Anti-icing structure suitable for aero-engine supporting plate and wing

An aero-engine and anti-icing technology, which is applied in the direction of engine components, machines/engines, aircraft parts, etc., can solve the problems of reduced engine performance, uneven protection effect, and single means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with specific implementation methods and accompanying drawings.

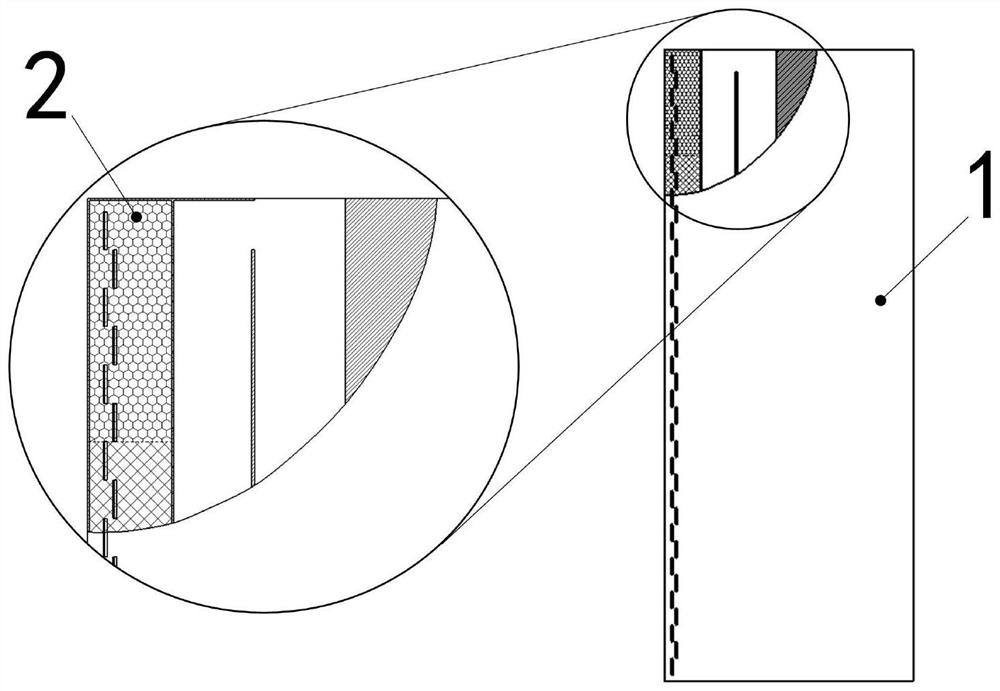

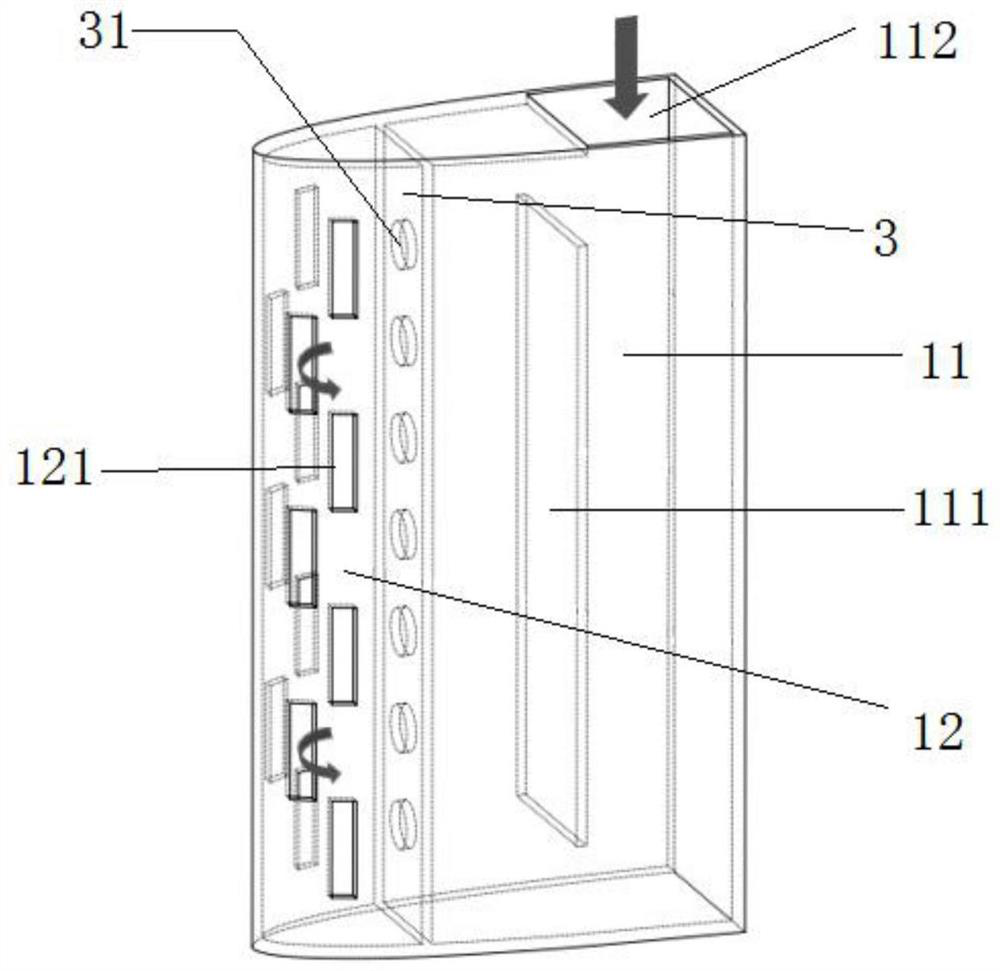

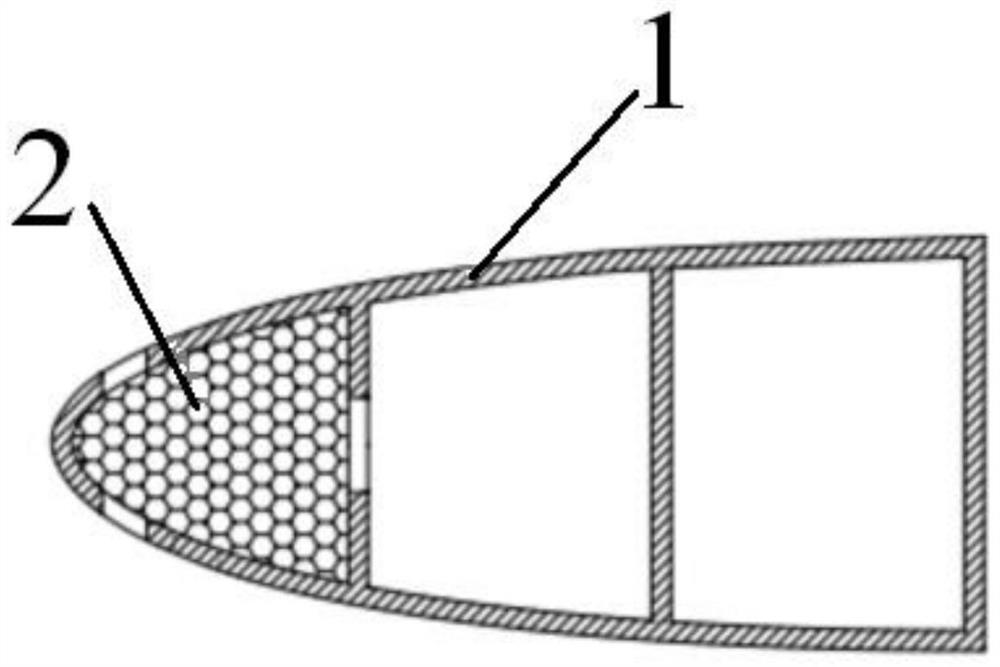

[0019] Such as figure 1 with figure 2 As shown, the present invention includes an anti-icing component 1 with a three-dimensional full-scale structure, and the material of the anti-icing component 1 is aluminum. A partition 3 is arranged inside the anti-icing component 1, and the partition 3 divides the internal space of the anti-icing component 1 into left and right parts. A plurality of jet holes 31 are set on the partition 3, and parameters such as impact distance, hole shape, hole size, hole spacing, and opening angle are adjusted for the jet holes 31 according to heat flow conditions and component sizes. In this embodiment, the jet holes 31 are circular and arranged in a single row with equal intervals. The air intake chamber 11 and the impingement chamber 12 communicate through the jet hole 31 , forming a convective-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com