Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Improve anti-toxic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

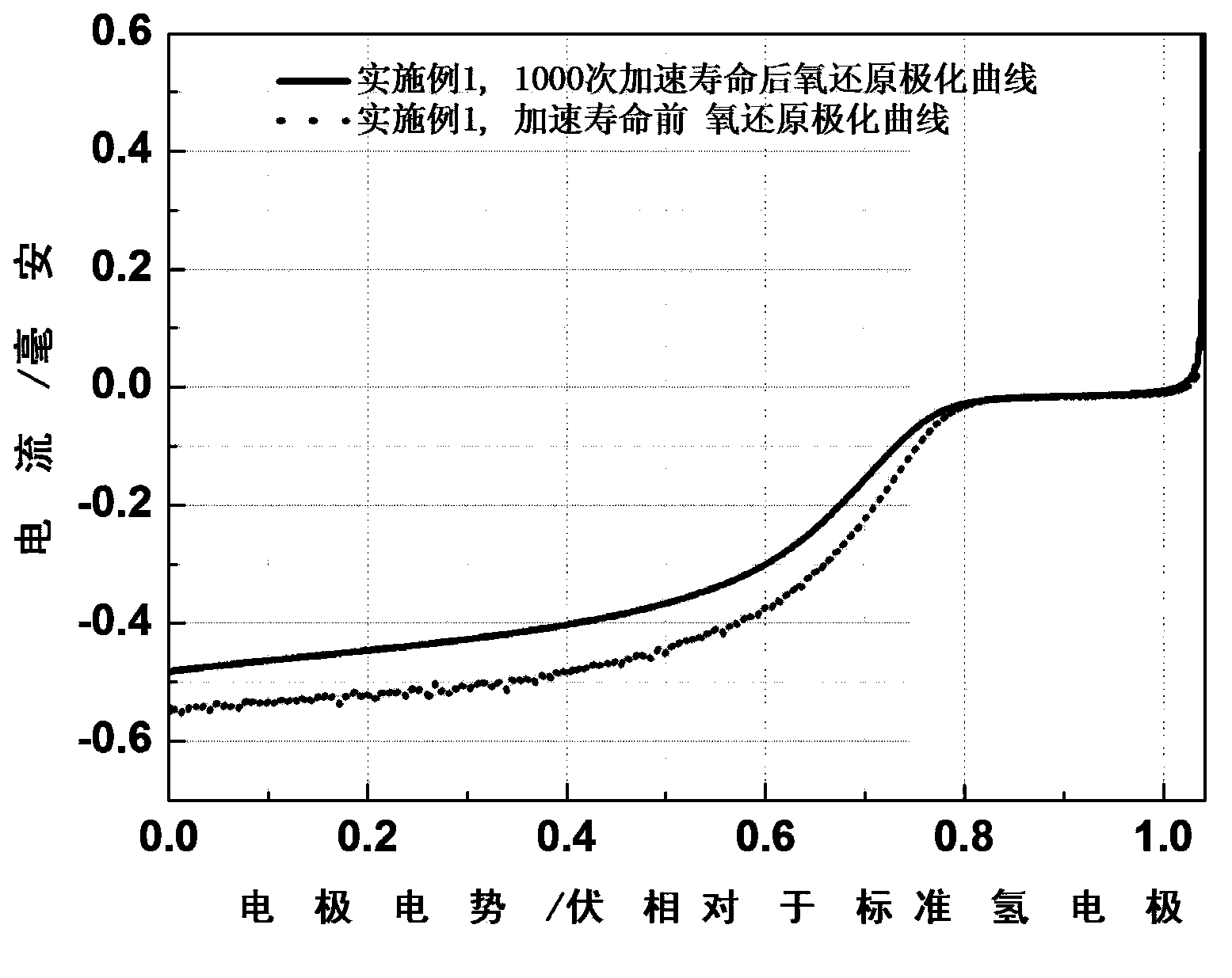

Nano carbon doped electrocatalyst for fuel cell, and application of nano carbon doped electrocatalyst

InactiveCN103050714AChange the microstructureChange Edge Face DefectsPhysical/chemical process catalystsCell electrodesMicrowave radiometryHigh heat

The invention relates to a nano carbon doped electrocatalyst for a fuel cell, and application of the nano carbon doped electrocatalyst. The electrocatalyst is prepared by adopting the steps of: complexing a nitrogen-containing and / or boron-containing organic precursor and a transition metal salt to form a composite; adding nano carbon as a carrier, and heating and reacting a mixture by adopting a microwave radiation method; and after the reaction is complete, filtering and drying, placing a product obtained after the reaction in an inert atmosphere and / or reducing atmosphere, and treating at a high temperature of 500-1500 DEG C to obtain the nano carbon doped electrocatalyst. The nano carbon doped electrocatalyst is very low in cost, high in activity and stability and excellent in anti-poisoning capacity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Nitrogen-doped nano carbon electrocatalyst for fuel cell, and preparation and application of nitrogen-doped nano carbon electrocatalyst

ActiveCN103041827AHigh catalytic activityImprove catalytic stabilityPhysical/chemical process catalystsCell electrodesCarbonizationOxygen

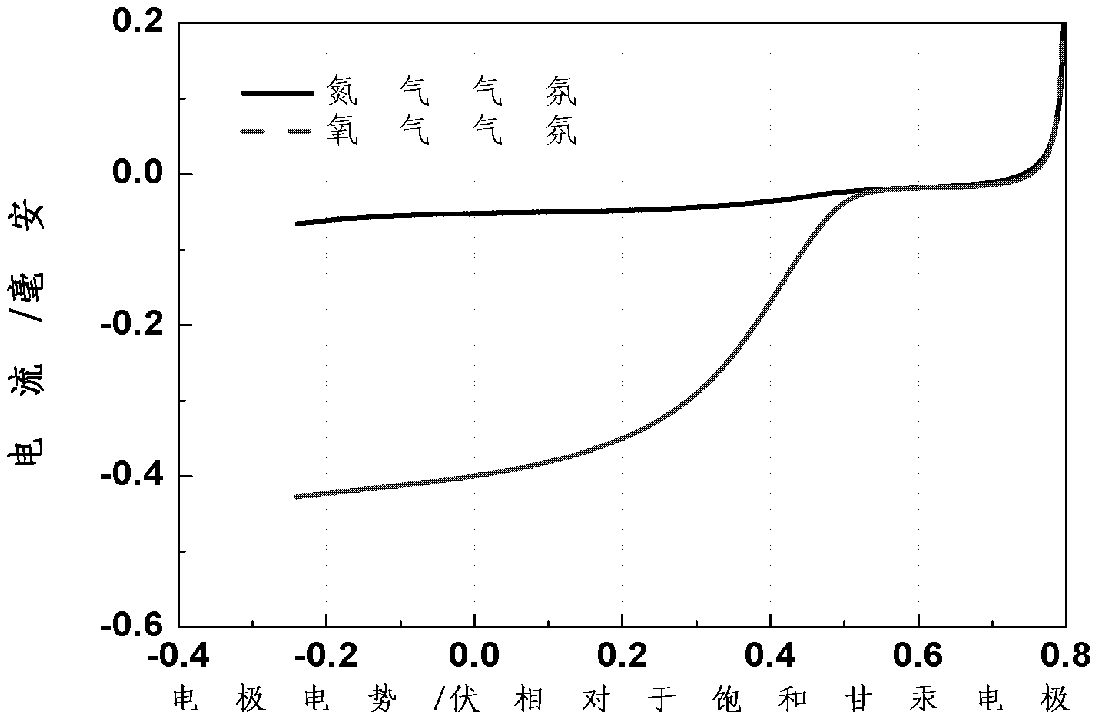

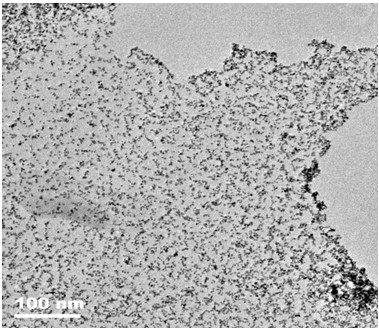

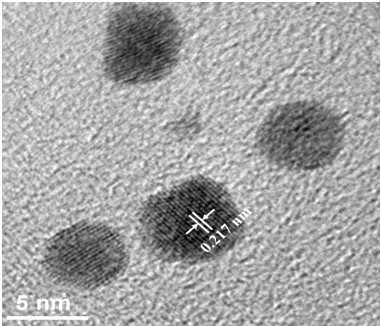

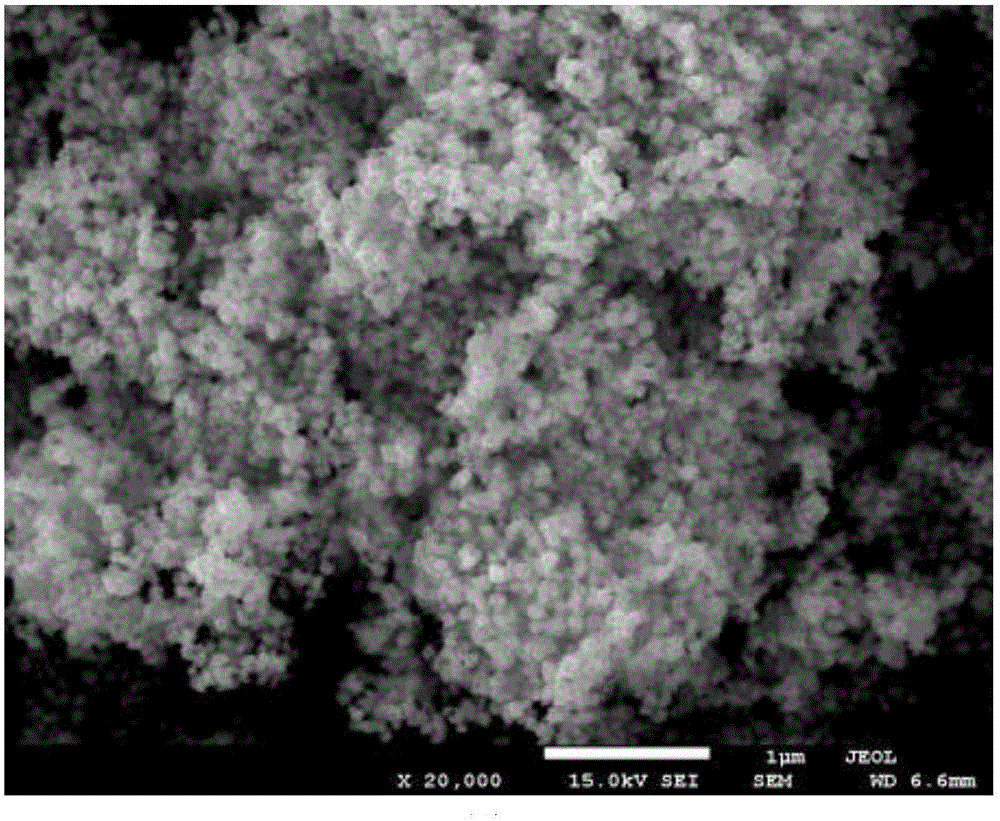

The invention relates to a nitrogen-doped nano carbon electrocatalyst for a fuel cell, and preparation and application of the nitrogen-doped nano carbon electrocatalyst. The electrocatalyst is prepared by adopting the steps of: with phenylamine as a reaction precursor, mixing the phenylamine, a surfactant and a soluble transition metal salt and then polymerizing under acidic and high-oxidization conditions, carrying out high-temperature carbonization on the polymer under the protection of an inert gas and / or ammonia atmosphere after drying, and finally carrying out acid treatment. The preparation method of the electrocatalyst is simply and easily controlled, and the mass production is easily realized. The nitrogen-doped nano carbon electrocatalyst has better oxygen reduction catalytic activity, stability and selectivity in an acidic medium fuel cell compared with Pt / C, and has higher catalytic activity and stability in an alkaline medium fuel cell compared with commercialized Pt / C. In addition, the nitrogen-doped nano carbon electrocatalyst also has the advantages of low cost and high anti-poisoning property, and is capable of replacing platinum to be used as a fuel cell oxygen reduction electrocatalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

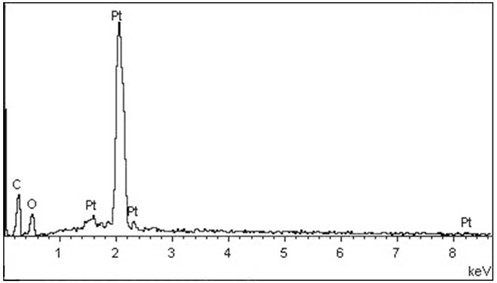

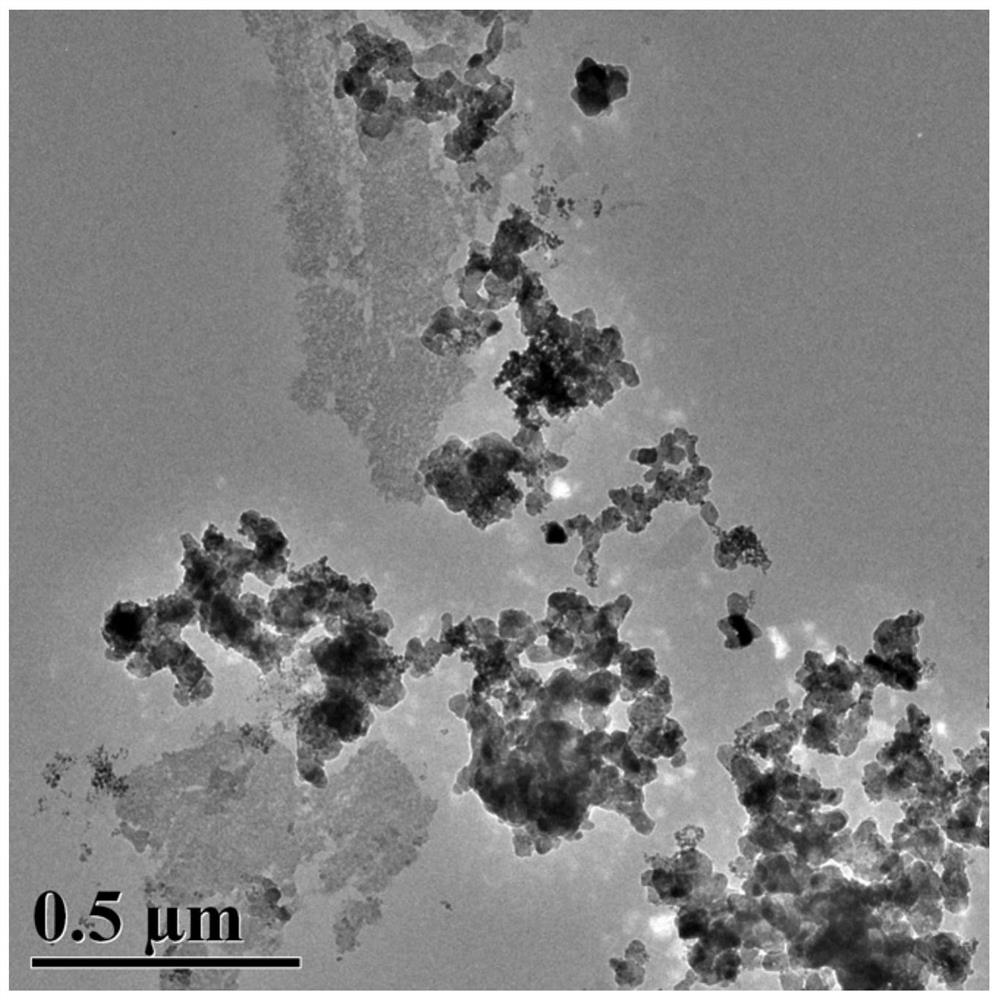

Method for preparing graphene-loaded platinum nano catalyst

InactiveCN101966453AUniform particle sizeSolve the technical problem of reunionCell electrodesMetal/metal-oxides/metal-hydroxide catalystsNano catalystPlatinum

The invention discloses a method for preparing a graphene-loaded platinum nano catalyst, which comprises the following steps of: (1) preparing graphene (GNS); (2) preparing polydiallyl dimethyl ammonium chloride (PDDA) functional graphene; and (3) preparing the graphene-loaded platinum nano (Pt / GNS) catalyst. The method has the advantages of uniformly adsorbing and distributing PtCl6<2-> with negative charge on the surface of the GNS through electrostatic adhesion by using positive charge uniformly distributed on the surface of the PDDA-modified GNS, solving the technical problem that metallic particles per se aggregate, realizing higher loading rate of PtNPs and having uniform grain size and controllable size.

Owner:NANCHANG UNIV

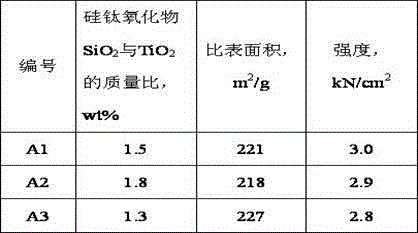

High-firmness honeycomb ceramic carrier and preparation method thereof

ActiveCN104549529ALarge specific surface areaImprove bindingCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsCordieriteSilicon oxide

The invention discloses a high-firmness honeycomb ceramic carrier and a preparation method thereof. Cordierite honeycomb ceramic is used as a base body; an aluminum oxide coating layer and a composite coating layer are arranged on the surface of the base body in sequence; by the total weight of the honeycomb ceramic carrier, the honeycomb ceramic carrier contains 85-95 percent of cordierite honeycomb ceramic, 2-7 percent of the aluminum oxide coating layer and 3-8 percent of the composite coating layer; by the total weight of the composite coating layer, the composite coating layer contains 40-80 percent of titanium dioxide, 5-35 percent of silicon dioxide, 1-10 percent of aluminum oxide and 10-40 percent of an auxiliary. The preparation method comprises the following steps: (1) immersing the cordierite honeycomb ceramic base body subjected to acid treatment into alumina sol for treatment, taking out the cordierite honeycomb ceramic base body, blowing away residual liquid, and drying and roasting to obtain the cordierite honeycomb ceramic base body loaded with the aluminum oxide coating layer; (2) soaking the carrier obtained by the step (1) in composite coating layer slurry for treatment, taking out the carrier, blowing away the residual liquid, and drying and roasting to obtain a final product. The coating layer load of the honeycomb ceramic carrier is large, the firmness is high, and the preparation technology is simple; the mechanical strength of the base body is not damaged; the high-firmness honeycomb ceramic carrier is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

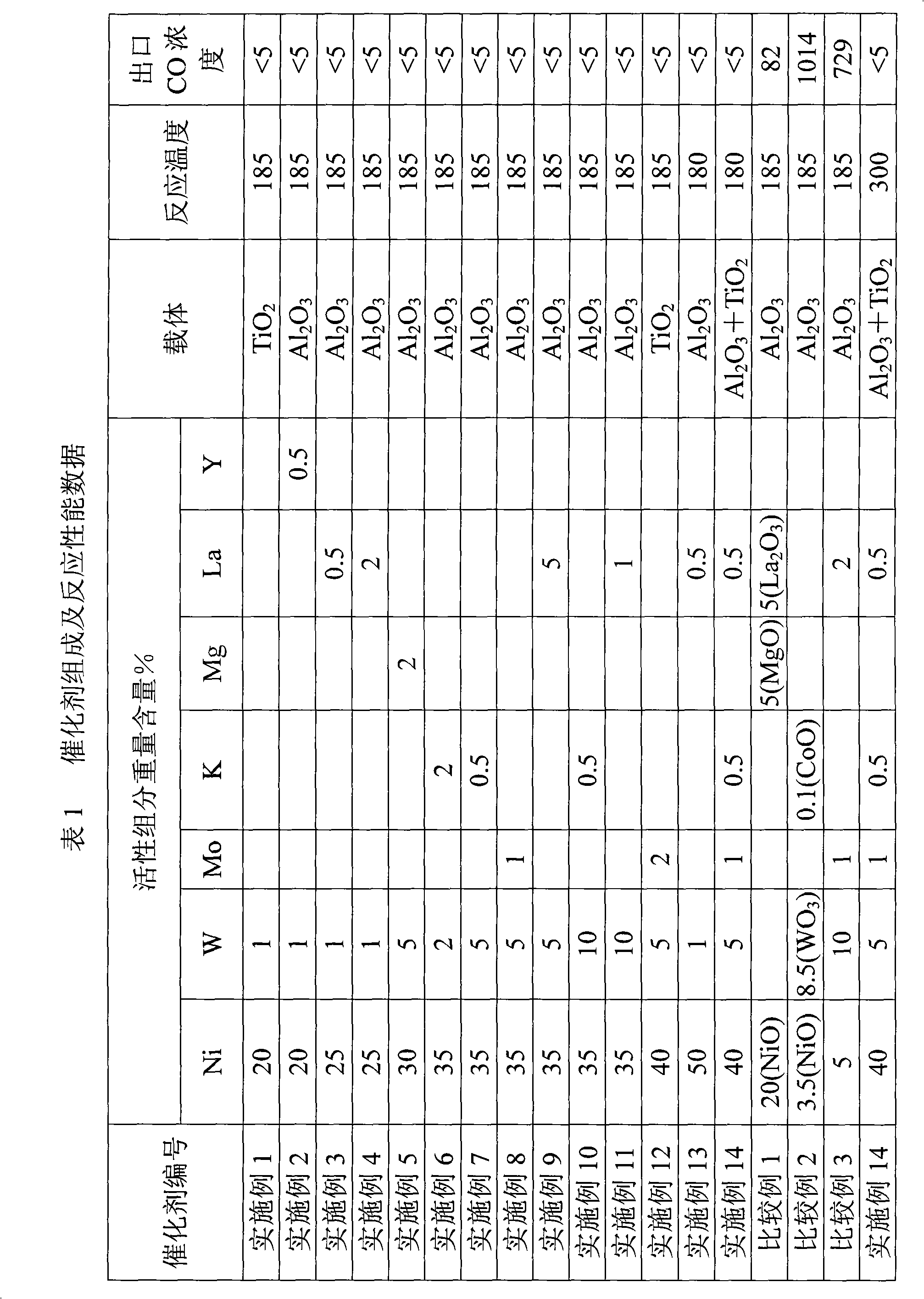

Methanation catalyst for removing trace amounts of oxycarbide

ActiveCN101347735AImprove anti-toxic performanceImprove thermal stabilityHydrogen separation using solid contactMetal/metal-oxides/metal-hydroxide catalystsMethanationAlkali metal oxide

The invention discloses a methanation catalyst of carbon oxides containing nickel, the methanation catalyst contains active components of a) nickel oxide, b) tungsten oxide and / or molybdenum oxide, and c) at least one active component which is selected from alkali metal oxides, alkaline earth metal oxides and rare earth metal oxides which are loaded on a carrier of the oxides, and the carrier of the oxides is aluminium oxide, silicon oxide, titanium oxide, zirconium oxide or the mixture thereof. The catalyst of the invention has very high activity at low temperature, high anti-poisoning capacity and thermal stability and broad application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

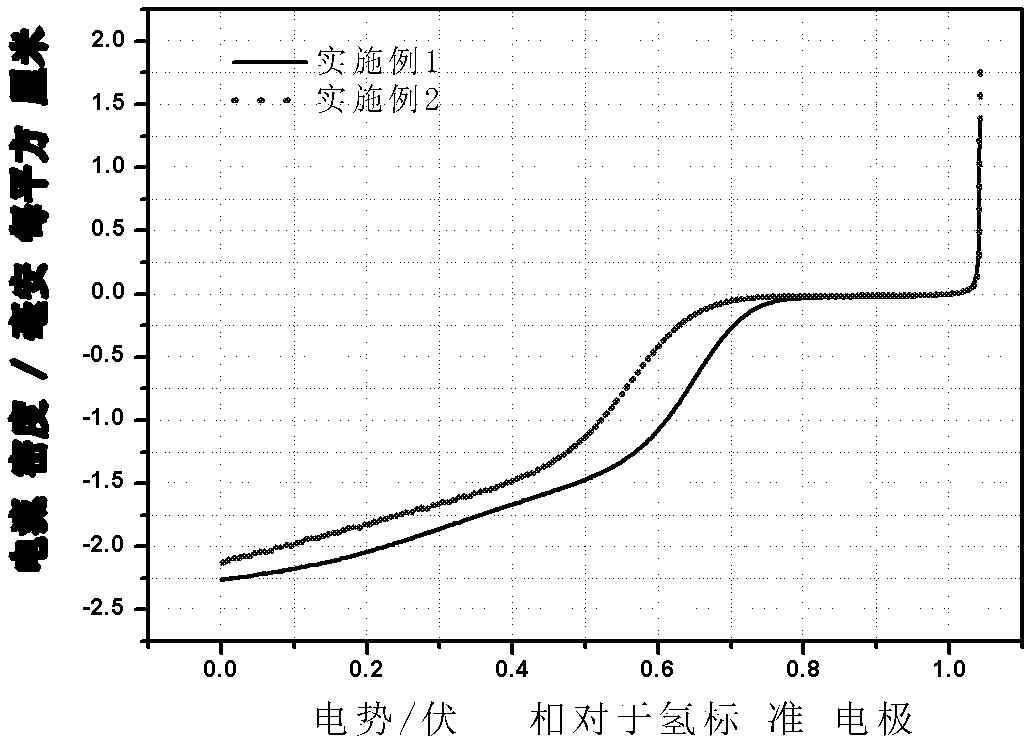

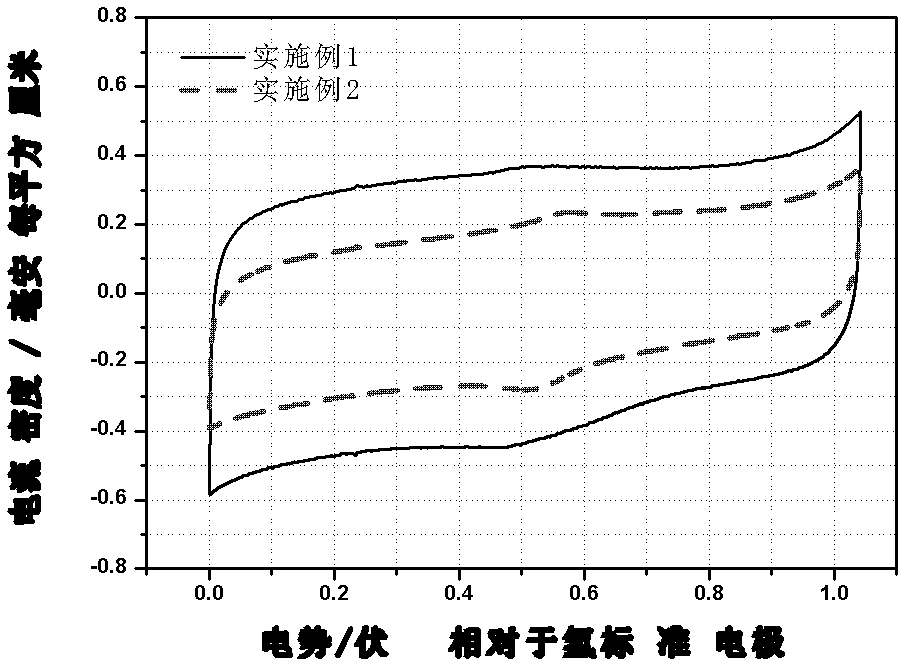

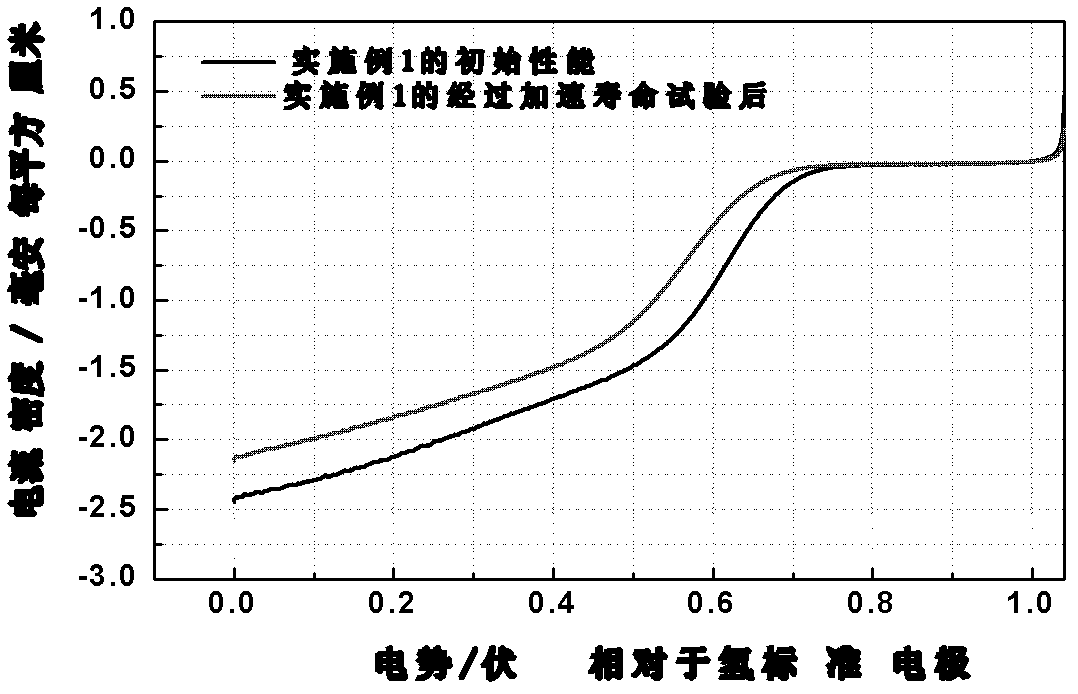

Electrocatalyst of negative electrode of fuel cell as well as preparation method and application thereof

ActiveCN103682380AGood catalytic activity and stabilityLow costPhysical/chemical process catalystsCell electrodesPyrolysisConductive polymer

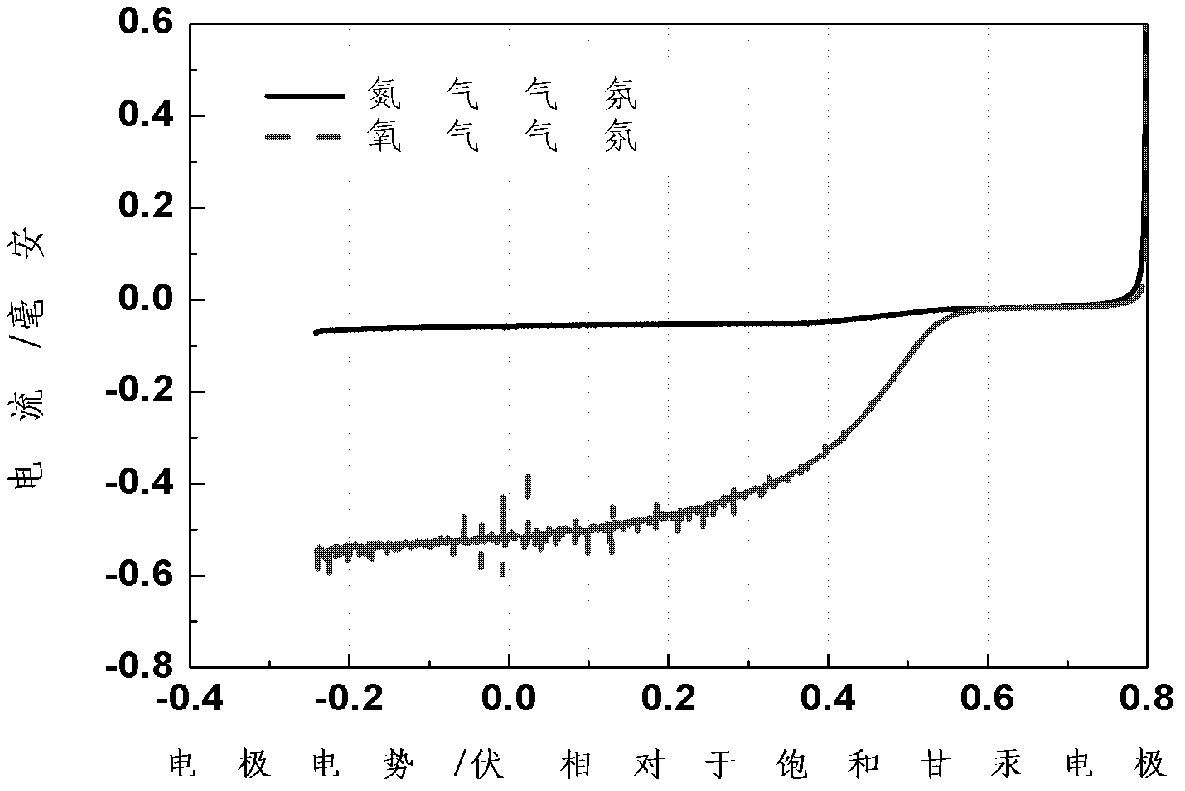

The invention relates to an electrocatalyst of a negative electrode of a fuel cell as well as a preparation method and application of the electrocatalyst. The catalyst adopts a conductive polymer as a reaction precursor, the conductive polymer is polymerized under the acid and oxidation condition to obtain polyaniline, the polyaniline is additionally provided with transition metal salt, and a phosphorus compound and / or a boron compound as a precursor, and the mixture is dried and is subjected to pyrolysis at the high temperature to obtain the electrocatalyst. The catalyst is N, phosphorus and / or boron co-doped nanometer carbon with a porous nanometer structure; the total mass percent of the doped heteroatom is 0.2 to 15 percent, the mass ratio of N to phosphorus and / or boron is 5:1 to 100:1, the weight percentage of metal is 0.1 to 10 percent, and the mass percent of the nanometer carbon is 75.0 to 99.7 percent.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of direct methanol fuel cell anode catalyst

InactiveCN102380371AHigh load rateUniform particle sizeCell electrodesMetal/metal-oxides/metal-hydroxide catalystsFunctionalized graphenePoly ethylene

The invention discloses a preparation method of a direct methanol fuel cell anode catalyst, and belongs to the technical field of electrocatalysis and energy. The method comprises the following steps: firstly preparing polyethyleneimine (PEI) functionalized graphene, then mixing H2PtCl6, CuCl2 and PEI functionalized graphene according to a certain mass ratio, dispersing in secondary water by ultrasonic, performing in-situ reduction of H2PtCl6 and CuCl2 by sodium borohydride under a room temperature condition so as to prepare a PtCu two-component nanoparticle / graphene catalyst (PtCu / graphene). The PtCu two-component nanoparticles (PtCuNPs) prepared by the method of the invention are uniformly dispersed on PEI functionalized graphene, and the particle size of the PtCu alloy nanoparticles is about 4-6 nm. Electrochemical experiment results show that the PtCu / graphene catalyst has excellent electrocatalytic activity for methanol oxidation; and the method is simple in operation, is mild and controllable in experiment conditions, and has extensive application prospects.

Owner:NANCHANG UNIV

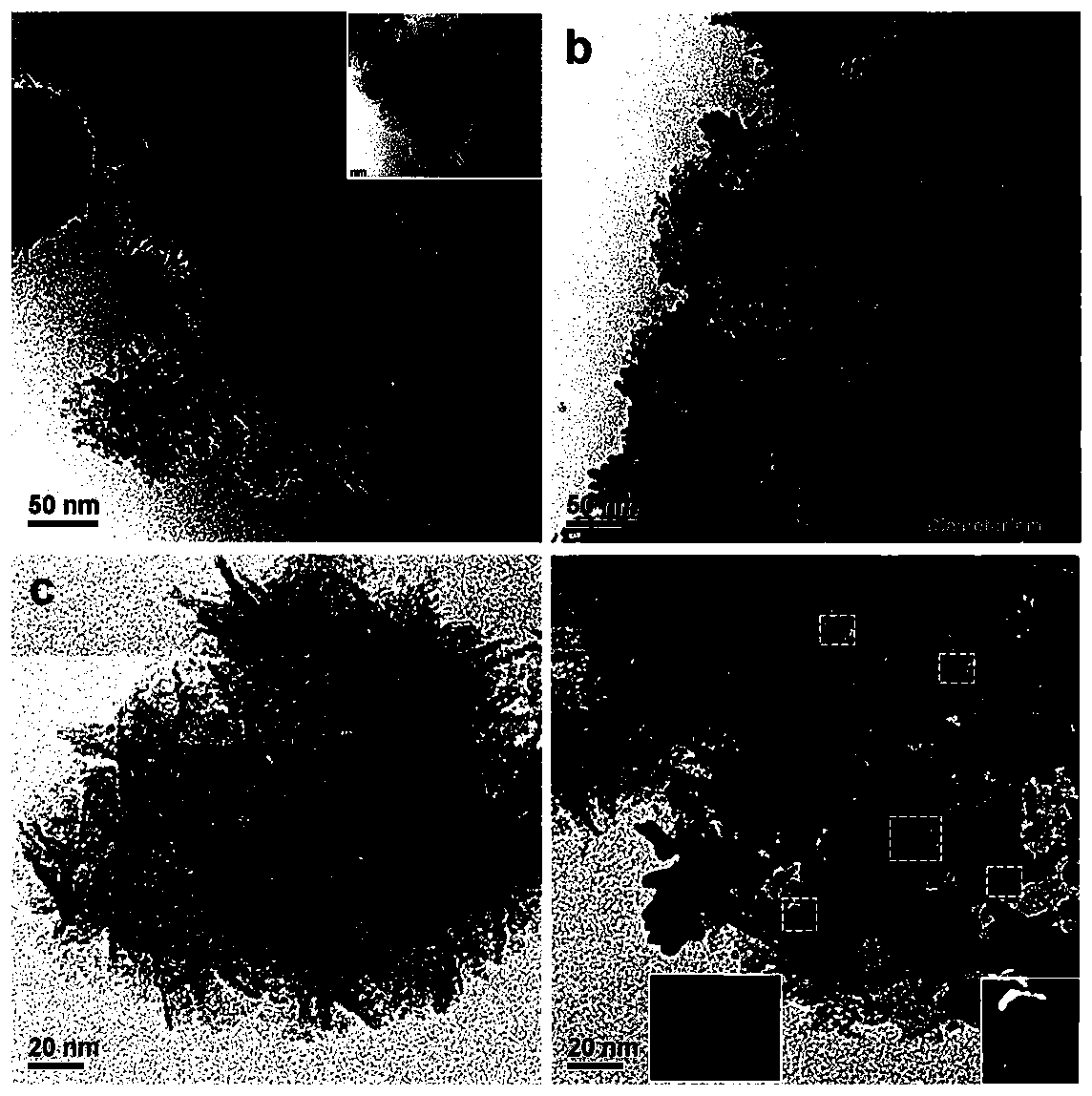

Preparation method of supported binary alloy direct alcohol fuel cell catalyst with porous hollow sphere structure

ActiveCN101937999ARich surface poresLarge specific surface areaCell electrodesMetal/metal-oxides/metal-hydroxide catalystsNano catalystBinary alloy

The invention discloses a preparation method of supported binary alloy direct alcohol fuel cell catalyst with a porous hollow sphere structure, relating to a preparation method of alcohol fuel cell catalyst. The invention solves the problems of Pt particle poisoning of nano catalyst, restricted transmission of alcohol fuel and high preparation cost of the catalyst which exist in the degradation mechanism of the existing direct alcohol fuel cell catalyst. The method is as follows: taking surface active agent as a template, and forming the supported binary alloy catalyst with the porous hollow sphere structure at different adsorbed layers in the form of electrostatic self-assembly according to the difference of charges of the surface active agent and metal precursor salt. The catalyst prepared by method of the invention is conducive to alcohol fuel transfer, and has the advantages of low cost, strong anti-drug performance of products, high activity and high stability. The products of the invention are mainly used catalyst for methanol fuel cells.

Owner:海卓健新能源材料(上海)有限公司

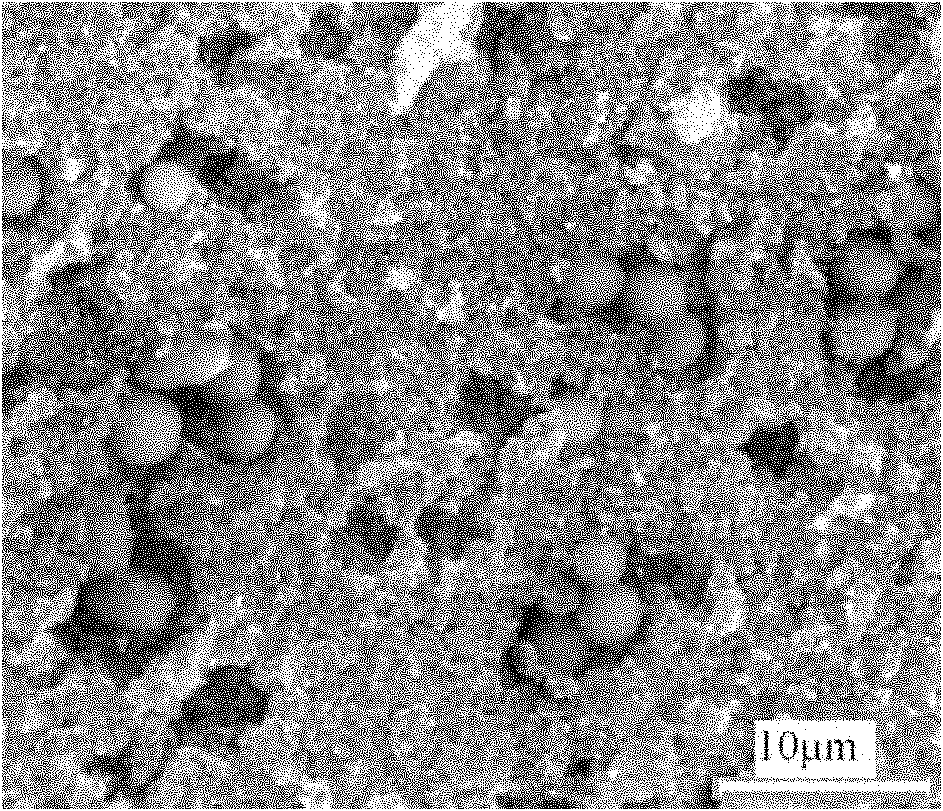

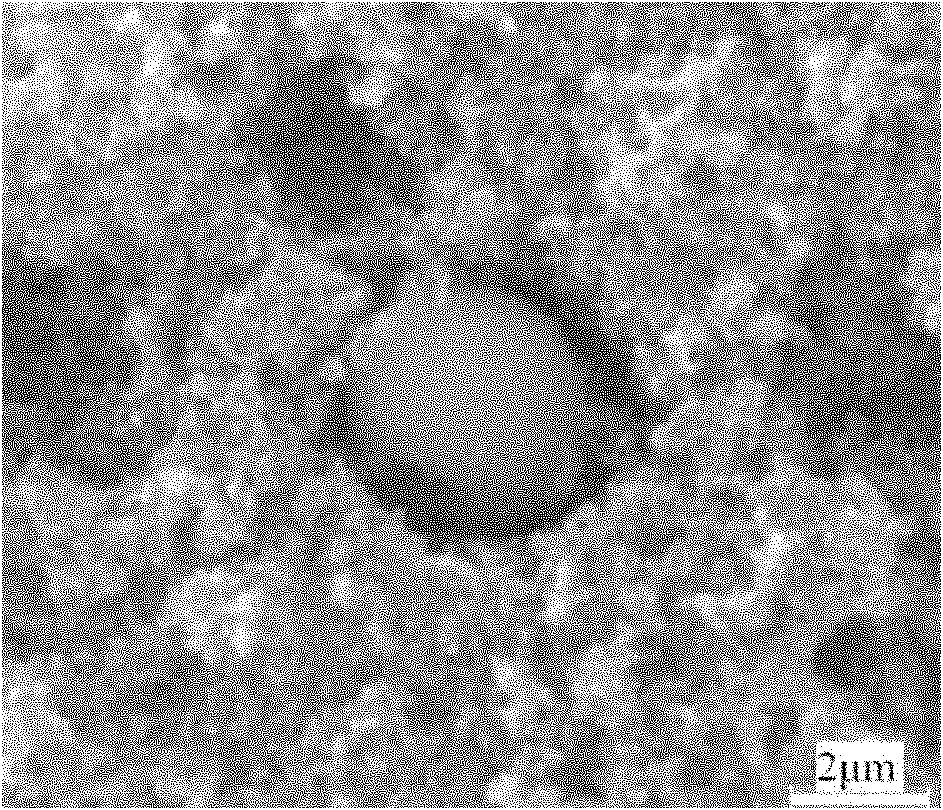

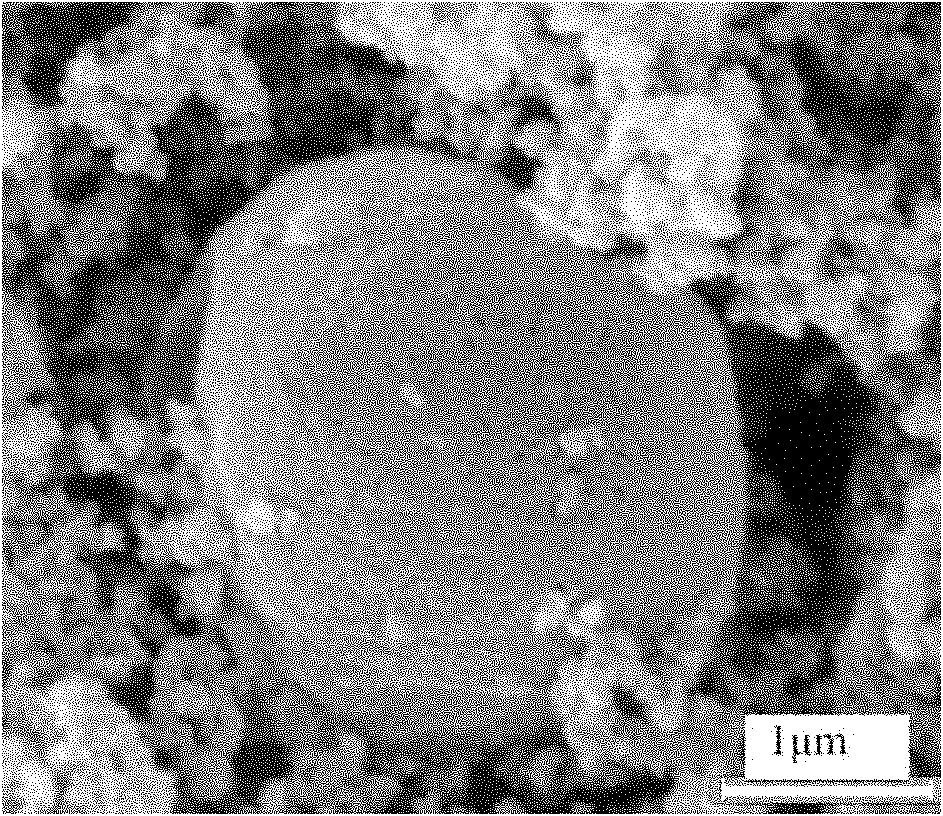

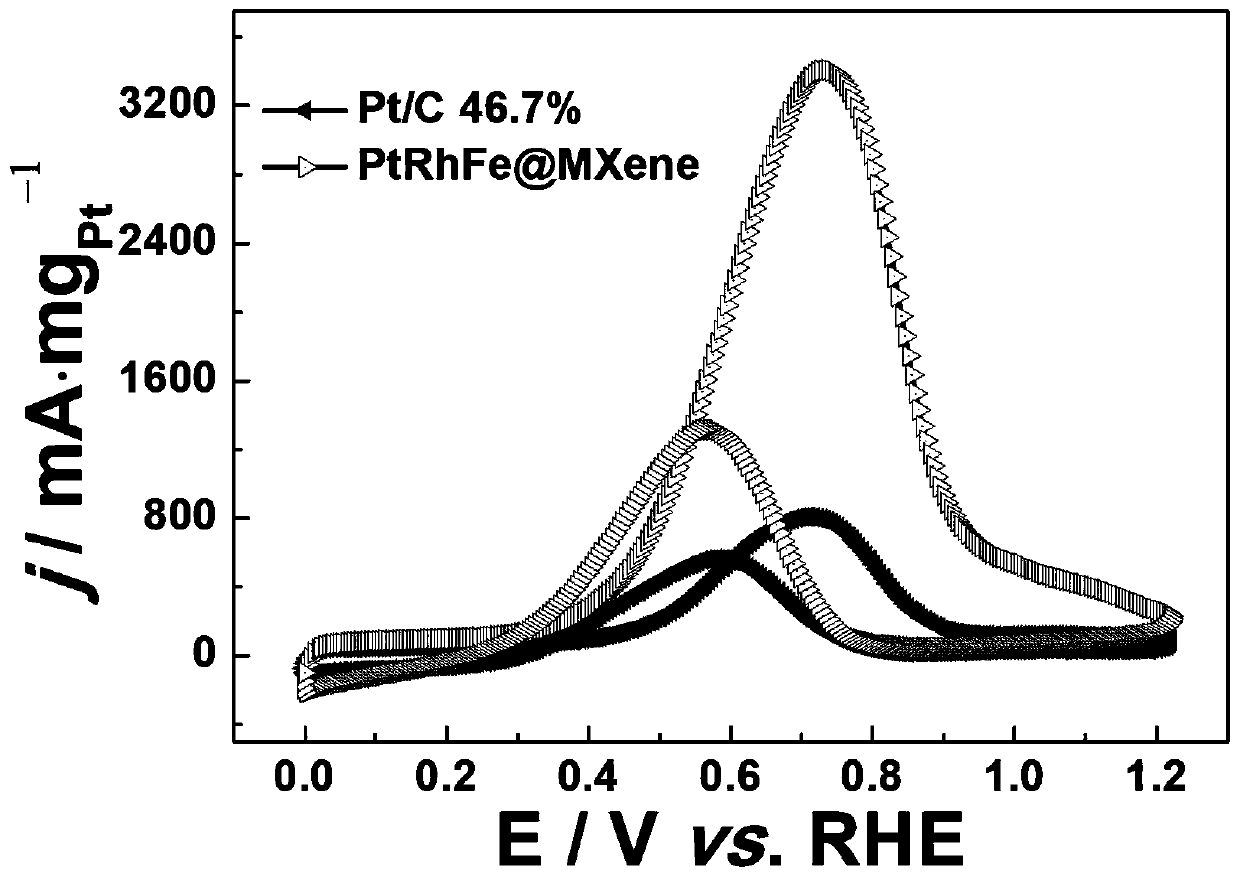

MXene loaded PtRhFe ternary alloy catalyst, and preparation method and formula thereof

ActiveCN109950564ASimple processGood repeatabilityMaterial nanotechnologyCell electrodesPotassium hydroxidePotassium

The invention discloses a preparation method of a MXene loaded PtRhFe ternary alloy catalyst. The method comprises that an organic solvent, a platinum source, a rhodium source, an iron source, a substrate material MXene powder and a surfactant are mixed and stirred uniformly, and make hydrothermal reaction; and centrifugation, washing, drying and grinding are carried out to obtain dry powder, namely a 2D material of MXene nanosheet loaded porous spherical PtRhFe ternary alloy particle product. The technology is simple, the repeatability is high, the prepared has an excellent enthanol oxidizability in an electrolyte including 1.0 mole / L potassium hydrate and 1.0 mole / L ethanol, and the peak current density can reach 3407milliampere / milligram which is 4.2 times of the peak current density ofa commercial platinum carbon catalyst in the platinum capacity of 46.7%. The catalyst can be widely applied to field of electrocatalysis enthanol oxidation, and enables large-scale commercializationof direct enthanol fuel cells.

Owner:SUN YAT SEN UNIV

Supported palladium-ultrathin CoNi-LDH (Layered Double Hydroxide) nanosheet composite material as well as preparation method and application thereof

InactiveCN110743565AEasy to prepareLarge electrochemical active areaMaterial nanotechnologyCell electrodesAlcoholNanoparticle

The invention discloses a supported palladium-ultrathin CoNi-LDH (Layered Double Hydroxide) nanosheet composite material as well as a preparation method and application thereof. The preparation methodcomprises the following steps: firstly, preparing ultrathin CoNi-LDH nanosheets by using a one-step hydro-alcohol thermal-solvent method, and supporting noble metal Pd nanoparticles by the ultrathinCoNi-LDH nanosheets as a carrier so as to obtain the supported palladium-ultrathin CoNi-LDH nanosheet composite material. The composite material can be applied to an electrocatalytic ethanol oxidationreaction, and has the advantages of high mass activity, good stability, good anti-poisoning ability and the like. The advantages can be attributed to the following aspects: (1), the ultrathin carriercan provide a larger electrochemical activity area, good electrical conductivity, and good CO poisoning resisting ability; and (2), the Ni-based LDH carrier can remove carbonaceous intermediates nearPdNPs sites, the Co element which is highly dispersed in laminates can achieve uniform and solid loading of PdNPs and is beneficial to sufficient utilization of PdNPs, and thus catalytic activity andstability can be synergistically improved.

Owner:BEIJING UNIV OF CHEM TECH

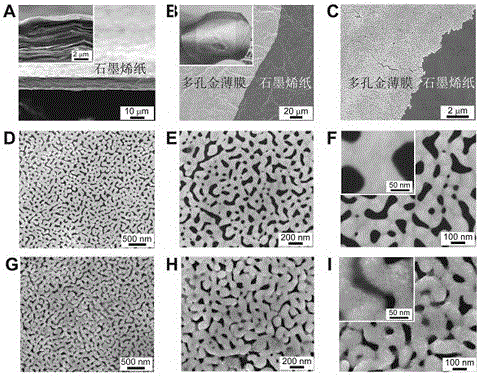

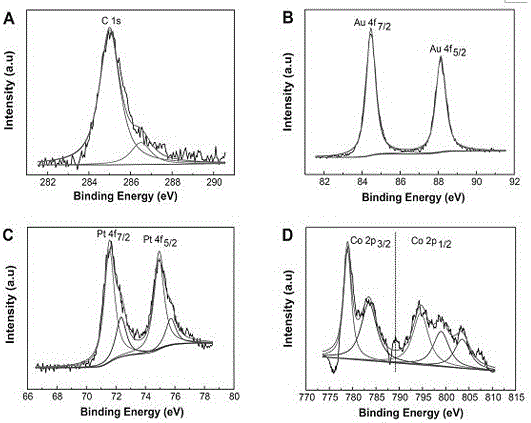

Nano platinum-cobalt/porous gold/graphene composite material and preparation method thereof

InactiveCN106770567AImprove effective utilizationImprove catalytic performanceMaterial nanotechnologyMaterial analysis by electric/magnetic meansGlucose sensorsLinear relationship

The invention relates to a nano platinum-cobalt / porous gold / graphene composite material and a preparation method thereof. The nano platinum-cobalt / porous gold / graphene composite material is used for manufacturing glucose-detection graphene composite paper electrodes and assembling electrochemical blood sugar sensors. The method comprises the following steps: supporting a nano porous gold film on the surface of high-strength high-flexibility high-stability high-electric-conductivity graphene paper, and growing platinum-cobalt bimetal nanoparticles on the nano porous gold film in situ by one-step electrodeposition, thereby obtaining the nano porous alloy / graphene paper-like composite material. The nano porous alloy supported on the graphene paper has high electrocatalytic oxidizing capacity on glucose; the glucose can generate an obvious catalytic current on the composite paper electrode surface; the magnitude of the current density has favorable linear relationship with the glucose concentration; and thus, when the electrode prepared from the nano platinum-cobalt / porous gold / graphene composite material is used for assembling the electrochemical glucose sensor system, the electrochemical glucose sensor system can be used for determining the glucose in the human blood sample in a stable, sensitive, accurate and fast way.

Owner:江苏丰格测控技术有限公司

Composite nano gold-platinum material, preparation method thereof and an application of composite nano gold-platinum material in direct methanol fuel cell anode catalyst

InactiveCN105680063AImprove surface catalytic activityHigh catalytic activityMaterial nanotechnologyCell electrodesFermi levelCorrosion resistant

The invention discloses a composite nano gold-platinum material. Nano gold is in a dendritic shape, spherical platinum particles are modified on the surface of the nano gold, a molar ratio of gold to platinum is 16: (4 to 5), the size of the nano gold is 0.1 to 7 micrometers, and the size of each platinum particle is 1.5 to 4 nanometers. The preparation method comprises the following two steps: step 1, electrically depositing an electrolyte solution containing chloroauric acid in a three-electrode system at a constant potential to obtain a nano gold modified electrode; and step 2, inserting the nano gold modified electrode into a reducing agent solution containing potassium chloroplatinite, carrying out the chemical reduction deposition, and depositing the platinum particles on the surface of the nano gold modified electrode to obtain the composite nano gold-platinum material. The composite nano gold-platinum material has high toxicity resistance and relatively high corrosion resistance to a reaction intermediate product CO; and after Au and Pt are composited, the internal atomic arrangement and the Fermi level of Pt can be changed, so that the surface performance of Pt is changed, and the surface catalytic activity, toxicity resistance and stability of the composite material are improved.

Owner:HUBEI UNIV

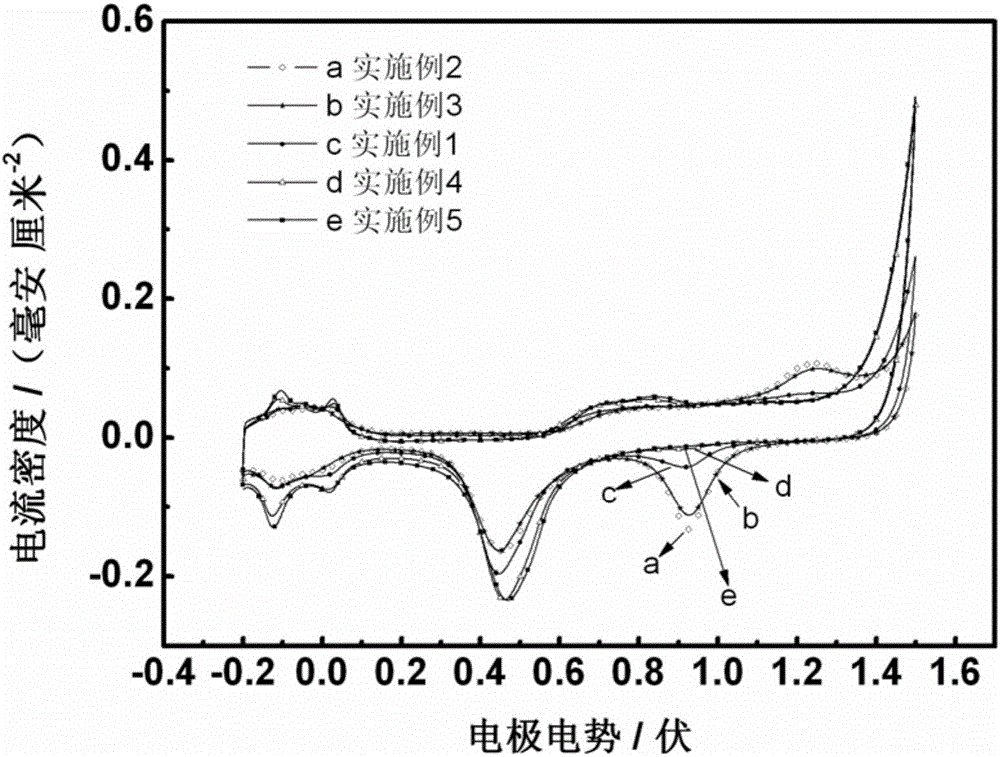

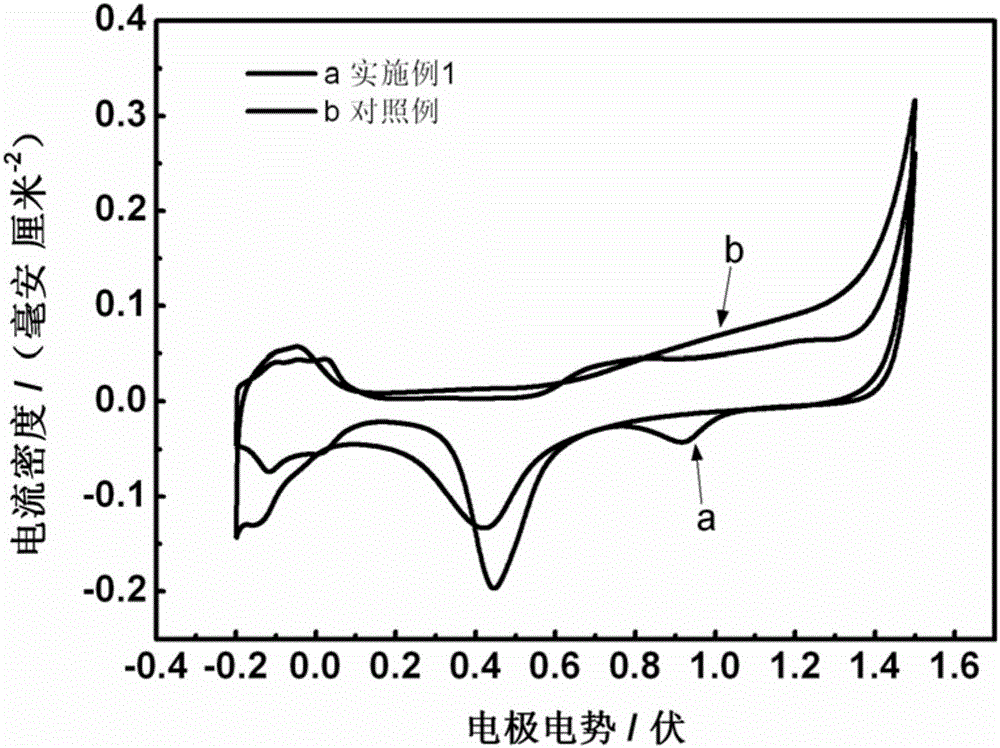

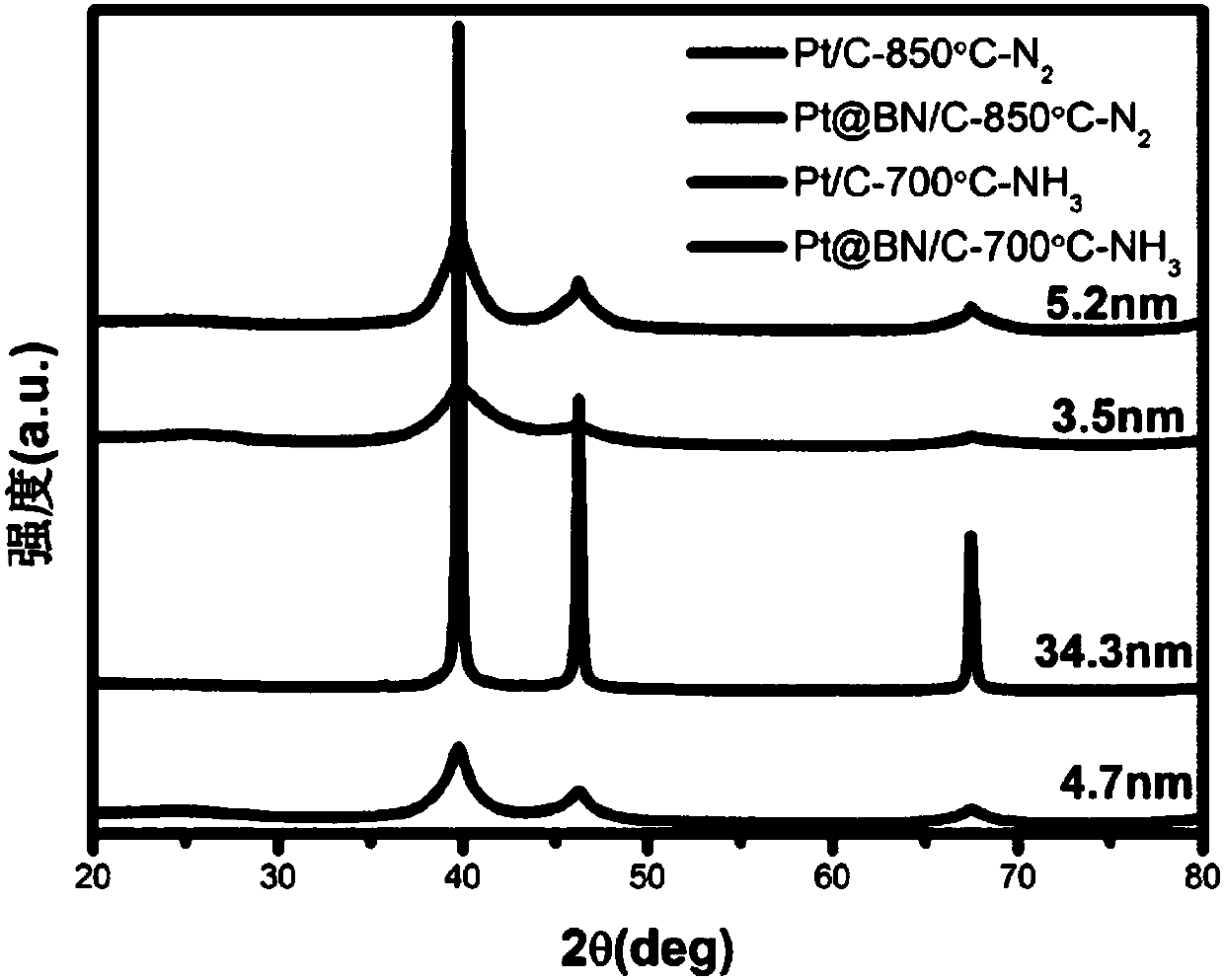

Anti-poisoning Pt-based nano-catalyst, and preparation method and application thereof

ActiveCN107732262AInhibition of CO poisoning effectExhibits anti-methanol poisoning performanceMaterial nanotechnologyCell electrodesNano catalystAlloy

The invention discloses an anti-poisoning Pt-based nano-catalyst, and a preparation method and application thereof. An ultrathin h-BN shell structure is formed on the surface of a carbon-supported Ptand Pt-based alloy nano-catalyst by utilizing a surface coating method to obtain a core-shell nano-structure of Pt@h-BN / C and PtTM@h-BN / C(TM is a transition metal, such as Ru, Sn, Au and Fe). The catalyst serves as an H2-O2 proton exchange membrane fuel cell anode catalyst which can remarkably inhibit the CO poisoning effect on a Pt-based catalyst; the catalyst can also be used in a direct methanol fuel cell and can show resistance to methanol poisoning.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

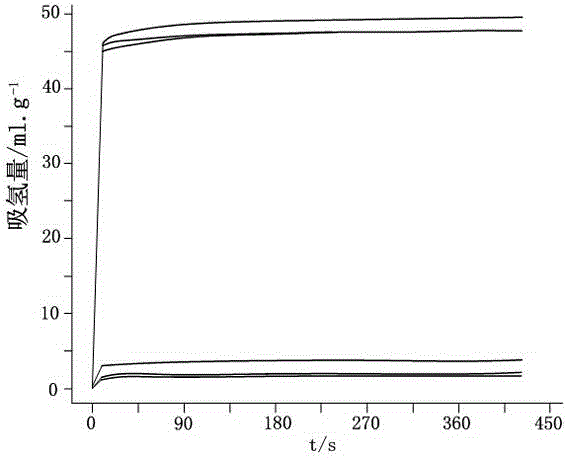

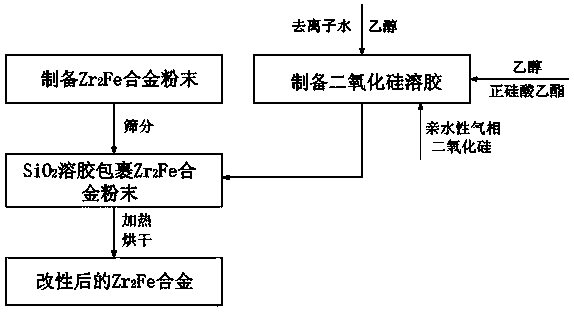

Method for enhancing performance of ZrCo alloy to resist CO, CO2 and air poison and anti-pulverization performance of alloy

The invention discloses a method for enhancing the performance of ZrCo alloy to resist CO, CO2 and air poison and the anti-pulverization performance of the alloy, which comprises the steps of S1: preparing ZrCo alloy powder; S2: sieving the ZrCo alloy powder; S3: mixing ethyl alcohol with deionized water, and stirring to obtain a mixed solution; S4: adding concentrated hydrochloric acid to adjust the pH value and obtain a first mixture; S5: mixing tetraethoxysilane with ethyl alcohol to obtain a second mixture; S6: mixing the first mixture with the second mixture to obtain a third mixture; S7: standing, and heating the third mixture to volatilize the ethyl alcohol; S8: adding hydrophilic gaseous phase silicon dioxide to the third mixture so as to obtain a silicon dioxide sol; S9: adding the ZrCo alloy powder to the silicon dioxide sol so as to obtain paste; S10: heating and drying the paste. According to the method disclosed by the invention, the problem that the ZrCo alloy is poor in anti-pulverization capability and poor in anti-poison capability is solved, the use stability of the ZrCo alloy is enhanced, and the service life of the ZrCo alloy is prolonged.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

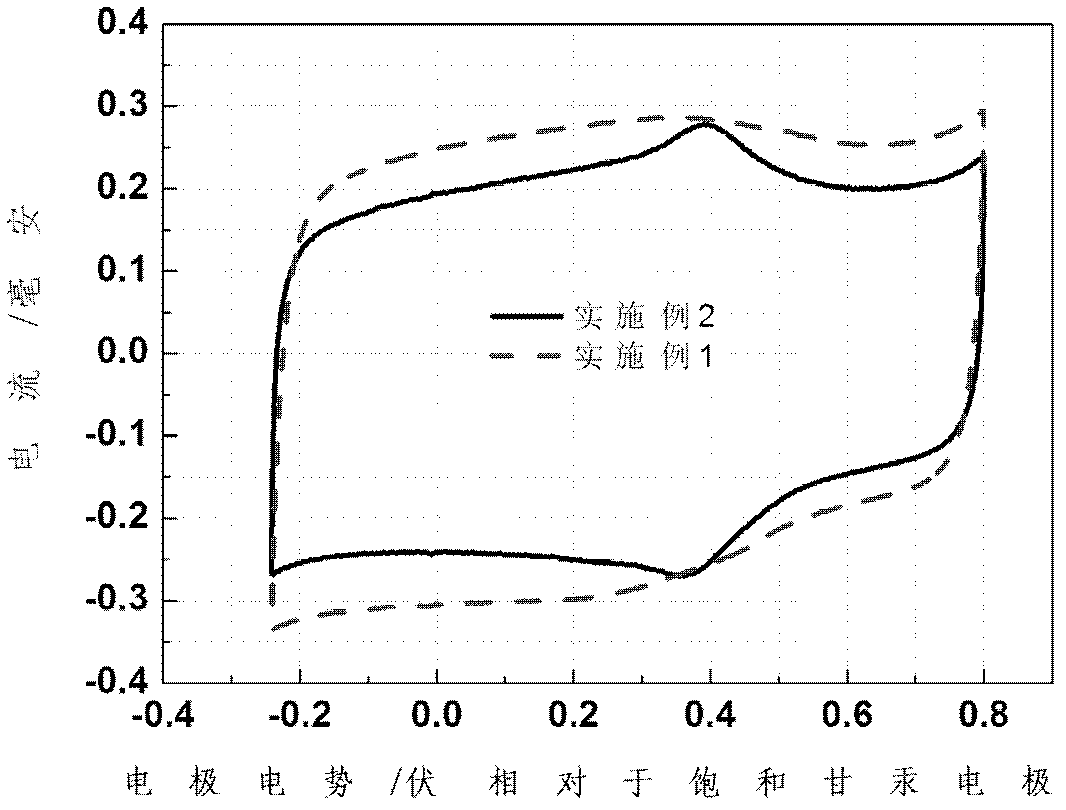

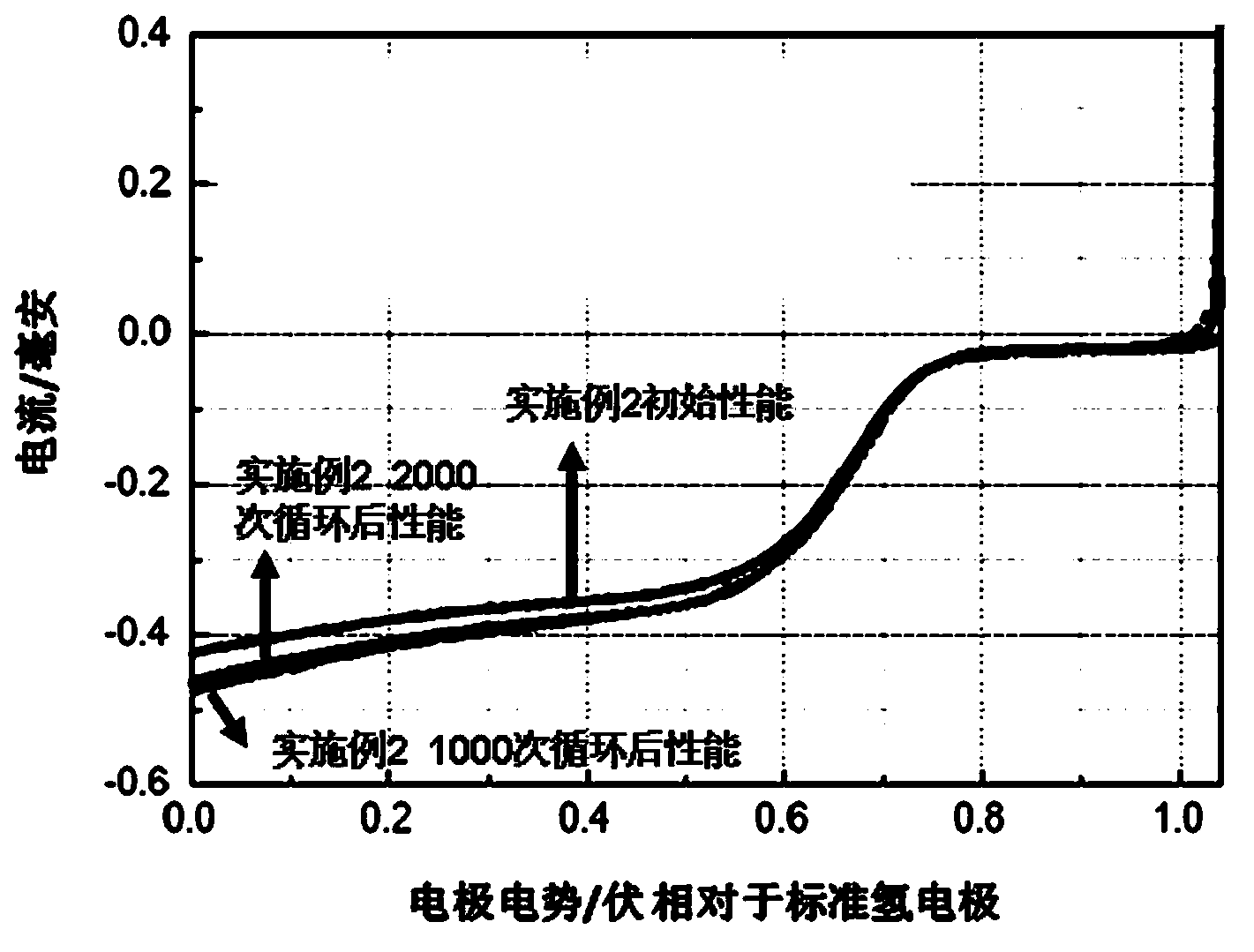

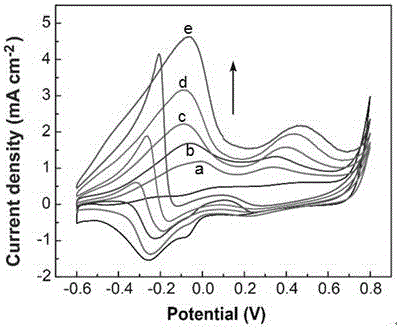

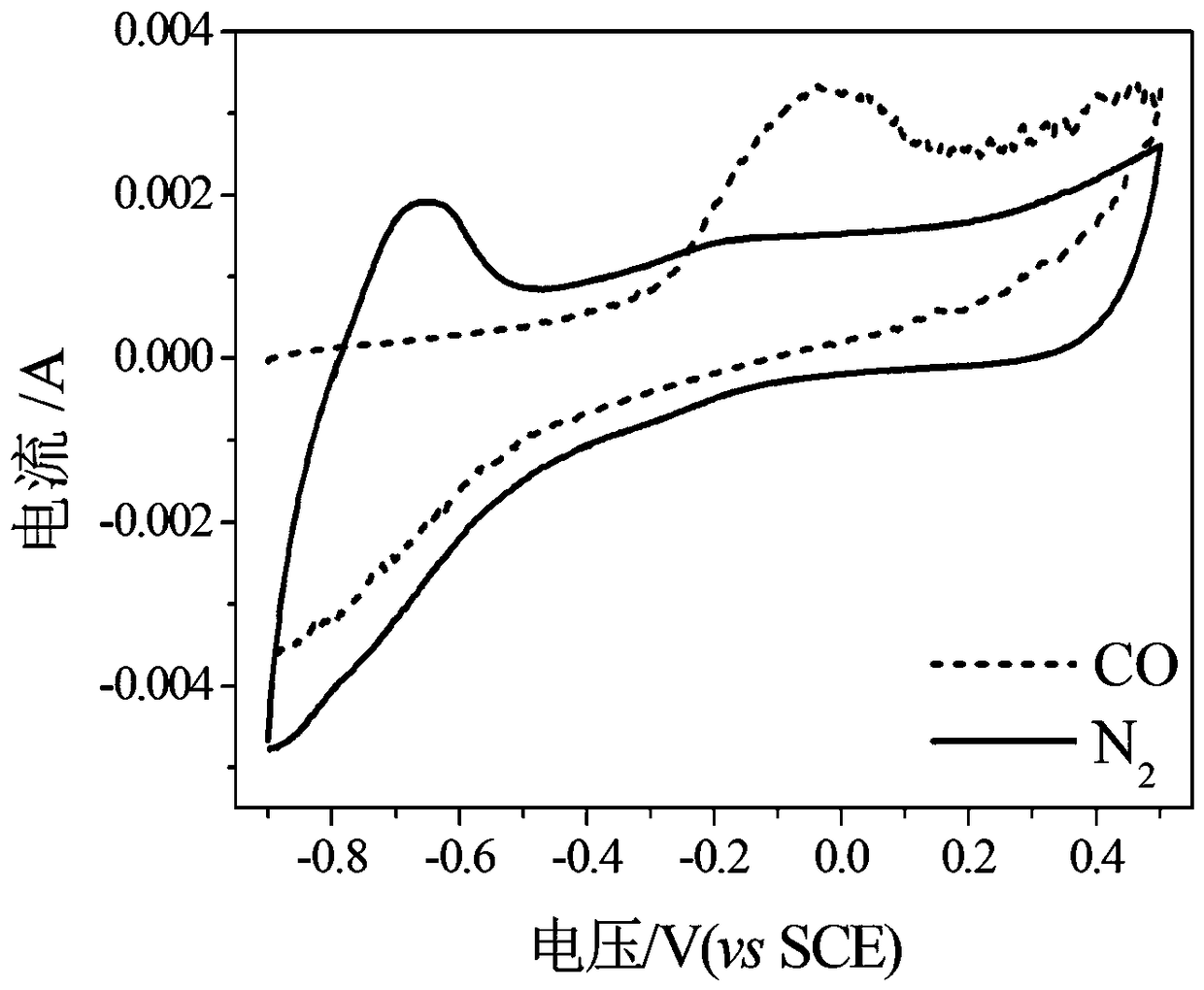

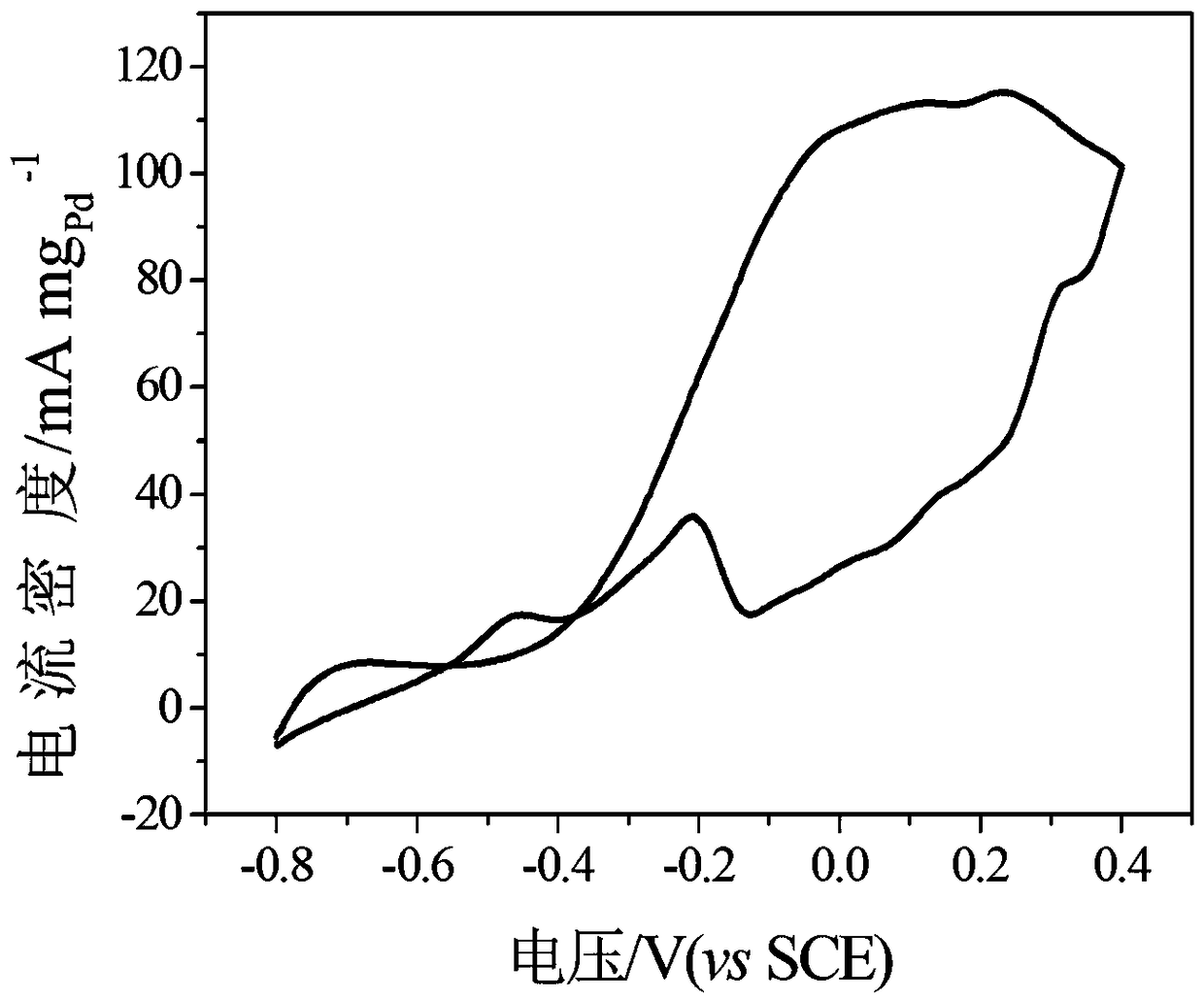

Ternary CoAuPd catalyst for fuel cells and preparation method and application thereof

The invention relates to a preparation method and application of a fuel cell catalyst. Electrochemical dealloying is performed. The synthesis method adopts a continuous reduction method, and includesthe steps that a triblock copolymer P123 serves as a protecting agent, and sodium borohydride serves as a reducing agent; a certain amount of P123 is taken and dissolved in redistilled water, a cobaltchloride solution is added to the P123 solution, before reaction, nitrogen is introduced to remove oxygen, continuous stirring is performed, and the reaction temperature is controlled to be room temperature (30 DEG C); a sodium borohydride solution is slowly dropwise added to the reaction liquid, 30 minutes after dropwise adding, a mixed solution of chloroauric acid and potassium chloropalladateis slowly dropwise added to the reaction liquid, and the reaction is stopped after lasting 4 hours; the reaction liquid is centrifuged and washed three to five times to obtain the ternary CoAuPd alloycatalyst for fuel cells. The special ternary CoAuPd alloy catalyst has excellent methanol catalytic oxidation performance and oxygen reduction catalytic activity after electrochemical gradient dealloying and is a fuel cell catalyst with broad development prospects.

Owner:CHINA THREE GORGES UNIV

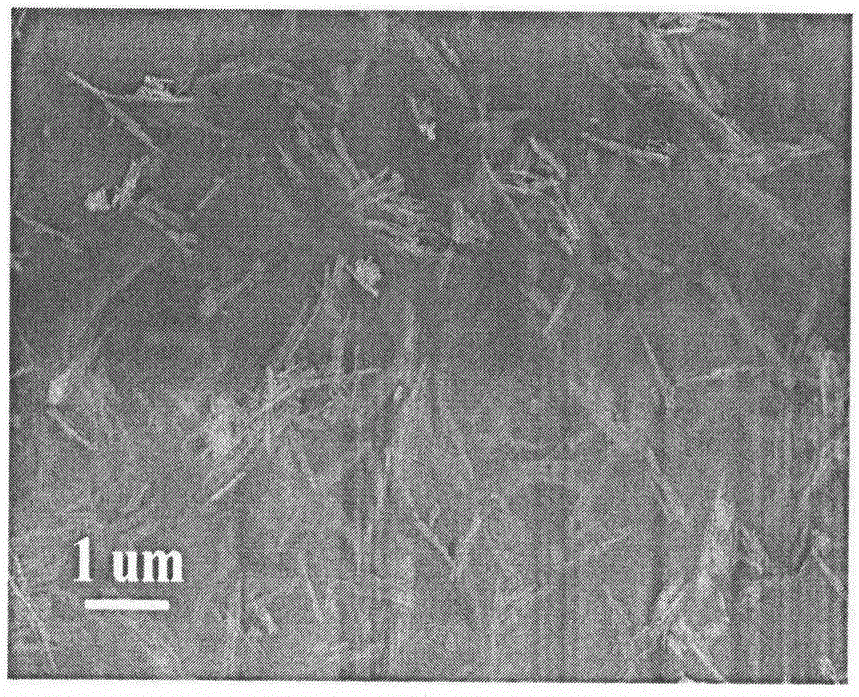

Nanoscale platinum-rhodium alloy powder and preparing method thereof

ActiveCN106623975AGood printabilityAvoid reunionMaterial nanotechnologyTransportation and packagingVolumetric Mass DensitySpherical shaped

The invention discloses nanoscale platinum-rhodium alloy powder and a preparing method thereof, and belongs to the field of preparing nano metal materials. The size distribution of the platinum-rhodium alloy powder is 50-100 nm, the average particle size is 65 nm, the open setting density is 1.2-1.6 g / cm<3>, and the tapping density is 1.8-2.0 g / cm<3>. The platinum-rhodium alloy powder is prepared through a hydrothermal method, and a chloroplatinic acid and rhodium trichloride mixed solution, an organic reducing agent and a dispersing agent are put into a stainless steel reaction kettle with a polytetrafluoroethylene lining and heated for a period of time to prepare the nanoscale platinum-rhodium alloy powder. The alloy powder prepared through the method is small in particle size, size distribution is concentrated, the nanoscale platinum-rhodium alloy powder can be used for preparing a catalytic electrode of a NOx sensor, and the preparing method is simple, easy to implement and beneficial for industrial production.

Owner:GRIKIN ADVANCED MATERIALS

Method for preparing nanowire sheet intercalated structure supported type direct alcohol fuel cell catalyst

InactiveCN106410221APromote oxidationFacilitate depositionMaterial nanotechnologyCell electrodesFuel cellsNanowire

A method for preparing a nanowire sheet intercalated structure supported type direct alcohol fuel cell catalyst and relates to a method for preparing a direct alcohol fuel cell catalyst. The problems that in an existing direct alcohol fuel cell catalyst performance degradation mechanism, nanoscale catalyst Pt particles are poisoned, alcohol fuel conveying is hindered, and catalyst preparation cost is high are solved. The method includes the steps that a graphite oxide sheet serves as a carrier, according to different properties of nanowires and graphene or a modified graphene carrier, and nanowires directly grow on the carrier to form the nanowire sheet intercalated structure supported type catalyst with different adsorption layers. The catalyst prepared through the method is beneficial to alcohol fuel conveying, and has the advantages of being low in cost, high in product poison resistance, high in activity and high in stability. The catalyst is mainly used for methyl alcohol fuel cells.

Owner:TIANJIN POLYTECHNIC UNIV

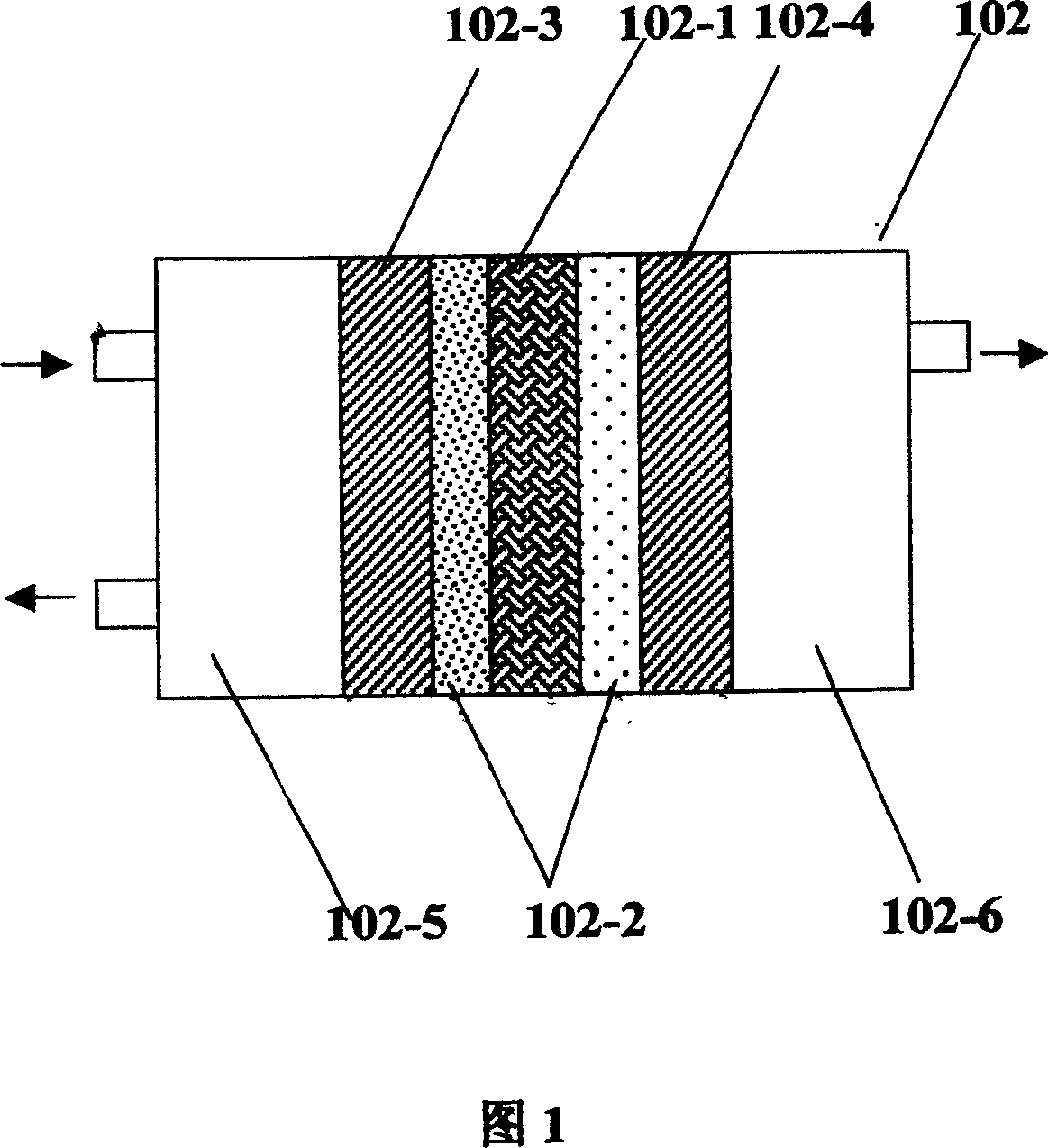

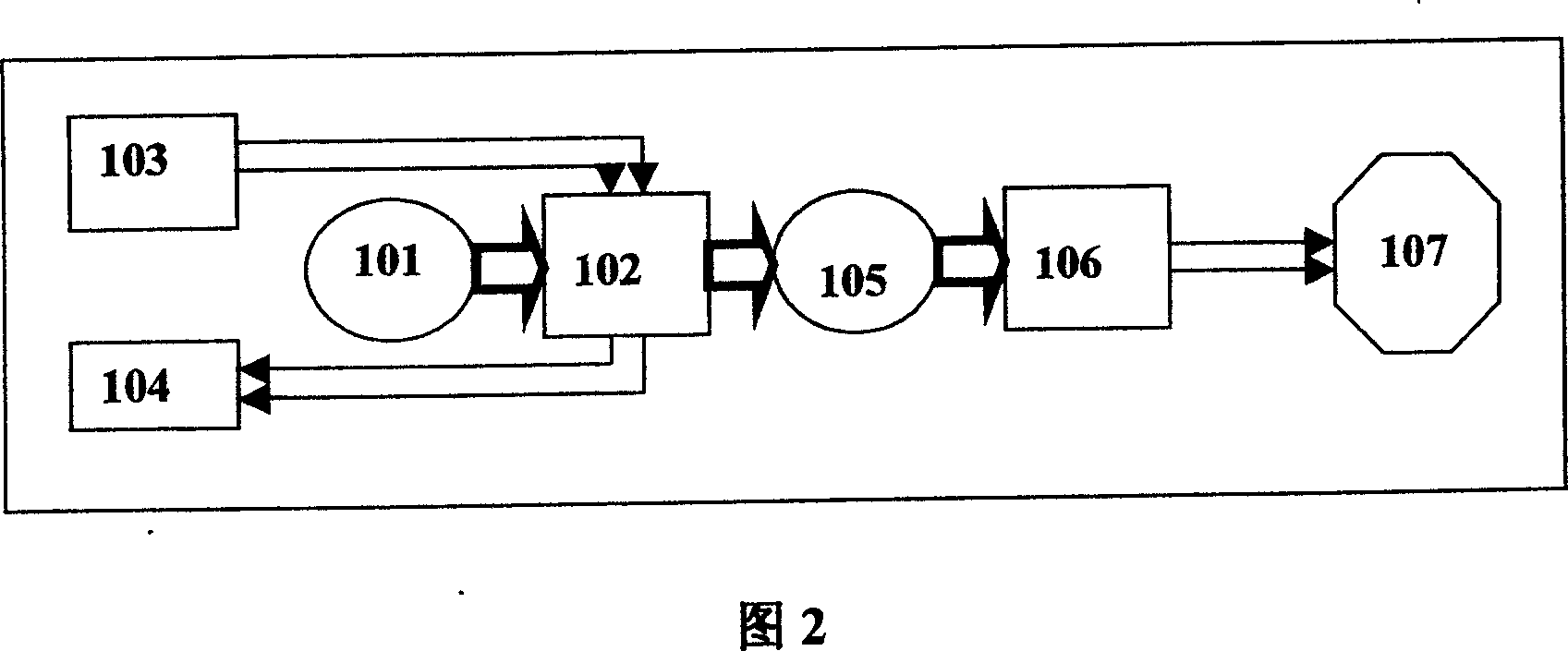

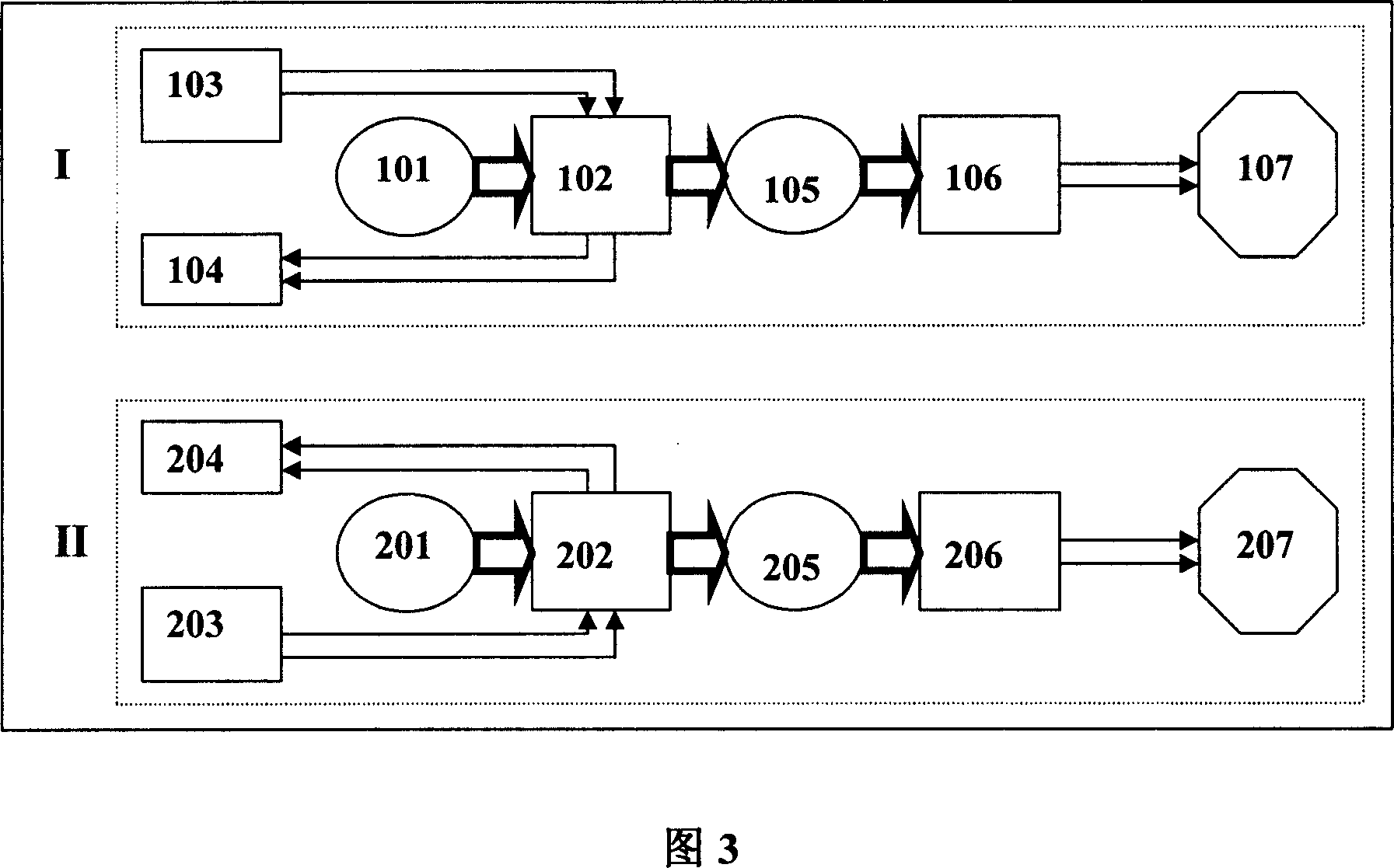

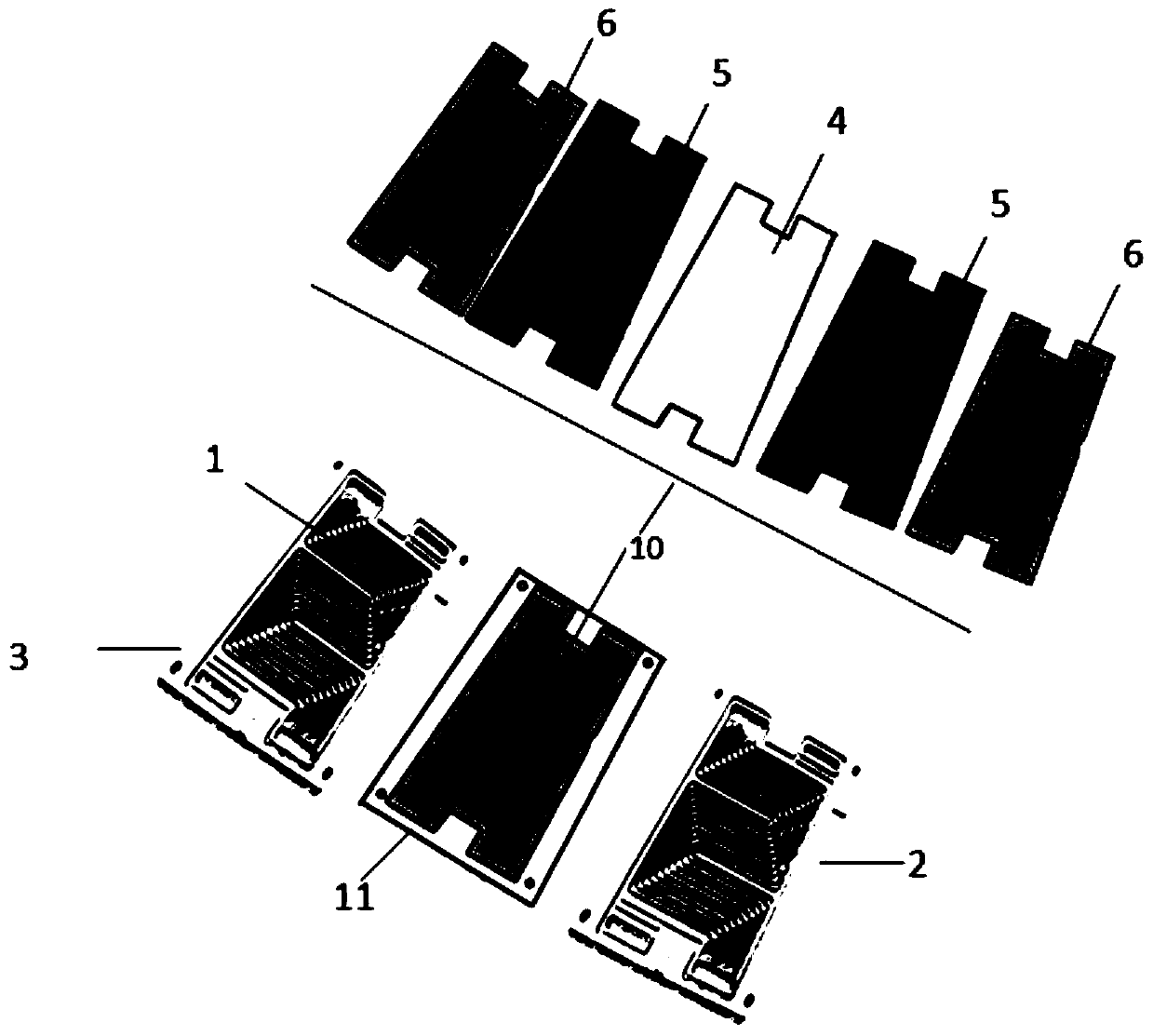

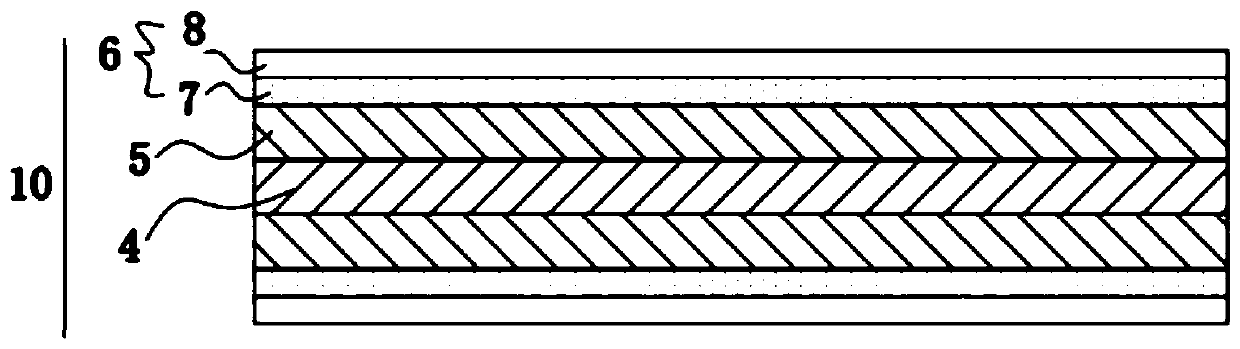

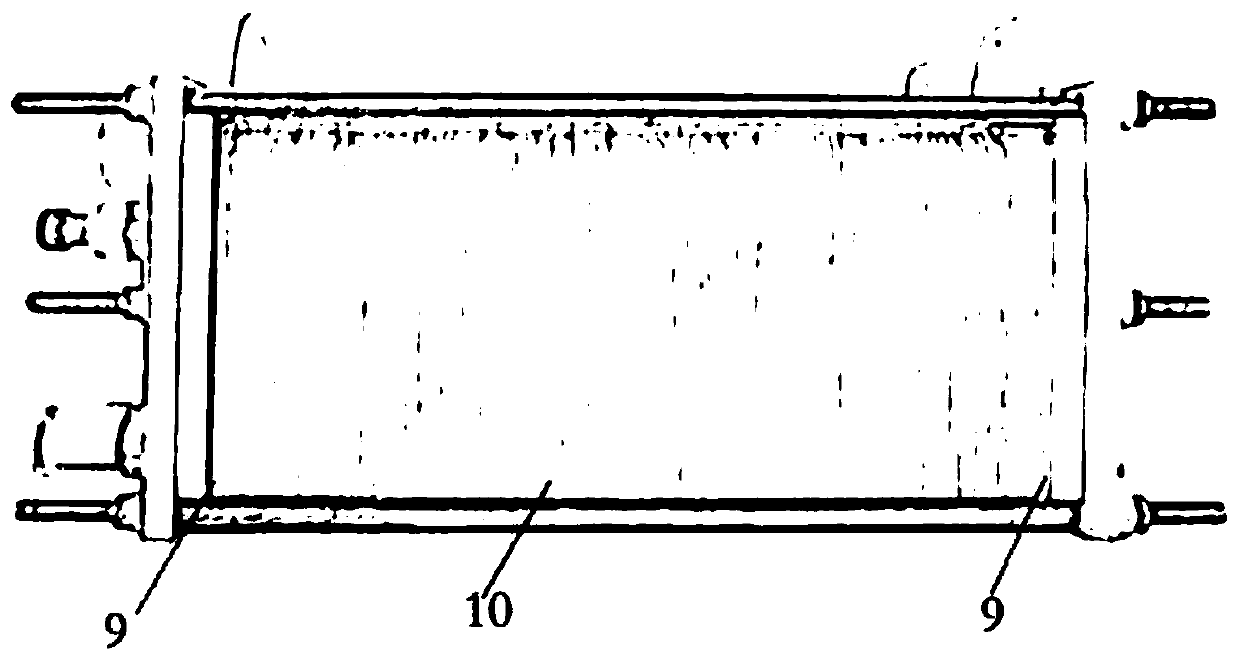

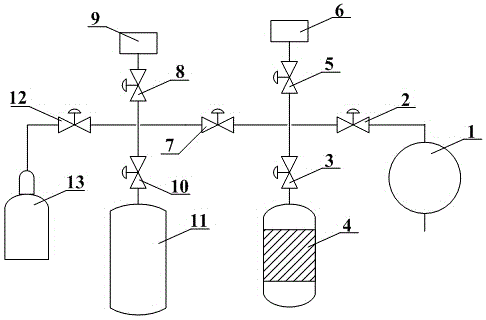

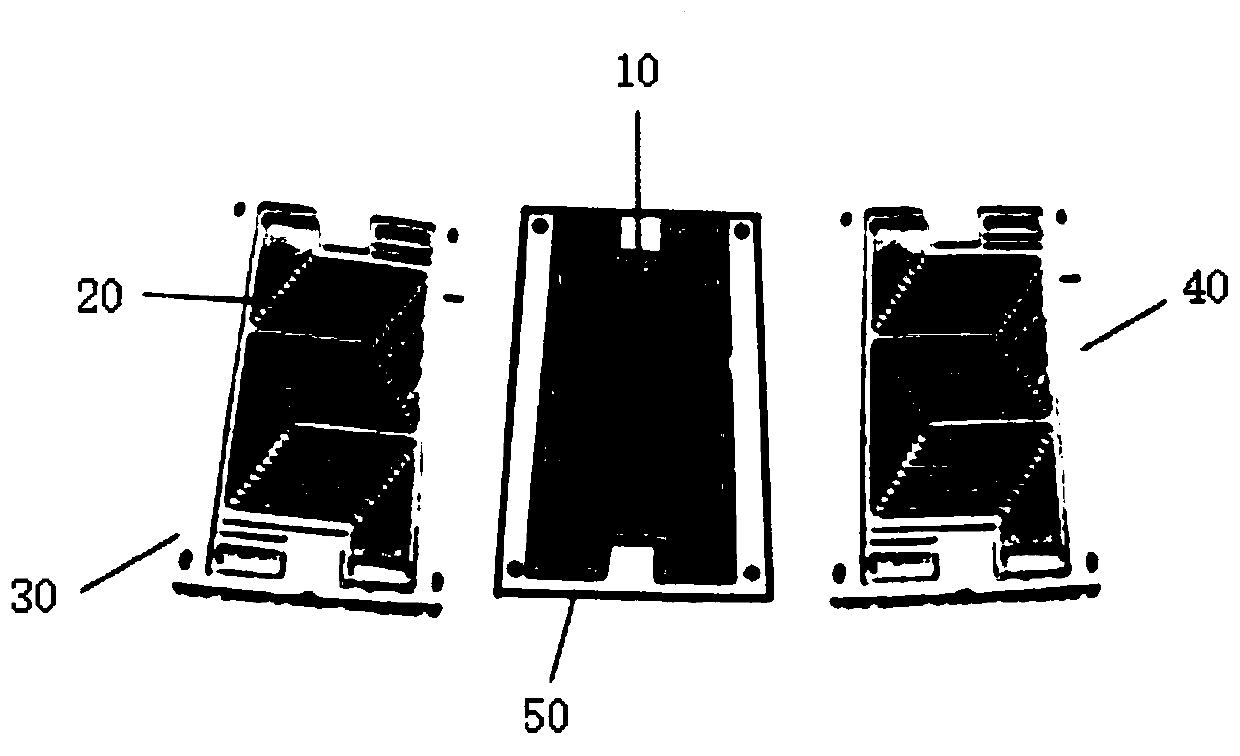

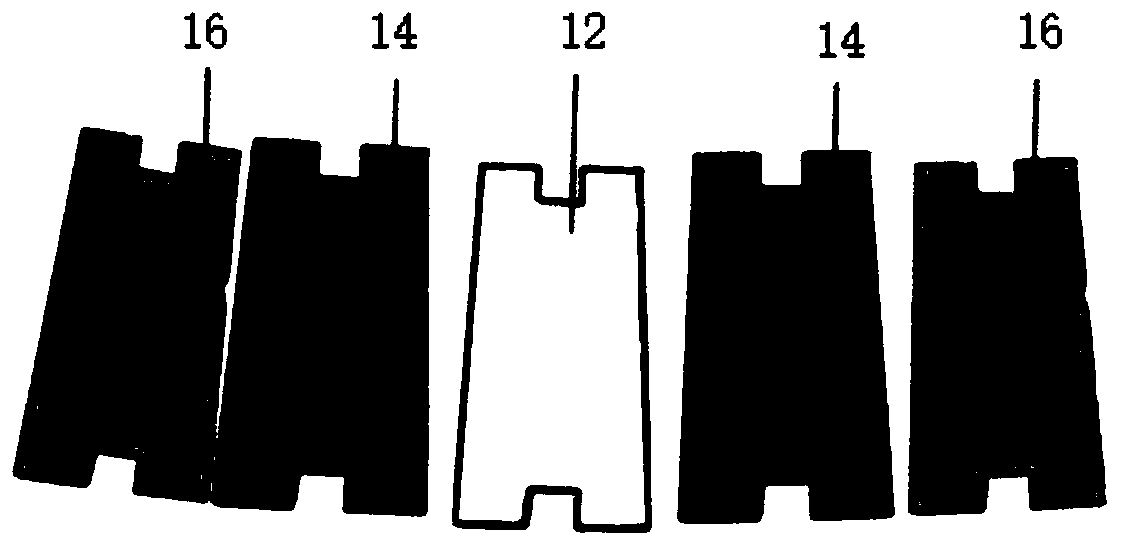

Hydrogen maker by direct alcohol electrolyzation and its integrated unit

InactiveCN1940138ACompact structureHigh activityElectrolysis componentsIntegrated circuitHydrogen production

The invention involves alcohol electrolysis for hydrogen production. It is an electrolytic cell with the structure of the proton exchange membrane for fuel cell stack, using alcohol-solid electrolyte-exchange membrane. The invention is also involved integrated device electrolyzing directly for hydrogen production from alcohol. The device was consist of alcohol container, hydrogen production set and hydrogen collection set, which was connected orderly with pipelines. The hydrogen production set is linked with DC power supply device, test and control systems -- link -- Link Load collection devices and hydrogen; the invention of low power consumption, small voltage Preparation, and other aspects of fuel cell technology for the practical application of and demand for hydrogen, can be used for teaching and scientific experiment.

Owner:SUN YAT SEN UNIV

Catalyst as well as preparation method and application thereof

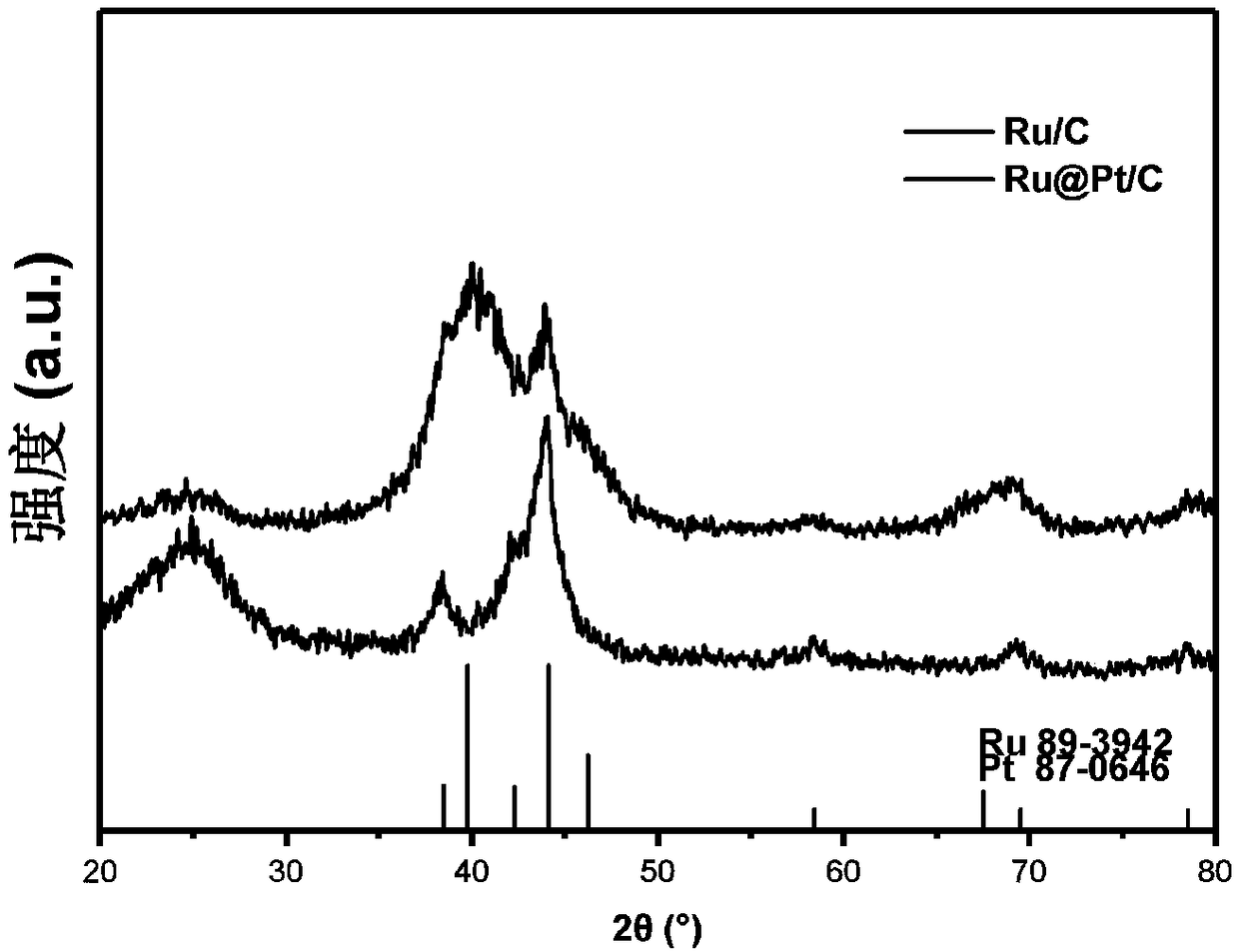

ActiveCN110911700AHigh catalytic activityReduce the binding forceCell electrodesFinal product manufactureNanotechnologyPtru catalyst

The embodiment of the invention discloses a catalyst as well as a preparation method and application thereof. The catalyst comprises a catalyst core and a catalyst shell coating the catalyst core, wherein the catalyst core is a compound of a carbon supporter and transition metal, the carbon supporter is a carrier, the transition metal is loaded on the carbon supporter, the catalyst shell is made of Pt, Pd, Ru, Rh or Au, and the thickness of the catalyst shell is 2.5 nm-4 nm. According to the present invention, the catalyst is prepared by using the strong reducing agent, the amine compound andthe polyol compound, such that the whole process is simple and easy to control, the catalyst with characteristics of low price, high poisoning resistance and strong catalytic activity can be prepared,and the important significance is provided for promotion of commercialization of PEM fuel cells.

Owner:深圳氢时代新能源科技有限公司

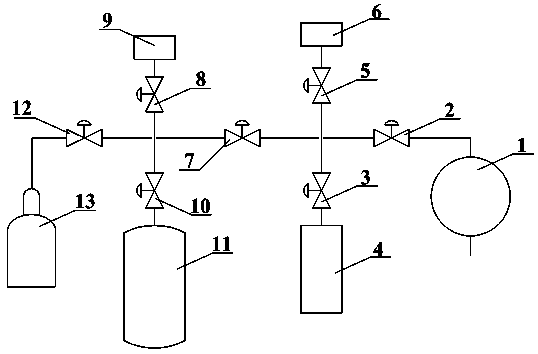

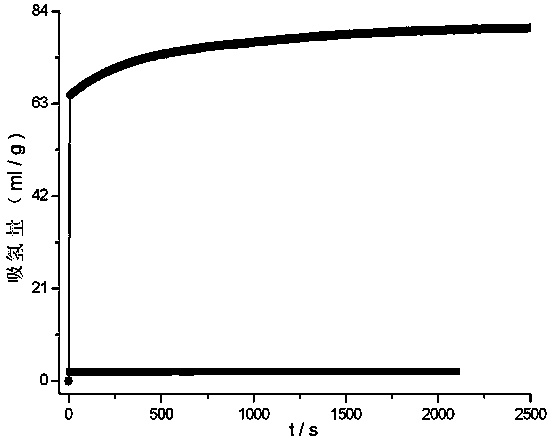

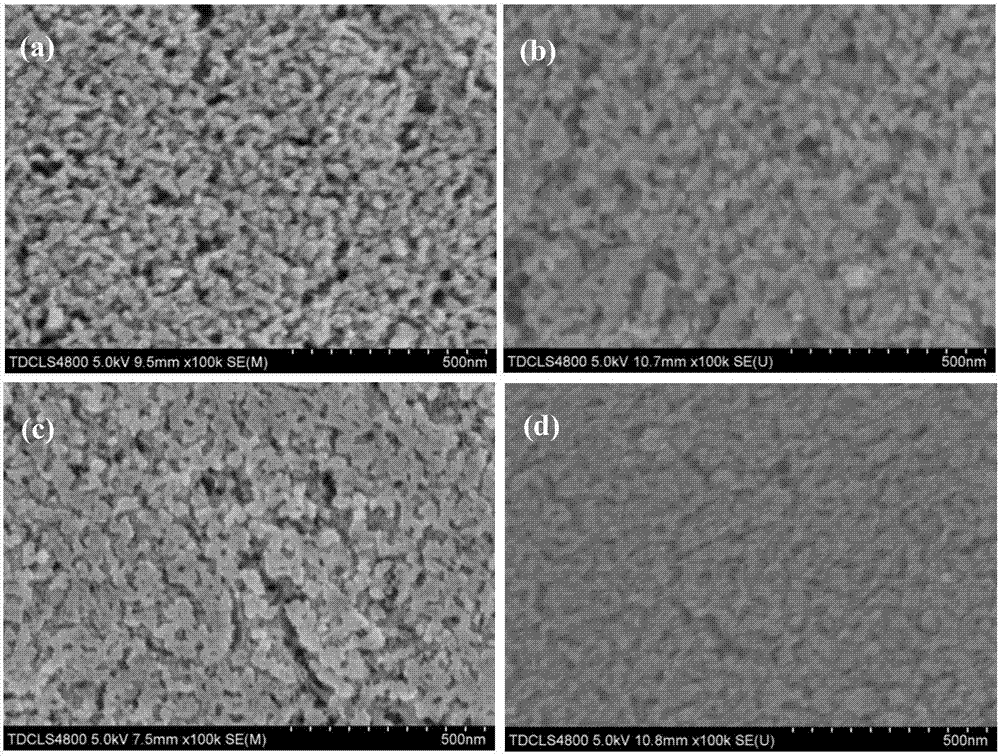

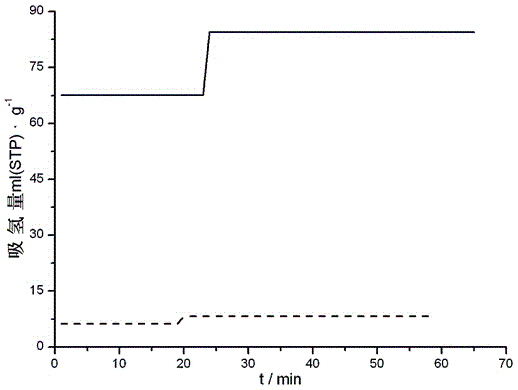

Method for enhancing air poison resistance of Zr2Fe alloy

The invention discloses a method for enhancing air poison resistance of Zr2Fe alloy. The method for enhancing the air poison resistance of the Zr2Fe alloy includes steps: S1, simultaneously loading Zr2Fe alloy particles and stainless steel balls into a stainless steel vacuum ball milling tank, and connecting the stainless steel vacuum ball milling tank with a hydrogen storage performance test system; S2, pumping gas out of the stainless steel vacuum ball milling tank, and inflating the stainless steel vacuum ball milling tank with argon gas; S3, performing ball milling on the Zr2Fe alloy particles; S4, inflating the stainless steel vacuum ball milling tank with the argon gas, and passivating the Zr2Fe alloy particles; S5, placing the stainless steel vacuum ball milling tank into a glove box, controlling air inflow of air, and exposing Zr2Fe alloy powder to air; S6, sieving the Zr2Fe alloy powder; S7, preparing silicon dioxide sol; S8, adding the Zr2Fe alloy powder into the silicon dioxide sol and stirring the Zr2Fe alloy powder so as to form cream; S9, heating and drying the cream. The method for enhancing the air poison resistance of the Zr2Fe alloy solves the problem that the Zr2Fe alloy is poor in air poison resisting ability, strengthens use stability of the Zr2Fe alloy, and prolongs use life of the Zr2Fe alloy.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

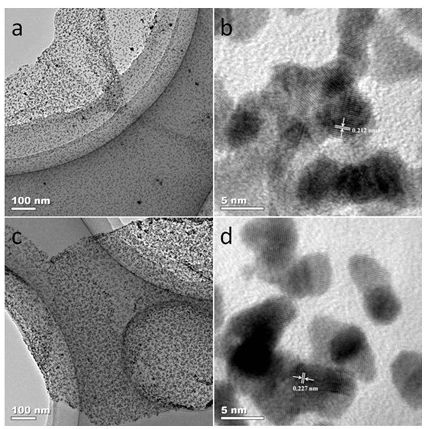

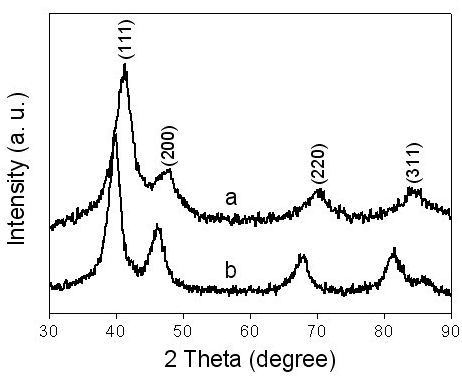

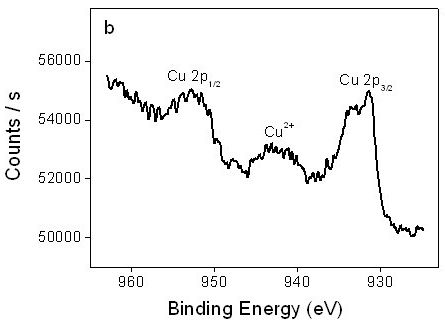

Preparation method and application of PdSn-CuO composite material with nano-porous structure

The invention discloses a preparation method of a PdSn-CuO composite material with a nano-porous structure. An Al-Pd-Sn-Cu amorphous alloy strip with the thickness of 10 to 30 [mu]m is prepared from the following components in percentage by atom: 81 to 84 percent of Al, 3 to 7 percent of Pd, 8 to 12 percent of Sn and 1 to 4 percent of Cu. The Al-Pd-Sn-Cu amorphous alloy strip is put into a hydrothermal reactor holding a certain amount of a corrosive liquid, an alloy is removed by using a hydrothermal reaction, and the PdSn-CuO composite material is obtained after the alloy-removed material is cleaned and dried. The composite material has large specific surface area and a stable structure; the interpenetration facilitates the transmission of electrons and ions. The preparation method has the advantages of simple operation, easiness in implementation, low cost, economy and high efficiency. The obtained composite material is used for electrocatalytic property of methanol; compared with a currently-used common commercial palladium carbon catalyst, the composite material has the advantages of higher electrocatalytic activity and long-term stability.

Owner:TIANJIN UNIV

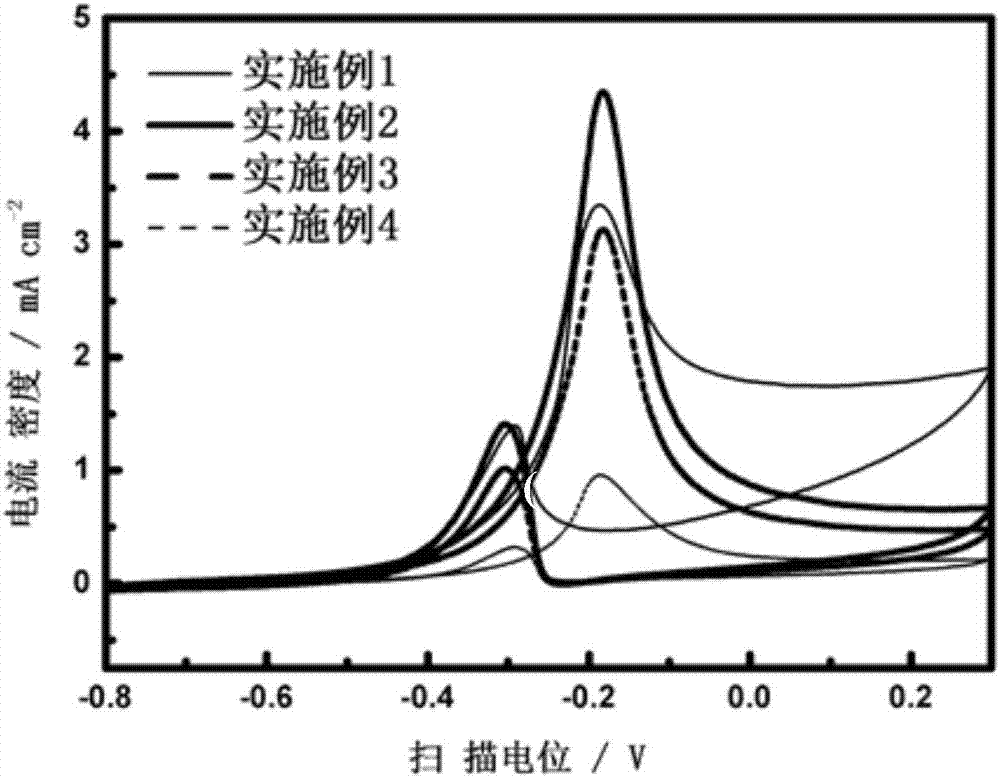

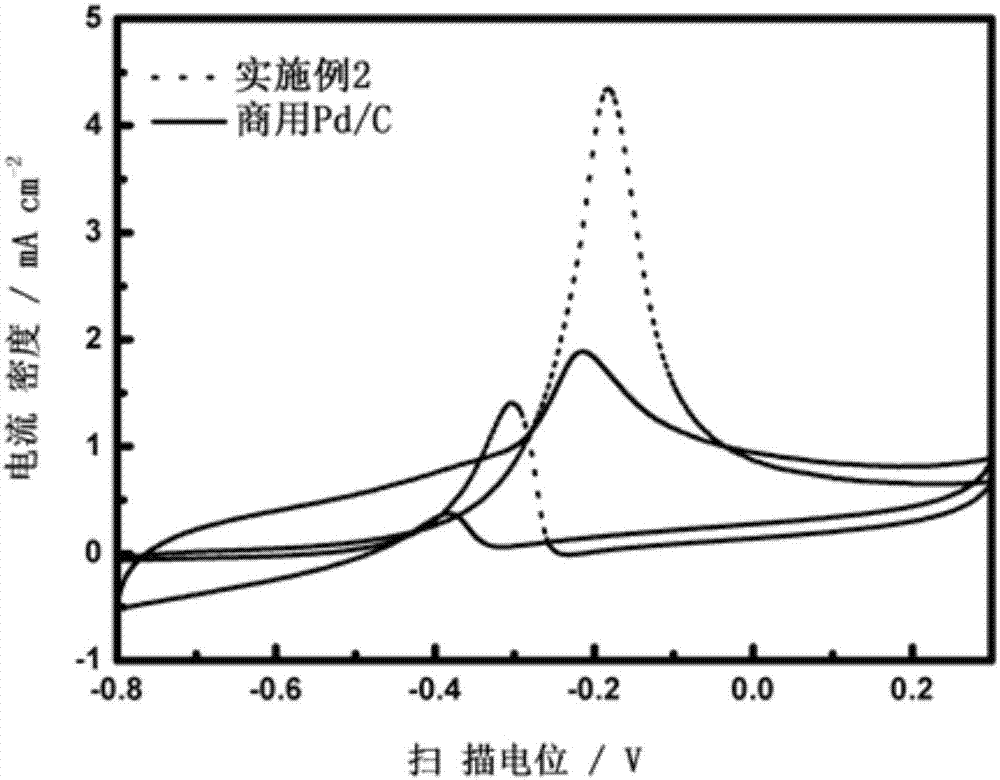

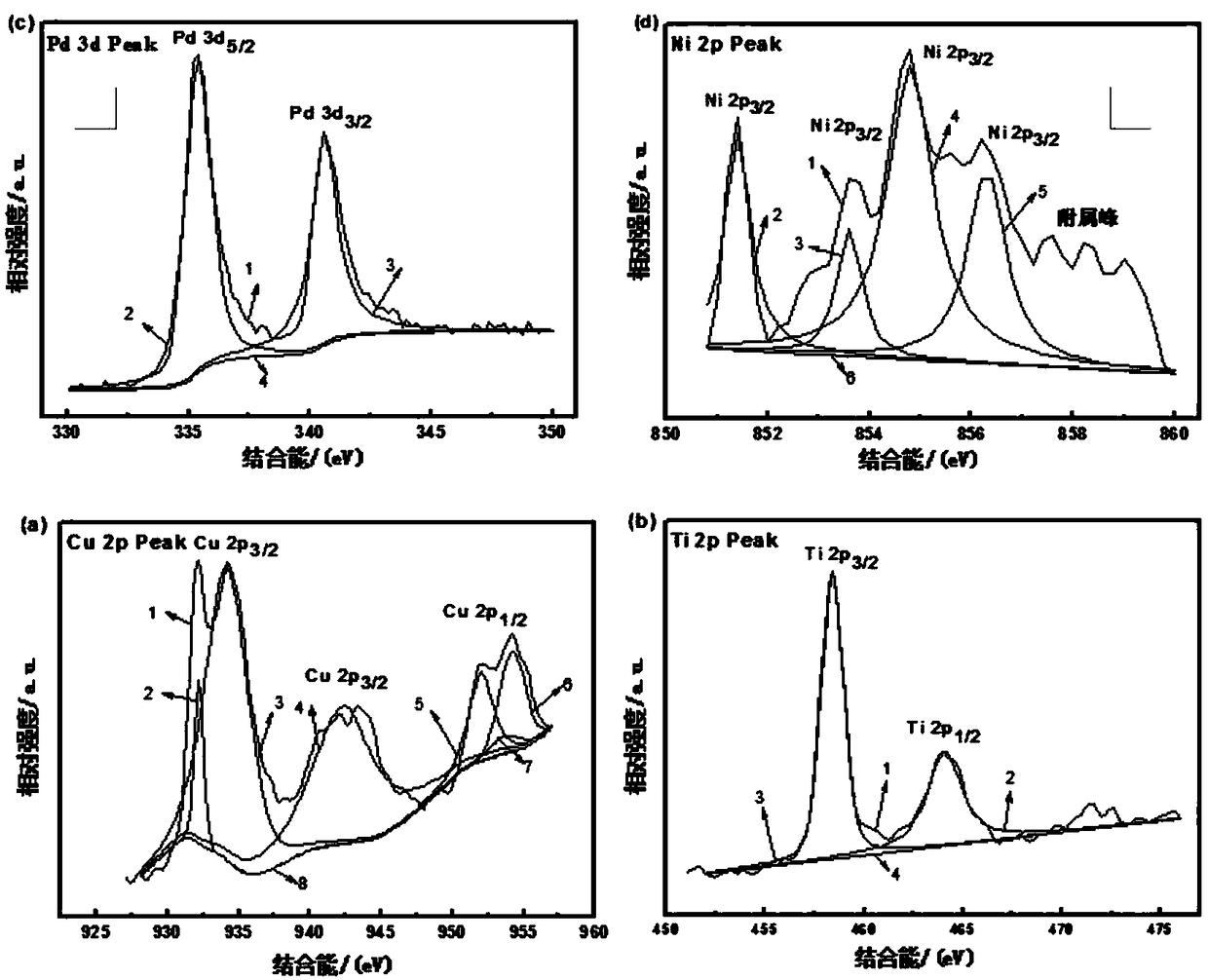

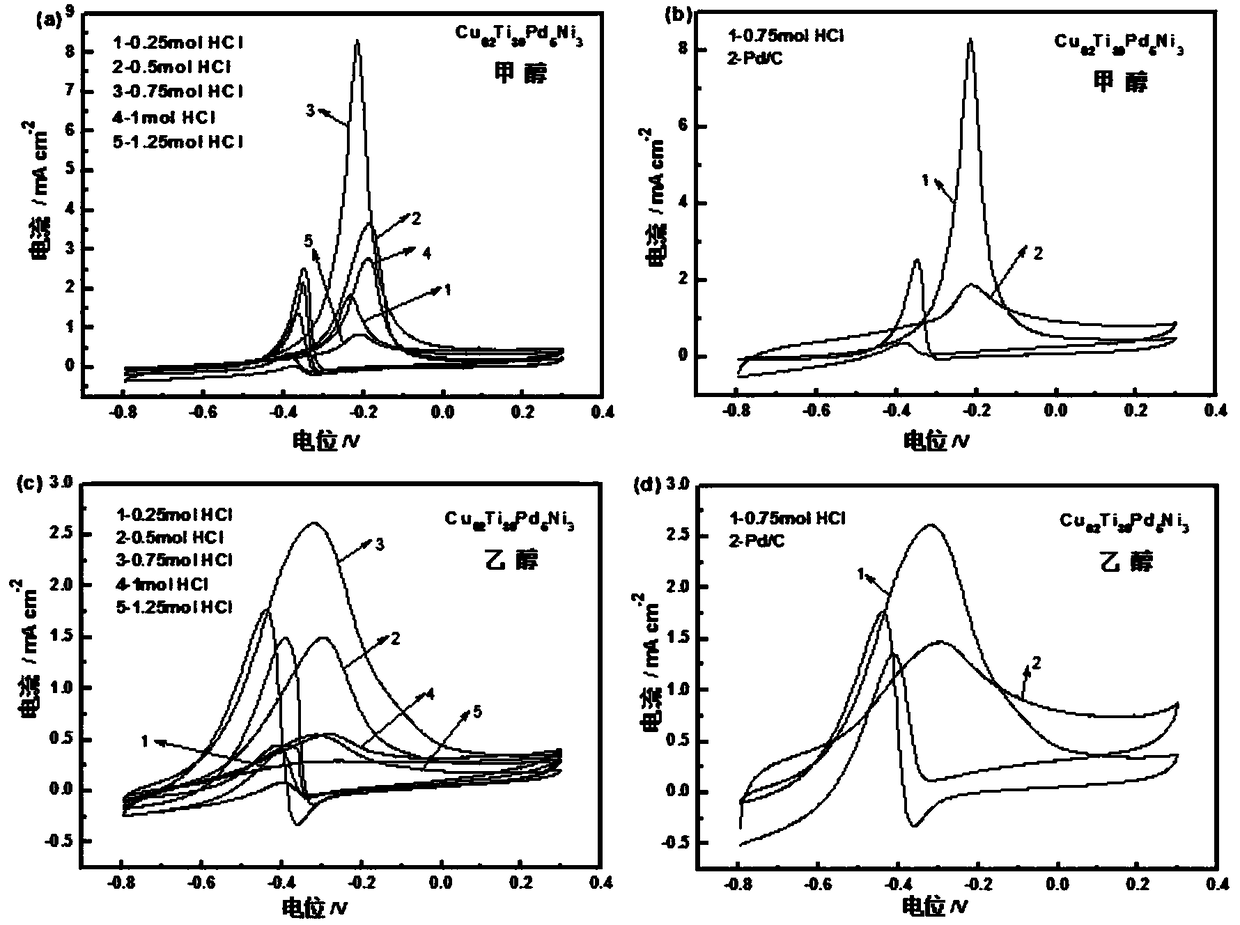

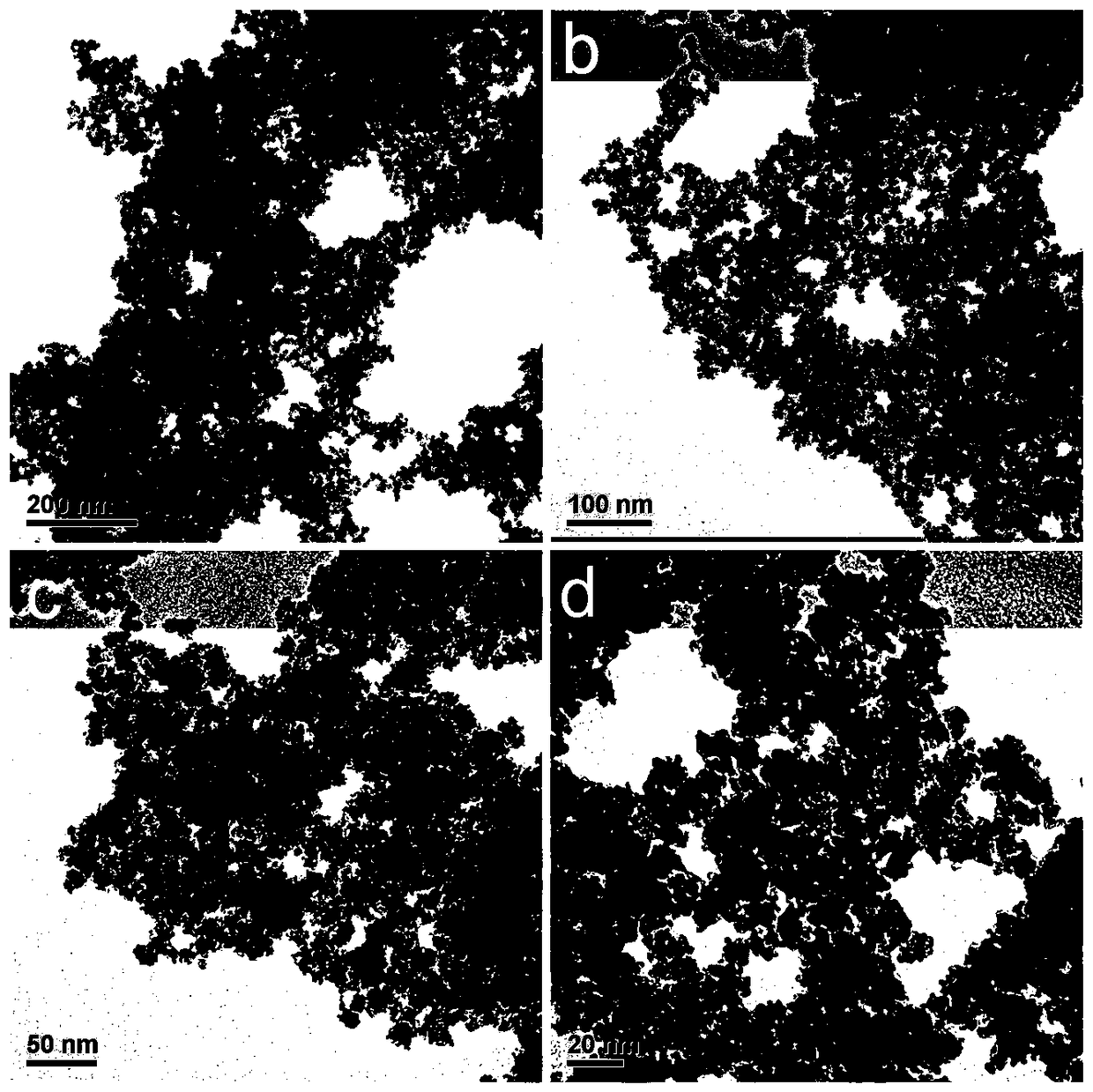

Nanoporous structure composite material and preparation method and alcohol catalytic property application

InactiveCN108091886AImprove electrocatalytic performanceLow costCell electrodesFuel cellsAlcoholAlloy

The invention discloses a nanoporous structure copper oxide-titanium dioxide-palladium-nickel oxide composite material and a preparation method thereof and alcohol catalytic property application. TheCuO-TiO2-Pd-NiO composite material with a uniform nanoporous structure is prepared from a Cu-Ti-Pd-Ni original amorphous alloy strip as a raw material by use of an aqueous hydrochloric acid solution as an etchant solution by a chemical de-alloying method. The method is low in cost, simple in operation, and easy to control, and has good feasibility, and the prepared CuO / TiO2 / Pd-NiO composite material has good electrocatalytic properties for alcohols.

Owner:TIANJIN UNIV

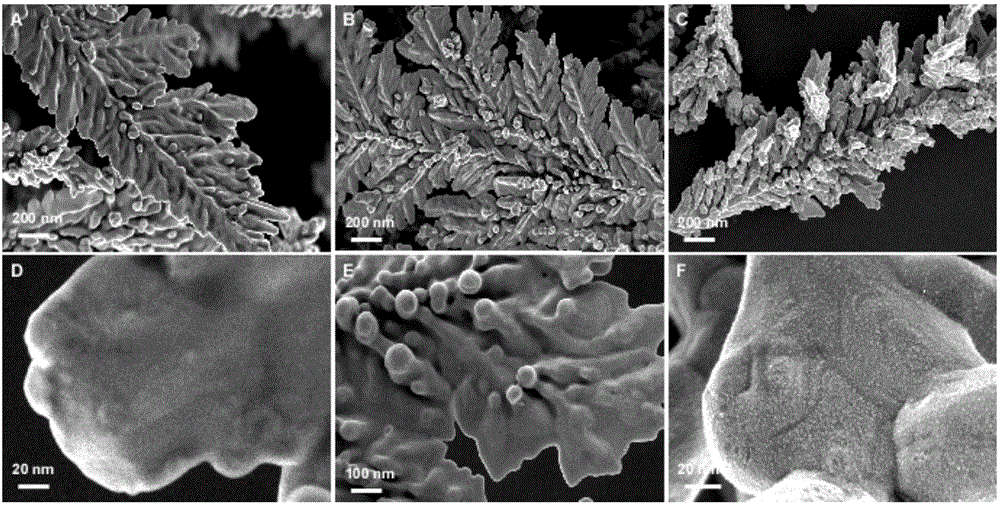

Preparation method and application of PdRh catalyst for fuel cell

ActiveCN108598501ASimple stepsMild reaction conditionsCell electrodesChemistryPolytetrafluoroethylene

The invention relates to preparation method, morphology control and application of a PdRh catalyst for a fuel cell. The method employs a hydrothermal reduction synthesis technology. The synthesis method comprises the following steps of dissolving a three-segment copolymer P123 in secondary distilled water; adding a potassium chloropalladite, rhodium chloride and potassium iodide solution into theP123 solution, and performing ultrasonic stirring and uniform mixing; transferring a mixed solution to an inner container of a 50mL polytetrafluoroethylene reaction kettle, placing the reaction kettlein a drying box, and performing reaction for 2-24 hours under 120-200 DEG C; and naturally cooling to a room temperature, and obtaining the PdRh catalyst for the fuel cell after centrifugal washing for 3 to 5 times. The P123 is used as a protection agent and a reduction agent, potassium iodide is used as a morphology control agent, the obtained PdRh catalyst has relatively good dispersion performance, is endowed with different special morphologies and a multi-stage structure, has excellent methanol catalytic oxidation performance, anti-poisoning performance and durability and is the catalysthaving great development prospect.

Owner:CHINA THREE GORGES UNIV

Preparation method of Mn-Ce/SBA-15 mesoporous molecular sieve catalyst containing active coating

ActiveCN109529913ALarge specific surface areaReduce areaGas treatmentMolecular sieve catalystsMolecular sieveFlue gas

The invention relates to the technical field of denitration, in particular to a preparation method of an Mn-Ce / SBA-15 mesoporous molecular sieve catalyst containing an active coating. The method comprises the steps of preparing an SBA-15 mesoporous molecular sieve; preparing an Mn-Ce / SBA-15 mesoporous molecular sieve, preparing a catalyst precursor, and preparing a catalyst finished product. The catalysis performance of the catalyst is high; the medium-low temperature denitration efficiency is high; the active temperature window is wide; the H2O poisoning resistant performance and SO2 poisoning resistant performance are good; the catalyst service life reduction due to the influence of SO2 in the flue gas is not liable to occur.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

SO2 toxicity-resistant fuel cell oxygen-reduction nobel metal catalyst and preparation method and application thereof

The invention discloses a SO2 toxicity-resistant fuel cell oxygen-reduction nobel metal catalyst and preparation method and application thereof. In the SO2 toxicity-resistant fuel cell oxygen-reduction nobel metal catalyst, the absorption energy of a SO2 oxide on Pt is changed by a catalyst metal core modification surface layer Pt electron structure, the competitive absorption with active oxygen-containing particle is reduced, and active sites can be timely released. With the SO2 toxicity-resistant fuel cell oxygen-reduction nobel metal catalyst disclosed by the invention, the toxicity-resistant performance of the catalyst is improved on the basis that the oxygen-reduction activity is not reduced; and compared with commercial Pt / C, the catalyst prepared by the invention has the advantagesthat the SO2 toxicity-resistant performance is obviously improved, and the commercial development of a fuel cell is favorably promoted.

Owner:HARBIN INST OF TECH

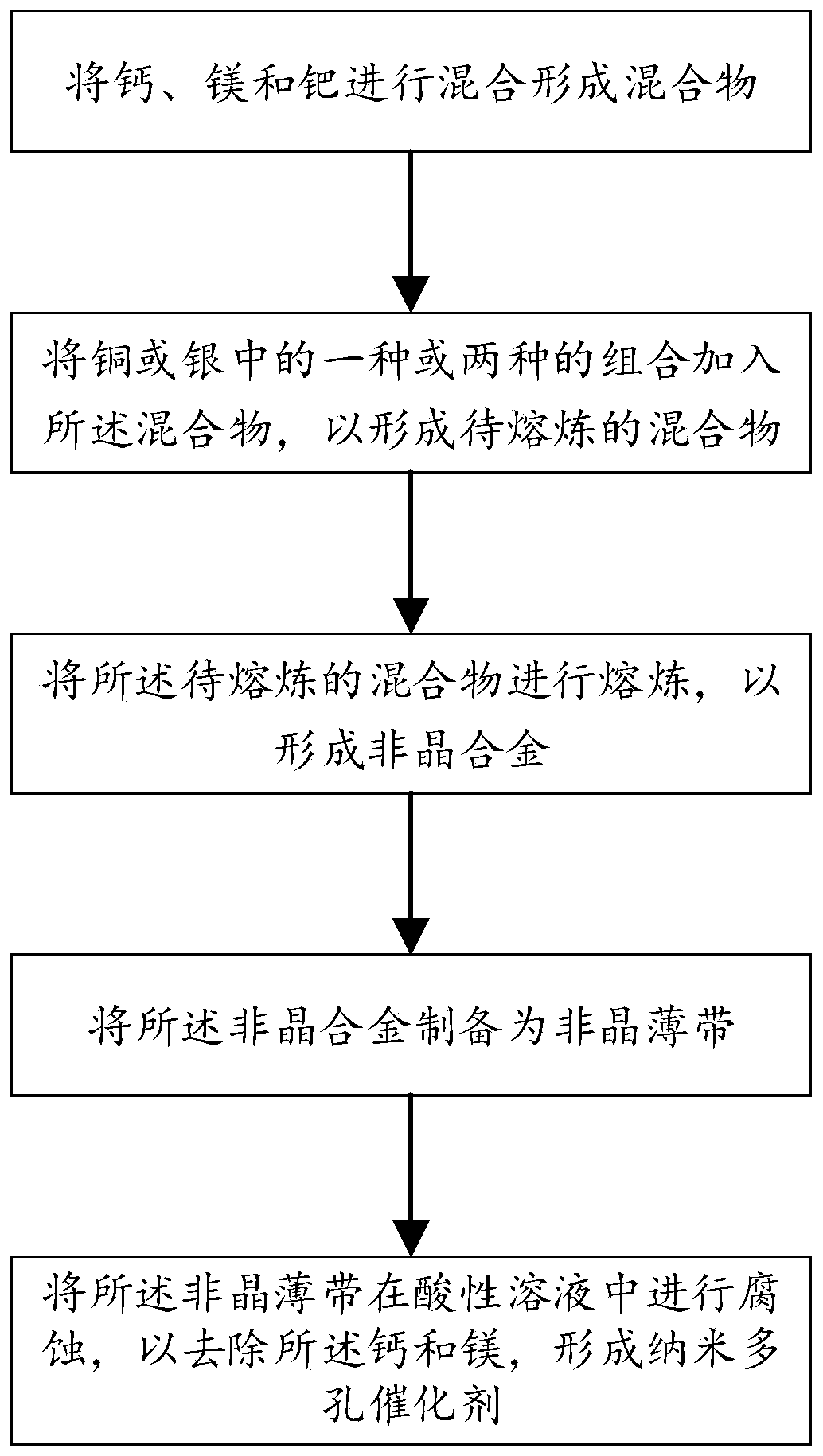

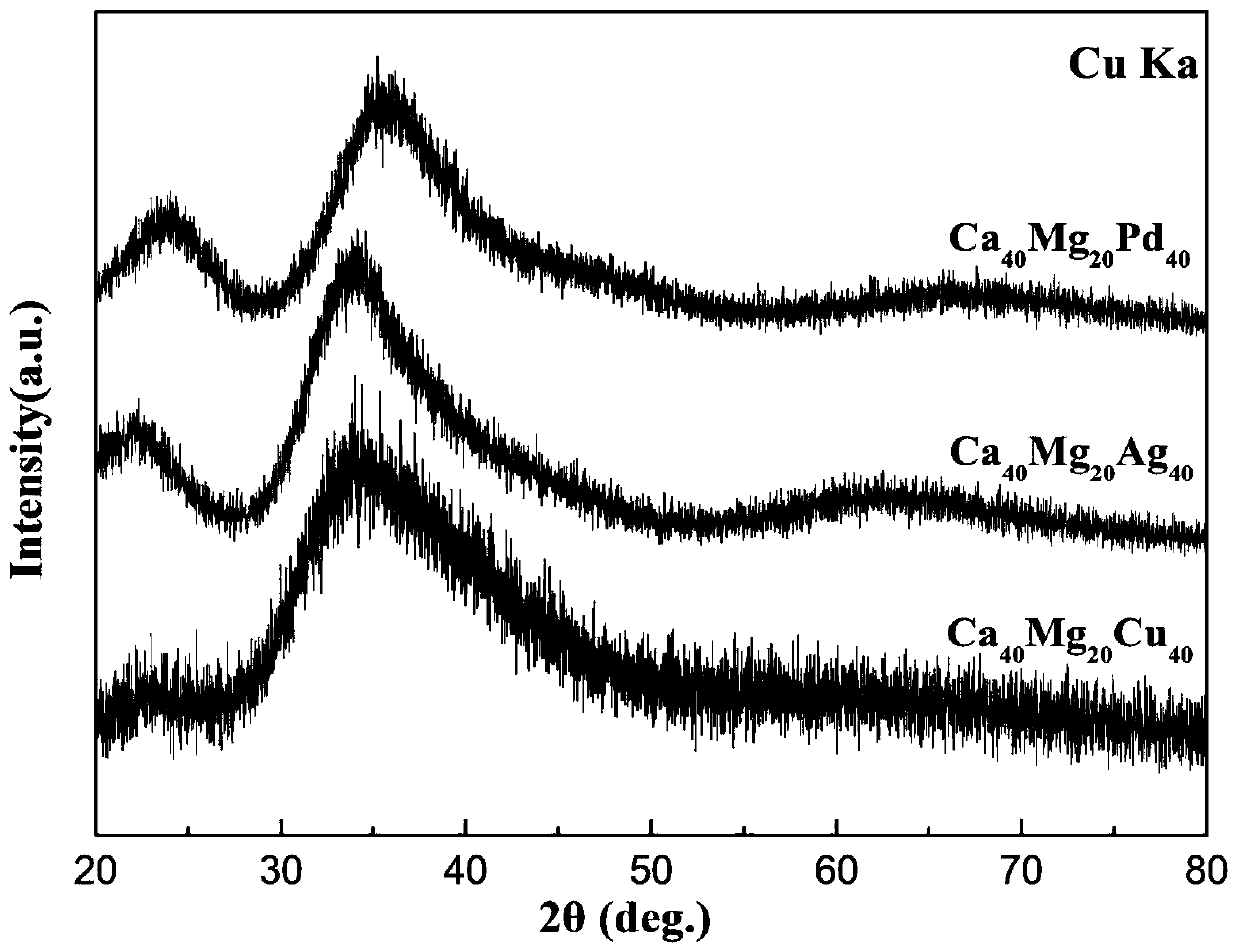

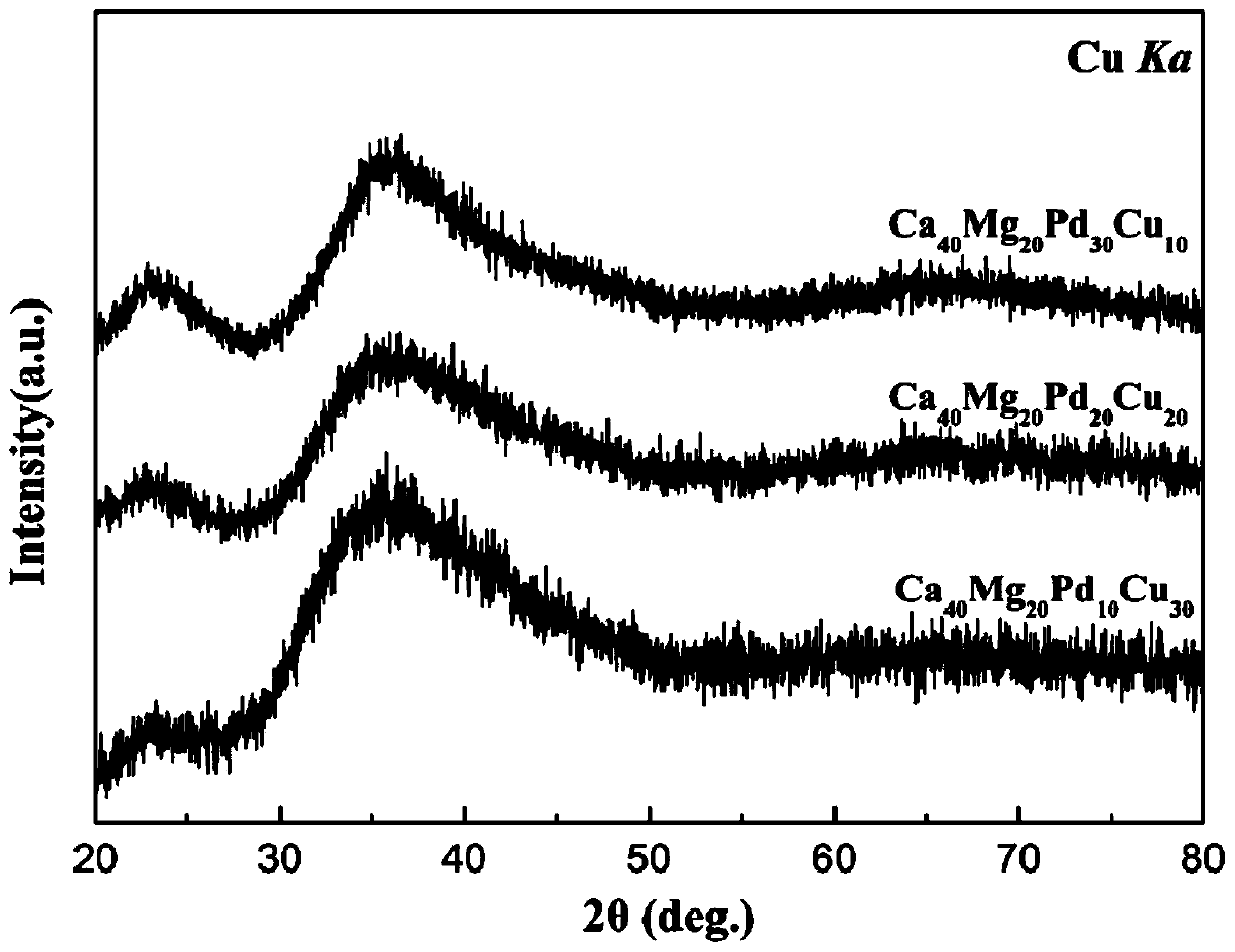

Preparation method of fuel cell catalyst

InactiveCN111200133AReduced strap sizeImprove methanol catalytic activity and anti-poisoning abilityCell electrodesFinal product manufactureCatalytic testEngineering

The invention provides a preparation method of a fuel cell catalyst. The preparation method comprises the steps of mixing calcium, magnesium and palladium to form a mixture; adding one or a combination of two of copper or silver to the mixture to form a mixture to be smelted; smelting the mixture to be smelted to form an amorphous alloy; preparing the amorphous alloy into an amorphous ribbon; andcorroding the amorphous ribbon in an acidic solution to remove calcium and magnesium so as to form the nano-porous catalyst. The catalyst prepared according to the preparation method of the fuel cellcatalyst has a high specific surface area; when the catalyst is applied to a methanol fuel cell anode catalyst, an electro-catalysis test result shows that the addition of Cu and Ag elements not onlycan significantly improve the methanol catalytic activity and poisoning resistance of nano-porous Pd, but also can reduce the cost of the catalyst, and the catalyst has a good application prospect inthe aspect of the methanol fuel cell anode catalyst.

Owner:内蒙古安陈碳科技有限公司 +1

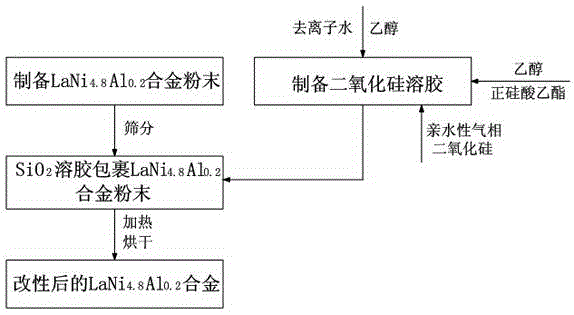

Method for enhancing performance of LaNi4.8Al0.2 alloy to resist CO, CO2 and air poison and anti-pulverization performance of alloy

The invention discloses a method for enhancing the performance of LaNi4.8Al0.2 alloy to resist CO, CO2 and air poison and the anti-pulverization performance of the alloy, which comprises the steps of S1: preparing LaNi4.8Al0.2 alloy powder; S2: sieving the LaNi4.8Al0.2 alloy powder; S3: mixing ethyl alcohol with deionized water to obtain a mixed solution; S4: adding concentrated hydrochloric acid to adjust the pH value and obtain a first mixture; S5: mixing tetraethoxysilane with ethyl alcohol to obtain a second mixture; S6: mixing the first mixture with the second mixture to obtain a third mixture; S7: standing, and heating the third mixture to volatilize the ethyl alcohol; S8: adding hydrophilic gaseous phase silicon dioxide to the third mixture so as to obtain a silicon dioxide sol; S9: adding the LaNi4.8Al0.2 alloy powder to the silicon dioxide sol so as to obtain paste; S10: heating and drying the paste. According to the method disclosed by the invention, the problem that the LaNi4.8Al0.2 alloy is poor in anti-pulverization performance and poor in anti-poison capability is solved, the use stability of the LaNi4.8Al0.2 alloy is enhanced, and the service life of the LaNi4.8Al0.2 alloy is prolonged.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

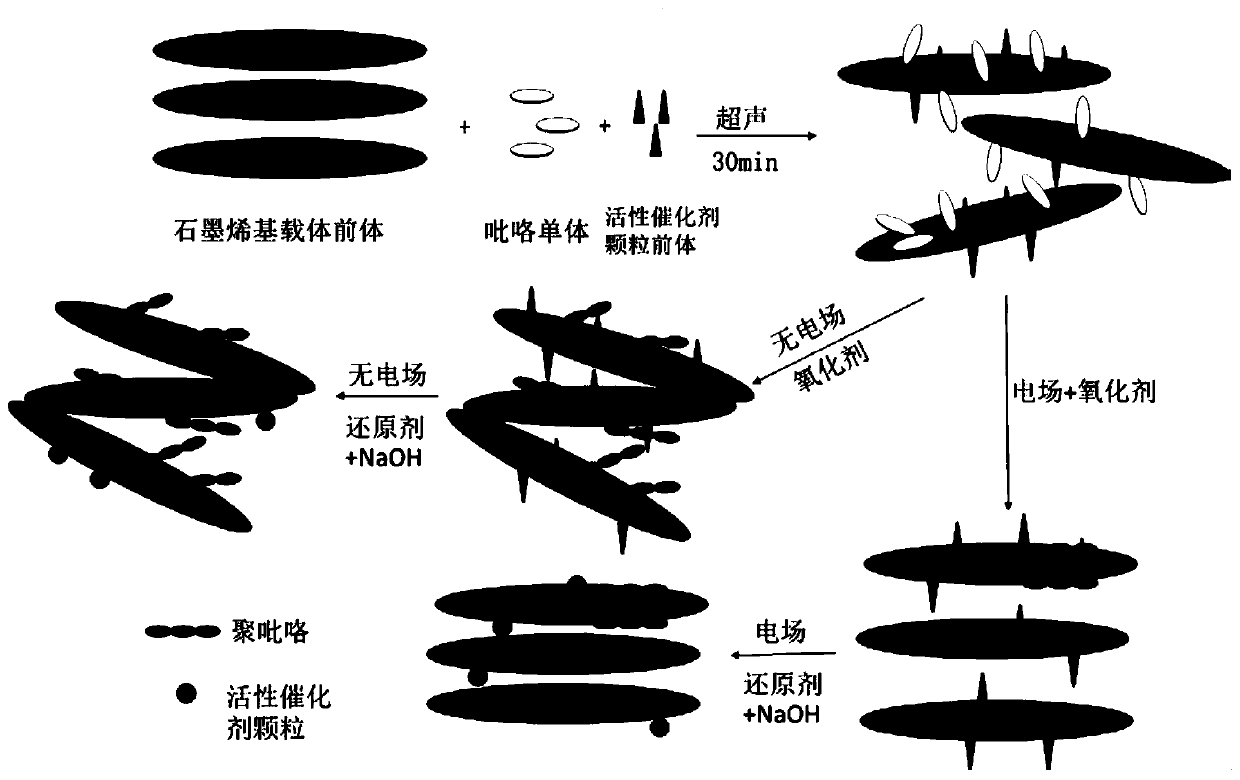

Graphene-based catalyst as well as preparation method and application thereof

ActiveCN111082081AImprove adsorption capacityAvoid migration mergesCell electrodesFuel cellsPtru catalystPolypyrrole

The embodiment of the invention discloses a graphene-based catalyst as well as a preparation method and application thereof. The graphene-based catalyst comprises a graphene-based carrier, a polypyrrole spacer and active catalyst particles loaded on the graphene-based carrier, the polypyrrole spacer is positioned between the two adjacent layers of graphene-based carriers; the polypyrrole spacers are arranged in an oriented manner; the graphene-based carriers are directionally arranged; the oriented arrangement direction of the polypyrrole spacers is the same as the oriented arrangement direction of the graphene-based carrier, the mass ratio of the graphene-based carrier to the polypyrrole spacers is 95: 5-70: 30, and the mass of the active catalyst particles accounts for 5-25% of the totalmass of the catalyst. The catalyst is prepared by applying an electric field. The catalyst prepared by the invention has the excellent characteristics of strong catalytic performance, high stability,strong conductivity, strong CO toxicity resistance and the like.

Owner:深圳氢时代新能源科技有限公司

Palladium/nitrogen-doped titanium dioxide electrocatalyst as well as preparation method and application thereof

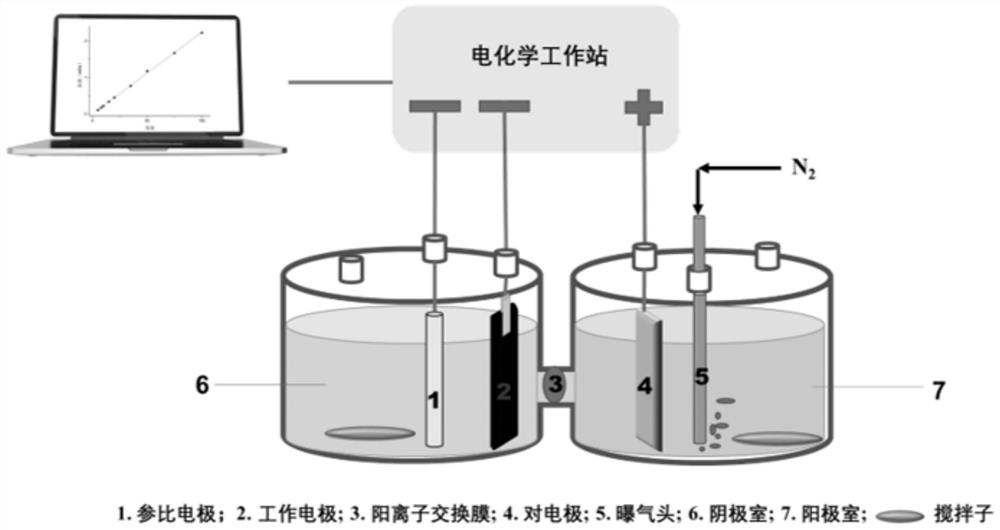

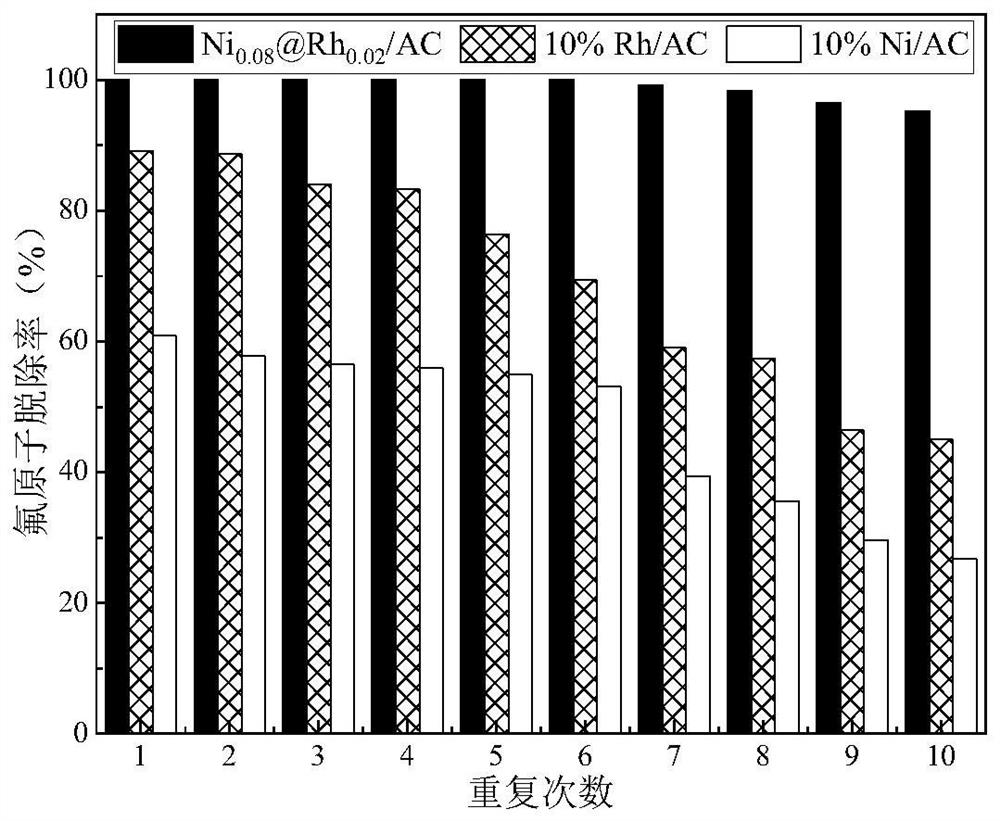

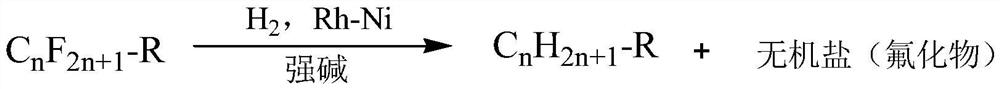

ActiveCN111617795ABalance pollutionAbility to balance productsWater contaminantsCatalyst activation/preparationElectronic structureNanoparticle

The invention discloses a palladium / nitrogen-doped titanium dioxide electrocatalyst as well as a preparation method and application thereof. The palladium / nitrogen doped titanium dioxide electrocatalyst comprises an N-TiO2 carrier and Pd nano particles, the N-TiO2 carrier is TiO2 doped with N, and the Pd nano particles are loaded on the N-TiO2 carrier. According to the Pd / N-TiO2 electrocatalyst, aPd electronic structure is optimized through regulation and control of a semiconductor energy band structure, so that the capacity of adsorbing chlorine-containing pollutants and products is balanced, the poisoning resistance of the Pd / N-TiO2 electrocatalyst is improved, the dechlorination performance of the Pd / N-TiO2 electrocatalyst is enhanced, and compared with a Pd / TiO2 electrocatalyst, the Pd / N-TiO2 electrocatalyst is obviously improved in activity and stronger in dechlorination performance.

Owner:CHONGQING TECH & BUSINESS UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com