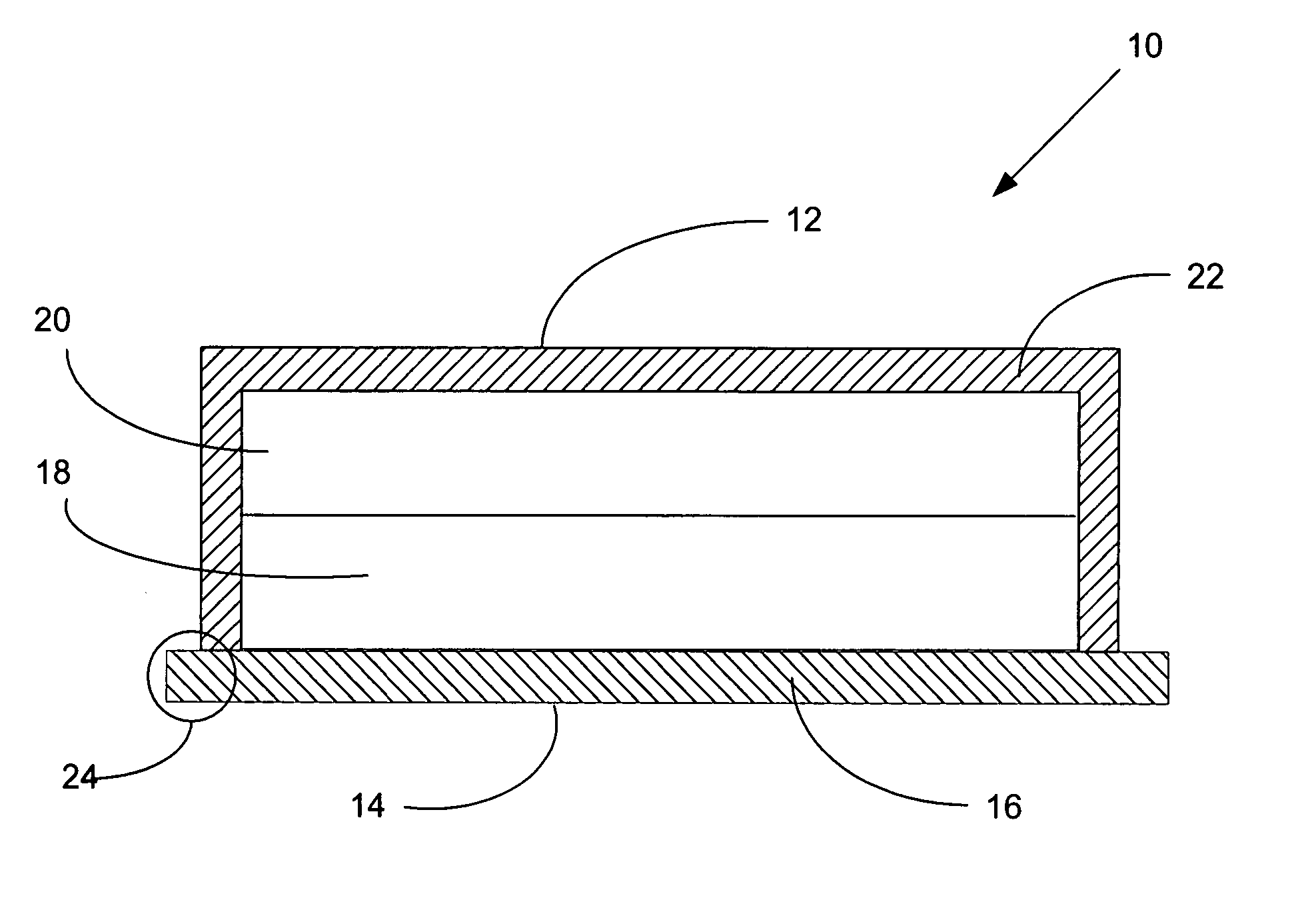

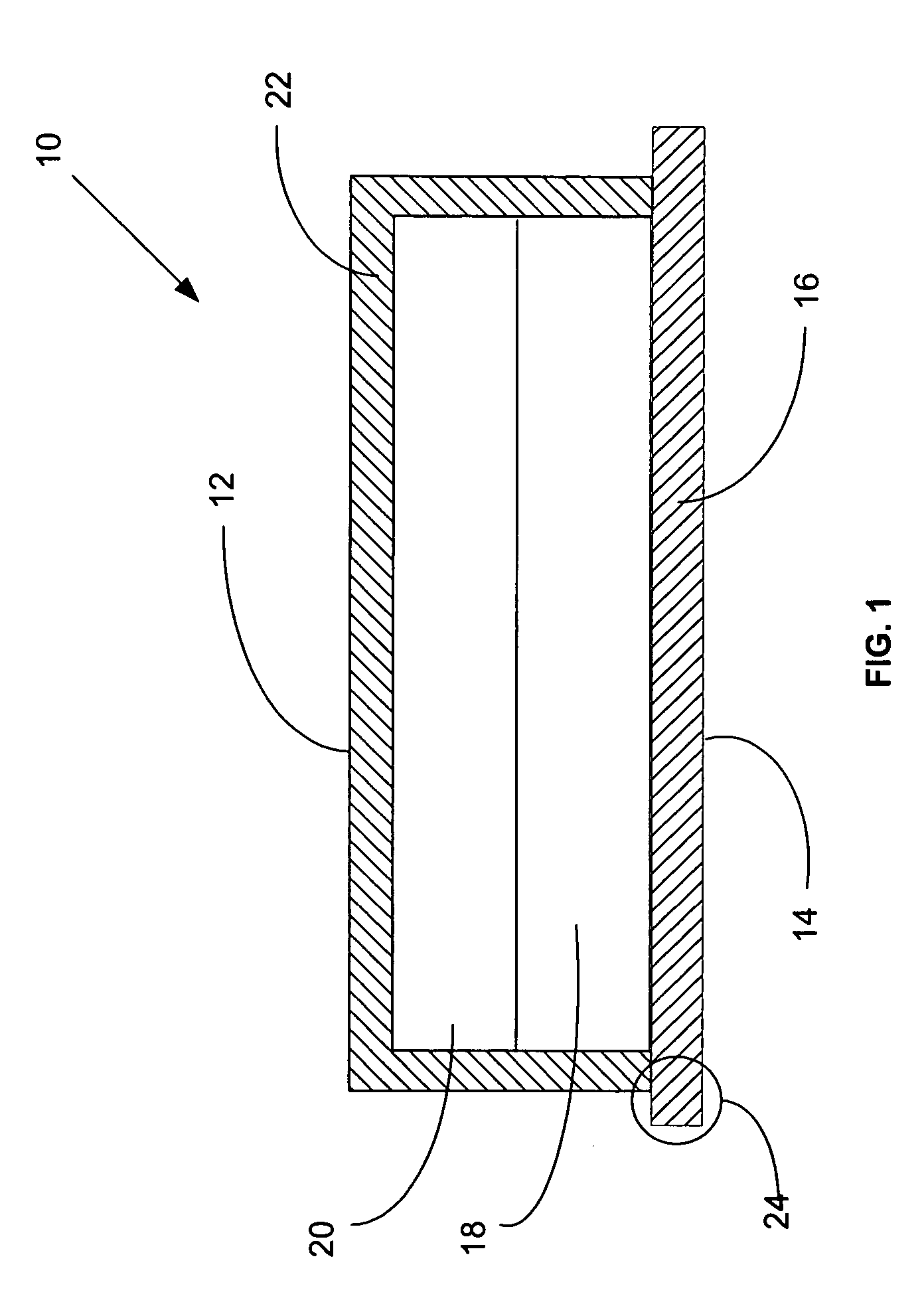

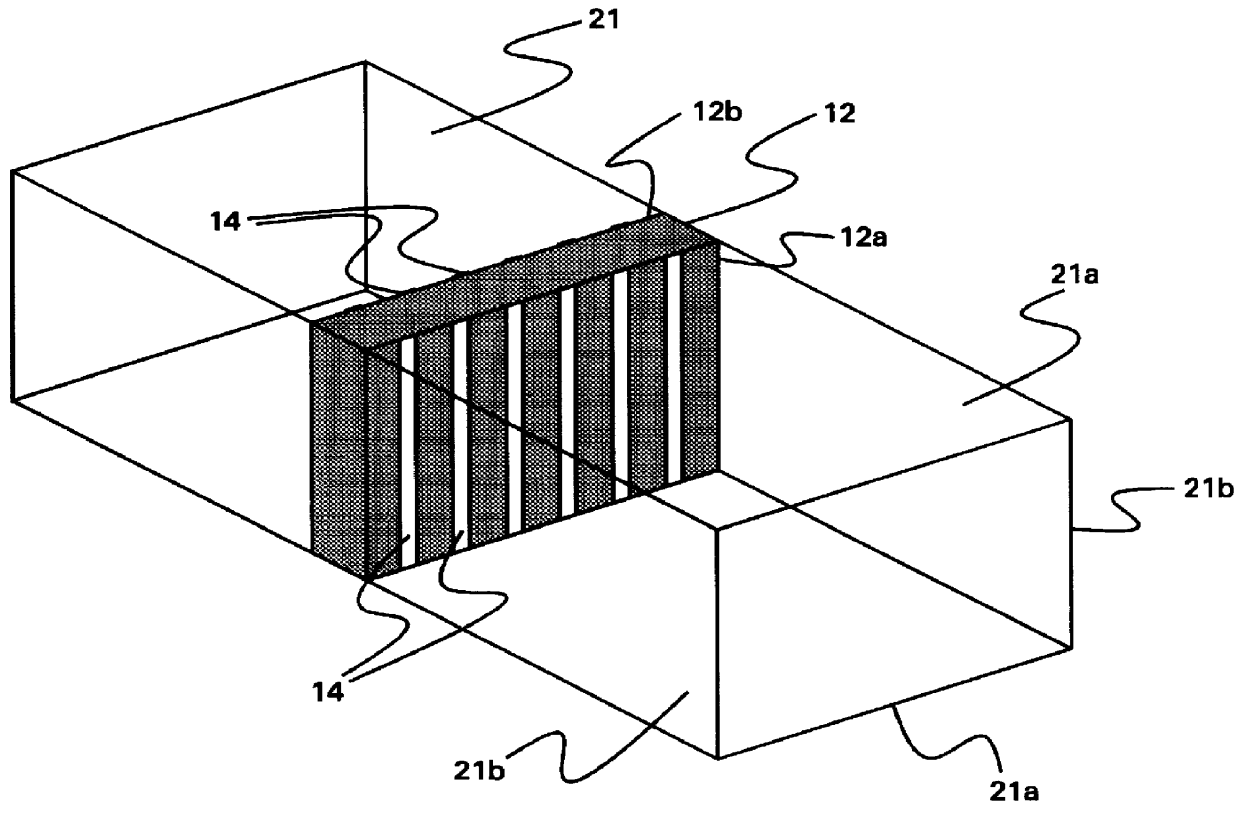

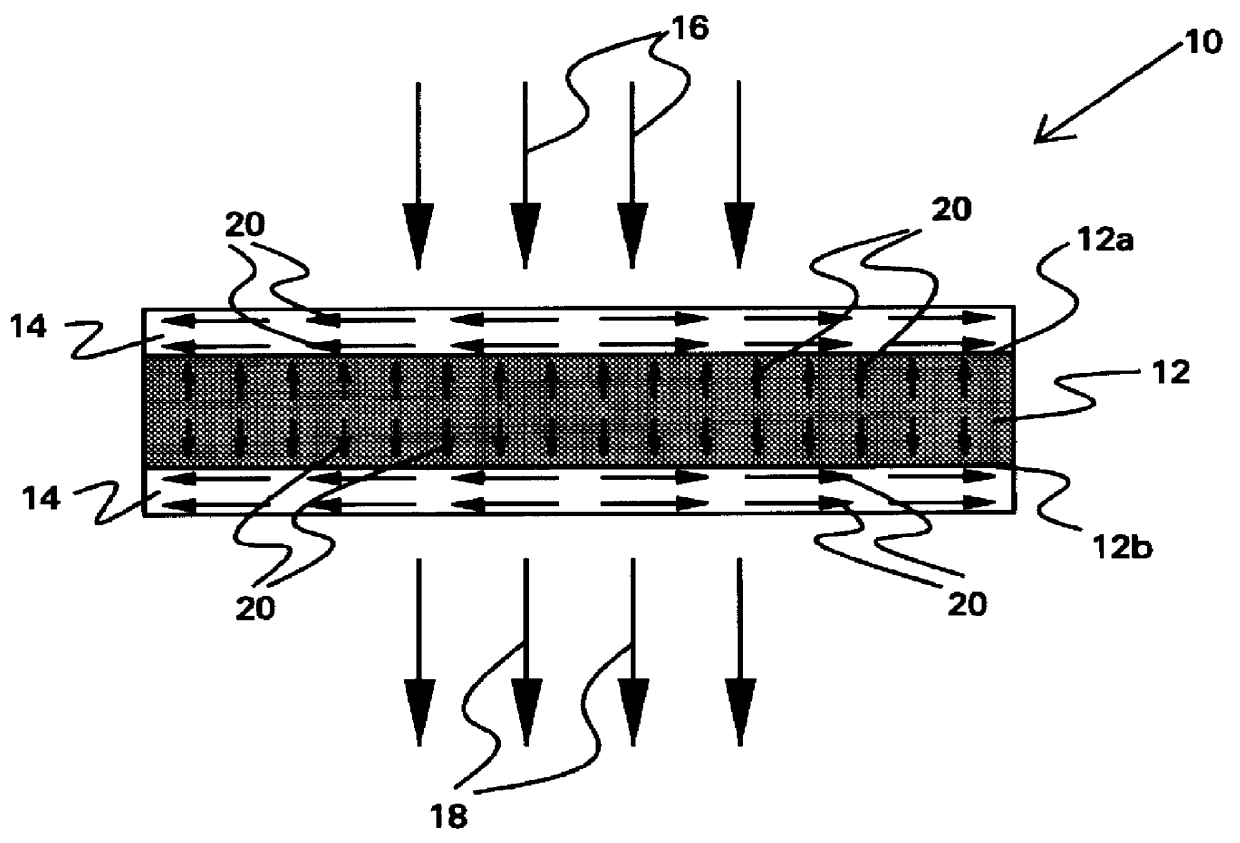

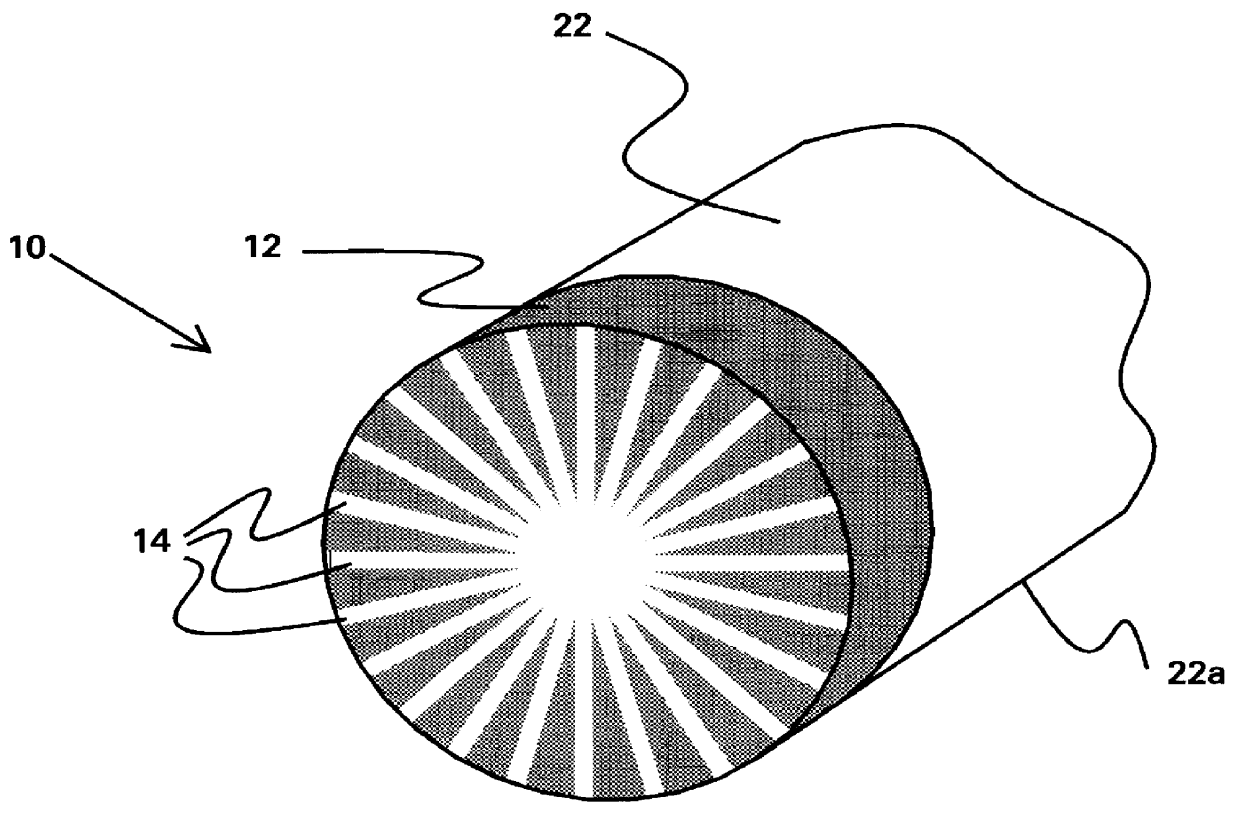

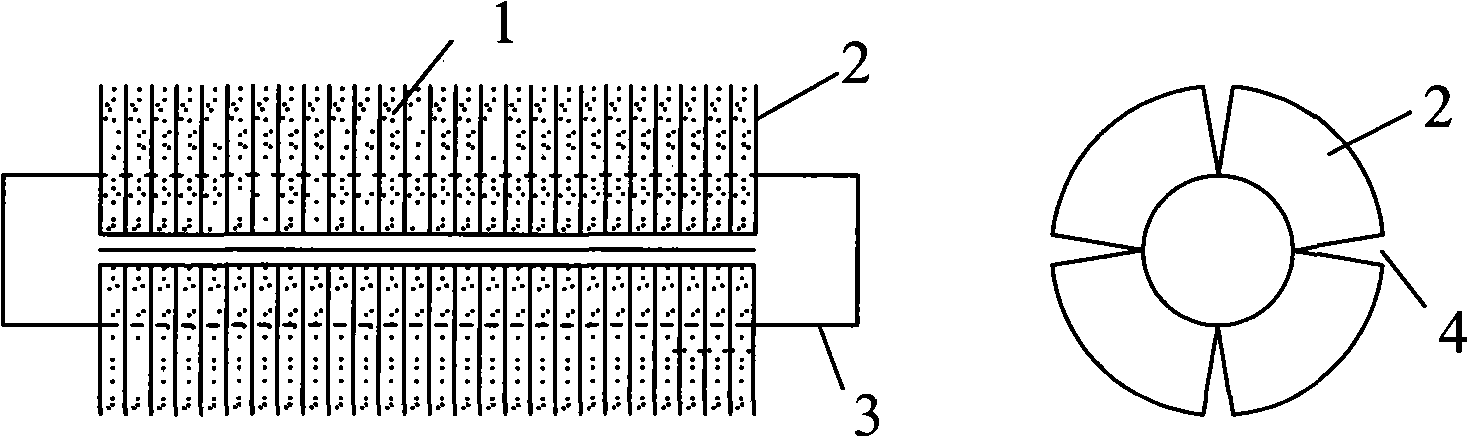

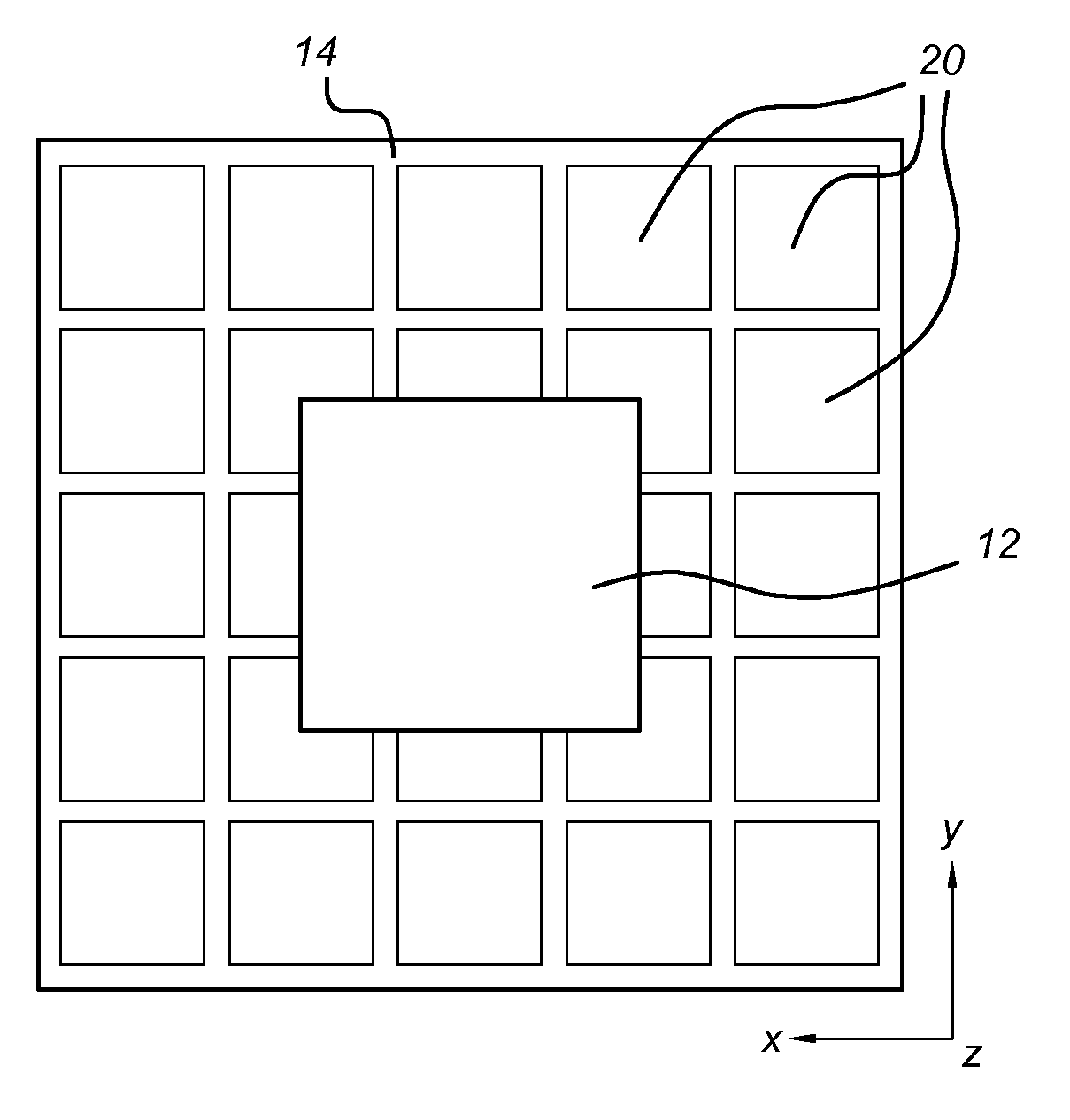

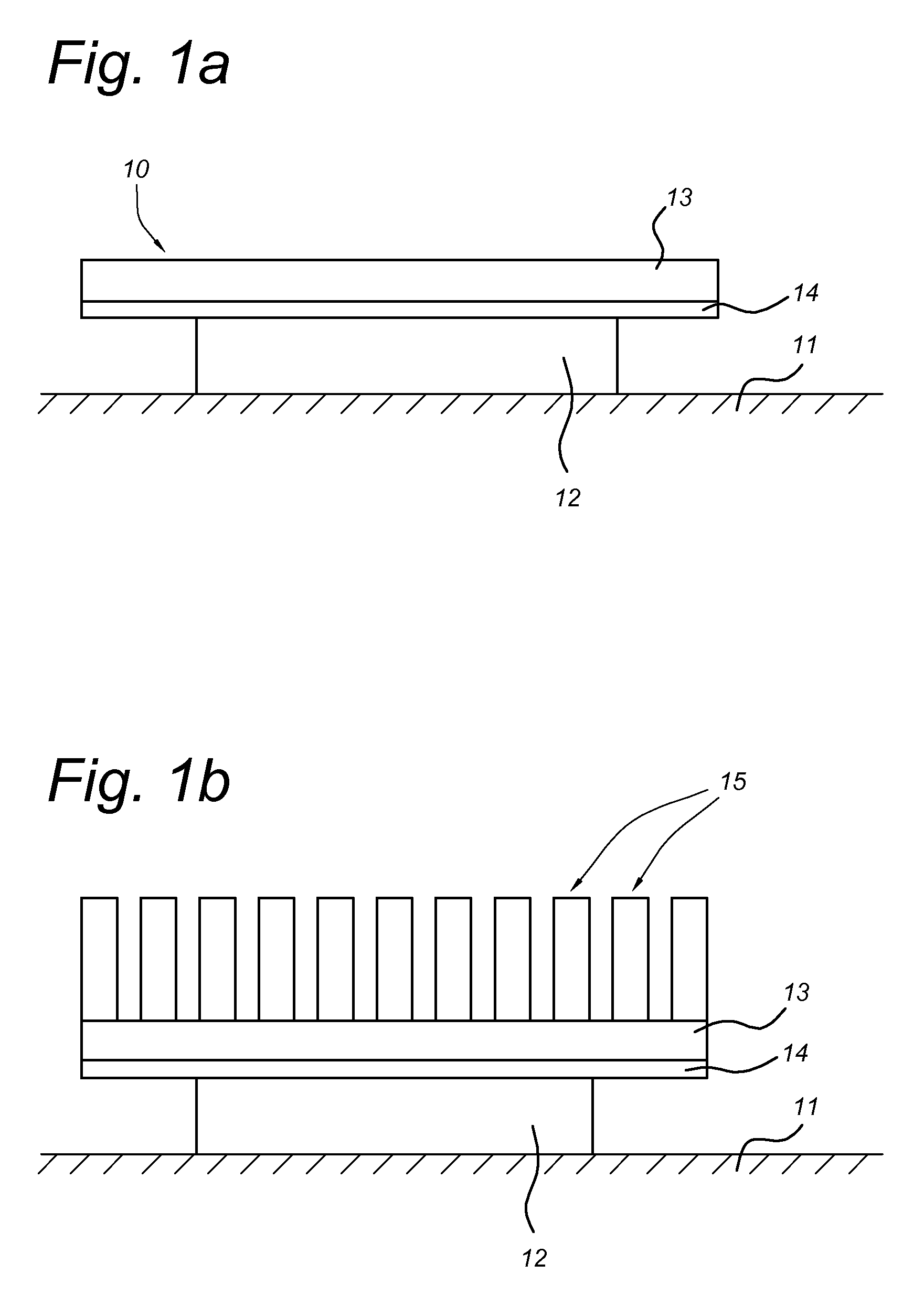

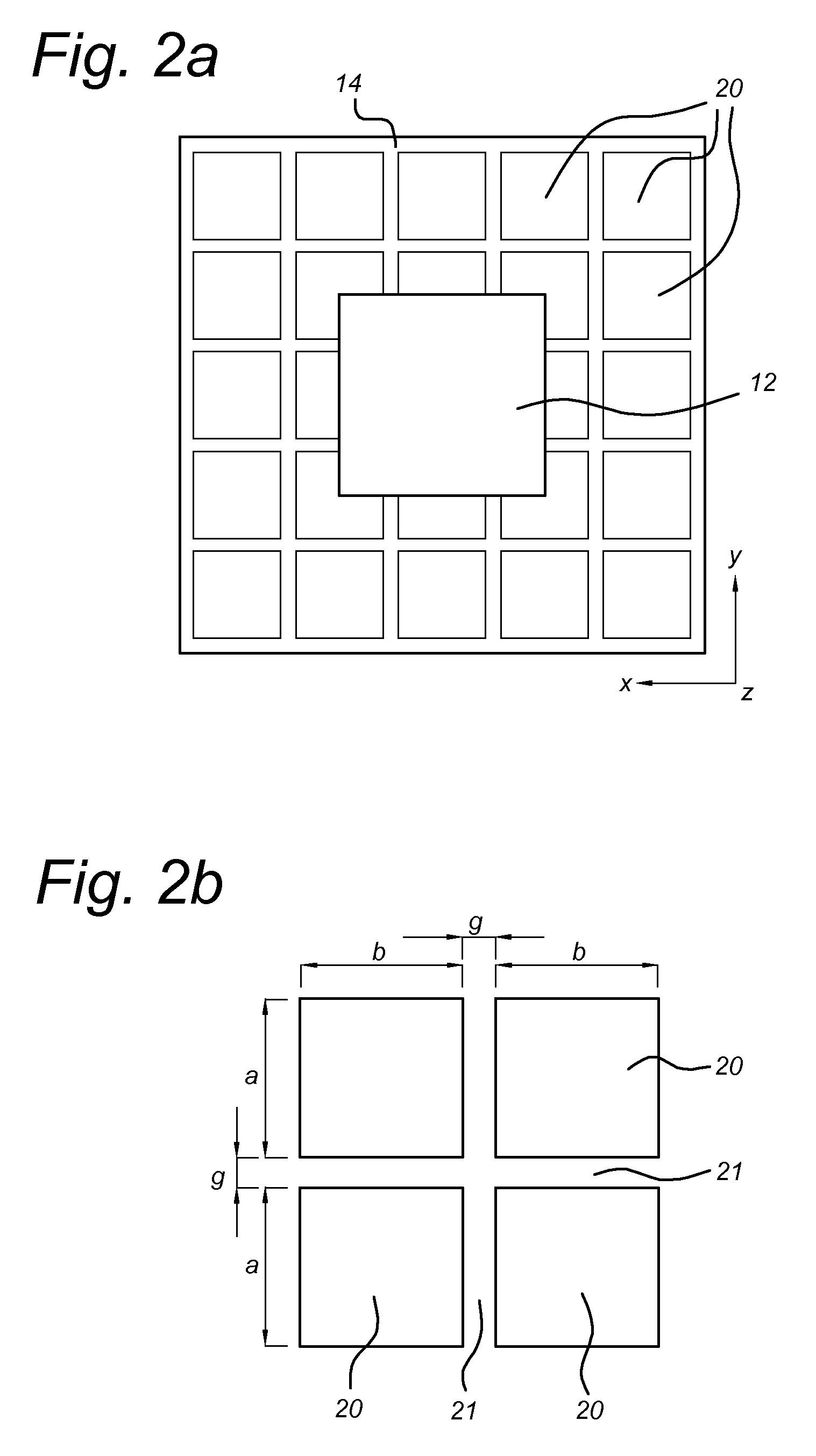

Heat conductor device and method of forming a heat conductor device

ActiveUS9572282B2Fast heat conductionImprove effective thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesElectromagnetic interferenceThermal transmittance

The invention provides a heat conductor device (10) for removing heat from an electrical component (12) operating in a frequency range, the device comprising a body (13) having a first thermal conductivity, characterized in that the body (13) is provided with a heat spreader (14) comprising a pattern of thermally conducting tiles (20, 50, 51, 52, 61) separated by gaps (21), the tiles having a second thermal conductivity higher than the first thermal conductivity, wherein each tile has at most a maximum area value and the gaps have at least a minimum gap width, and the maximum area and the minimum width are dimensioned for conforming to a predetermined electromagnetic interference characteristic of the heat conductor device when combined with the electrical component operating in the frequency range. The invention also provides a method for forming a heat conductor device.

Owner:TOP VICTORY INVESTMENTS

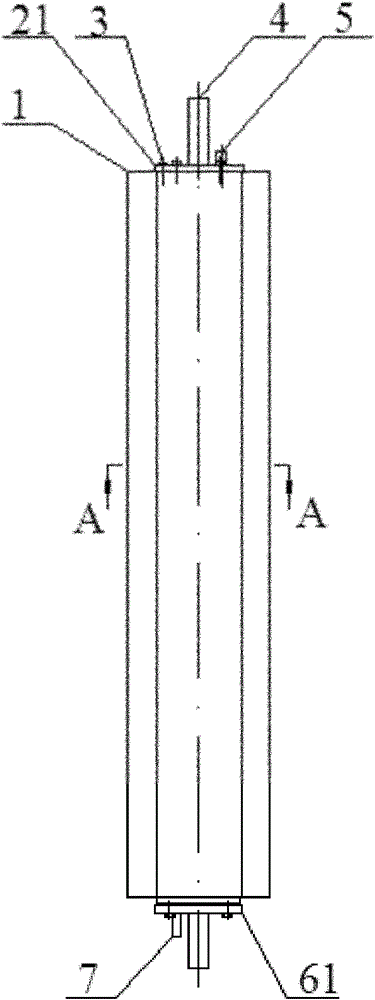

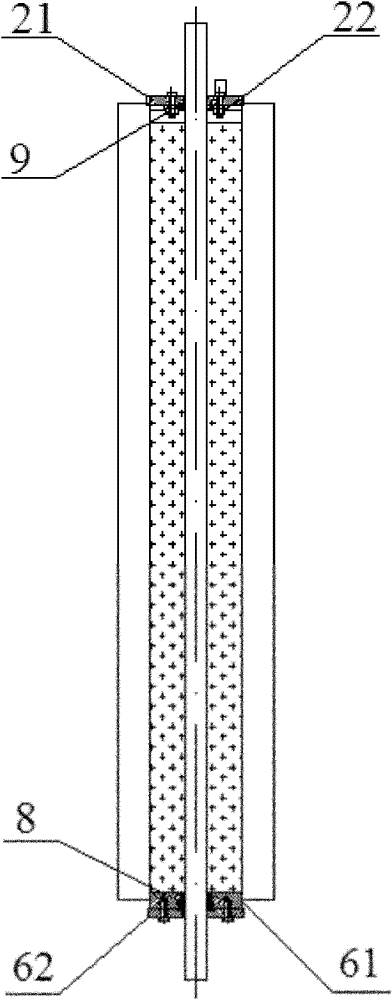

Efficient three-medium phase change coupled cold-accumulating and heat-exchanging device

InactiveCN102080906BImprove effective thermal conductivityReduce heat transfer resistanceDomestic cooling apparatusTubular elementsEngineeringPhase change

The invention relates to a heat exchange technology with a cold accumulation function and discloses an efficient three-medium phase change coupled cold-accumulating and heat-exchanging device which comprises an inner tube of a bidirectional fin, a housing tube with an outer straight rib, an upper end plate and a lower end plate. The efficient three-medium phase change coupled cold-accumulating and heat-exchanging device is characterized in that the inner side of the inner tube of the bidirectional fin is provided with an inner ripple fin, the outer side of the inner tube is provided with a plurality of axial straight fins; the outer side of the housing tube is provided with a plurality of axial straight fins used for exchanging heat with a cold carrying fluid of a cold utilizing system; the axial straight fins at the outer side of the inner tube are in soldering connection with the inner wall of the housing tube; and a low-temperature solid-liquid phase change material is filled in a multi-channel interlayer cavity formed between the inner tube and the housing tube. The invention provides a cold-accumulating and heat-exchanging device which stores and regulates low-temperature cold released by low-temperature liquefied liquid in a gas liquefying rewarming process by adopting the phase change latent heat of the low-temperature solid-liquid phase change material, and the cold-accumulating and heat-exchanging device has a function of storing and regulating low-temperature cold, can ensure the continuity and the stability of supplying the cold by using a cold utilizing system, and is a key device of the low-temperature liquefied gas cold recycling technology.

Owner:XI AN JIAOTONG UNIV

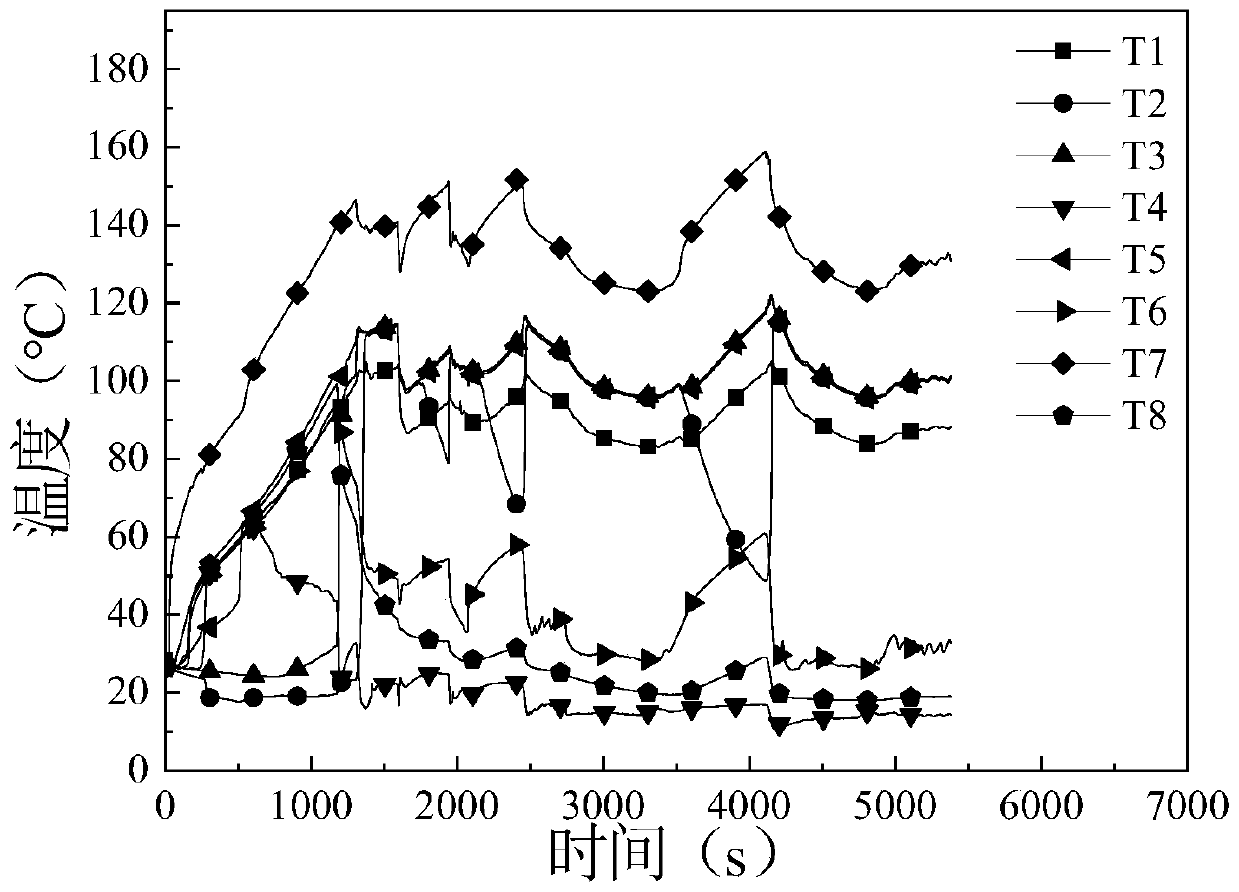

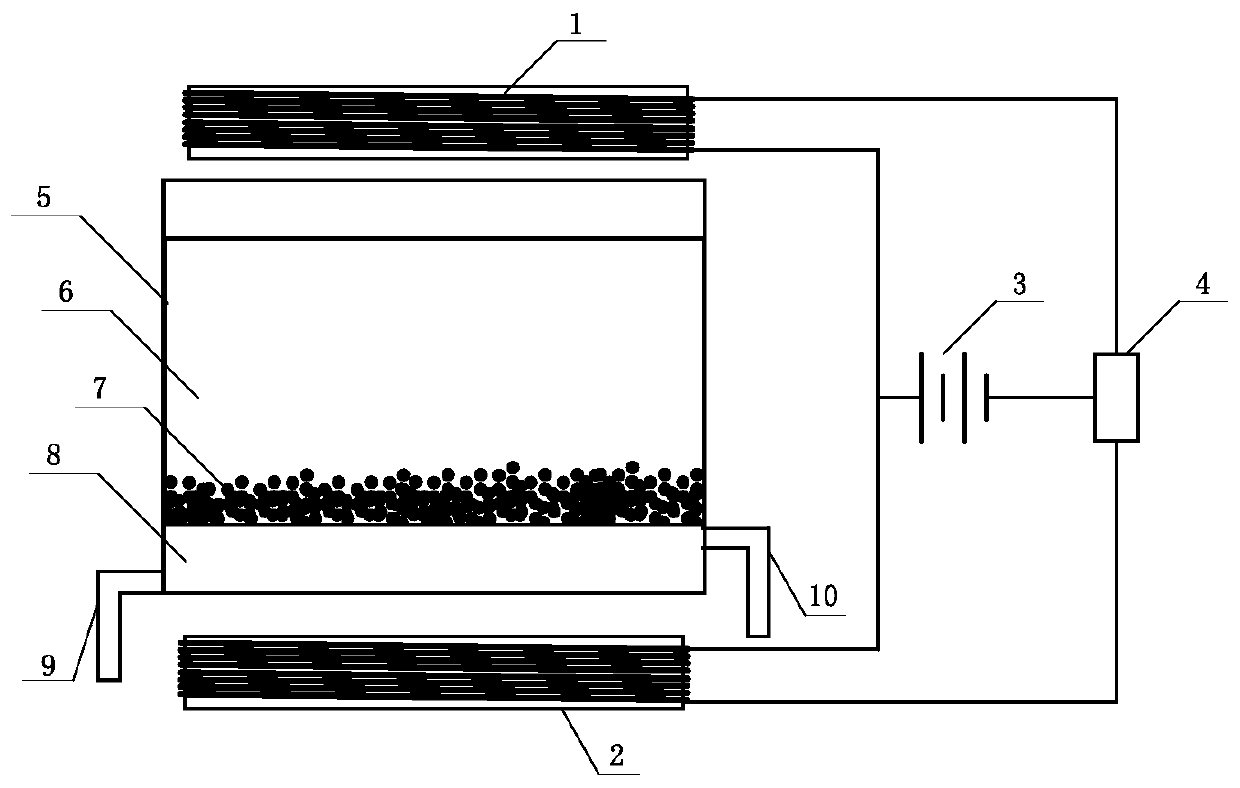

Alternating magnetic field based phase change heat accumulation enhancing device and operation method thereof

ActiveCN110671957AIncreased phase transition rateImprove effective thermal conductivityHeat storage plantsThermodynamicsLiquid state

The invention discloses an alternating magnetic field based phase change heat accumulation enhancing device and an operation method thereof. The alternating magnetic field based phase change heat accumulation enhancing device comprises a first electromagnet, a second electromagnet, a power supply, a cyclic delay relay, a heat accumulator shell, a phase change material, magnetic particles, a heat transfer fluid channel, a heat transfer fluid inlet and a heat transfer fluid outlet. Through the alternating magnetic field based phase change heat accumulation enhancing device, when the phase changematerial accumulates heat or releases heat, the first electromagnet and the second electromagnet operate alternately under the action of the power supply and the cyclic delay relay to pull the magnetic particles to move up and down on a solid-liquid interface and a liquid-stage interval to transfer heat, and meanwhile, the magnetic particles drive the liquid-stage phase change material to conductforced convection. The alternating magnetic field based phase change heat accumulation enhancing device enhances the phase change process of the phase change material from the two aspects of heat conduction and flowing and can remarkably increase the phase change rate of the phase change material.

Owner:ZHEJIANG UNIV

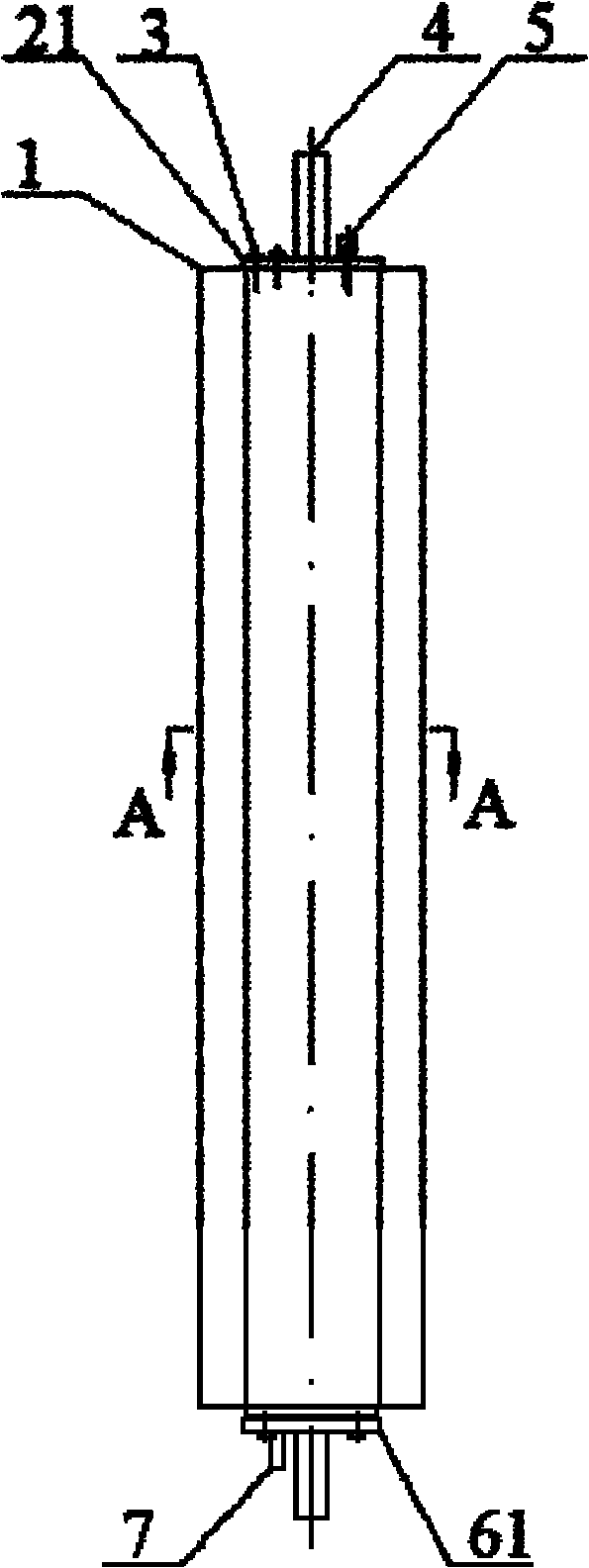

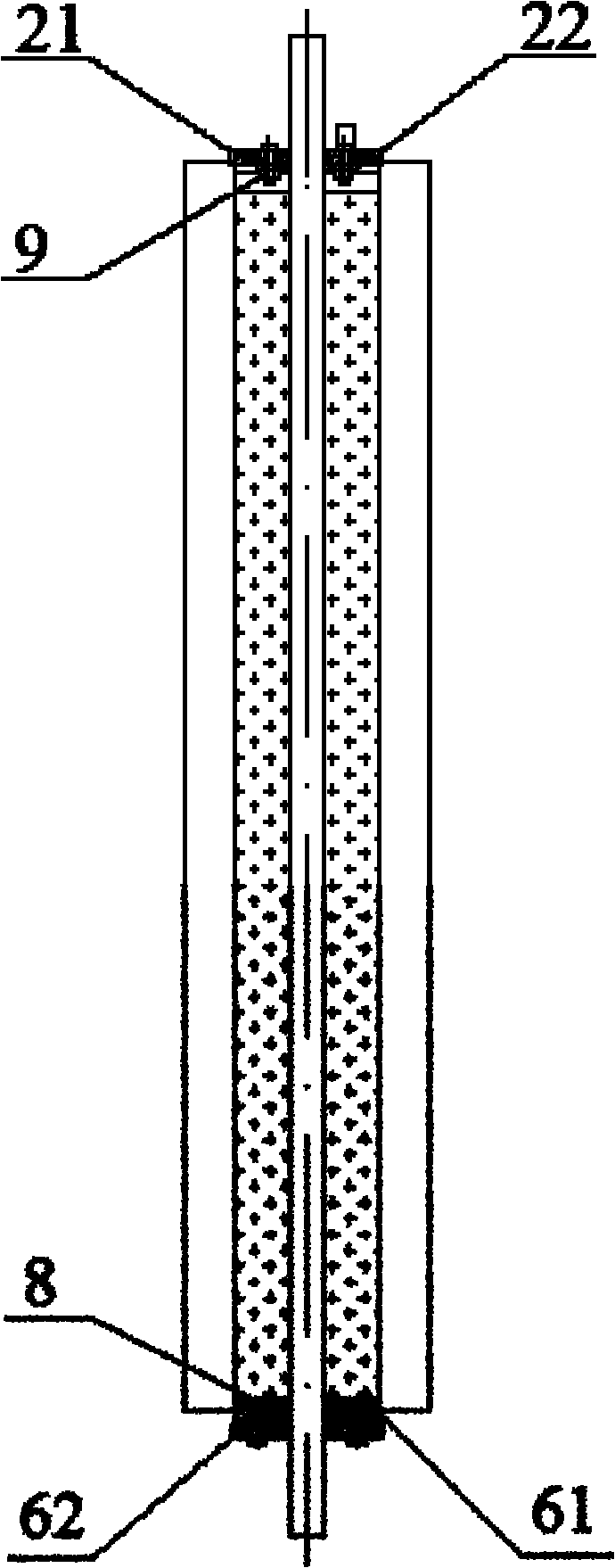

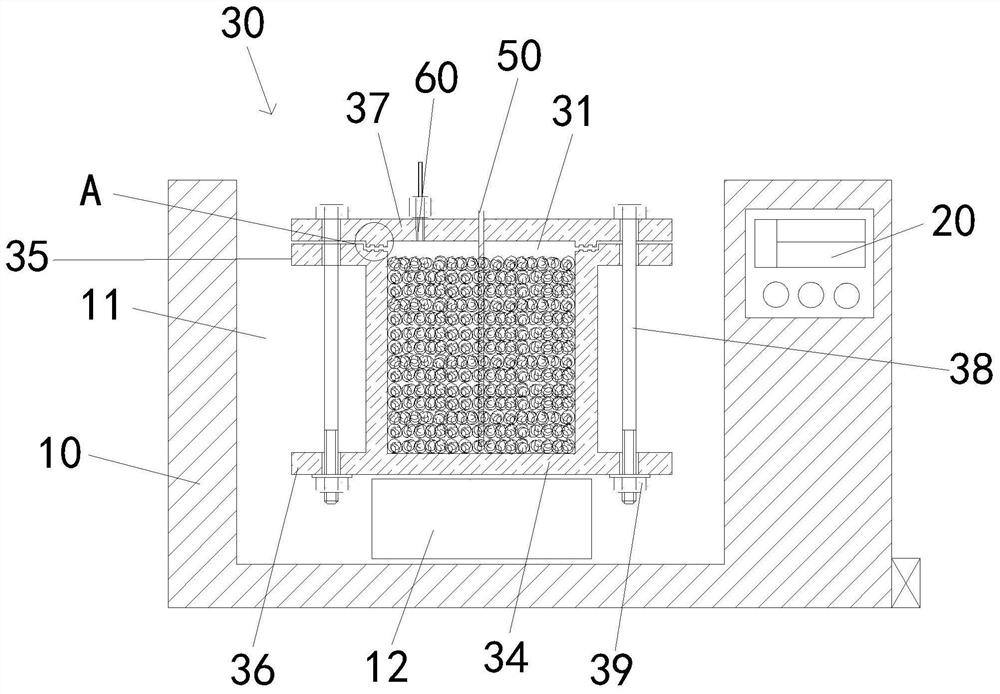

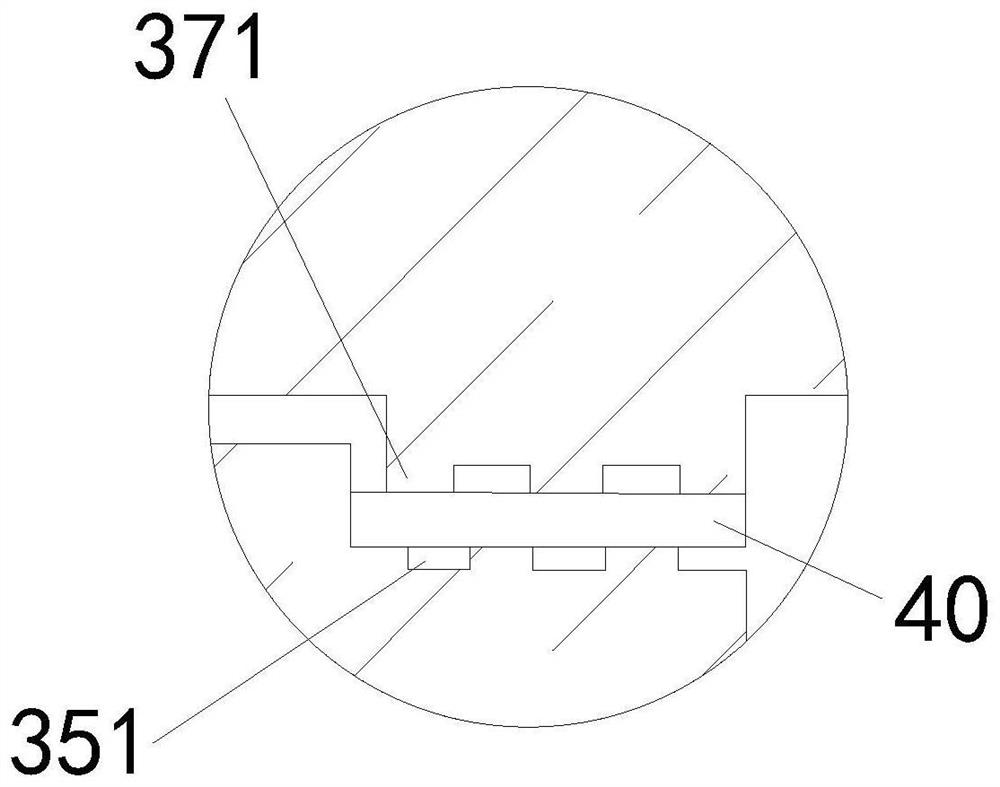

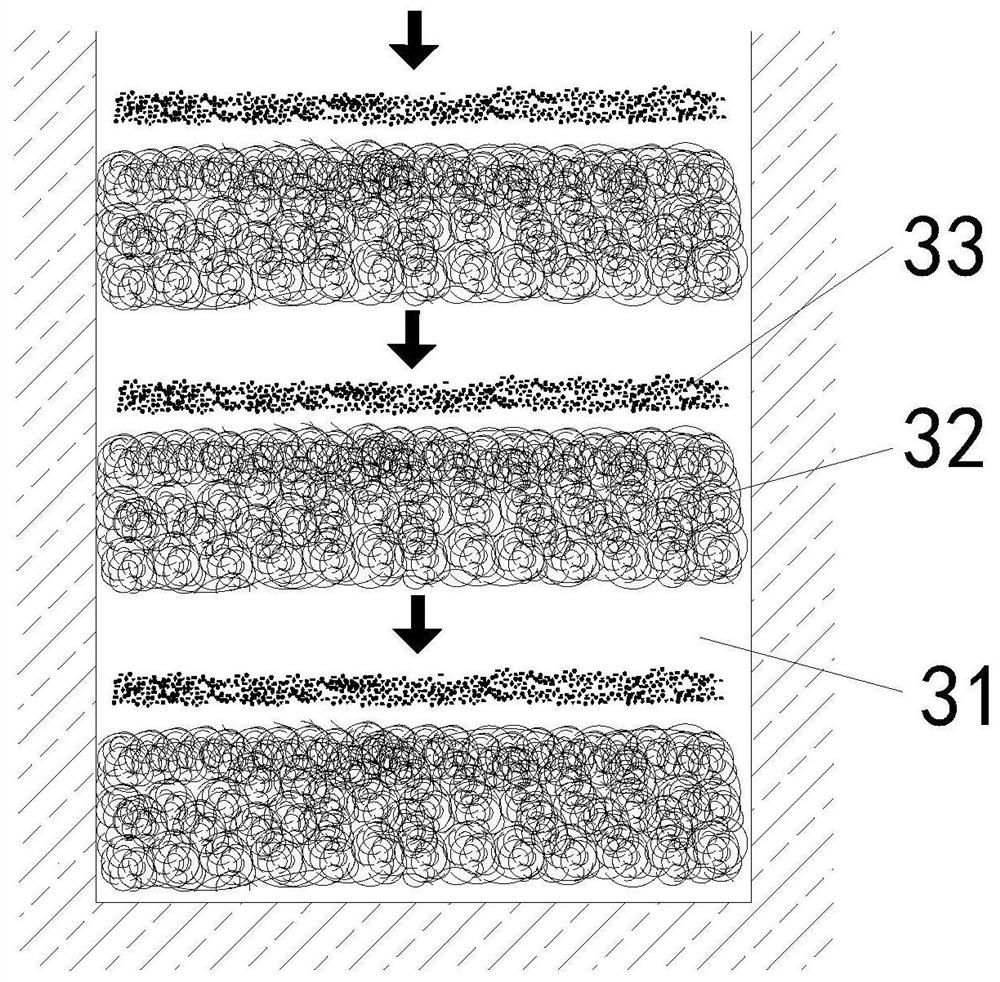

Metal hydride hydrogen absorption and desorption reactor capable of effectively improving heat conduction capability of reaction bed

ActiveCN113351130ALow costImprove thermal conductivityChemical/physical/physico-chemical stationary reactorsMetallic hydrogenChemistry

The invention discloses a metal hydride hydrogen absorption and desorption reactor capable of effectively improving the heat conduction capability of a reaction bed. The metal hydride hydrogen absorption and desorption reactor comprises a bath pot, a controller and a reactor, a heating cavity is formed in the bath pan; the controller is arranged on the bath pot and used for adjusting and controlling the heating temperature of the heating cavity; the reactor is arranged in the bath pot, a storage cavity is formed in the reactor, a plurality of steel wire ball layers and a plurality of metal hydride layers are arranged in the storage cavity, the steel wire ball layers and the metal hydride layers are alternately stacked, and gaps of the steel wire ball layers are filled with metal hydride; therefore, by introducing the steel wire balls into the reaction bed and filling the pores of the steel wire balls with the metal hydride, the effective heat conductivity coefficient of the reaction bed can be effectively improved, and better temperature difference driving is provided for the dynamics of hydrogen absorption and desorption reaction, so that the working speed and efficiency of hydrogen absorption and desorption of the metal hydride are effectively improved, and the problem that the cost and the heat conduction capability are difficult to consider in the prior art is practically solved.

Owner:SUN YAT SEN UNIV

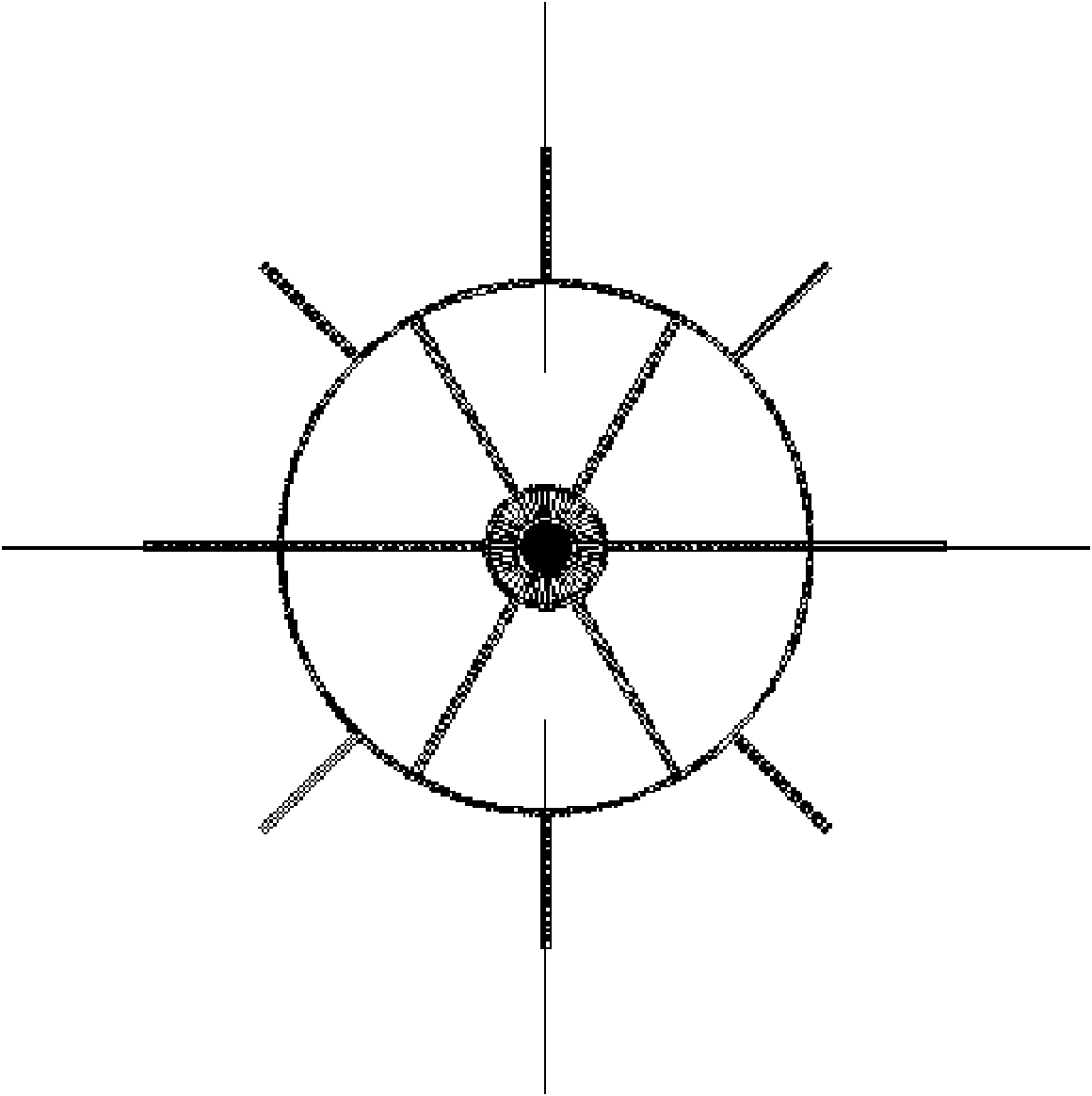

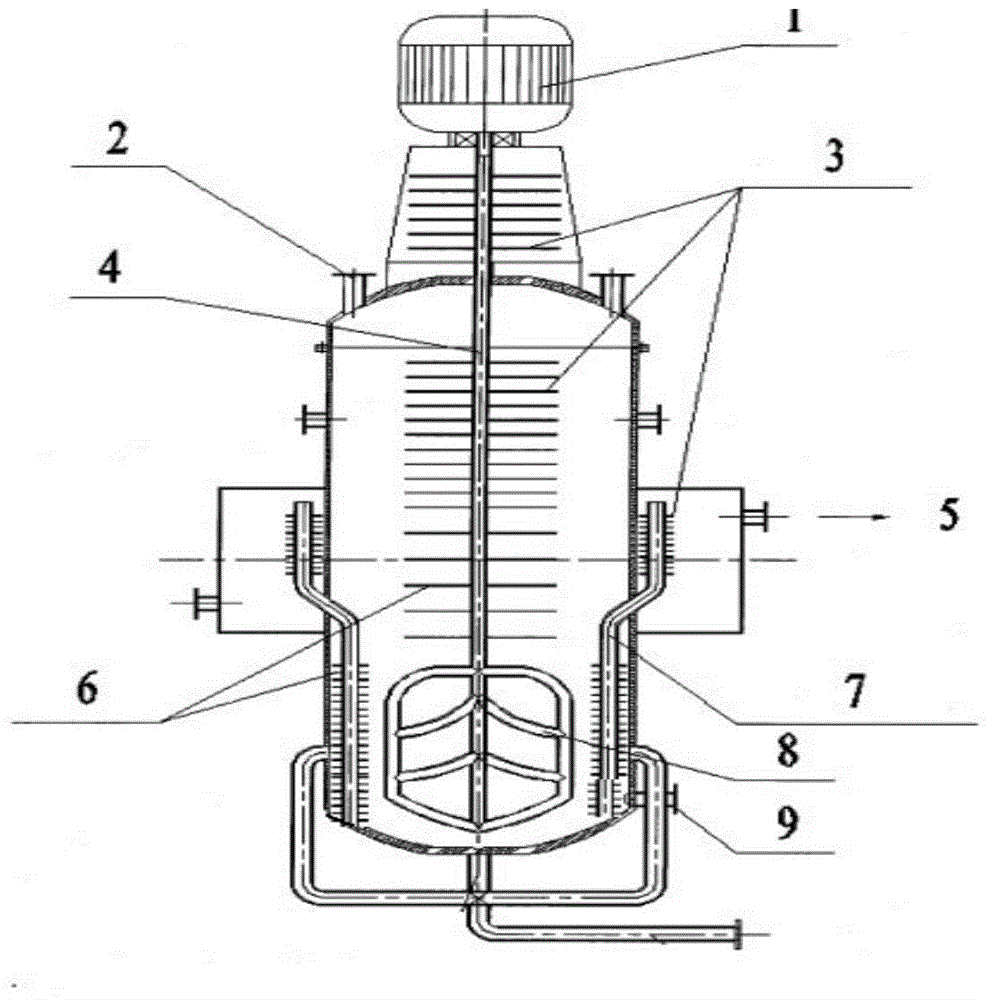

Strong oxidation reaction stirring reaction kettle

InactiveCN104437321AHigh heat fluxImprove thermal conductivityChemical/physical/physico-chemical stationary reactorsNuclear engineeringHeat pipe

The invention relates to a strong oxidation reaction stirring reaction kettle which comprises a liquid sucking core type heat pipe type stirring shaft, heat radiation fins and heat absorption fins, wherein liquid sucking cores of liquid sucking core type heat pipes which extend into the reaction kettle from cooling tanks in a bent manner both comprise upper support rings, lower support rings and metal bars which are arranged inside heat pipe bodies; a plurality of metal bars are fixedly connected between the upper support rings and the lower support rings and are uniformly distributed in the circumferential directions of the upper support rings and the lower support rings; the metal bars are made of porous metal foams and the cross sections take the shape of inclined trapezoids; gaps between adjacent parallel metal bars and inclined trapezoid runners form channels of the liquid sucking cores together; the liquid sucking core type heat pipes which extend into the reaction kettle from the cooling tanks comprise vertical straight pipe sections and pulsation type bent pipe sections. The phenomenon of temperature runaway is effectively prevented.

Owner:成都索伊新材料有限公司

Porous copper-wood fiber/polystyrene double-layer composite capillary core for loop heat pipe and preparation method thereof

ActiveCN111189346BReduced back heat conductionImprove thermal conductivityIndirect heat exchangersFiberPolystyrene

The invention discloses a porous copper-wood fiber / polystyrene double-layer composite capillary core for a loop heat pipe and a preparation method thereof. NaCl or anhydrous sodium carbonate is ground and sieved to obtain a particle size of 50-75 μm. The pore-forming agent is dry and ready for use; polystyrene, wood fiber and pore-forming agent are mixed and pressed, and the porous wood fiber / polystyrene composite capillary core is obtained by sintering and washing; the electrolytic copper powder and the pore-forming agent are mixed and pressed The porous copper-wood fiber / polystyrene double-layer composite capillary core is obtained by sintering and washing; then the two are superimposed and compounded, wherein the porous copper core is close to the evaporation end of the loop heat pipe, and the porous composite material capillary core is close to the loop heat pipe compensation room. The invention applies the double-layer composite capillary core to the loop heat pipe, which can not only strengthen the internal heat and mass transfer, but also form a gradient thermal resistance in the radial direction, thereby reducing back-to-back heat leakage and effectively reducing the operation of the loop heat pipe. temperature, stabilizing the phase change interface, thereby improving the operating performance of the loop heat pipe.

Owner:CHINA UNIV OF MINING & TECH

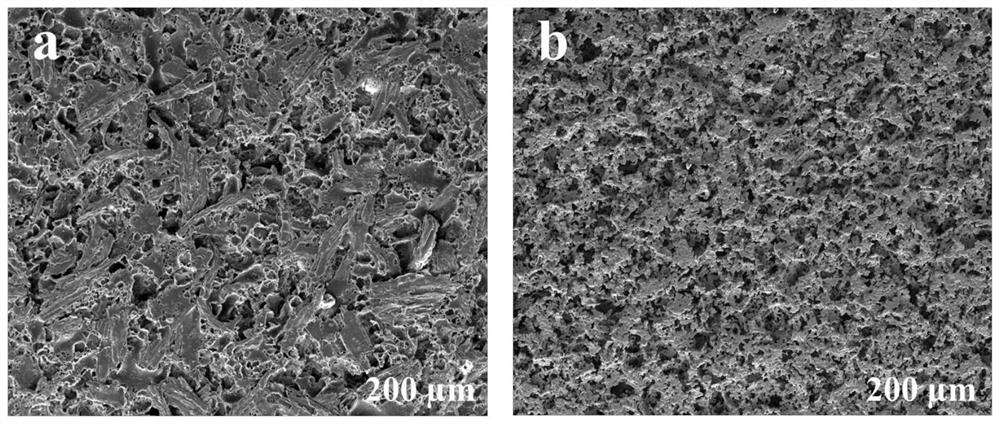

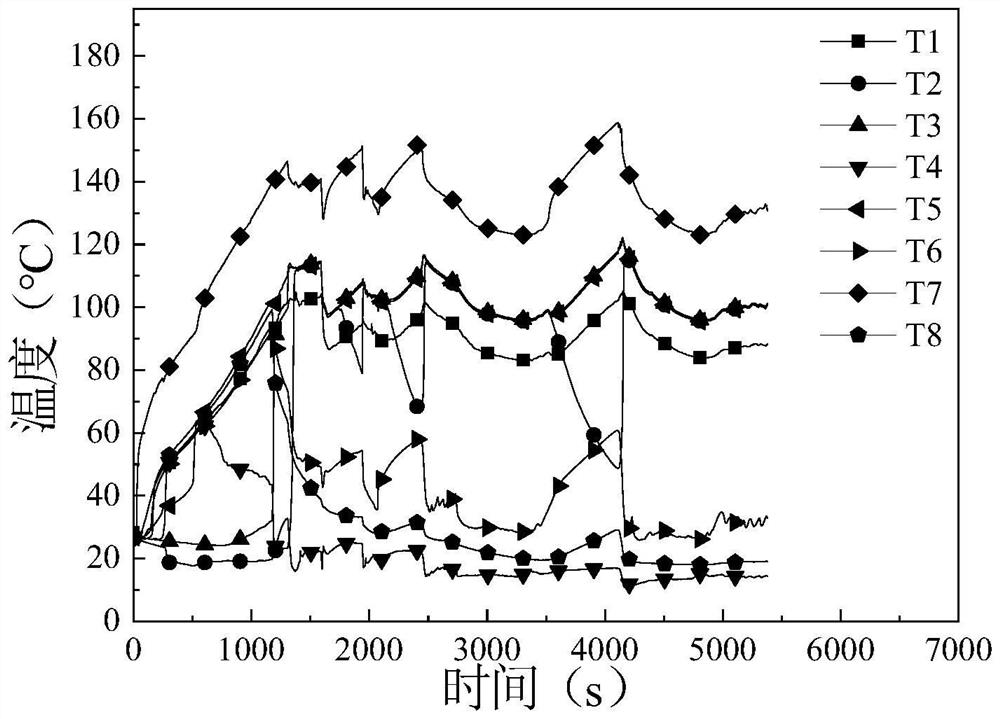

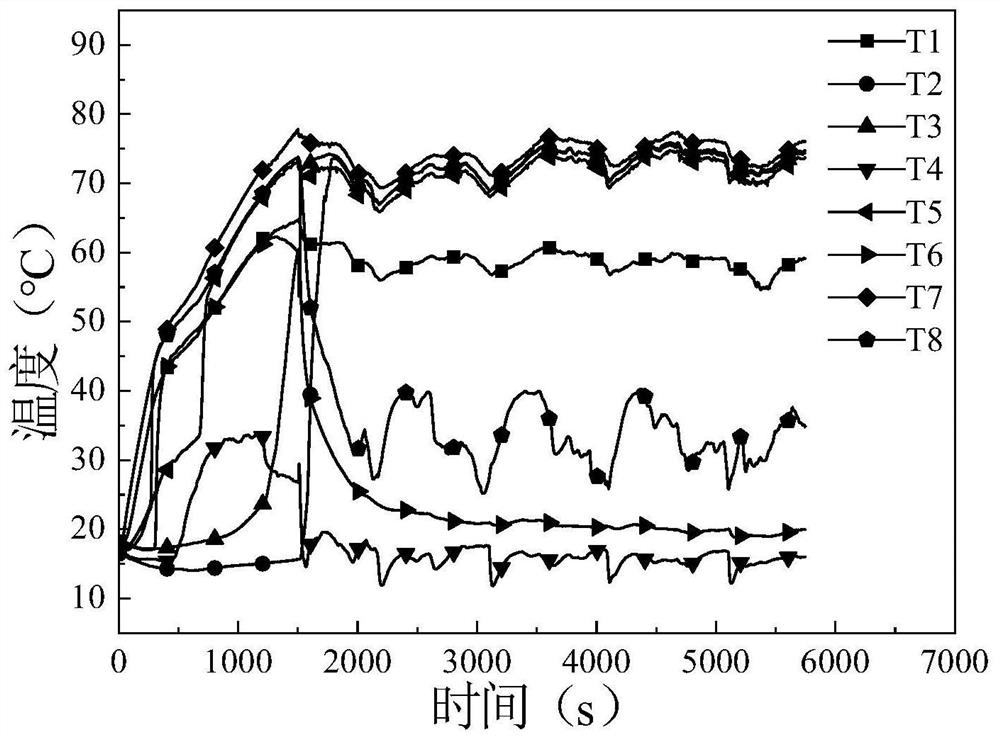

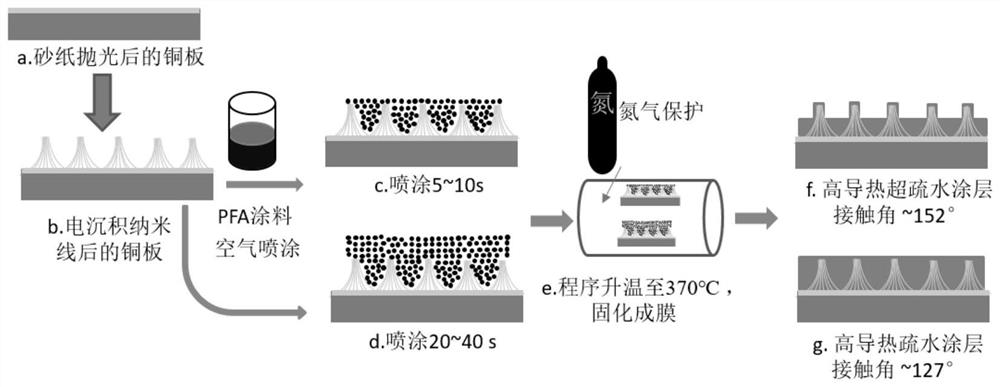

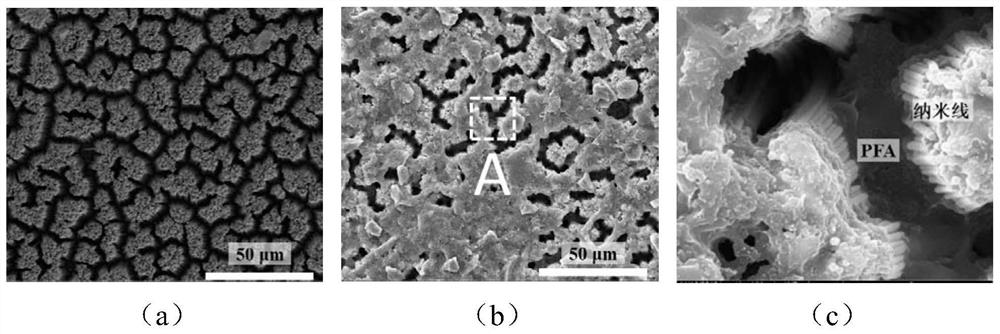

Nanowire-fluorocarbon composite coating and preparation method thereof

ActiveCN112657805AImprove effective thermal conductivityAvoid accumulationMaterial nanotechnologyPretreated surfacesNanowirePetrochemical

The invention provides a nanowire-fluorocarbon composite coating and a preparation method thereof. According to the method, a directionally-arranged high-thermal-conductivity nanowire network is introduced into a traditional fluorocarbon coating, so that the nanowire-fluorocarbon composite coating is prepared. The prepared composite coating can remarkably improve the effective heat conduction performance of a fluorocarbon coating by 150 times or above to the maximum extent, meanwhile, the bonding strength of the coating and a substrate can reach the zero level, the surface contact angle is increased to about 152 degrees, the problems that a traditional heat exchanger coating is poor in heat conduction, short in service life, prone to dust accumulation and the like can be effectively solved, and the composite coating can be used for power generation, petrochemical engineering, seawater desalination and other industrial processes.

Owner:DALIAN UNIV OF TECH

Metal hydrides plate-fin heat exchanger

InactiveCN101307994BIncrease the heat exchange areaImprove effective thermal conductivityStationary plate conduit assembliesFiltrationEngineering

Disclosed is a metal hydride plate-fin heat exchanger, which belongs to the industrial heat exchange and energy saving technique field. The invention comprises: an upper cover plate, a fluid path flattine fin, a spacer plate, reaction bed units, a fluid path tail sealing tape, a lower cover plate, a bolt component, a through hole flanged disc, a blind plate flanged disc, a fluid path head sealingtape, a hydrogen pipe, a fluorine rubber flange gasket, a rear enclosing cover, a front enclosing cover, a liquid inlet, a liquid outlet, a filter sheet gasket and a millipore filter sheet. Each reaction bed unit includes an upper cover plate, a unit tail sealing tape, a unit lateral sealing tape, a lower cover plate and a unit serrate fin. Each reaction bed unit has an open end and is welded with a serrate fin in the inside, thereby the heat exchange area and the effective thermal conductivity are greatly increased, and the intensity of a heat exchange unit can also be ensured under the condition of increasing the heat capacity of the heat exchange unit indistinctively. In addition, filtration and sealing difficulties of metal hydrides are greatly reduced by adopting the structure that all the reaction bed units are connected and fixed on the through hole flanged disc in parallel, meanwhile, the mass transfer capability of hydrogen will not be reduced.

Owner:SHANGHAI JIAO TONG UNIV

A forced convection micro-channel cooling structure, manufacturing method and electronic device

ActiveCN110335854BImprove effective thermal conductivityMeet cooling needsSemiconductor/solid-state device detailsSolid-state devicesThermal dilatationThermodynamics

The invention provides a forced convection micro-channel heat dissipation structure. The forced convection micro-channel heat dissipation structure comprises: at least two heat dissipation units whichare sequentially stacked; a plurality of heat dissipation channels, wherein the heat dissipation channels are arranged on each heat dissipation unit; at least one inlet and at least one outlet, wherein the at least one inlet and the at least one outlet are opened on the heat dissipation units being in contact with a chip; at least two circulation channels which are arranged on other heat dissipation units not in direct contact with the chip so as to communicate the heat dissipation channels on the adjacent heat dissipation units; at least two negative thermal expansion bodies, wherein one negative thermal expansion body is correspondingly filled in one circulation channel and is used for conducting or not conducting the heat dissipation channels of the adjacent heat dissipation units; anda cover plate covering the heat dissipation unit on the top layer, wherein at least one air inlet and at least one air outlet are formed in the cover plate, and the at least one air inlet and the atleast one air outlet communicate with the heat dissipation channel on the heat dissipation unit on the top layer. The invention also provides a manufacturing method of the heat dissipation structure and an electronic device applying the heat dissipation structure.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com