Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131 results about "CO poisoning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon monoxide (CO) poisoning occurs when carbon monoxide gas is inhaled. CO is a colorless, odorless, highly poisonous gas that is produced by incomplete combustion.

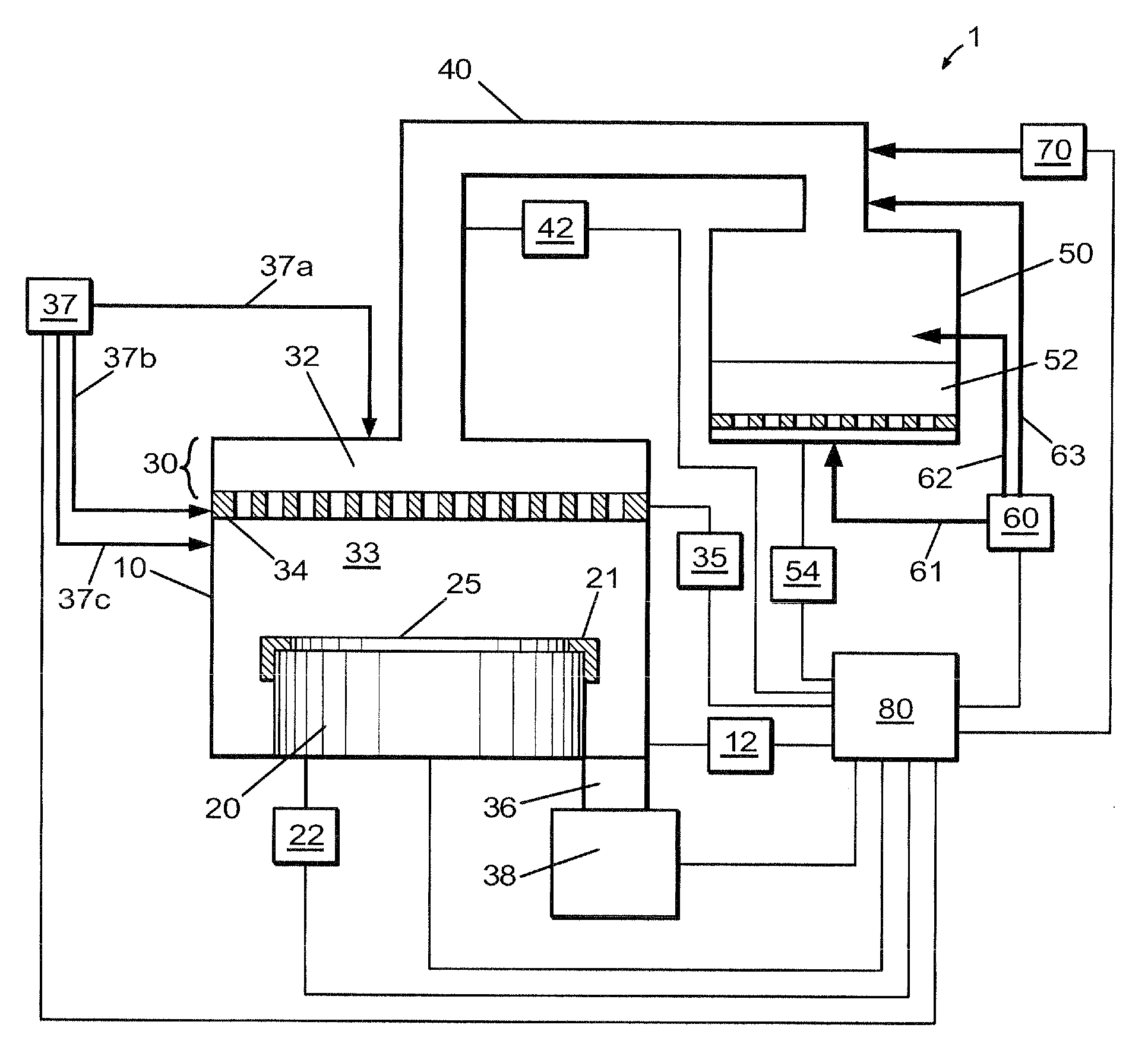

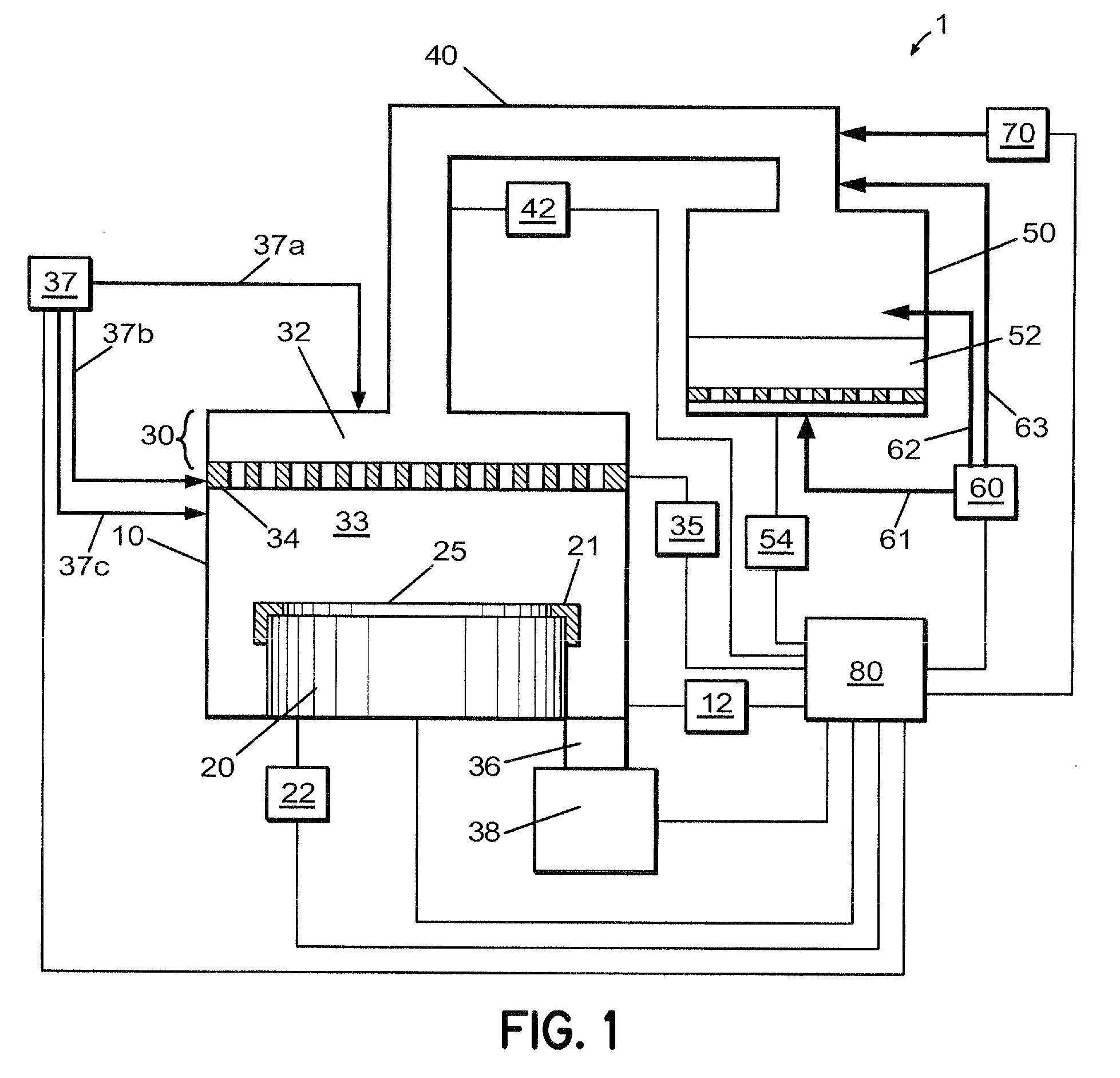

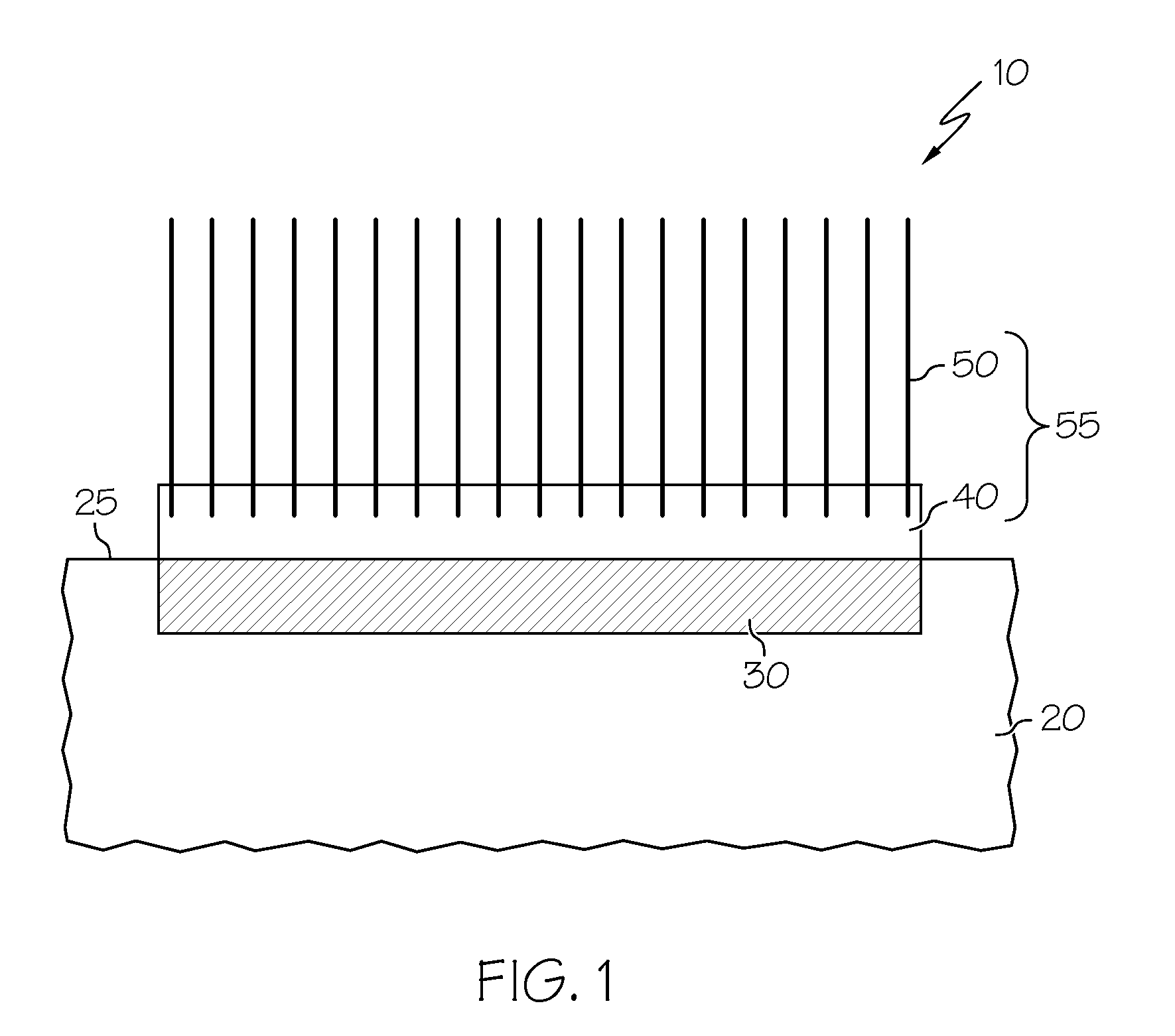

Method and apparatus for reducing carbon monoxide poisoning at the peripheral edge of a substrate in a thin film deposition system

InactiveUS20070234955A1Reduce CO poisoningSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCO poisoningOptoelectronics

A method and apparatus is described for reducing CO poisoning of a thin metal film formed on a substrate using a metal carbonyl precursor. The thin metal film is formed on the substrate resting on a substrate holder in a thin film deposition system. The substrate holder comprises a shield ring positioned on a peripheral edge of the substrate holder and configured to surround the peripheral edge of the substrate, whereby the shield ring reduces the production of CO by-products at the peripheral edge of the substrate.

Owner:TOKYO ELECTRON LTD

Island-shaped porous tri-metal nano rod with gold core/silver-platinum alloy shell structure and method for preparing same

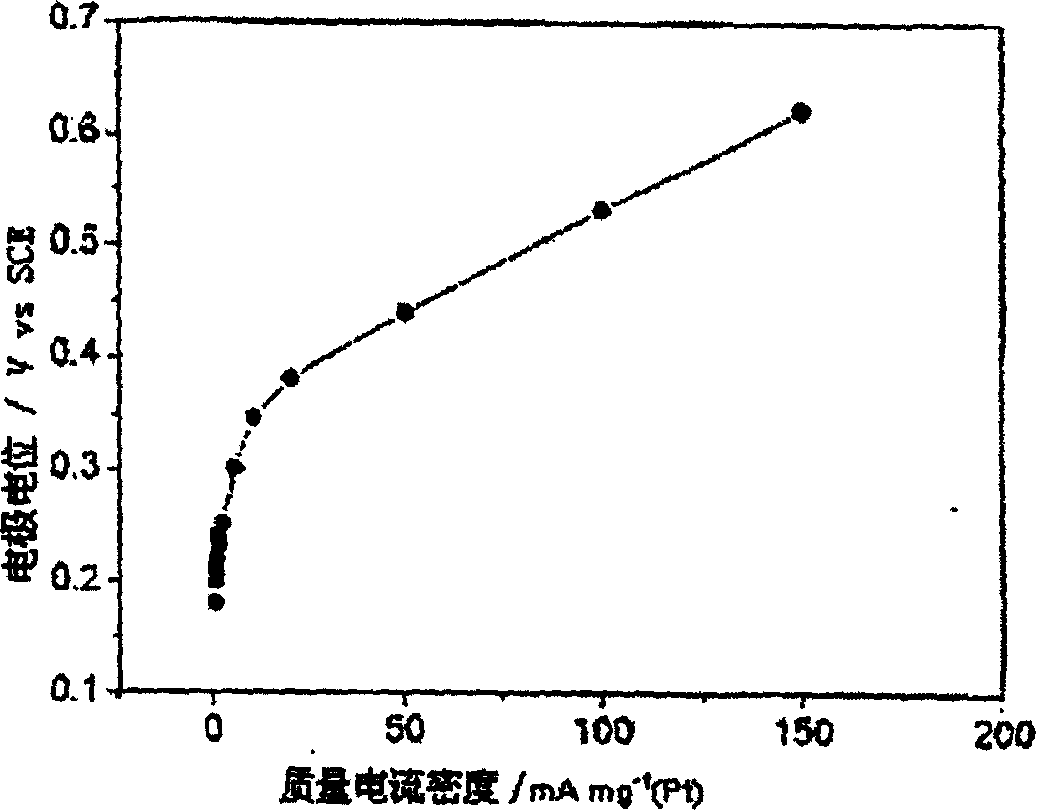

InactiveCN101623762AEasy to achieve topographyEasy to achieve component contentCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPlatinumMethanol fuel

The invention relates to an island-shaped porous tri-metal nano rod with a gold core / silver-platinum alloy shell structure, which adopts the gold core / silver-platinum alloy shell structure formed by a cylindrical gold nano rod core and an island-shaped porous silver-platinum alloy shell coated on the outer surface of the cylindrical gold nano rod core. The preparation method comprises the following steps of preparation of gold crystal seed solution, preparation and purification of gold nano rod solution, preparation of solution of a platinum coated gold core / platinum shell nano rod, preparation of island-shaped porous tri-metal nano rod with the gold core / silver-platinum alloy shell structure and the like. The tri-metal nano rod has the advantages of stronger ability of catalyzing the methanol oxidation, stronger CO poisoning resistant ability, lower cost and the like, and can be widely used for preparing a methanol fuel battery catalyst; and the preparation method has the advantages of simplicity, low consumption, environmental protection, and high efficiency, and by the method, the island-shaped porous tri-metal nano rod with the gold core / silver-platinum alloy shell structure with high yield and narrow size distribution can be obtained.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

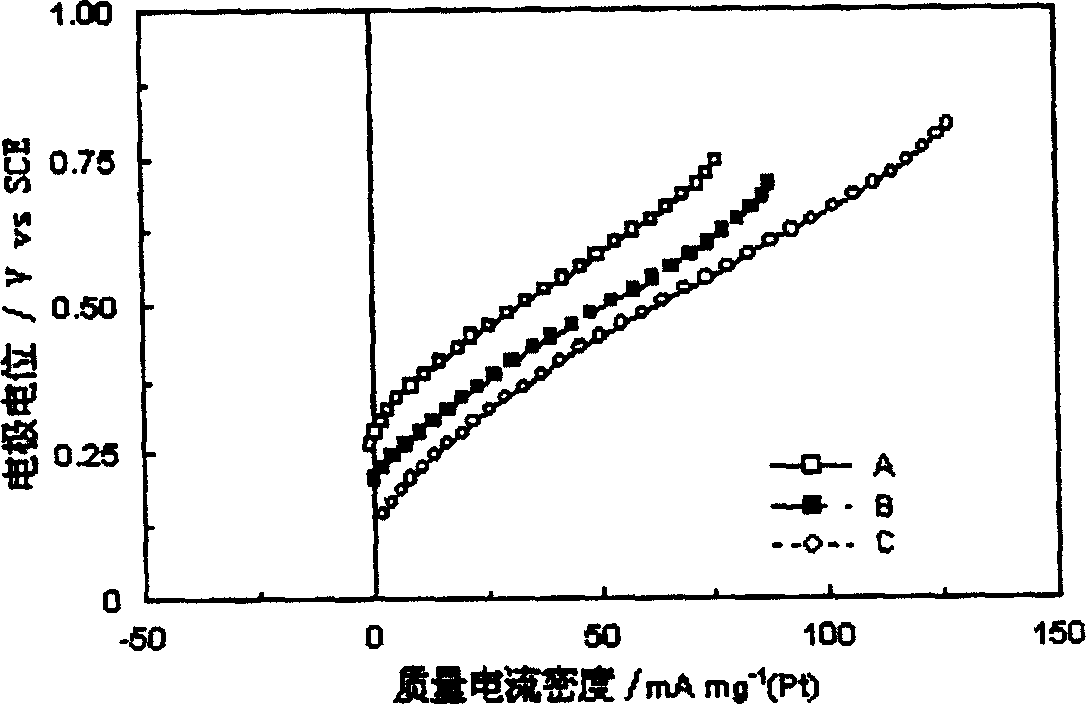

Metal-free vertically-aligned nitrogen-doped carbon nanotube catalyst for fuel cell cathodes

ActiveUS20100183950A1High catalytic activityImprove long-term stabilityFuel cell auxillariesActive material electrodesConductive polymerCO poisoning

Metal-free fuel cell cathodes having a catalytic layer of vertically-aligned, nitrogen-doped carbon nanotubes (VA-NCNTs) are provided. The fuel cell cathodes comprise a cathode body, a binder layer attached to an outer surface of the cathode body, and the catalytic layer, which is supported by the binder layer. The binder layer may comprise a composite of a conductive polymer and doped or undoped nonaligned carbon nanotubes. In a method for forming the fuel cell cathodes, the VA-NCNTs may be formed by pyrolysis of a metalorganic compound and integration of the nanotubes with nitrogen. The binder layer is applied, and the resulting supported nanotube array may be attached to the cathode body. Fuel cells comprising the fuel cell cathodes are provided. The fuel cell cathodes comprising VA-NCNTs demonstrate superior oxygen-reduction reaction performance, including for electrocatalytic activity, operational stability, tolerance to crossover effects, and resistance to CO poisoning.

Owner:UNIV OF DAYTON

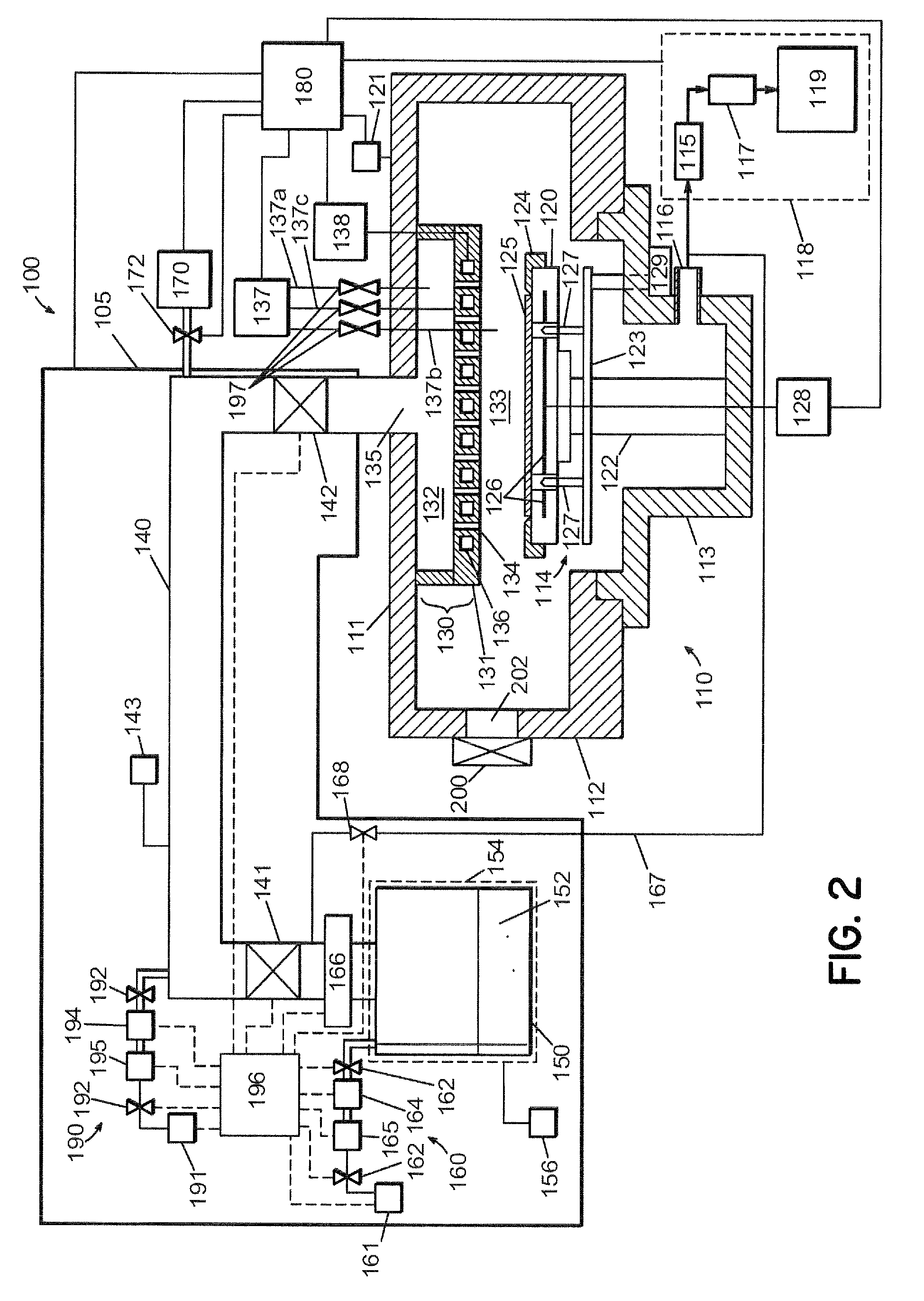

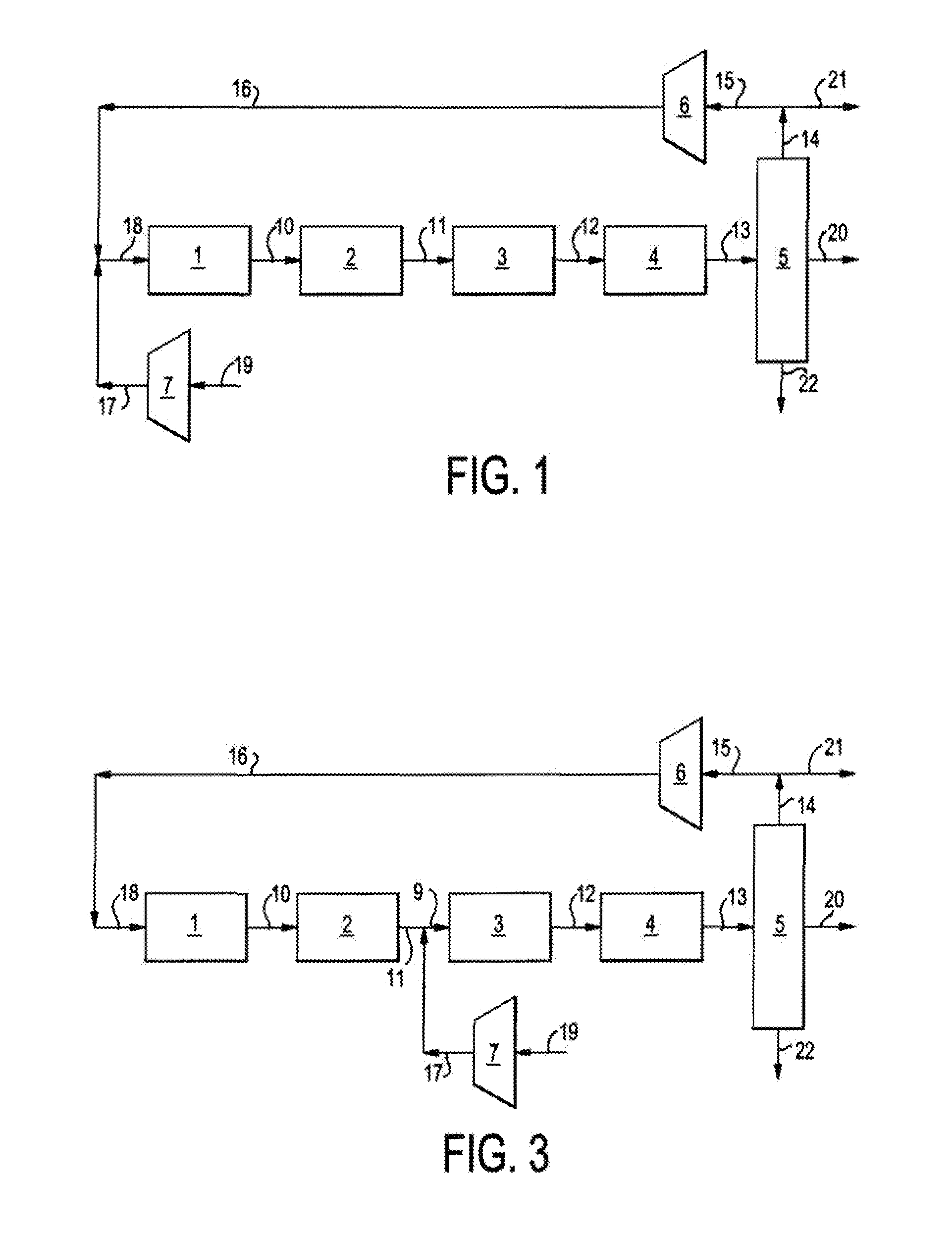

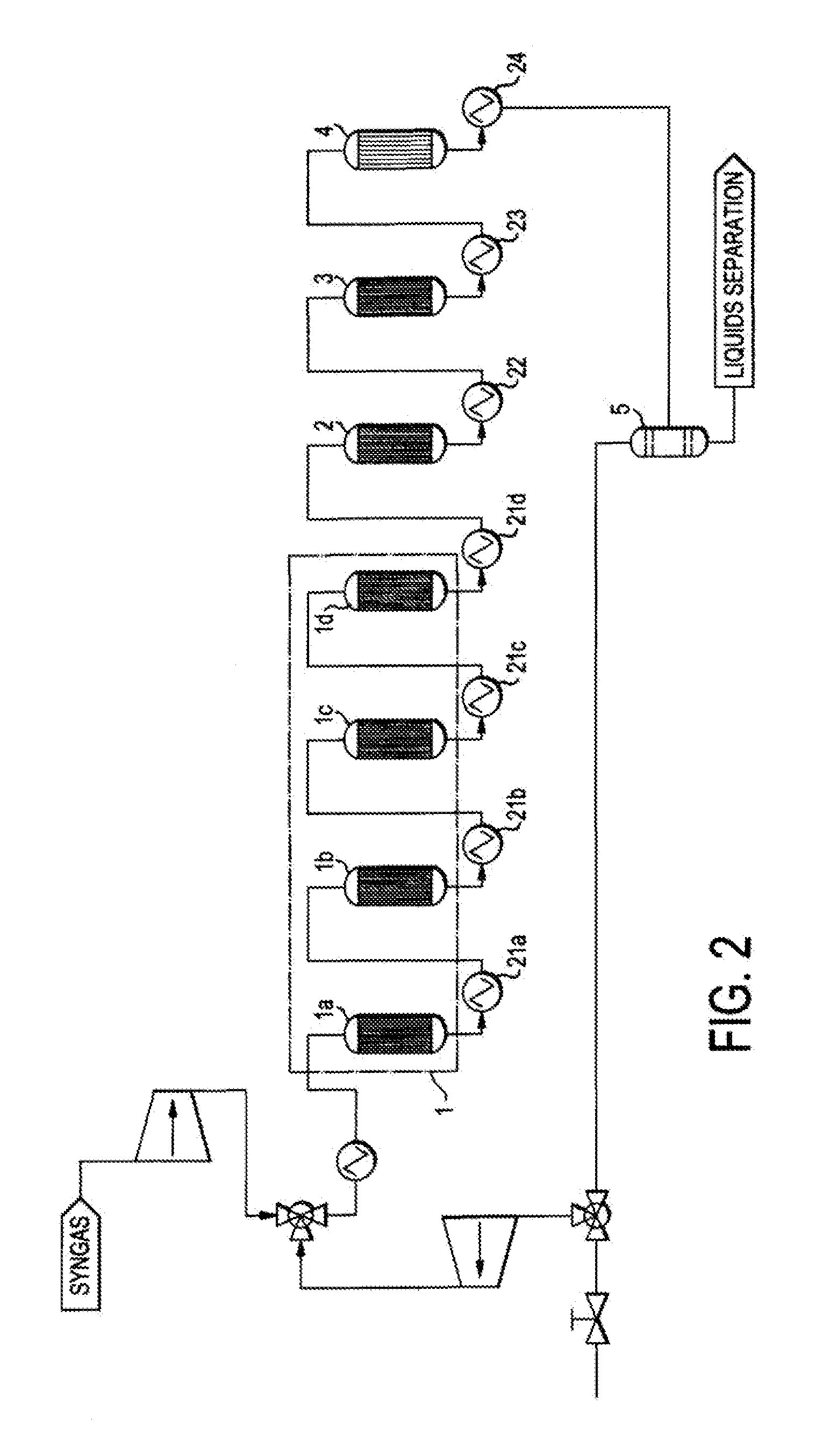

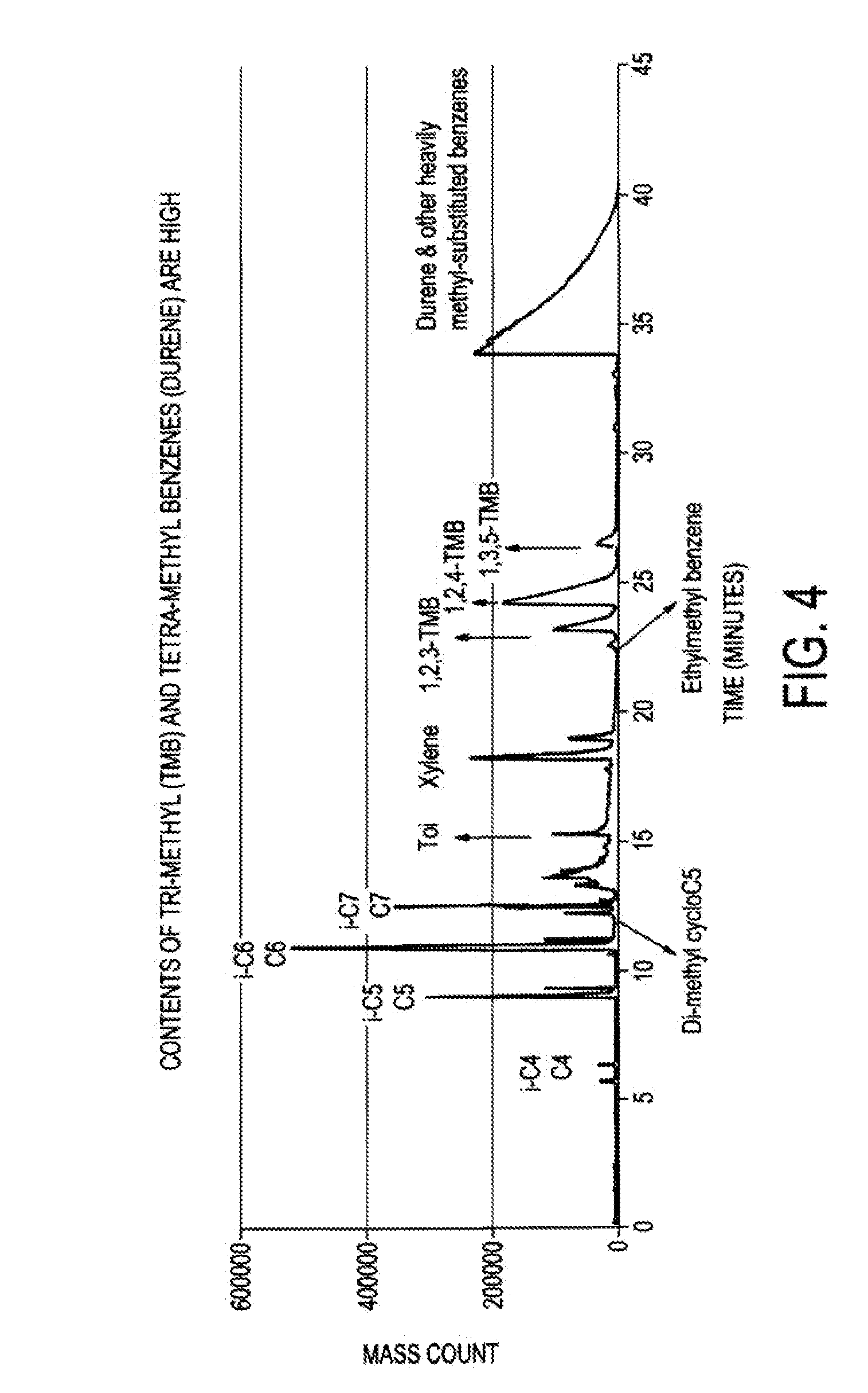

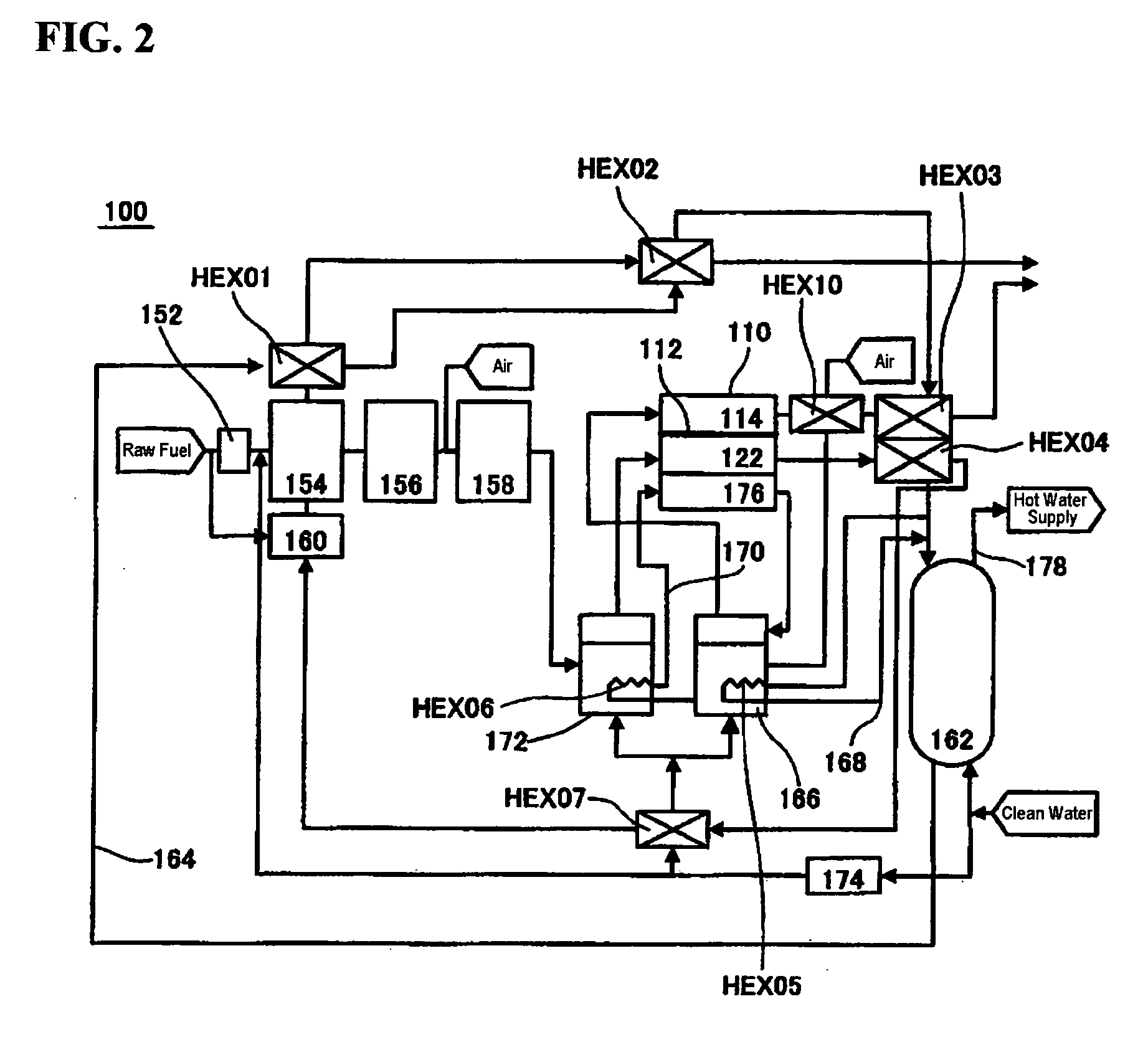

Single loop multistage fuel production

ActiveUS20120116137A1Speed up the conversion processImprove utilization efficiencyRefining to change hydrocarbon structural skeletonHydroxy compound preparationLiquid fuelHigh pressure

Synthetic fuels are produced from synthesis gas in a four-stage reactor system with a single recycle loop providing the requisite thermal capacity to moderate the high heat release of the reactions and to provide the reactants and reaction environments for the efficient operation of the process. The first stage converts a portion of the synthesis gas to methanol, the second stage converts the methanol to dimethylether, the third stage converts the methanol and dimethylether to fuel and the fourth stage converts the high melting point component, durene, and other low volatility aromatic components such as tri- andtetra-methylbenzenes to high octane branched paraffins. The four-stage catalyst used for hydrotreating is resistant to CO poisoning. The reactions i produce water as a side product that is carried through to a high pressure separator after the fourth stage. The streams from the separator are a liquid fuel stream, a water stream and a gaseous stream that contains light hydrocarbon gases and the unreacted synthesis gas. The larger part of this gas stream is recycled to the inlet of the first stage and mixed with the fresh synthesis gas stream. Alternatively, the fresh synthetic gas stream is mixed with the product of the second stage. The smaller part of the gas stream from the separator is sent to hydrocarbon recovery and to fuel gas used for providing preheat of various streams. The liquid fuel is sent for blending into fuel products, such as gasoline, jet fuel, or diesel, and the water stream can be sent, for example, to the synthesis gas producing plant for steam generation.

Owner:BLUESCAPE CLEAN FUELS LLC

Method for preparing carbon-supported nano Pt-M fuel cell catalyst

ActiveCN101912778AGood dispersionSimple processCell electrodesMetal/metal-oxides/metal-hydroxide catalystsElectro catalystPlatinum

The invention provides a method for preparing a carbon-supported nano Pt-M fuel cell catalyst. The method comprises the following steps of: (1) dissolving H2PtCl6.6H2O and an M compound with alcohol respectively, combining the dissolved H2PtCl6.6H2O and M compound and ultrasonically processing the mixture for 10 to 20 minutes at the temperature of between 25 and 60 DEG C; (2) performing dry-dipping on a Pt-M active precursor prepared in the step (1) on a carbon support and dehydrating the carbon support with microwave to a constant weight; (3) adding water into the carbon support obtained by the step (2) for pasting and adding a reducing agent into the carbon support for reduction; and (4) filtering, washing and dehydrating the obtained product with microwave to obtain a Pt-M / C catalyst. The nano Pt-M binary alloy fuel cell catalyst prepared by the method of the invention solves the problems of difficult control over graininess and dispersion degree, high platinum load, low adsorption rate, agglomeration and the like existing in the conventional method for preparing an electro-catalyst and has the advantages of simple process, environmental friendliness, relatively low cost, high anti-CO poisoning capacity, high dispersion degree, small grain size, high catalytic performance and the like.

Owner:CHENZHOU GAOXIN MATERIAL

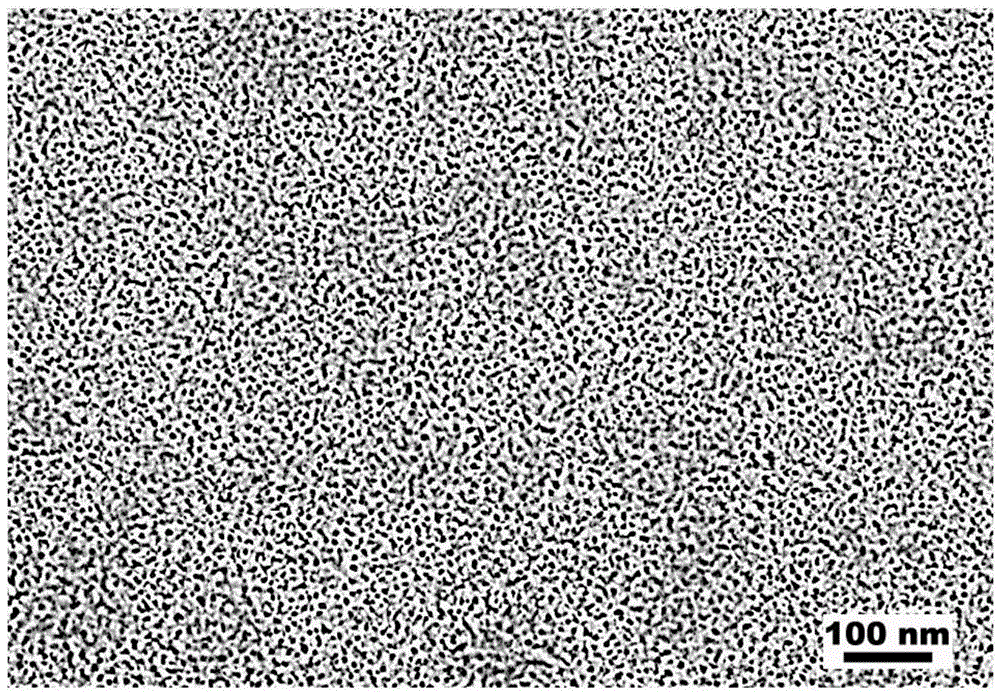

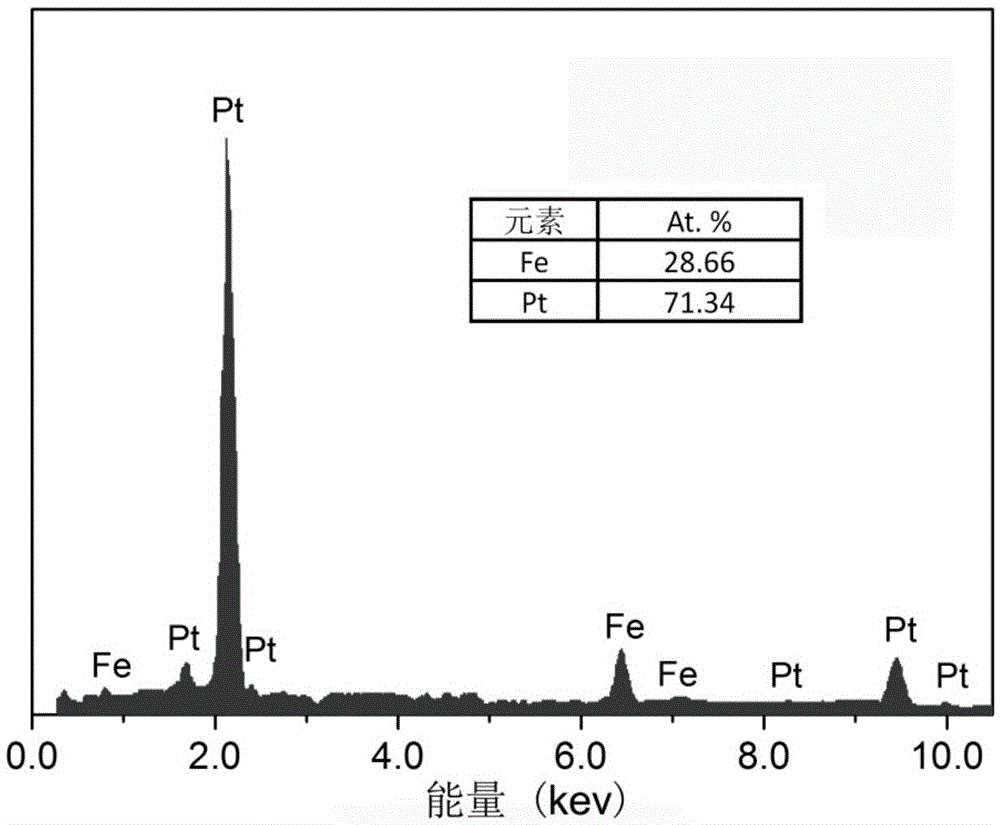

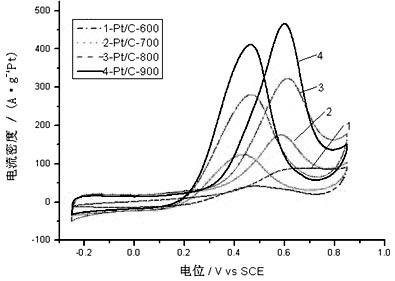

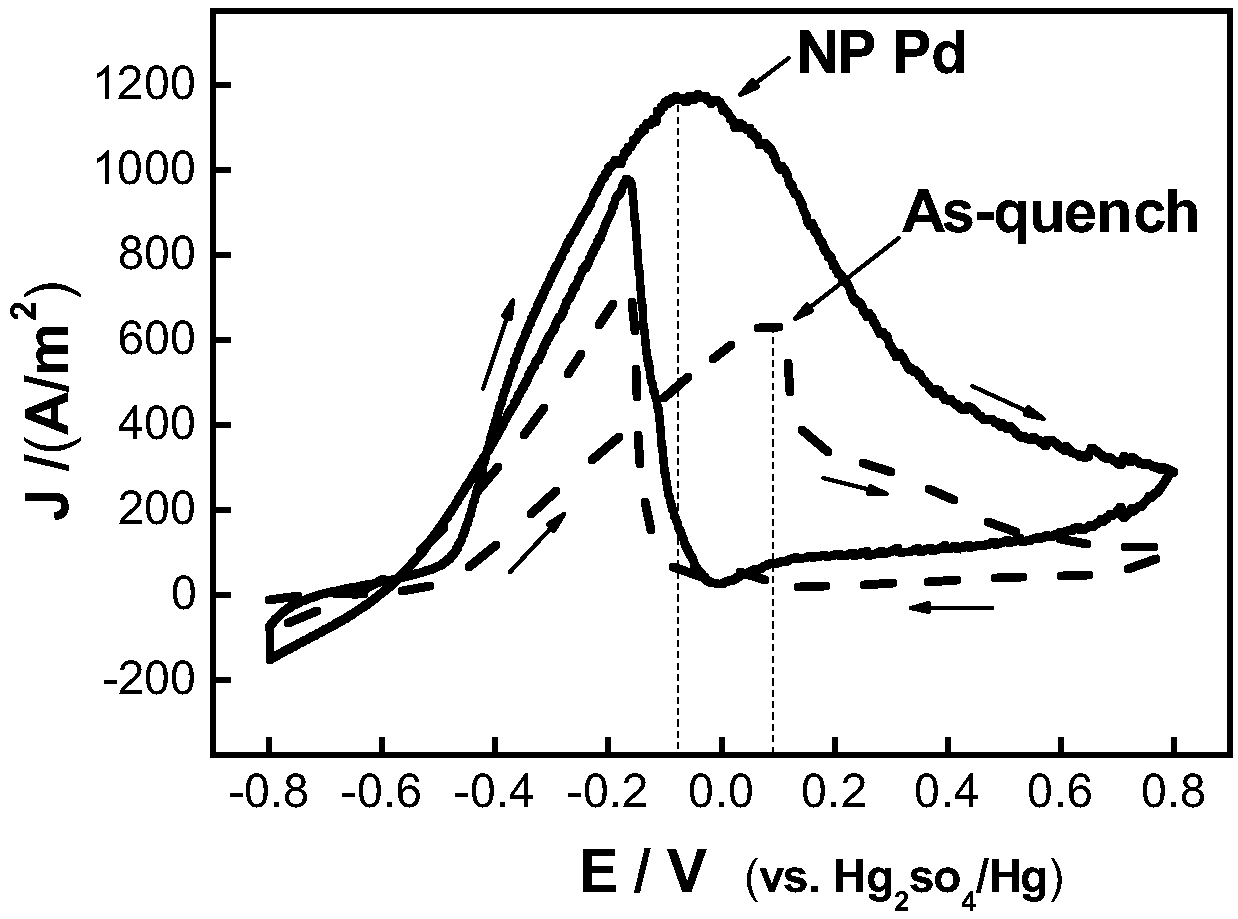

Preparation method of magnetic nano porous Fe-Pt alloy with electro-oxidation catalytic performance

InactiveCN105648478AGood electro-oxidation catalytic performanceHigh catalytic activityNanotechnologyElectric arc furnaceCO poisoning

The invention provides a preparation method of magnetic nano porous Fe-Pt alloy with electro-oxidation catalytic performance and belongs to the technical field of new materials. An electric arc furnace or induction melting furnace is used for preparing Fe-Pt-(B, Si) system alloy master alloy ingots, and a precursor alloy strip with an amorphous or amorphous / nanocrystalline structure is prepared through a single-roller melt-spinning method; and precursor alloy is used as a working electrode, elements such as Fe, B and / or Si in the alloy are selectively etched off through a dealloying process in a room-temperature and acid environment, and the nano porous Fe-Pt alloy with the pore size ranging from 3 nm to 18 nm and the pore wall thickness ranging from 5 nm to 22 nm is obtained. According to the preparation method, the process is simple, the procedure is short, and high efficiency and energy conservation are achieved. The obtained magnetic nano porous Fe-Pt alloy is uniform and controllable in pore size, has good catalytic activity and anti-CO-poisoning capacity for an electro-oxidation reaction in methyl alcohol and other substances in acid liquid, is easy to recycle and serves as a catalyst for an anodic reaction in fuel cells such as acidic methanol.

Owner:DALIAN UNIV OF TECH

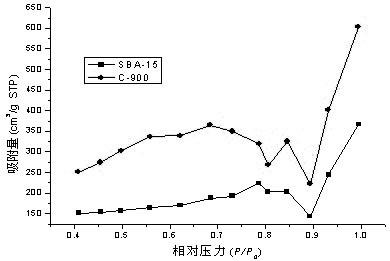

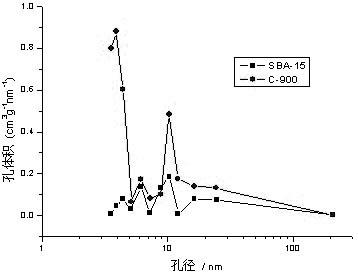

Mesoporous carbon supported Pt nano catalyst and preparation method thereof

InactiveCN102125865ALarge specific surface areaImprove stabilityMolecular sieve catalystsNano catalystActivated carbon

The invention discloses a mesoporous carbon supported Pt nano catalyst and a preparation method thereof. The method comprises the following steps of: burning mesoporous silicon oxide SBA-15 serving as a template and cane sugar serving as a carbon source to form mesoporous carbon, further supporting Pt nano particles, and finally obtaining the mesoporous carbon supported Pt nano catalyst. In the mesoporous carbon supported Pt nano catalyst, the diameter of the Pt nano particles is in a range of 3 to 5 nanometers; and the mesoporous carbon has larger specific surface area compared with active carbon, the average specific surface area of the mesoporous carbon is 825 m<2> / g, the average aperture is 13.8 nanometers, agglomeration of the Pt nano particles can be better inhibited, and the stability of the Pt catalyst is further improved. The mesoporous carbon supported Pt nano catalyst prepared at a high temperature has higher oxidation effect on CO, namely the catalyst has better CO poisoning resistance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Preparation method of PdAg/TiO2 nanotube direct methanol fuel cell anode catalyst

InactiveCN102836708AReduce dosageLow costMaterial nanotechnologyCell electrodesTio2 nanotubeCO poisoning

The invention discloses a preparation method of a PdAg / TiO2 nanotube direct methanol fuel cell anode catalyst. The PdAg / TiO2 nanotube direct methanol fuel cell anode catalyst consists of a TiO2 nanotube and nano-PdAg. The method comprises the following steps of: preparing a TiO2 nanotube; and preparing a TiO2 nanotube dispersion liquid; preparing Pd / TiO2 and the like. The electric conductivity of TiO2 and the catalytic performance of TiO2 on methanol are enhanced through PdAg compounding, intermediate products such as CO and the like produced by methanol oxidation are adsorbed and transferred onto the surface of a composite catalyst and are directly oxidized into a final product, i.e., CO2 deeply, the price of PdAg is much lower than those of noble metals such as Pt, Ru and the like, and the using amount of PdAg in the catalyst is small, so that the catalytic oxidation performance of the catalyst on methanol can be enhanced greatly, the cost of the catalyst is reduced, and the CO poisoning resistance of the catalyst is enhanced.

Owner:NANTONG UNIVERSITY

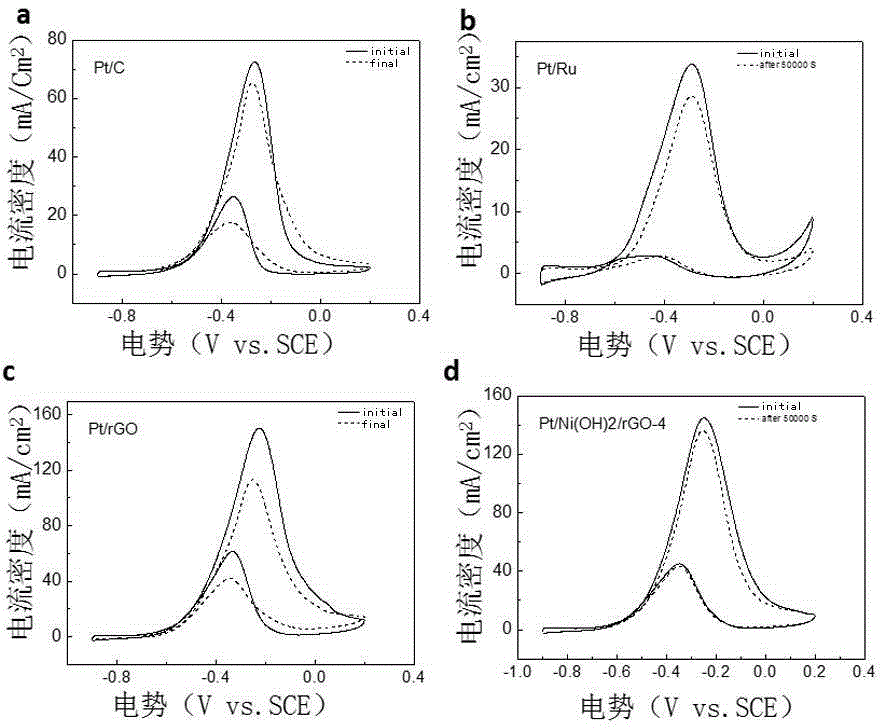

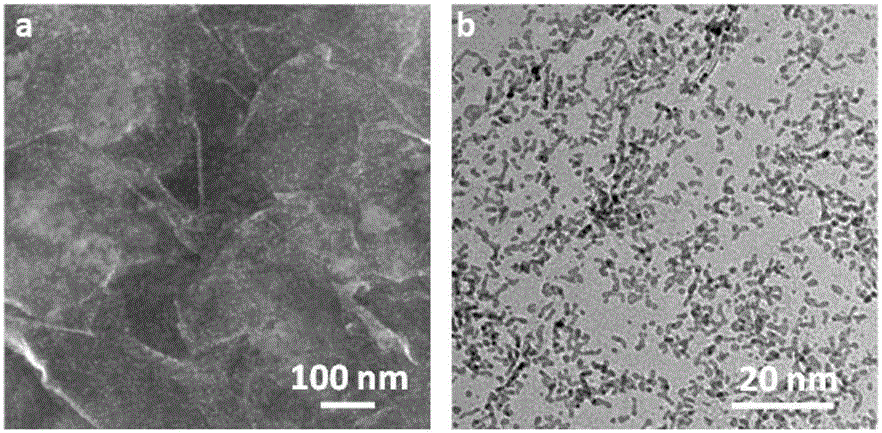

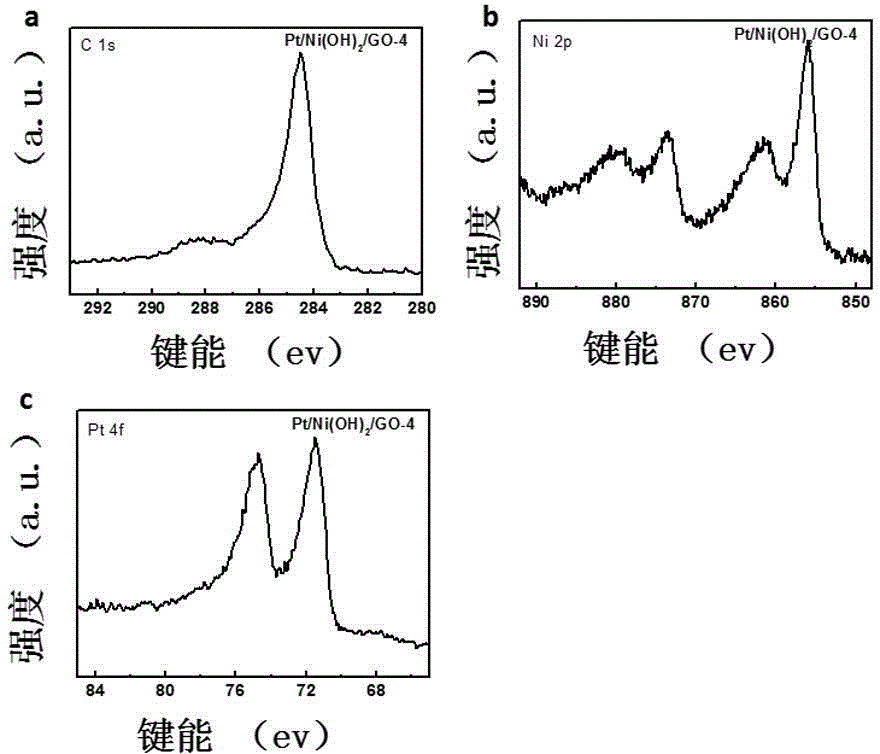

Small-molecular alcohol oxidation electro-catalysis material and preparation method and application therefor

ActiveCN105406088AAvoid reunionUniform growthMaterial nanotechnologyCell electrodesAlcohol fuelAlloy catalyst

The invention discloses a small-molecular alcohol oxidation electro-catalysis material and a preparation method and an application therefor. The small-molecular alcohol oxidation electro-catalysis material is a noble metal-metal hydroxide-carbon material ternary composite system and prepared by two steps; firstly, a carbon material and a metal salt solution are used as the raw materials to be subjected to a first time of reaction to grow metal hydroxide particles on the surface of the carbon material; then, the noble metal salt is taken as the raw material to be subjected to a second time of reaction to grow noble metal particles on the surface of the carbon material loaded with the metal hydroxide particles to obtain the noble metal-metal hydroxide-carbon material ternary composite system. When the small-molecular alcohol oxidation electro-catalysis material is used as the positive electrode catalyst of a direct alcohol fuel cell, efficient and stable alcohol electro-catalysis oxidation is realized, and an outstanding anti-CO-poisoning capability is achieved as well; and in addition, the small-molecular alcohol oxidation electro-catalysis material is lower in cost compared with the commercialized Pt-Ru alloy catalyst.

Owner:SUZHOU UNIV

Method of synthesizing Pt-CeO*/C electro-catalyst with one-step method microwave

InactiveCN101108346AImprove efficiencyFine and uniform particle sizeElectrolysis componentsElectrolytic organic productionSodium acetateAlcohol fuel

The invention discloses a one-step microwave compounding Pt-CeO2 / C catalyst method, which dissolves chloroplatinic acid in ethylene glycol, the concentration of the chloroplatinic acid in the solution is between 0.002 to 0.005mol / L; then adding ammonium ceric nitrate water solution with certain volume and make the mol ratio of Pt and Ce in the solution is 1 / 1 to 2.5 / 1; then add small volume sodium acetate water solution in the solution as stabilizer, the concentration of the sodium acetate in solution is between 0.01 to 0.03mol / L. Add a certain volume Nami carbon as carrier, use supersonic process to dissolve the Nami carbon material in the solution fully. Heat the even mixture with microwave for 6 to 12min under the situation of reflow, compound to achieve Pt-CeO2 / C catalyst, the quality per centage of Pt in the catalyst is 20 per cent, the mol ratio of Pt and Ce is between 1 / 1 to 2.5 / 1, the Nami carbon as the carrier is XC-72 Nami carbon or carbon Nami tube. The Pt-CeO2 / C catalyst compounded by the method in the invention has higher electrocatalysis activity and better anti-CO poisoning performance to the oxidizing of methanol, which has wide application in direct alcohols fuel battery.

Owner:ZHEJIANG UNIV

Sulfur-doped carbon nanotube Pt-loaded catalyst for direct methanol fuel cell and preparation method of catalyst

ActiveCN104538642ASimple processModerate and controllable operating conditionsCell electrodesFuel cellsSulfur

The invention discloses a sulfur-doped carbon nanotube Pt-loaded catalyst for a direct methanol fuel cell and a preparation method of the catalyst. The preparation method comprises the following steps: (1) preparing a PEDOT functional MWCNTs composite material; (2) preparing a sulfur-doped MWCNTs composite material; and (3) obtaining the sulfur-doped MWCNTs Pt-loaded catalyst. The preparation method is simple in process and mild and controllable in operating condition, and deposited Pt nano particles are small in size and high in electrochemical activity superficial area and are uniformly dispersed on the sulfur-doped MWCNTs. The catalyst prepared by the method disclosed by the invention represents the characteristics of good electrochemical activity, high stability and strong anti-CO poisoning capacity on methanol oxidation.

Owner:GUANGXI NORMAL UNIV

Metal-free vertically-aligned nitrogen-doped carbon nanotube catalyst for fuel cell cathodes

ActiveUS8221937B2High catalytic activityImprove long-term stabilityFuel cell auxillariesActive material electrodesConductive polymerCO poisoning

Metal-free fuel cell cathodes having a catalytic layer of vertically-aligned, nitrogen-doped carbon nanotubes (VA-NCNTs) are provided. The fuel cell cathodes comprise a cathode body, a binder layer attached to an outer surface of the cathode body, and the catalytic layer, which is supported by the binder layer. The binder layer may comprise a composite of a conductive polymer and doped or undoped nonaligned carbon nanotubes. In a method for forming the fuel cell cathodes, the VA-NCNTs may be formed by pyrolysis of a metalorganic compound and integration of the nanotubes with nitrogen. The binder layer is applied, and the resulting supported nanotube array may be attached to the cathode body. Fuel cells comprising the fuel cell cathodes are provided. The fuel cell cathodes comprising VA-NCNTs demonstrate superior oxygen-reduction reaction performance, including for electrocatalytic activity, operational stability, tolerance to crossover effects, and resistance to CO poisoning.

Owner:UNIV OF DAYTON

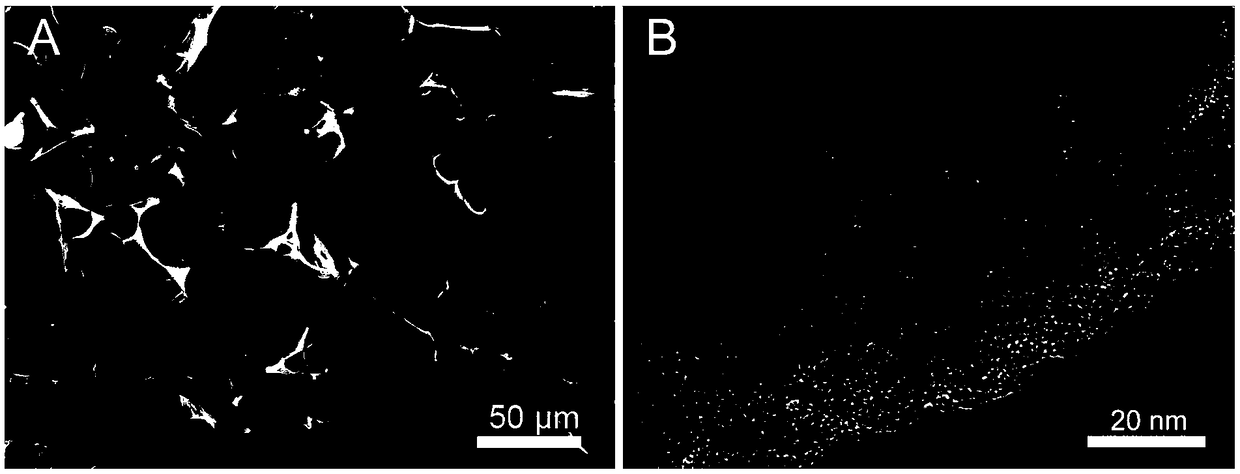

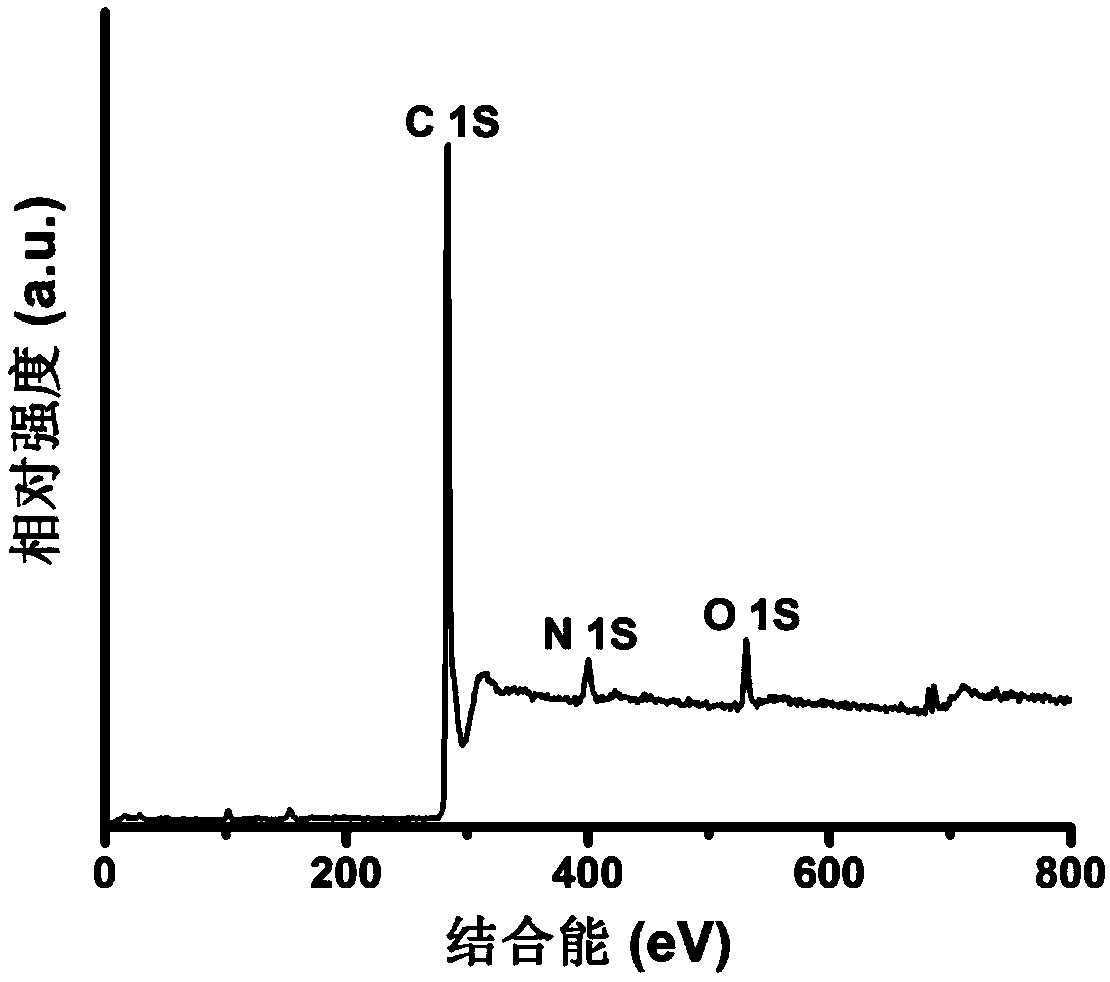

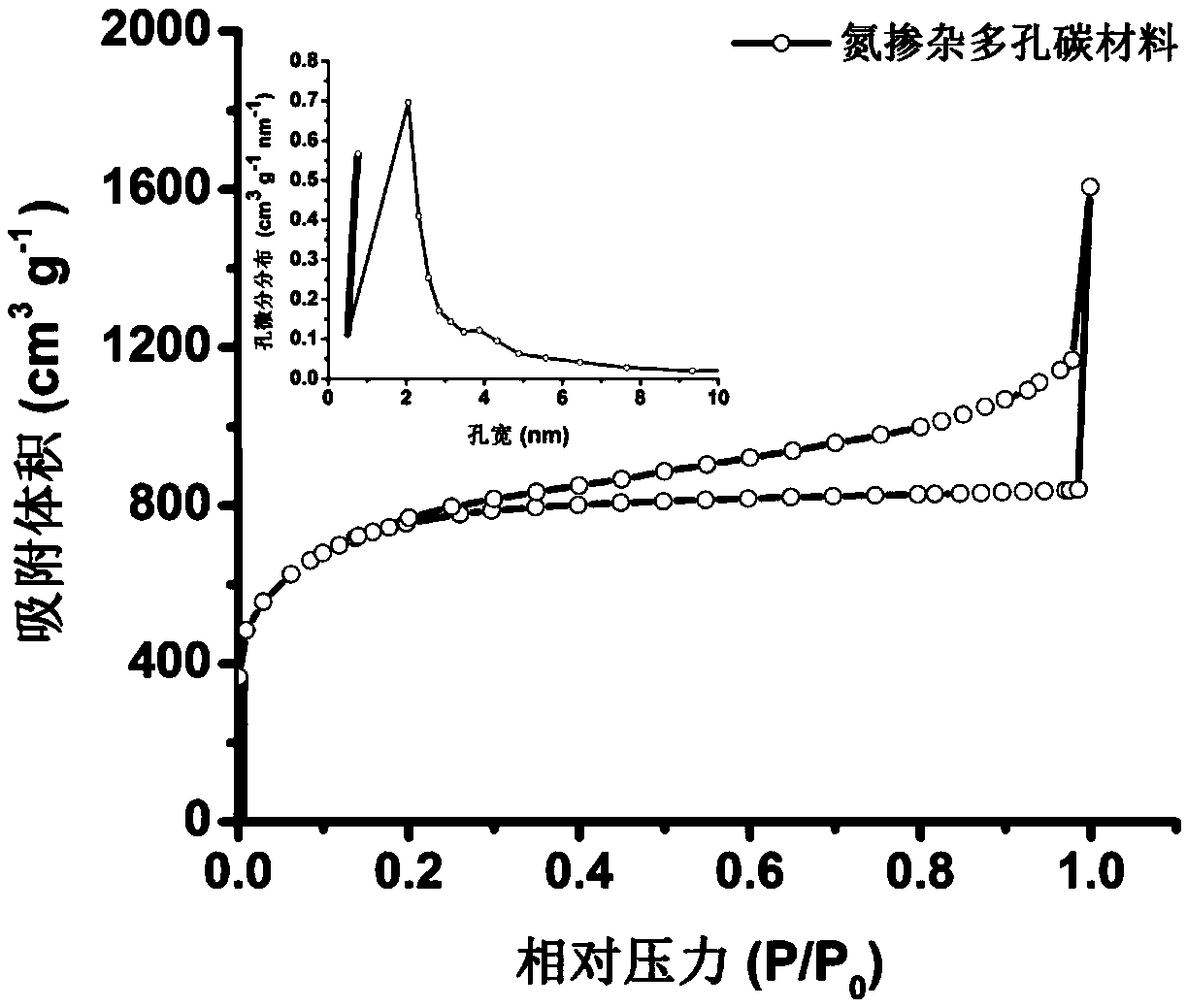

A method for preparing a high-performance nitrogen-doped porous carbon-supported PtNi alloy particle methanol fuel cell catalyst

ActiveCN109103474ADifferent structureLow costMaterial nanotechnologyCell electrodesPtru catalystFuel cells

The invention relates to a method for preparing a high-performance nitrogen-doped porous carbon supported PtNi alloy particle methanol fuel cell catalyst. The method uses waste cigarette end filter core as carbon source and nitrogen source to generate nitrogen-doped porous carbon material in one step; Non-noble metal Ni and noble metal Pt alloy particles are supported on nitrogen-doped porous carbon materials to form catalysts. The invention provides a simple preparation method of nitrogen-doped porous carbon-supported PtNi binary alloy (PtNi / N-HPC) catalyst, which improves the CO poisoning disadvantage of a single Pt-based catalyst.

Owner:HEBEI UNIV OF TECH

Method of preparing platinum ruthenium/carbon two-element compounded catalyst of positive electrode of alcohol fuel cell

InactiveCN1243390CCell electrodesMetal/metal-oxides/metal-hydroxide catalystsAlcohol fuelCO poisoning

Owner:UNIV OF SCI & TECH BEIJING

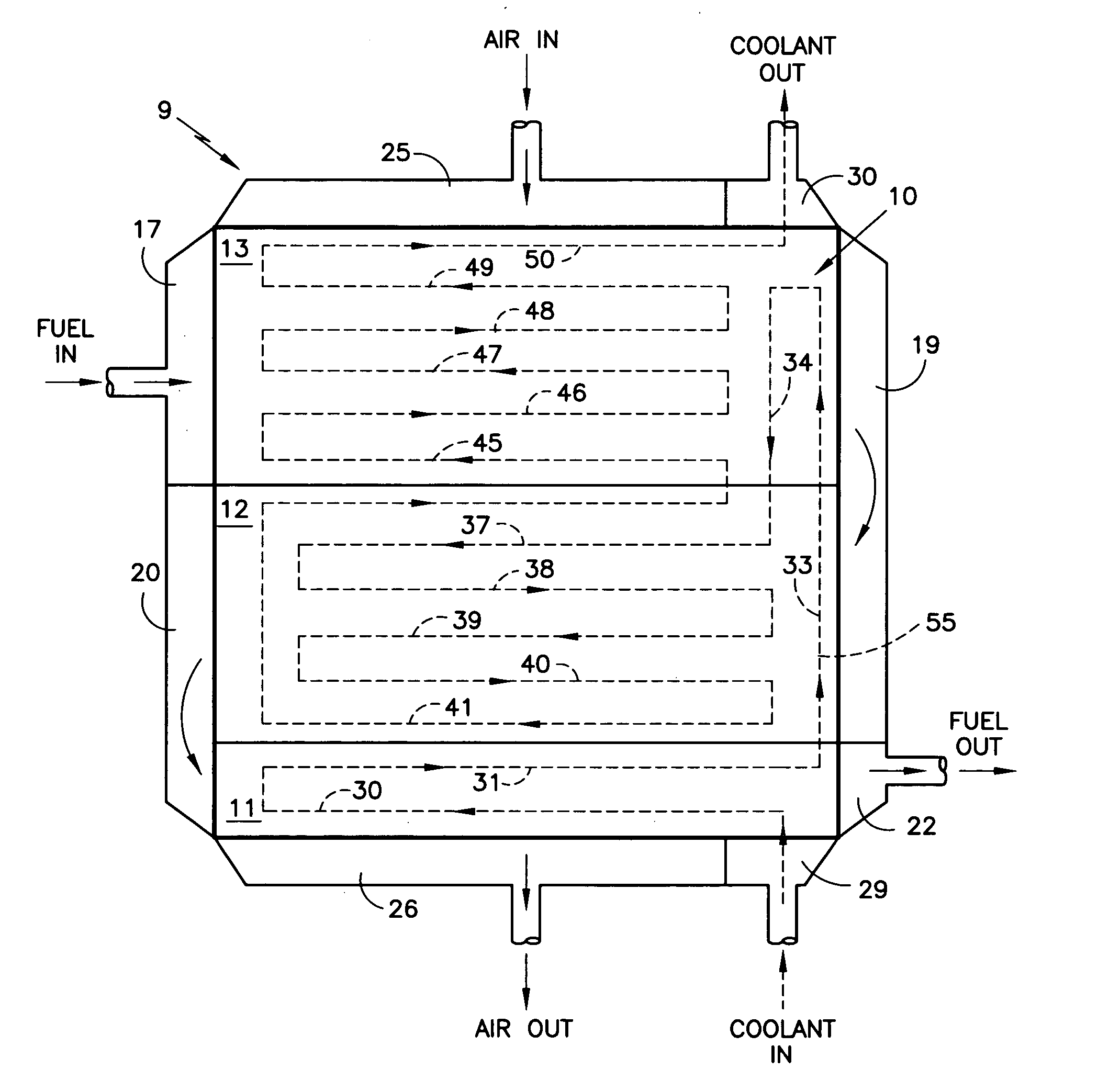

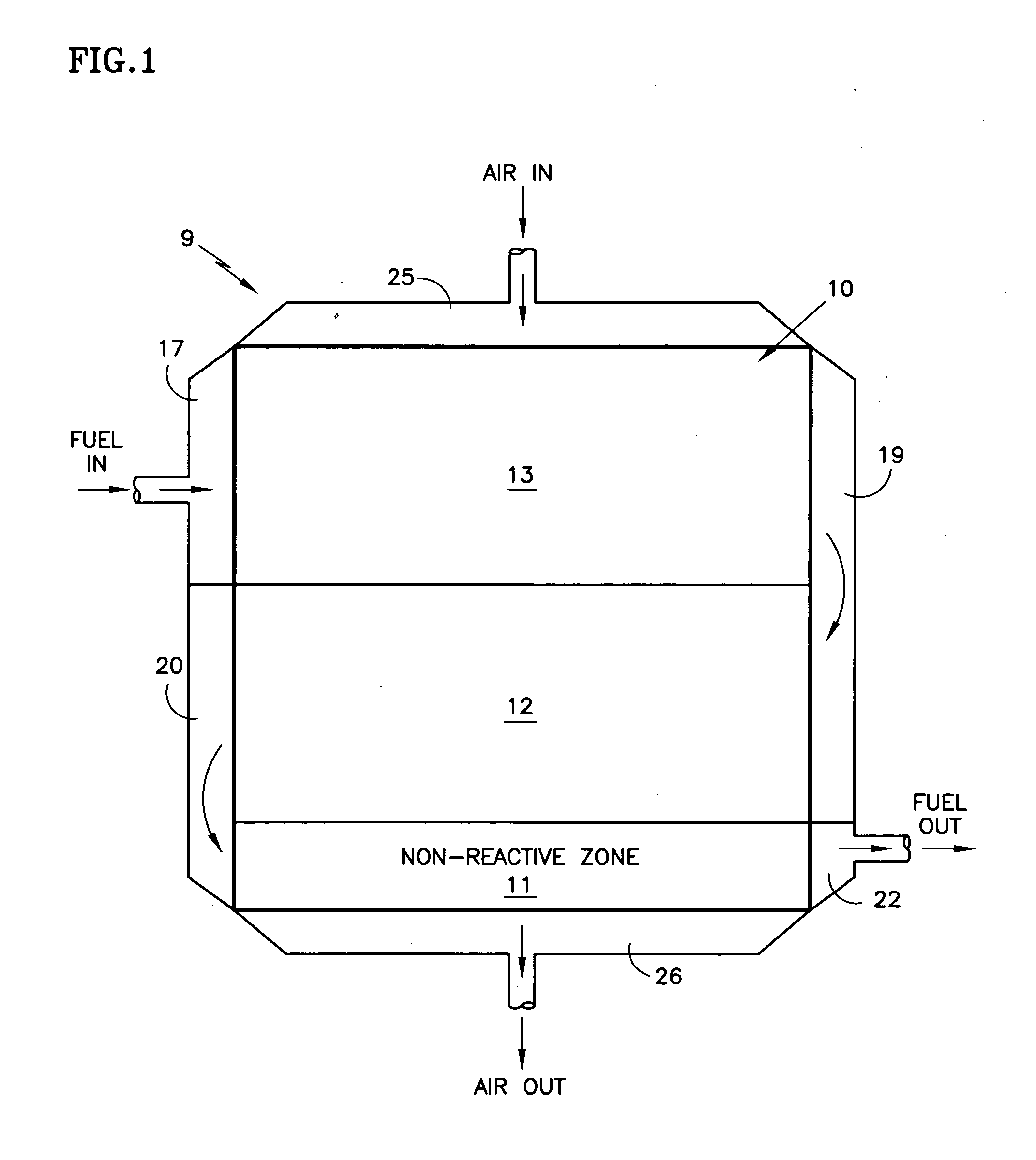

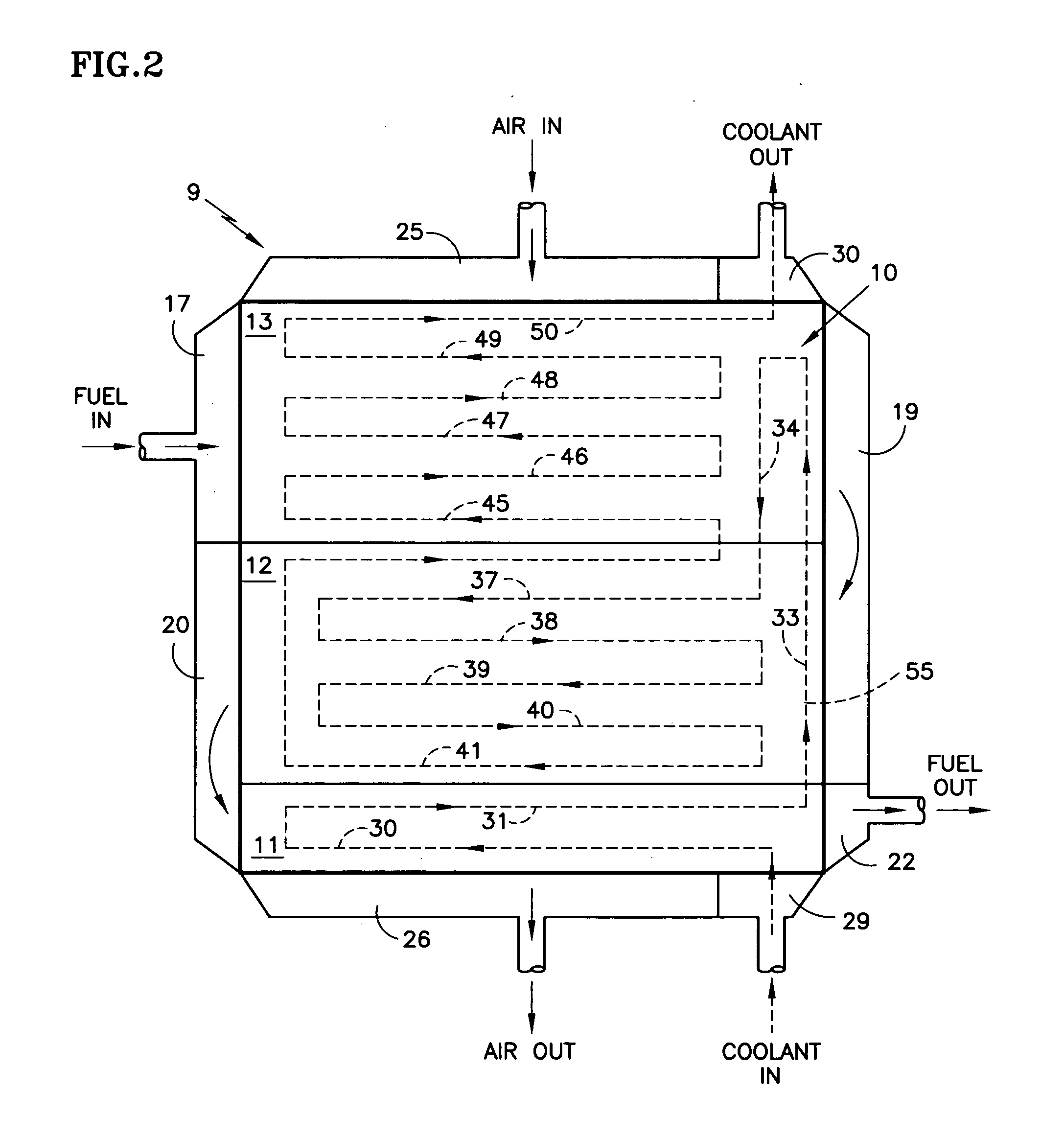

Fuel cell coolers with inverse flow and condensation zone

ActiveUS20060141312A1Life maximizationWithout cell performanceFuel cells groupingElectrolyte stream managementFuel cellsNuclear engineering

A fuel cell system having a fuel cell stack (9) employing a phosphoric acid or other electrolyte, includes a non-reactive zone (11) in each of a group of fuel cells between corresponding coolant plates (55), the coolant entering the coolant plates in an area adjacent to the non-reactive zones (29-31). Each fuel cell has three-pass fuel flow fields, the first pass substantially adjacent to a third zone (13), remote from the first zone, the second pass substantially adjacent to a second zone contiguous with the first zone, the coolant flowing (33, 34) from a coolant inlet (29) through the first zone, to the far side of the second zone, and (37-41) from the near side of the second zone to the third zone and thence (45-50) to a coolant exit manifold (30), which assures temperatures above 150° C. (300° F.), to mitigate CO poisoning of the anode within the reactive zones, and assuring temperatures below 140° C. (280° F.) to promote sufficient condensation of evaporated electrolyte in the non-reactive zones, so as to provide a long system life.

Owner:HYAXIOM INC

Preparation method of direct methanol fuel cell anode composite membrane catalyst

ActiveCN102658201AImprove electrocatalytic activityEasy to prepareOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesCO poisoningPlatinum catalyst

The invention relates to a preparation method of a direct methanol fuel cell anode composite membrane catalyst, which comprises the following steps: previously preparing functional modified graphene, and pretreating a glassy carbon electrode substrate; carrying out layer-by-layer selfassembly on the functional modified graphene and polyoxometalate on the electrode to obtain a composite membrane of which the outermost layer is the functional modified graphene and polyoxometalate; and carrying out in-situ electrodeposition to obtain the anode composite membrane catalyst composed of the Pt nanoparticles, functional modified graphene and polyoxometalate. The composite membrane catalyst provided by the invention is prepared for the first time, and can be used as a direct methanol fuel cell anode catalyst. Compared with the pure platinum catalyst, the introduction of the functional modified graphene and polyoxometalate obviously enhances the electrocatalytic activity and CO poisoning resistance of the composite membrane catalyst; and the preparation method is simple, and has the advantage of lower cost. The invention provides a novel direct methanol fuel cell anode catalyst.

Owner:FUJIAN NORMAL UNIV

Hydrogenation catalyst and preparation method thereof, and method for preparing citronellal by citral hydrogenation

ActiveCN110961154AExtend your lifeSuppresses Poison ChanceCatalyst protectionOrganic compound preparationPtru catalystCO poisoning

The invention discloses a hydrogenation catalyst and a preparation method thereof, and a method for preparing citronellal by citral hydrogenation. The hydrogenation catalyst comprises a rare earth hydride, a metal oxide and Pd. Under the action of the hydrogenation catalyst, preferably in the presence of an N-heterocyclic compound additive, citral is hydrogenated to prepare citronellal. The hydrogenation catalyst has the advantages of CO poisoning resistance and long service life, reduces the possibility that citral is subjected to aldehyde group decomposition to generate CO, inhibits the poisoning probability of the active component Pd, and has a good industrial prospect.

Owner:WANHUA CHEM GRP CO LTD +1

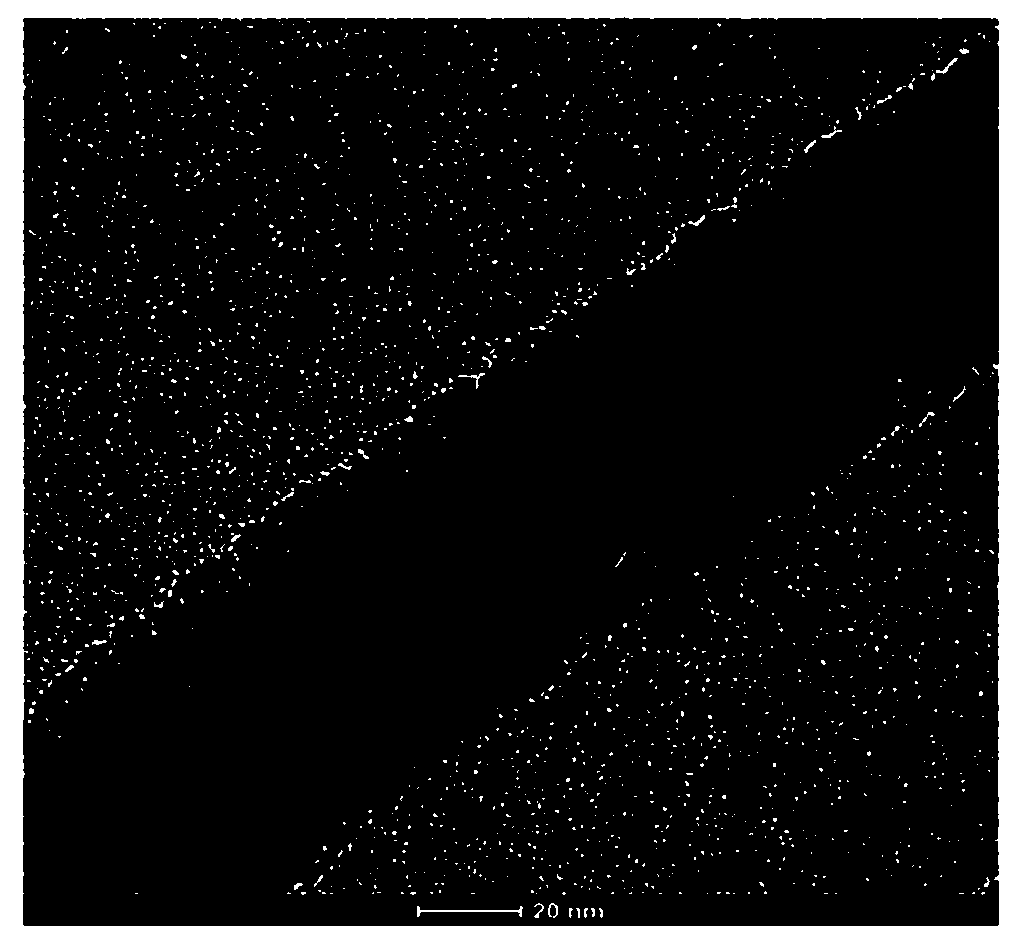

Multiwalled carbon nanotube-loaded PdSn catalyst based on deep eutectic solvent, and preparation method and application of catalyst

ActiveCN104607186ASimple processMild operating conditionsCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCO poisoning

The invention discloses a multiwalled carbon nanotube-loaded PdSn catalyst based on a deep eutectic solvent and a preparation method and application of the catalyst, and relates to a simple and novel method for preparing an anode electrocatalyst for a direct formic acid fuel cell. According to the method, by taking a deep eutectic solvent as a medium, the catalyst is prepared by using a chemical reduction method. The preparation method of the catalyst is simple in process, and mild and environmentally friendly in operating condition. The dimension of catalyzing nano-particles can be obviously reduced by using a deep eutectic solvent system, so that the metal nanoparticles grow along the surface of a carbon nano tube and are agglomerated to form a special chain-like cluster structure, the electrochemical activity surface area of noble metals is increased, and moreover, the charge transfer interaction among the components in a composite material catalyst is further enhanced. Therefore, the electrocatalytic activity and stability of the catalyst on formic acid oxidation are hugely improved, and the catalyst has the excellent anti-CO poisoning capacity.

Owner:GUANGXI NORMAL UNIV

Preparation method of PtRu/C binary alloy nano catalyst

ActiveCN101829565AGood dispersionInhibition of agglomerationMetal/metal-oxides/metal-hydroxide catalystsNano catalystDispersity

The invention discloses a preparation method of a PtRu / C binary alloy nano catalyst. The preparation method comprises the following steps of: dissolving active carbon in water and then heating up and stirring to obtain carbon paste; sequentially dropping H2PtCl6, RuCl3 and a metal protector into the carbon paste, then stirring by using ultrasound and regulating the pH value to 8; slowly dropping a reducing agent; and carrying out vacuum filtration, washing and vacuum drying after reacting to finally obtain the PtRu / C binary alloy nano catalyst. The obtained PtRu / C binary alloy nano catalyst has good dispersity and strong capacity of resisting CO poisoning, and meanwhile, because the particle size range of the obtained PtRu / C binary alloy nano catalyst is 3-5 nm, the PtRu / C binary alloy nano catalyst has the characteristic of narrow particle size range; the agglomeration of PtRu / C binary alloy particles is slowed down, and the stability of the alloy is increased; meanwhile, the catalytic activity of the PtRu / C binary alloy nano catalyst to methanol is also improved to certain degree. The preparation method has the advantages of simple and convenient operation, less time consumption, and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

Supported palladium-ultrathin CoNi-LDH (Layered Double Hydroxide) nanosheet composite material as well as preparation method and application thereof

InactiveCN110743565AEasy to prepareLarge electrochemical active areaMaterial nanotechnologyCell electrodesAlcoholNanoparticle

The invention discloses a supported palladium-ultrathin CoNi-LDH (Layered Double Hydroxide) nanosheet composite material as well as a preparation method and application thereof. The preparation methodcomprises the following steps: firstly, preparing ultrathin CoNi-LDH nanosheets by using a one-step hydro-alcohol thermal-solvent method, and supporting noble metal Pd nanoparticles by the ultrathinCoNi-LDH nanosheets as a carrier so as to obtain the supported palladium-ultrathin CoNi-LDH nanosheet composite material. The composite material can be applied to an electrocatalytic ethanol oxidationreaction, and has the advantages of high mass activity, good stability, good anti-poisoning ability and the like. The advantages can be attributed to the following aspects: (1), the ultrathin carriercan provide a larger electrochemical activity area, good electrical conductivity, and good CO poisoning resisting ability; and (2), the Ni-based LDH carrier can remove carbonaceous intermediates nearPdNPs sites, the Co element which is highly dispersed in laminates can achieve uniform and solid loading of PdNPs and is beneficial to sufficient utilization of PdNPs, and thus catalytic activity andstability can be synergistically improved.

Owner:BEIJING UNIV OF CHEM TECH

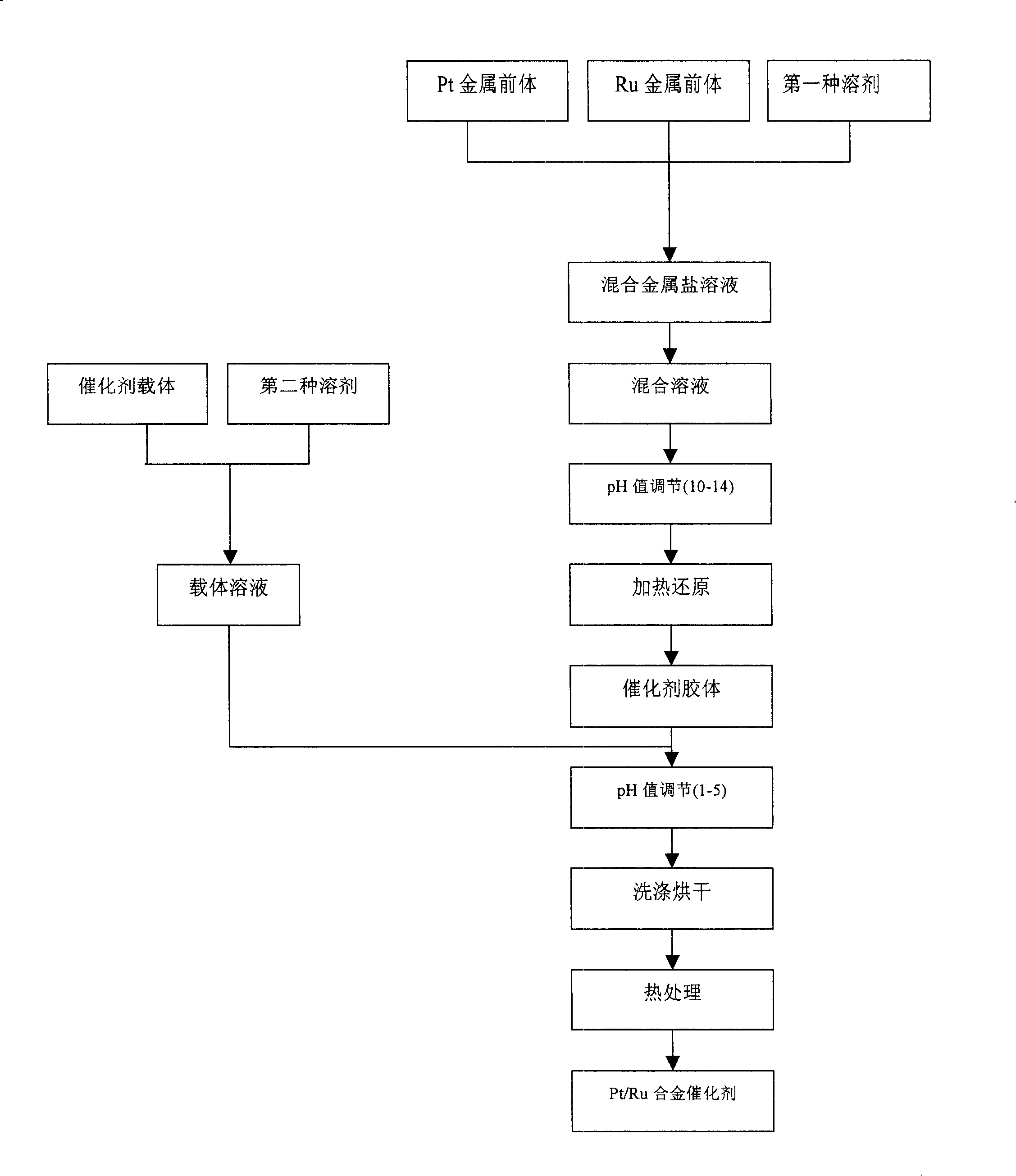

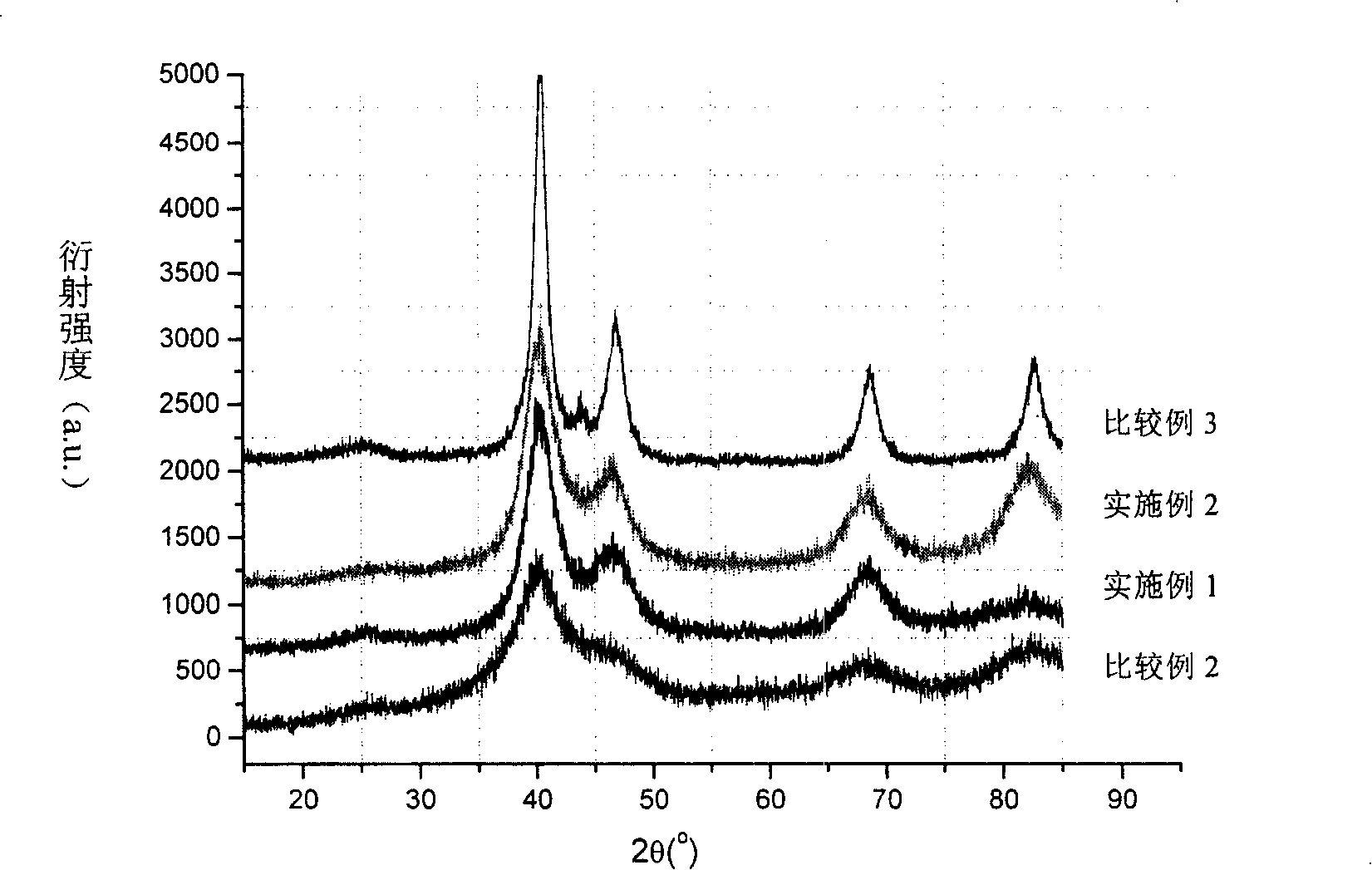

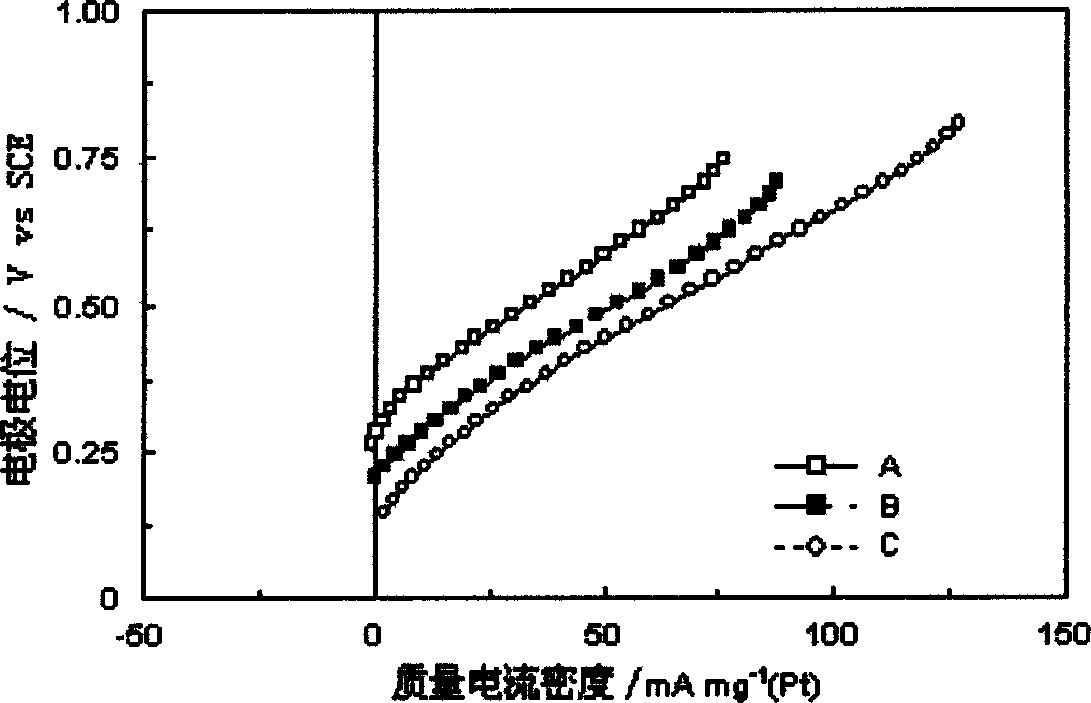

Supported PtRu alloy catalyst and preparing method thereof

InactiveCN101224435ASmall particle sizeEvenly distributedFinal product manufactureCell electrodesPtru catalystCO poisoning

The preparation of a supported PtRu alloying catalyst is realized by the following steps: First, the precursor solutions of Pt and Ru are mixed to prepare a metal salt solution, then the pH value of the solution is adjusted, and the solution is heated, so as to obtain a catalyst colloidal solution. Carriers are dispersed to a solution and mixed with the catalyst colloidal solution, and then the pH value of the mixed solution is adjusted for facilitating the deposition of the catalyst colloidal particles on the carriers. The catalyst is filtered, washed and heat treated in a reducing atmosphere with appropriate proportions to obtain the supported PtRu alloying catalyst. The invention improves the crystallinity of PtRu catalyst by combing the polyol method and heat treating in a reducing atmosphere, removes adsorption species on the catalyst surface effectively during polyol method process and also improves the methanol oxidability and the resistance of CO poisoning of alloying catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Method of preparing platinum ruthenium/carbon two-element compounded catalyst of positive electrode of alcohol fuel cell

InactiveCN1564356ACell electrodesMetal/metal-oxides/metal-hydroxide catalystsAlcohol fuelCO poisoning

The method includes steps: treating carrier of carbon black by using high alkaline solution containing weak reducing agent stannous to make active sites on surface of carbon black distribute evenly; adding chloro-platinic acid solution containing high chemical valence ruthenium to deoxidize and deposit ruthenium ions and ions of chloroplatinic acid radical on active sites on surface of carbon black; optimizing figure platinum of ruthenium so as to generate PtRu / C duality catalytic composite. Features are as following: favorable catalytic activity at lower platinum loading, and high capability of against CO poisoning. The product prepared by the invention can be applied to anodic catalytic in methanol fuel cells directly, as well as applicable to other fuel cell and cracking organic etc.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing direct methanol fuel cell Pt-Ru/C catalyst

InactiveCN101635359ASimple stepsMild operating conditionsFinal product manufactureCell electrodesCO poisoningSlurry

The invention relates to a method for preparing direct methanol fuel cell Pt-Ru / C catalyst, which is characterized by comprising the following steps: (1) adding a carbon carrier into surface active agent and carrying out ultrasonic oscillation to obtain dispersed slurry; (2) adding an aqueous solution of a Pt compound and an Ru compound and carrying out the ultrasonic oscillation to obtained dispersed slurry; (3) dropwise adding a reducing agent for reducing; (4) completely reacting and then filtering, washing and drying to obtain the finished Pt-Ru / C catalyst of which Pt and Ru are electrically deposited on the carbon carrier. The invention has the following technical advantages that: (1) simple step, mild operation condition and easy mass production are achieved; and (2) the Pt-Ru / C catalyst prepared by the method can be used as a positive electrode catalyst and has high electro-catalysis oxidative activity of the methanol and lower carrying capacity which is only 1-2mg / cm<2> lower than common 2-4 mg / cm<2> and higher CO poisoning resistance.

Owner:江苏雷石新能源科技有限公司

Fe-Pd-based nano-porous material and preparation method thereof

ActiveCN108767277ALow costSimple manufacturing processMaterial nanotechnologyCell electrodesNew energyCO poisoning

The invention provides a nanoporous material and a preparation method thereof, and belongs to the technical field of new materials. The nanoporous material, namely a catalytic material, with a uniformnet structure is prepared by adopting Fe-Pd-P amorphous alloy as precursor alloy and adopting a chemical dealloying process under the acid environment at room temperature, and the prepared Fe-Pd-based nanoporous material has a high electro-catalytic property on methanoic acid and the like. The prepared nanoporous material is used as an electrode material, so that the electro-catalytic property onmethanoic acid is obviously improved. Compared with traditional metal material, the prepared nanoporous material is uniform in structure, high in specific surface area and high in stability, and hasno CO poisoning phenomenon in the electro-catalytic process of methanoic acid; the chemical dealloying method is low in cost, simple and efficient, and easy to realize industrial production; and the prepared nanoporous material is widely applied in the field of new energy electrode materials such as fuel cells.

Owner:UNIV OF SCI & TECH LIAONING

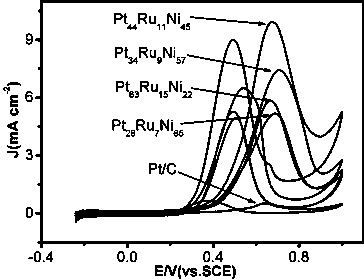

Preparation method for optimizing performance of porous dendritic Pt-Ru-Ni alloy nanoparticles

The invention discloses a preparation method for optimizing performance of porous dendritic Pt-Ru-Ni alloy nanoparticles. Platinum acetylacetone, ruthenium acetylacetone and nickel acetylacetone are used as metal precursors, oleyamine is used as a solvent, oleyamine and oleic acid are used as surfactants, oleyamine and formaldehyde are used as reducing agents, and the porous dendritic Pt-Ru-Ni alloy nanoparticles with higher selectivity are synthesized through assistance of an oven. The method is easy to operate and has high repeatability and enriches the design idea of the Pt-based alloy nanoparticle catalyst. The obtained porous dendritic Pt-Ru-Ni alloy nanoparticles have high specific surface area and large pore capacity, improve and increase active sites and can fully utilize the active sites, show excellent durability and CO poisoning resistance and have wide application prospect.

Owner:UNIV OF JINAN

Fuel electrode catalyst for fuel cell, electrode/membrane assembly, and fuel cell and fuel cell system provided with the electrode/membrane assembly

InactiveUS20090246600A1High CO poisoning resistanceStable power generationActive material electrodesFuel cellsFuel cellsAlloy catalyst

A fuel electrode catalyst for fuel cell excellent in CO poisoning resistance, an electrode / membrane assembly using the fuel electrode catalyst for fuel cell, and a fuel cell and a fuel cell system including the electrode / membrane assembly are provided. The fuel electrode catalyst for fuel cell comprises a platinum-ruthenium first alloy catalyst and a second alloy catalyst obtained by partially substituting ruthenium of the platinum-ruthenium first alloy catalyst by a metal lower dissolving potential than ruthenium. The electrode / membrane assembly 7 comprises three layers of a second alloy catalyst layer 3, a first alloy catalyst layer 4, and a ruthenium catalyst layer 5 arranged in this order from a polymer electrolytic membrane 1 side toward a gas diffusion layer 13 side.

Owner:JX NIPPON OIL & ENERGY CORP

Preparation method for N-C-doped TiO<2> nanofiber loaded Pd@Ni positive electrode catalyst for direct methanol fuel cell

ActiveCN105845953AImprove catalytic performanceLow costMaterial nanotechnologyCell electrodesCatalytic oxidationTio2 nanofibers

The invention discloses a preparation method for an N-C-doped TiO<2> nanofiber loaded Pd@Ni positive electrode catalyst for a direct methanol fuel cell. The catalyst comprises the high-conductivity N-C-doped TiO<2> nanofiber and nanometer Pd@Ni with a core-shell structure, wherein the mass content of the N-C-doped TiO<2> nanofiber is 95-97%; the mass content of the nanometer Pd@Ni is 3-5%; and the ratio of n(Pd) to n(Ni) is 1:1. The catalyst provided by the invention has relatively high catalytic oxidation performance; the intermediate products of CO and the like generated by methanol oxidization are absorbed and moved to the surface of the composite catalyst, and are directly and deeply oxidized into a final product-CO<2>; the costs of Ni and Pd are far below than that of noble metals, such as Pt, Ru and the like, and the dosages of Ni and Pd are relatively low in the catalyst; and therefore, the cost of the catalyst is greatly lowered, the catalytic performance and the CO poisoning resistance of the catalyst are greatly improved.

Owner:NANTONG WUJING HIGH PRESSURE PUMP

Preparation and application of carbon-supported amorphous metallic nickel

InactiveCN102614880AImprove stabilityHigh activityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCO poisoningMetallic materials

The invention provides a preparation method for carbon-supported amorphous metallic nickel, which belongs to the technical field of metallic materials. The carbon-supported amorphous metallic nickel provided in the invention is prepared by using NiCl2.6H2O and ethylene diamine tetraacetic acid as raw materials and employing a hydrothermal process for reduction; amorphous metallic nickel has good dispersibility and a small specific surface area on a carbon support; a fuel cell noble metal catalyst using amorphous metallic nickel as a precursor has the characteristics of good stability, high activity, a long service life and the like, shows good catalytic activity during the process of catalytic oxidation of the anode of a fuel cell and is a high performance catalyst for a fuel cell. Since amorphous metallic nickel can produce electronic effects and synergism together with noble metal atoms (e.g., platinum atoms, palladium atoms, platinum-ruthenium atoms and the like), the catalysis effect of the catalyst is promoted, resistance to CO poisoning of the catalyst is enhanced, the usage amount of noble metals is effectively reduced, and cost for the catalyst is reduced.

Owner:NORTHWEST NORMAL UNIVERSITY

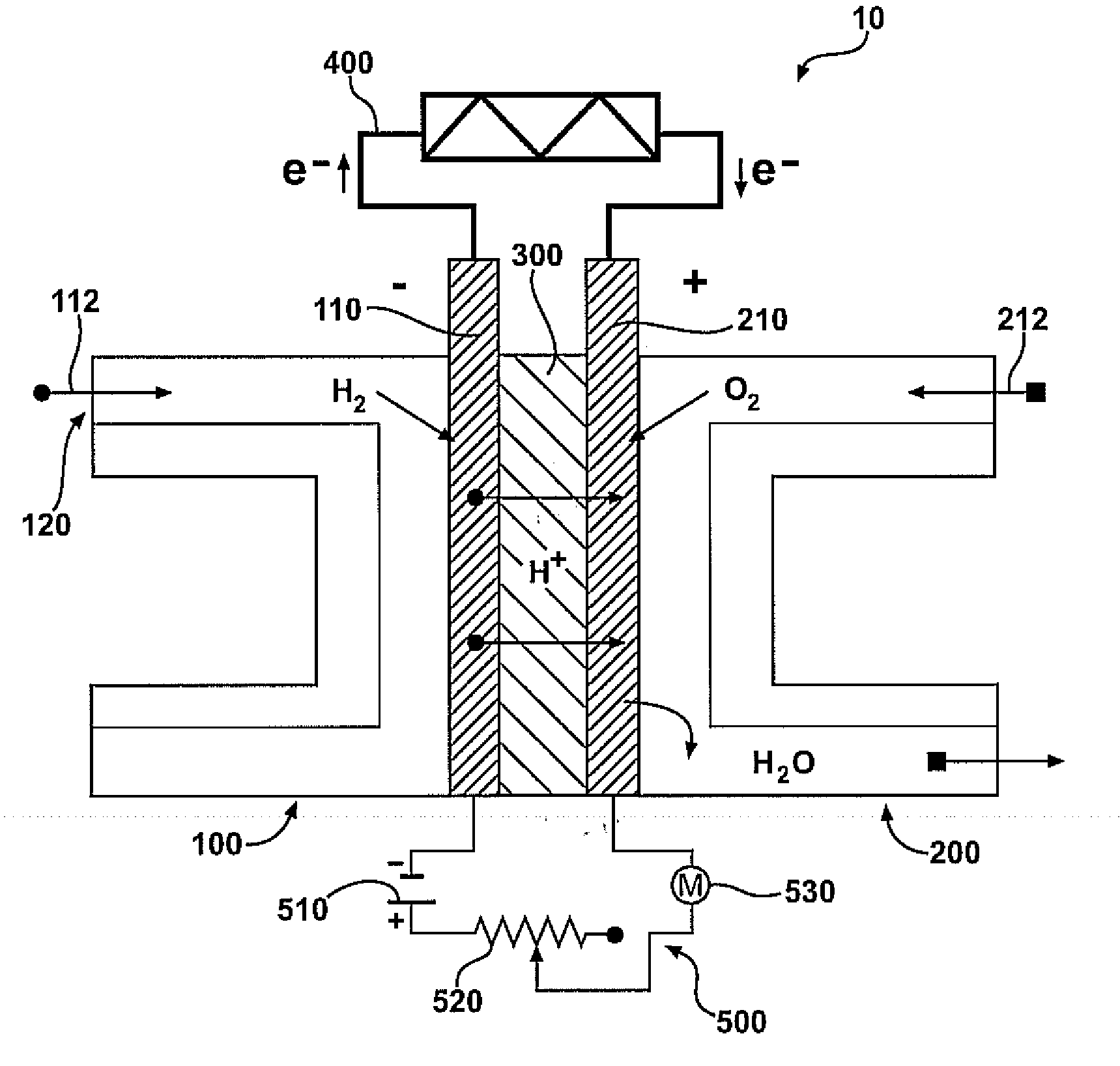

Rapid response sensor for carbon monoxide

InactiveUS20070166585A1High precisionMitigation and graceful degradationWeather/light/corrosion resistanceVolume/mass flow measurementFinite-state machineCO poisoning

Species detection techniques are described based on measurement of a dynamic response to an external stimulus. One embodiment includes a voltage stimulus applied to a polymer electrolyte fuel cell (PEFC), with the response to said stimulus used to measure CO concentration on the anode catalyst. The principles of symbolic dynamics, finite state machines or a simplified peak response-to-asymptotic value measurement can be used to achieve a high degree of precision for measuring CO concentrations. Using the techniques of the present invention, CO poisoning of a fuel cell can be monitored and diagnosed before reaching a critical condition, thereby allowing early implementation of mitigation or graceful degradation strategies.

Owner:PENN STATE RES FOUND

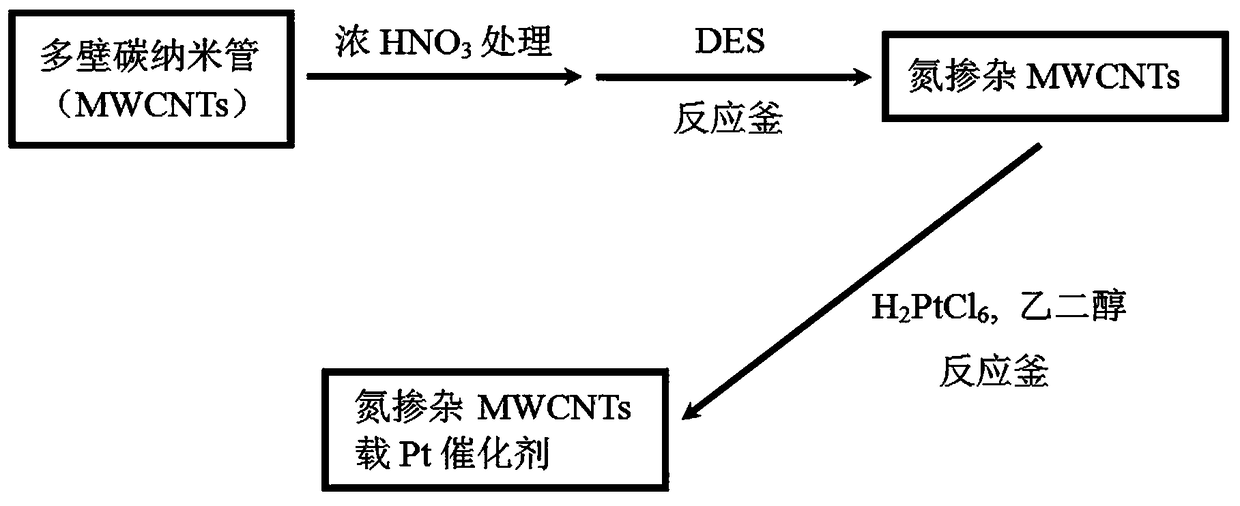

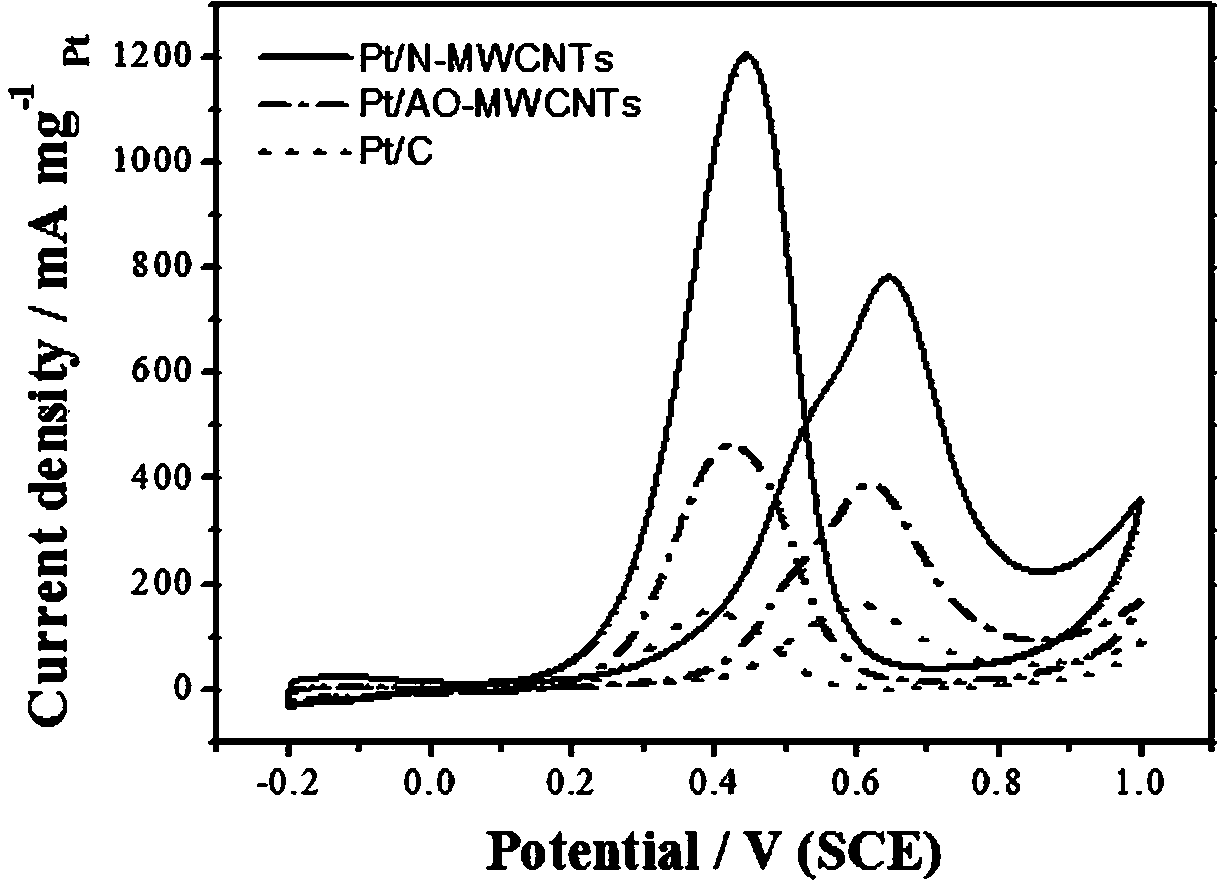

Nitrogen-doped carbon nanotube-loaded Pt catalyst based on eutectic solvent, preparation method and application thereof

ActiveCN108878911AImprove electrochemical performanceImprove stabilityFinal product manufactureCell electrodesCO poisoningSolvent

The invention discloses a nitrogen-doped carbon nanotube-loaded Pt catalyst based on a eutectic solvent, a preparation method and application thereof. The method comprises the following steps: 1) taking choline chloride / urea eutectic solvent as a medium, and processing MWCNTs through a solvothermal method to prepare nitrogen-doped MWCNTs composite material; 2) then, depositing Pt nano particles by taking the nitrogen-doped MWCNTs as a carrier, so as to prepare the nitrogen-doped MWCNTs-loaded Pt catalyst. The method is simple in process, mild and environment-friendly in operation process andlow in cost; the prepared Pt nano particle catalyst is excellent in electrochemical performance and has a good application prospect. The Pt nano-particle catalyst prepared by the method can improve the electrocatalytic activity and stability of methanol oxidation, and the CO poisoning resistant capability.

Owner:GUANGXI NORMAL UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com