Nanoporous structure composite material and preparation method and alcohol catalytic property application

A nanoporous and composite material technology, applied in structural parts, fuel cells, electrochemical generators, etc., can solve the problems of insufficient Pd-based catalysts, and achieve good electrocatalytic performance, easy control, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] with Cu 64 Ti 30 PD 5 Ni 1 Preparation of Nanoporous CuO / TiO from Amorphous Alloy Ribbons 2 / Pd-NiO composite material, the steps are as follows:

[0026] Step 1: According to the content of Ni at 1%, Cu at 64%, Ti at 30%, and Pd at 5%, an amorphous alloy strip is prepared.

[0027] Step 2: Cut the amorphous alloy strip obtained in Step 1 into strips with a thickness of 20um, a width of 20mm, and a length of 2cm.

[0028] Step 3: Take 0.05 g of the amorphous alloy strip obtained in Step 2 and 30 ml of aqueous hydrochloric acid solution with a molar concentration of 0.75 and place them together in a closed container, and place them in a drying oven with a reaction temperature of 90° C. for 5 hours.

[0029] Step 4. Wash the sample obtained after the reaction in step 3 with deionized water and absolute ethanol repeatedly, and dry it in a 40°C drying oven. The sample obtained is CuO / TiO with a nanoporous structure. 2 / Pd-NiO composites.

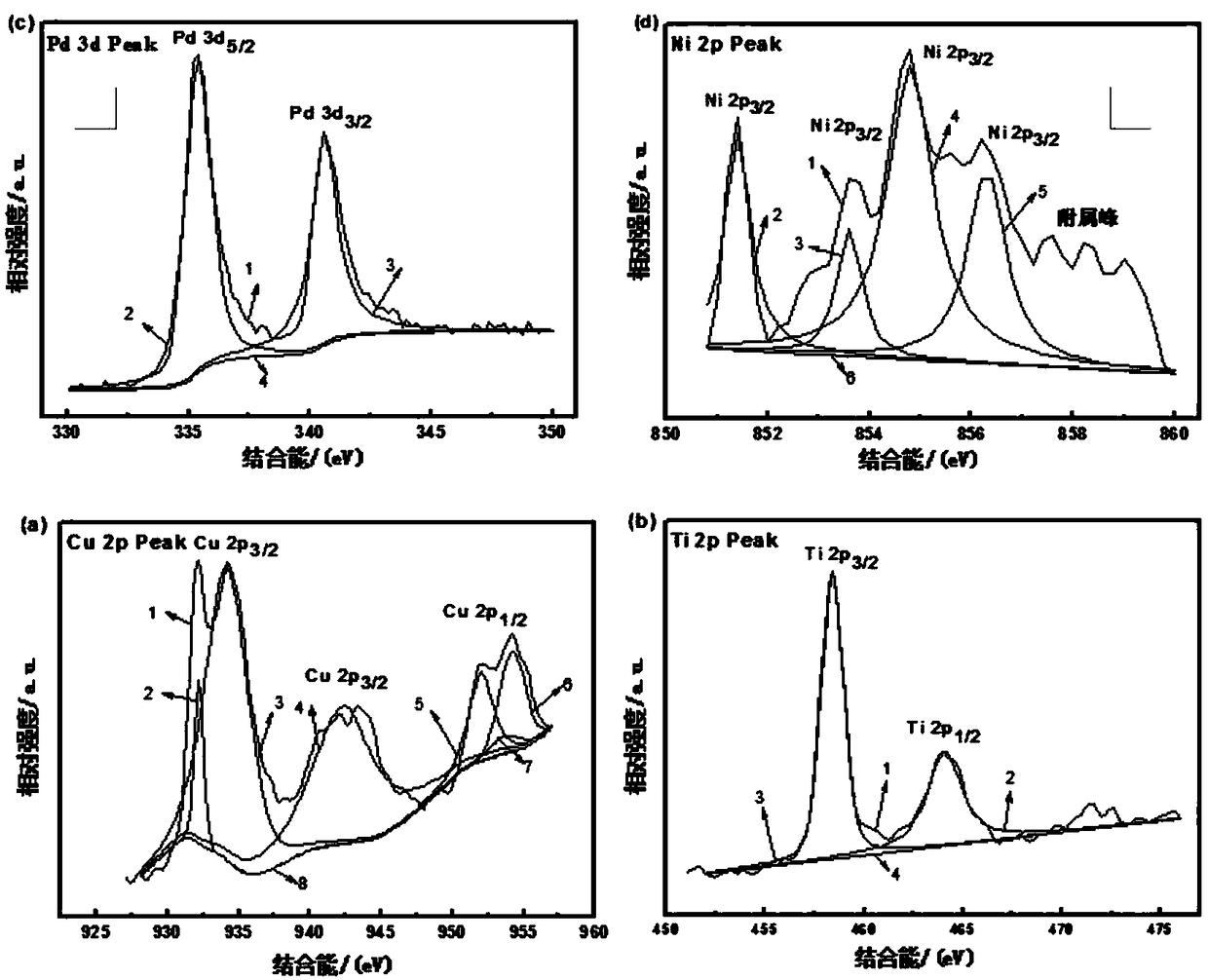

[0030] figure 1 (a) shows ...

Embodiment 2

[0036] with Cu 62 Ti 30 PD 5 Ni 3 Preparation of Nanoporous CuO / TiO from Amorphous Alloy Ribbons 2 / Pd-NiO composite material, identical with step two and three in embodiment 1, only be that the atomic percent content of Cu and Ni in step one is different, namely:

[0037] Step 1: Prepare an amorphous alloy strip according to the content of Ni at 3%, Cu at 62%, Ti at 30%, and Pd at 5%.

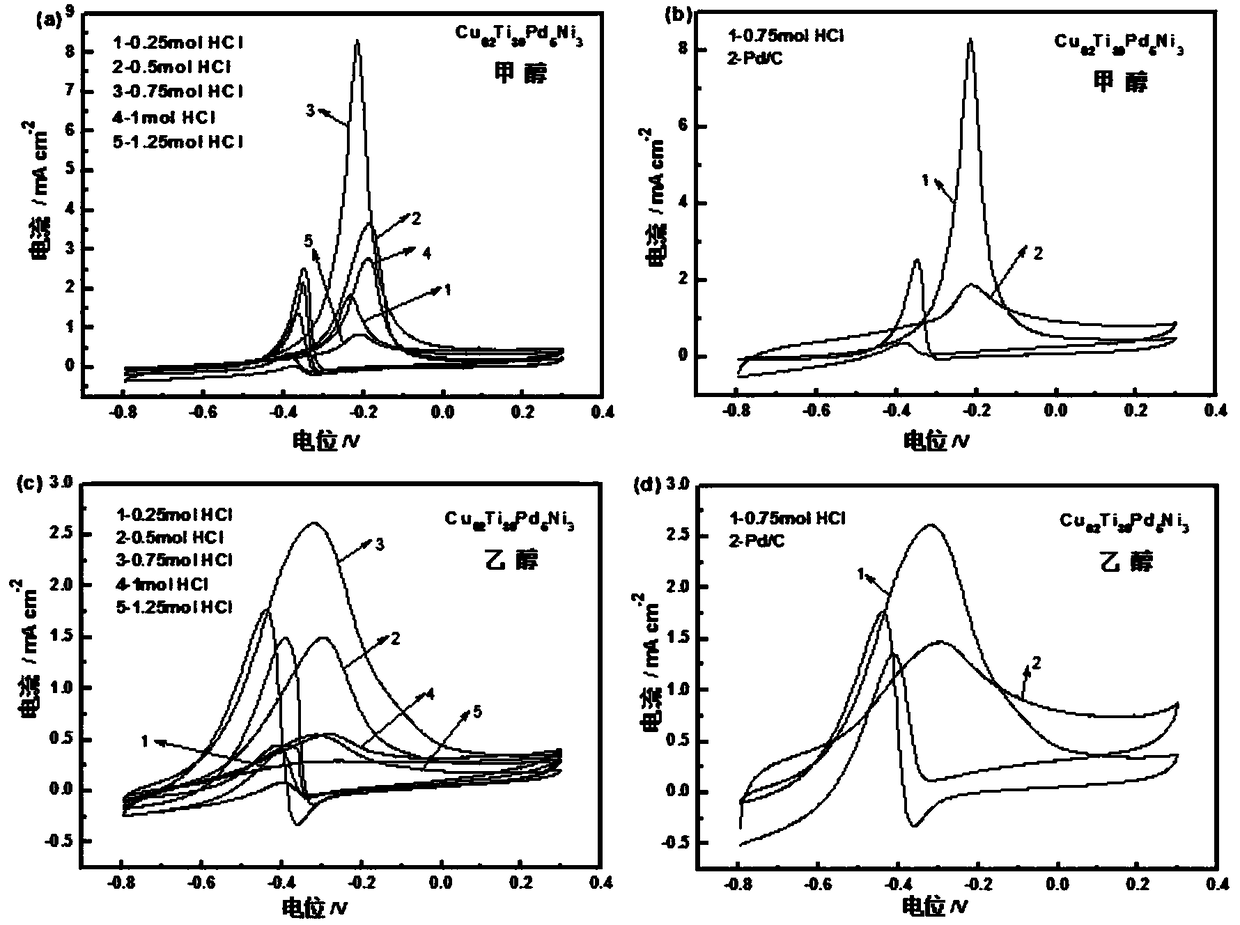

[0038] figure 1 (b) shows the CuO / TiO with nanoporous structure prepared by Example 2 2 / Pd-NiO composite material microscopic morphology photograph; The CuO / TiO that this embodiment prepares 2 / Pd-NiO composites were used in the performance test of electrocatalytic methanol and ethanol under alkaline conditions, figure 2 (a), (b) respectively show the CuO / TiO obtained in Example 2 2 Cyclic voltammetry curves of / Pd-NiO composites for methanol and ethanol.

Embodiment 3

[0040] with Cu 58 Ti 30 PD 5 Ni 7 Preparation of Nanoporous CuO / TiO from Amorphous Alloy Ribbons 2 / Pd-NiO composite material, identical with step two and three in embodiment 1, only be that the atomic percent content of Cu and Ni in step one is different, namely:

[0041] Step 1: According to the content of Ni at 7%, Cu at 58%, Ti at 30%, and Pd at 5%, an amorphous alloy strip is prepared.

[0042] figure 1 (c) in shows the CuO / TiO of nanoporous structure prepared by embodiment 3 2 / Pd-NiO composite microstructure photos. The CuO / TiO prepared in this embodiment 2 / Pd-NiO composites were used in the performance test of electrocatalysis of methanol and ethanol under alkaline conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com