Preparation method of supported binary alloy direct alcohol fuel cell catalyst with porous hollow sphere structure

A binary alloy, fuel cell technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of nano-scale catalyst Pt particle poisoning, catalyst preparation cost Problems such as high and alcohol fuel transmission obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

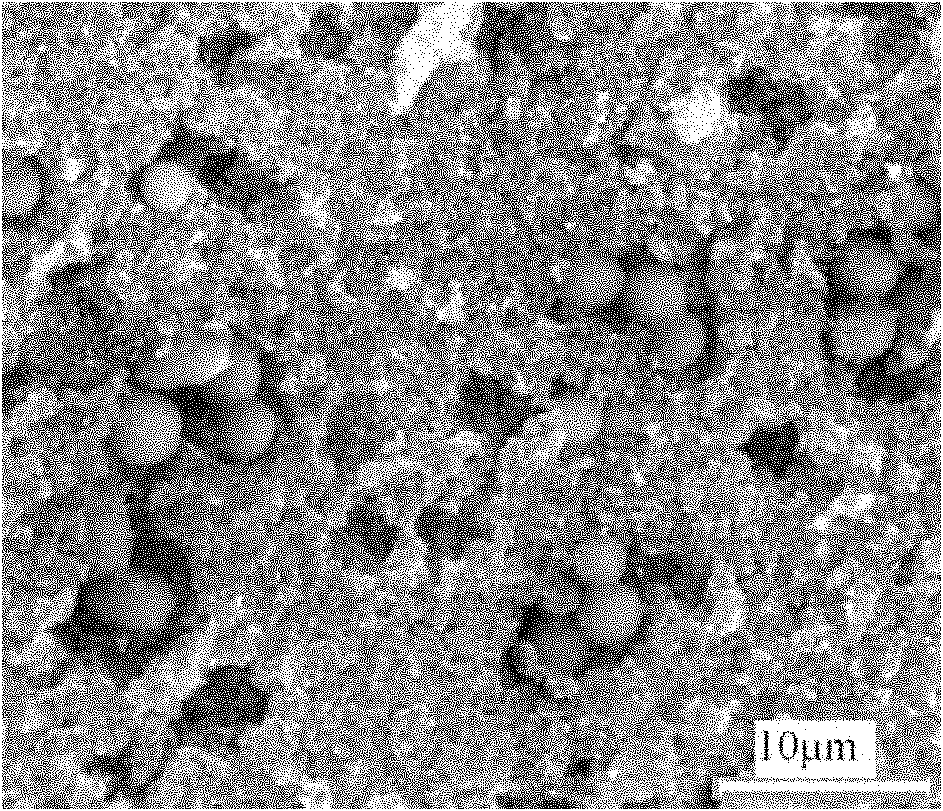

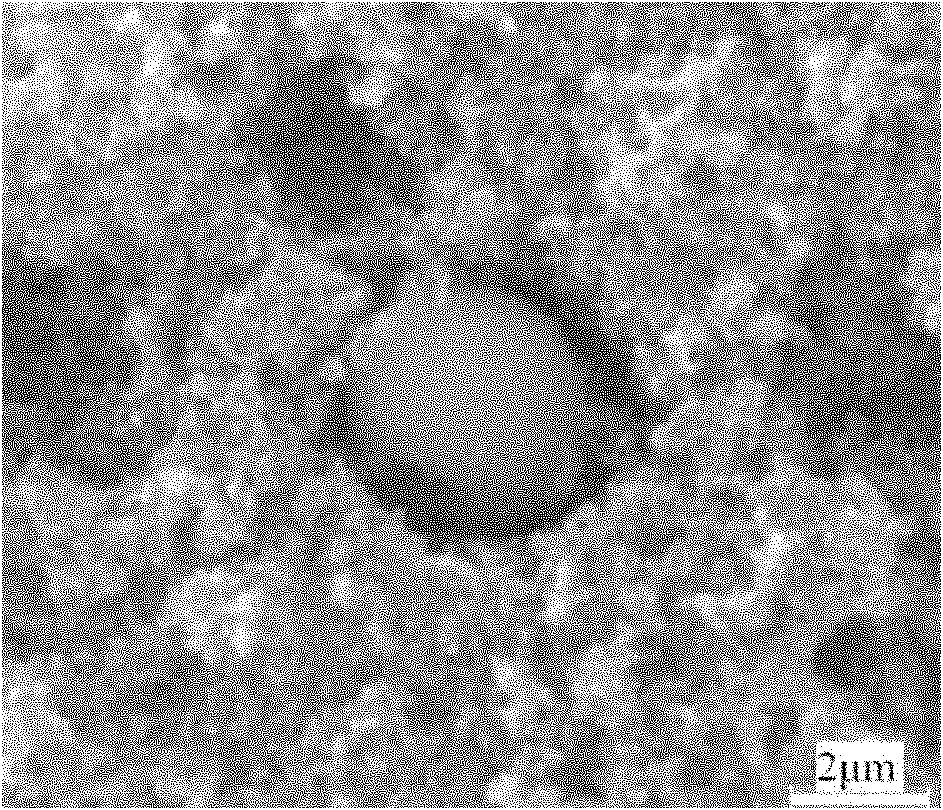

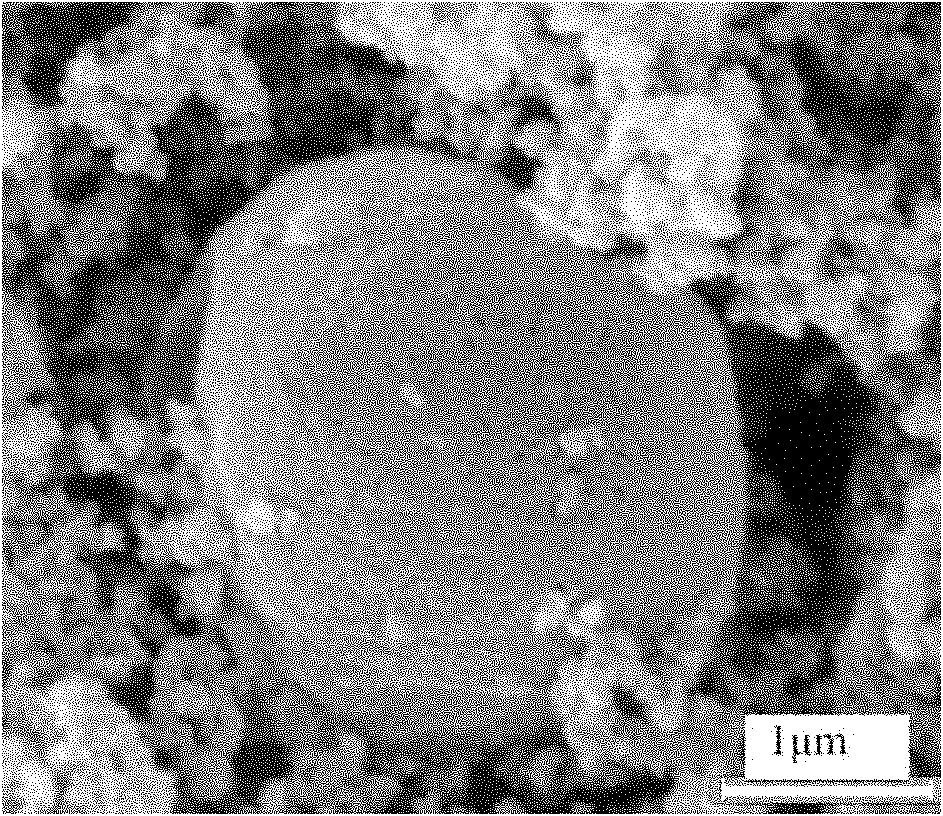

Image

Examples

specific Embodiment approach 1

[0007] Embodiment 1: In this embodiment, the preparation method of binary alloy-supported porous hollow sphere structure direct alcohol fuel cell catalyst is realized according to the following steps: 1. Anionic surfactant and carrier are dissolved in polyhydric alcohol, Mechanical stirring after ultrasonic treatment to obtain a uniform mixture, the concentration of the anionic surfactant in the mixture is 0.5 to 3 times the critical micelle concentration, the carrier is XC-72 carbon black, carbon nanotubes, mesoporous carbon or carbon fiber , the anionic surfactant has stearic acid, oleic acid, lauric acid, sodium lauryl sulfate, sodium lauryl sulfate, sodium dodecylbenzenesulfonate or glycocholic acid; 20% to 60% of the total loading of the metal element in the bulk salt and the complex. Add the metal precursor salt and the complex to the above mixture in sequence to form a mixed slurry, wherein the metal precursor salt is PdCl 2 , PtCl 4 , AuCl 3 , AgNO 3 , IrCl 3 or Rh...

specific Embodiment approach 2

[0009] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the polyhydric alcohol in Step 1 is ethylene glycol, propylene glycol, glycerol, 1,3-butanediol or pentaerythritol. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the concentration of the surfactant in the mixture described in step 1 is 0.5 to 3 times the critical micelle concentration. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com