Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

627 results about "Ruthenium catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ruthenium catalyst is highly active in hydrogenation of aliphatic carbonyl compound and aromatic ring. Hydrogenation is possible without side reaction in mild conditions. When mixing water with reacting system, water becomes a co-catalyst and can show high activity.

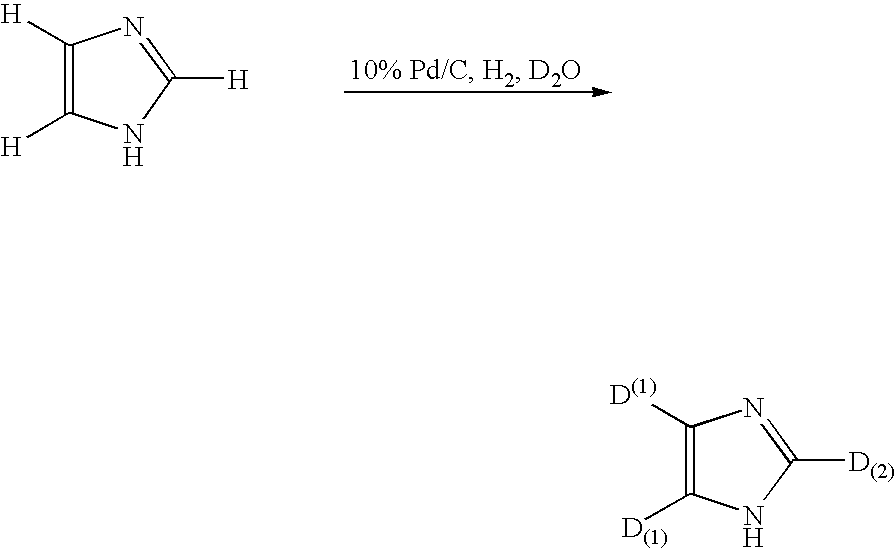

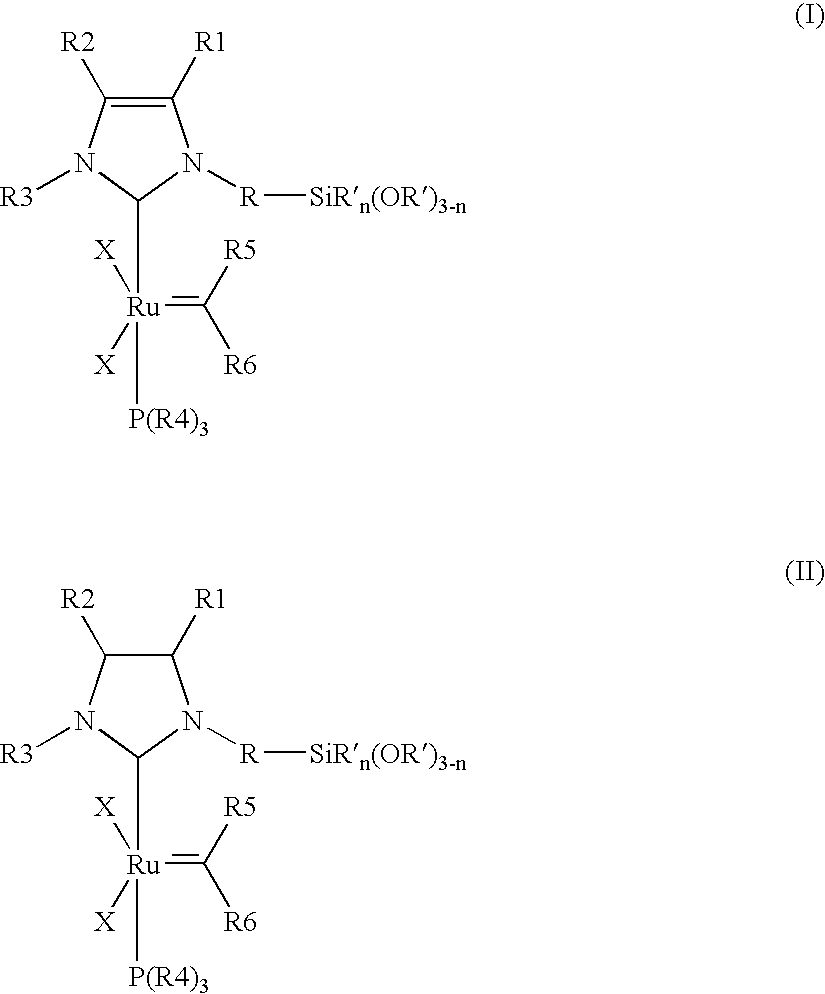

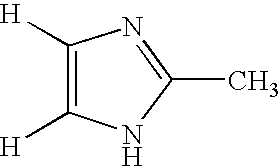

Method for deuteration of a heterocyclic ring

ActiveUS7517990B2Isotope introduction to heterocyclic compoundsSugar derivativesNickel catalystHydrogen atom

The present invention relates to a method for deuteration of a heterocyclic ring, which comprises subjecting a compound having a heterocyclic ring to sealed refluxing state in a deuterated solvent in the presence of an activated catalyst selected form a palladium catalyst, a platinum catalyst, a rhodium catalyst, a ruthenium catalyst, a nickel catalyst and a cobalt catalyst. In accordance with a method of the present invention, a hydrogen atom belonging to a heterocyclic ring of a compound having a heterocyclic ring can be very efficiently deuterated because temperature of deuteration reaction can be maintained at higher than boiling point of the solvent.Further, a method for deuteration of the present invention can be applied widely to deuteration of various compounds having a heterocyclic ring which are liable to decomposition under supercritical conditions or acidic conditions, leading to industrial and efficient deuteration of a compound having a heterocyclic ring.

Owner:FUJIFILM WAKO PURE CHEM CORP

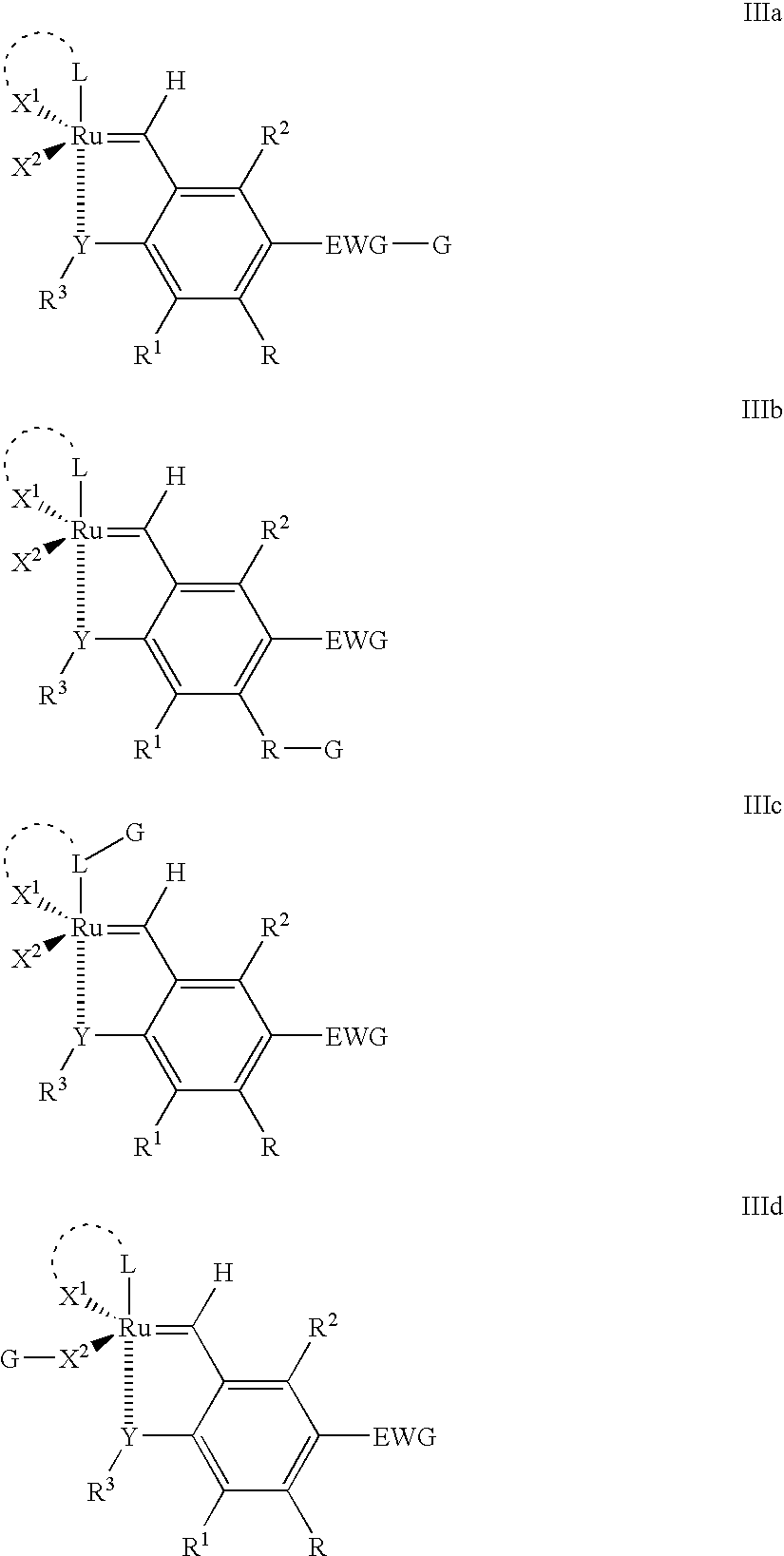

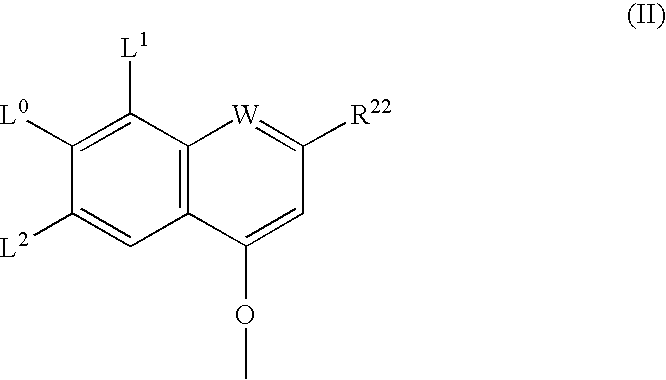

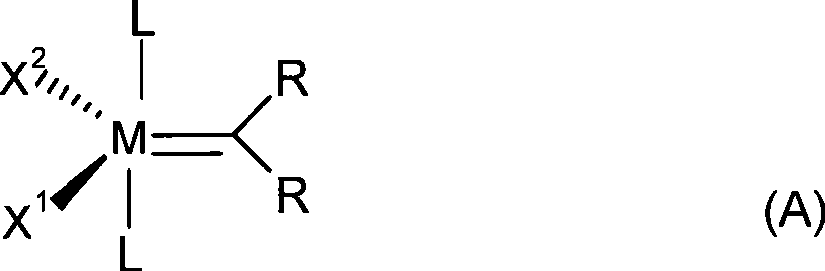

Recyclable ruthenium catalysts for metathesis reactions

ActiveUS20070043180A1Utility and advantageWide applicationRuthenium organic compoundsOrganic compound preparationAlkeneEfficient catalyst

The invention relates to novel carbene ligands and their incorporated monomeric and resin / polymer linked ruthenium catalysts, which are recyclable and highly active for olefin metathesis reactions. It is disclosed that significant electronic effect of different substituted 2-alkoxybenzylidene ligands on the catalytic activity and stability of corresponding carbene ruthenium complexes, some of novel ruthenium complexes in the invention can be broadly used as catalysts highly efficient for olefin metathesis reactions, particularly in ring-closing (RCM), ring-opening (ROM), ring-opening metathesis polymerization (ROMP) and cross metathesis (CM) in high yield. The invention also relates to preparation of new ruthenium complexes and the use in metathesis.

Owner:ZANNAN SCITECH

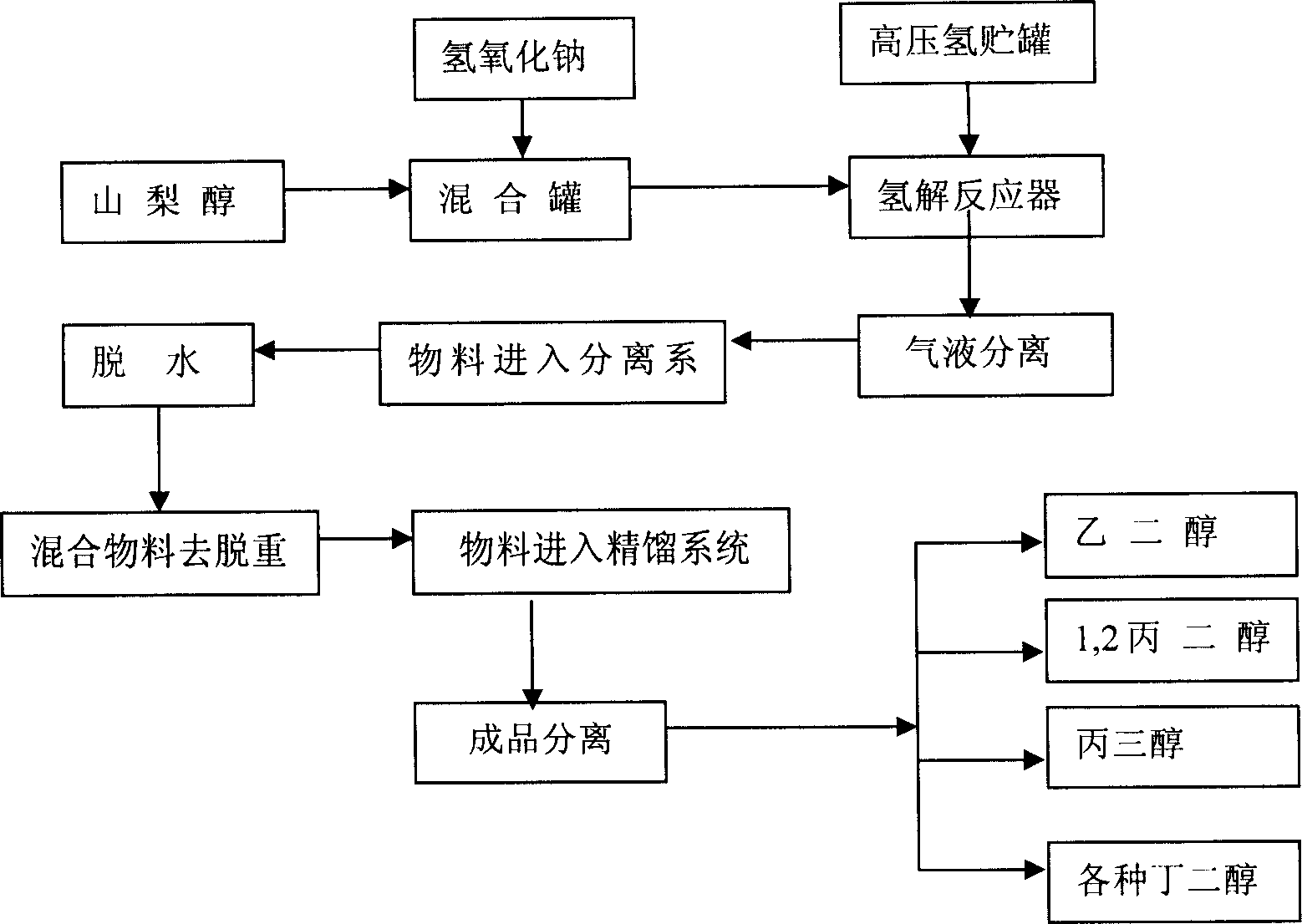

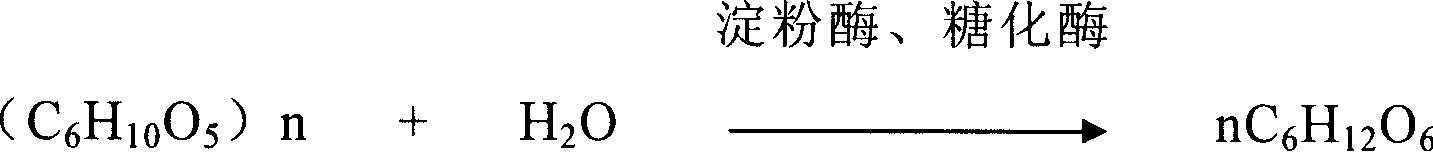

Process for producing diatomic alcohol and polyol from cracking sorbierite

InactiveCN1683293AQuality improvementIncreased production flexibilityOrganic compound preparationOrganic chemistry methodsPolyolAlcohol

The present invention relates to sorbierite cracking process to prepare C2-C4 diatomic alcohol and polyol, and is especially the process of preparing sorbierite with corn material and hydrocracking sorbierite to prepare C2-C4 diatomic alcohol and polyol. The process includes hydrocracking sorbierite to prepare the mixture of C2-C4 diatomic alcohol and polyol at high temperature and high pressure in the presence of cracking sodium hydroxide and nickel / ruthenium catalyst, separation and refining to obtain single product. The production process of the present invention has the advantages of novel production path, unique technological condition, simultaneous production of several kinds of alcohol and high product quality. In addition, using grains, such as corn, as material to replace non-regenerable resource is significant.

Owner:王宗国

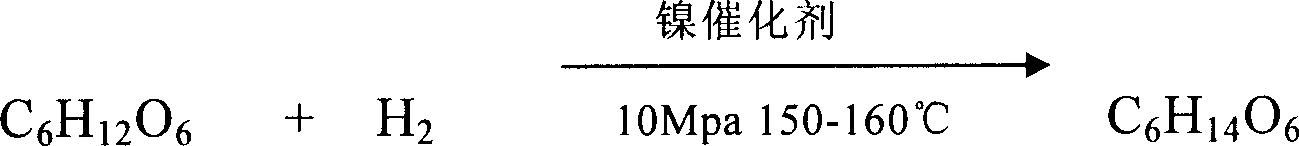

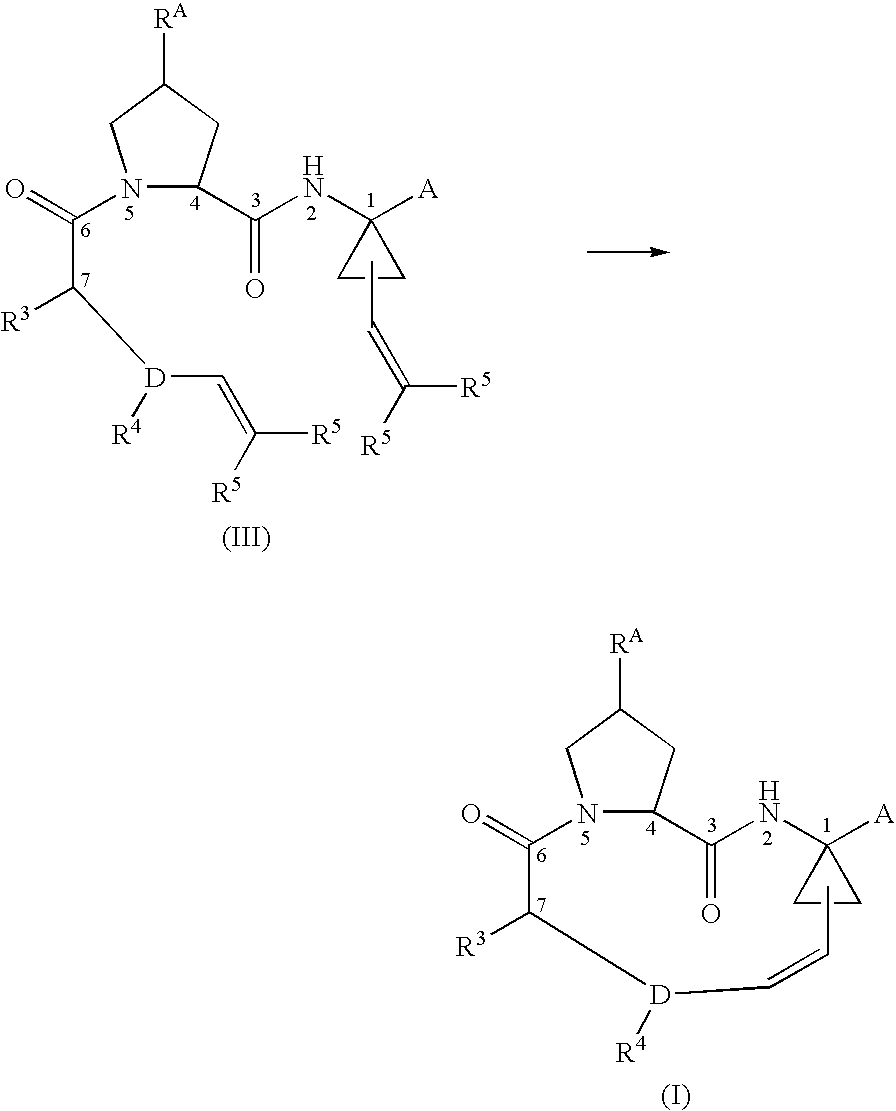

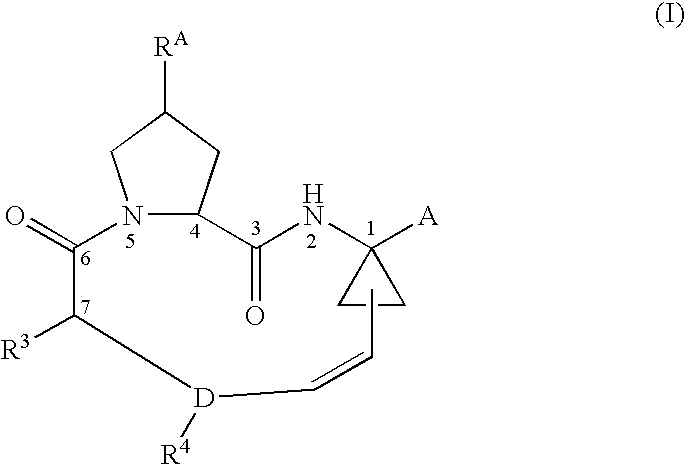

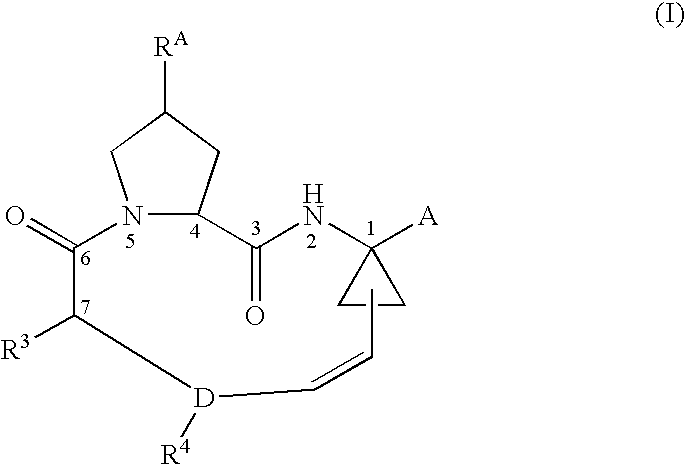

Ring-closing metathesis process in supercritical fluid

Disclosed is a process for preparing a compound of formula I comprising cyclizing a diene compound of formula III in the presence of a ruthenium catalyst in a suitable organic solvent, wherein the process is performed in a gaseous fluid at supercritical or near-supercritical conditions: The compounds of formula (I) are active agents for the treatment of hepatitis C viral (HCV) infections or are intermediates useful for the preparation of anti-HCV agents.

Owner:BOEHRINGER INGELHEIM INT GMBH

Ring-closing metathesis process in supercritical fluid

Disclosed is a process for preparing a compound of formula I comprising cyclizing a diene compound of formula III in the presence of a ruthenium catalyst in a suitable organic solvent, wherein the process is performed in a gaseous fluid at supercritical or near-supercritical conditions:The compounds of formula (I) are active agents for the treatment of hepatitis C viral (HCV) infections or are intermediates useful for the preparation of anti-HCV agents.

Owner:BOEHRINGER INGELHEIM INT GMBH

Method for Deuteration of an Aromatic Ring

ActiveUS20070255076A1Improve working environmentAmino preparation from aminesOrganic compound preparationNickel catalystHydrogen

The present invention relates to a method for deuteration of a compound having an aromatic ring, using an activated catalyst, and the method comprises reacting a compound having an aromatic ring with heavy hydrogen source in the presence of an activated catalyst selected from a platinum catalyst, a rhodium catalyst, a ruthenium catalyst, a nickel catalyst and a cobalt catalyst.

Owner:FUJIFILM WAKO PURE CHEM CORP

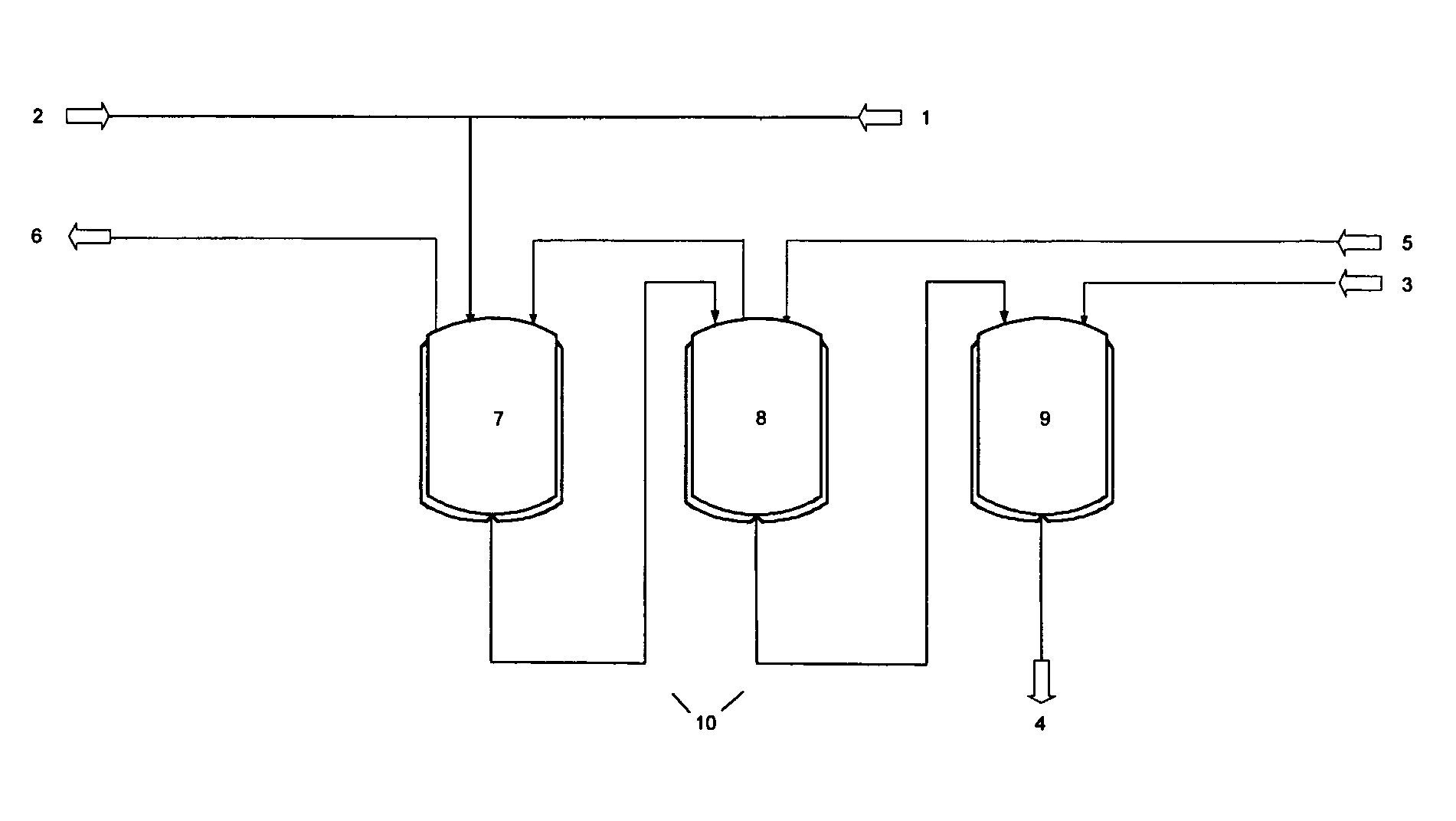

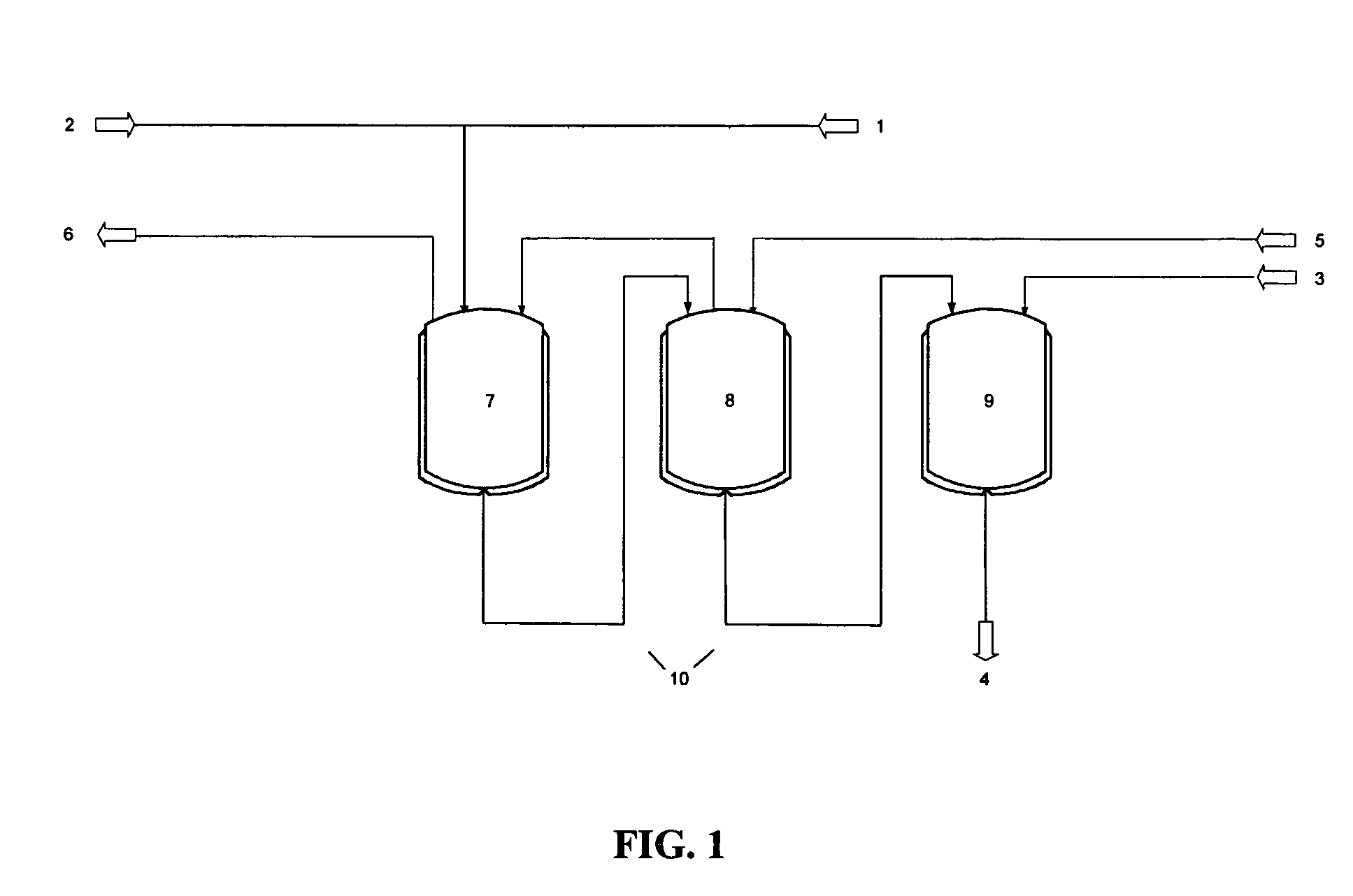

Process for continuous ruthenium-catalysed metathesis

InactiveUS20060009667A1Less fluctuationReduce riskHydrocarbon by isomerisationOrganic-compounds/hydrides/coordination-complexes catalystsChemistryRuthenium catalyst

The invention relates to a process for carrying out metathesis reactions, wherein the process is carried out continuously and a ruthenium-containing catalyst is used.

Owner:BOEHRINGER INGELHEIM INT GMBH

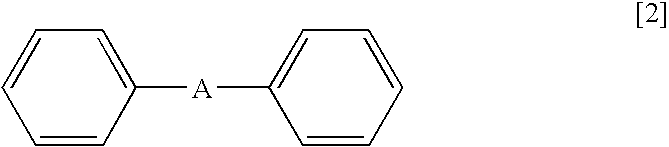

Ruthenium(II) catalysts for use in stereoselective cyclopropanations

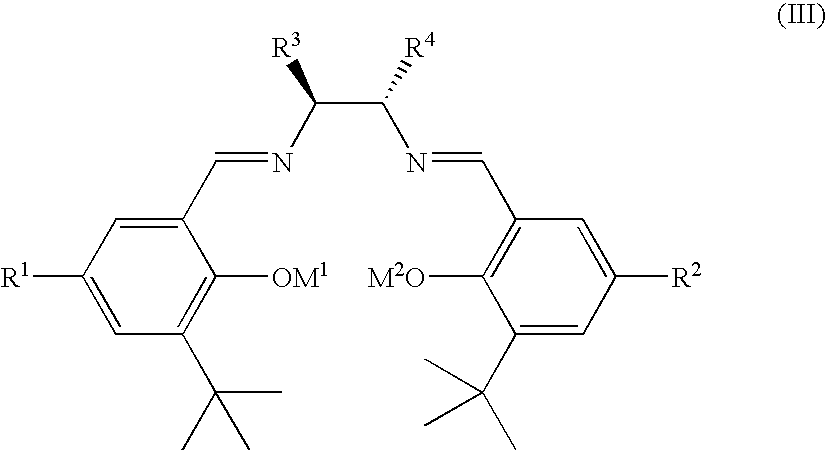

ActiveUS7754902B2High stereoselectivityHigh yieldRuthenium organic compoundsCobalt organic compoundsProtonationSalen ligand

Chiral ruthenium catalysts comprising salen and alkenyl ligands are provided for stereoselective cyclopropanation, and methods of cyclopropanation are provided. The chiral ruthenium catalyst is prepared in situ by combining an alkenyl ligand, a deprotonated chiral salen ligand, and a ruthenium (II) metal. A preferred catalyst is prepared in situ by combining 2,3-dihydro-4-venylbenzofuran, deprotonated 1,2-cyclohexanediamino-N,N′-bis(3,5-di-t-butyl-salicylidene) and RuCl2(p-cymene)]2.

Owner:VANDA PHARMA INC

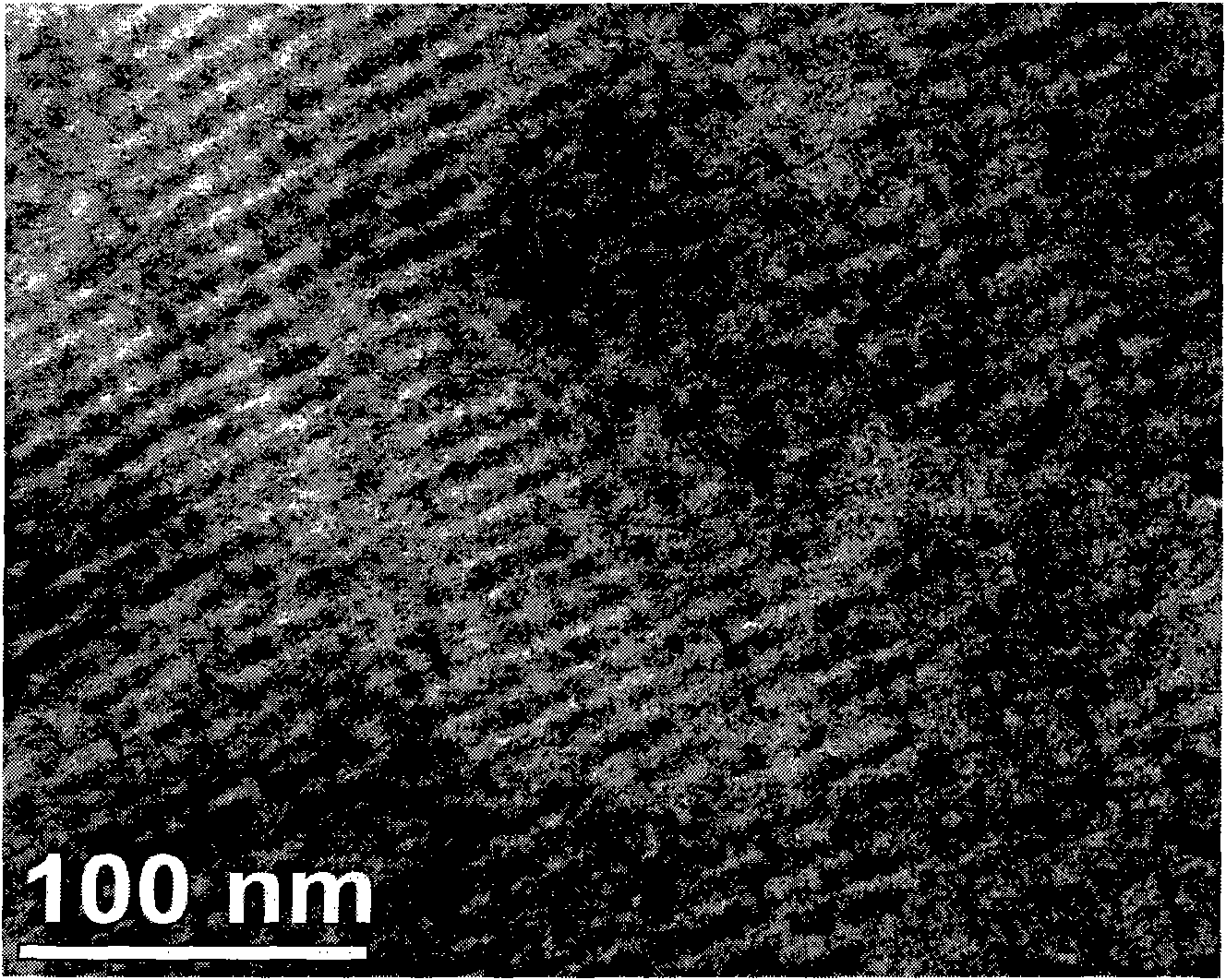

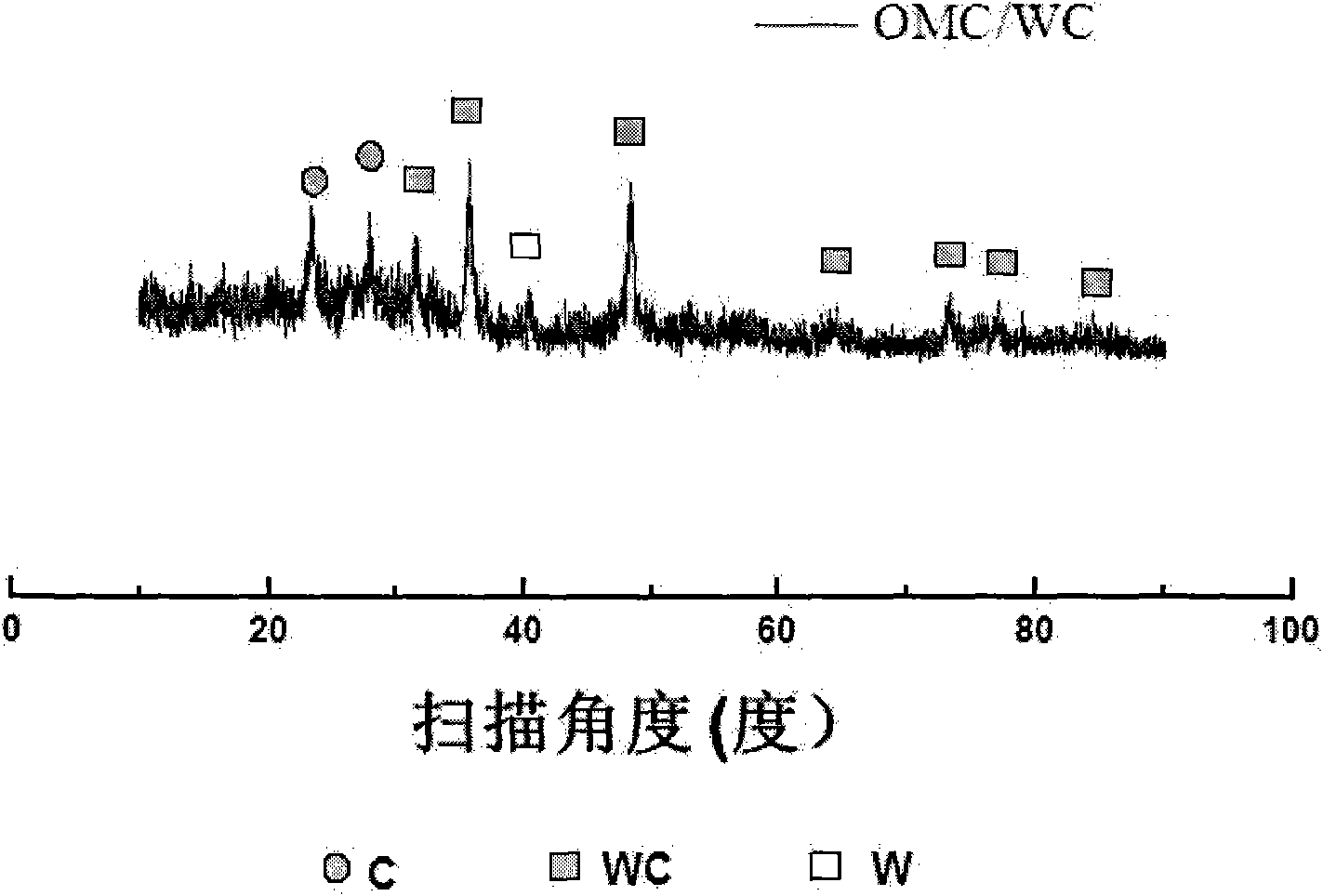

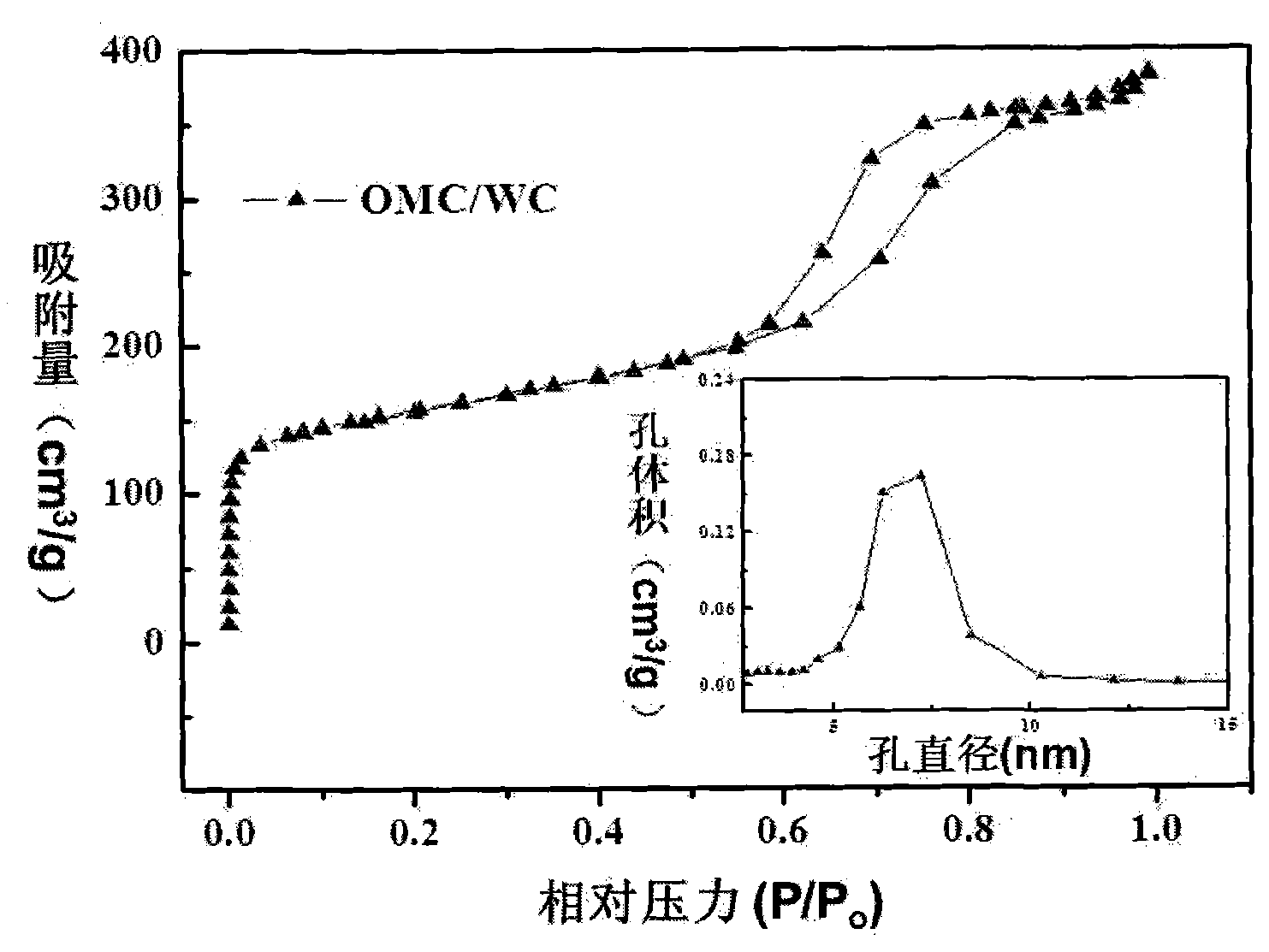

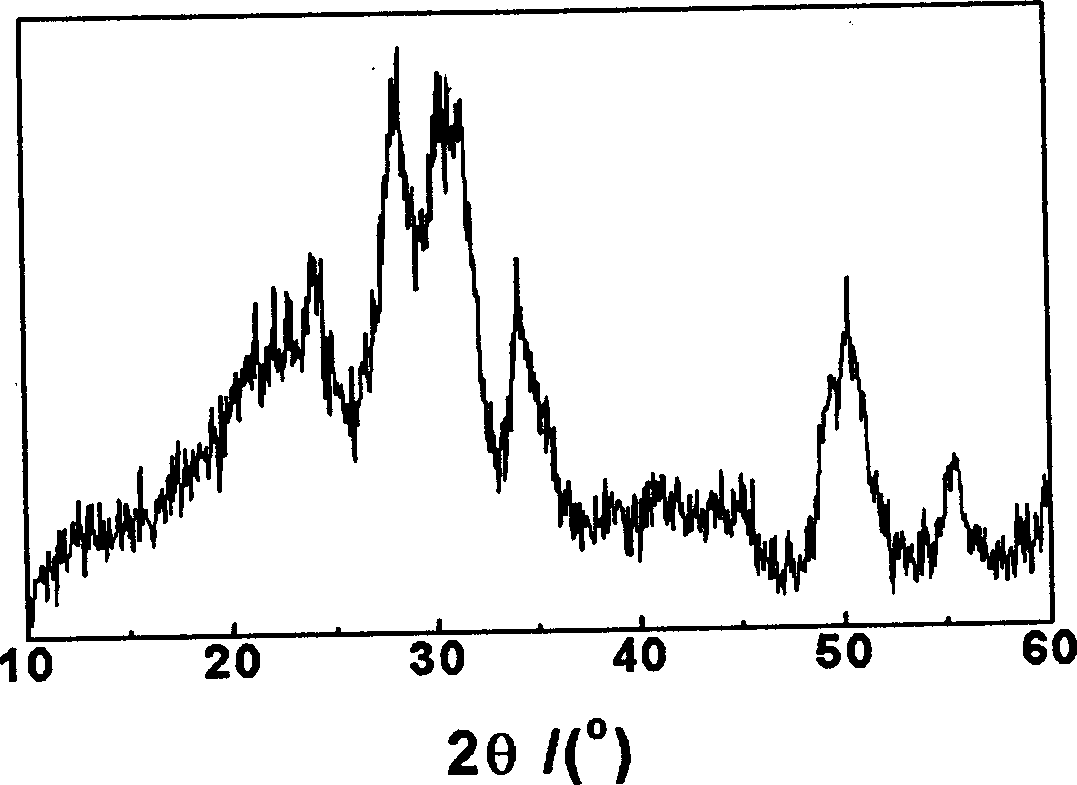

Ordered mesoporous carbon/tungsten carbide composite material and supported catalyst thereof and preparation method thereof

InactiveCN101869853AHigh degree of aperture orderNarrow pore size distributionCatalyst carriersCell electrodesSolventPt element

The invention discloses a preparation method for an ordered mesoporous carbon / tungsten carbide composite material and a supported catalyst thereof. In the method, an organic matter and a tungsten salt are separately used as a carbon source and a tungsten source, and the carbon source and the tungsten source are mixed with a surfactant; and a precursor of the ordered mesoporous carbon / tungsten carbide is synthesized by a solvent-evaporation induced self-assembly method, and then the precursor is subject to high-temperature treatment in the inert atmosphere to form the ordered mesoporous carbon / tungsten carbide composite material. The ordered mesoporous carbon / tungsten carbide composite material prepared by the method has the characteristics of high degree of order, narrow aperture distribution, large specific surface area (greater than 500 m<2> / g) and the like. The invention further comprises a supported catalyst prepared by supporting active components on the ordered mesoporous carbon / tungsten carbide composite material which is prepared by the method; and because of the synergistic effect and the structure effect of the ordered mesoporous carbon / tungsten carbide composite material, the catalyst has higher methanol electro-oxidation catalytic activity than a commercial carbon platinum-ruthenium catalyst.

Owner:SUN YAT SEN UNIV

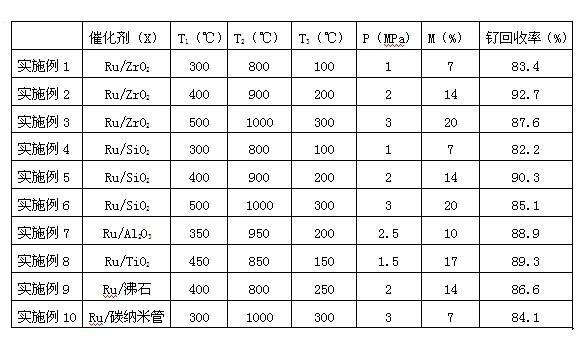

Method for recycling ruthenium in supported type ruthenium catalyst

ActiveCN102108444AReduce recycling stepsEasy to recycleProcess efficiency improvementEconomic benefitsNitrogen

The invention discloses a method for recycling ruthenium in a supported type ruthenium or ruthenium oxide catalyst. The method comprises the following technological steps: (1) placing a supported type ruthenium catalyst or a supported type ruthenium oxide catalyst in an airtight container, heating to 300-500 DEG C, and roasting for 1-2 hours; and feeding nitrogen for protection during roasting process; (2) stopping the feeding of nitrogen stream in the step (1), continuing to heat to 800-1000 DEG C, and roasting for 2-10 hours; and obtaining black solids after cooling; (3) grinding black solids into powder, placing in the airtight container, and heating to 100-300 DEG C; and feeding oxygen / ozone to oxidize solid powder and generate ruthenium tetroxide gas; and (4) feeding the ruthenium tetroxide gas into diluted hydrochloric acid, and restoring the acid combined with the gas into a red and brown ruthenium trichloride solution. According to the device, the step of recycling the catalyst is reduced; not only is the cost reduced during the recycling process of ruthenium catalyst, but also the recycling process is simplified; and economic benefit and the environment benefit are greatly improved.

Owner:KAILUAN ENERGY CHEM

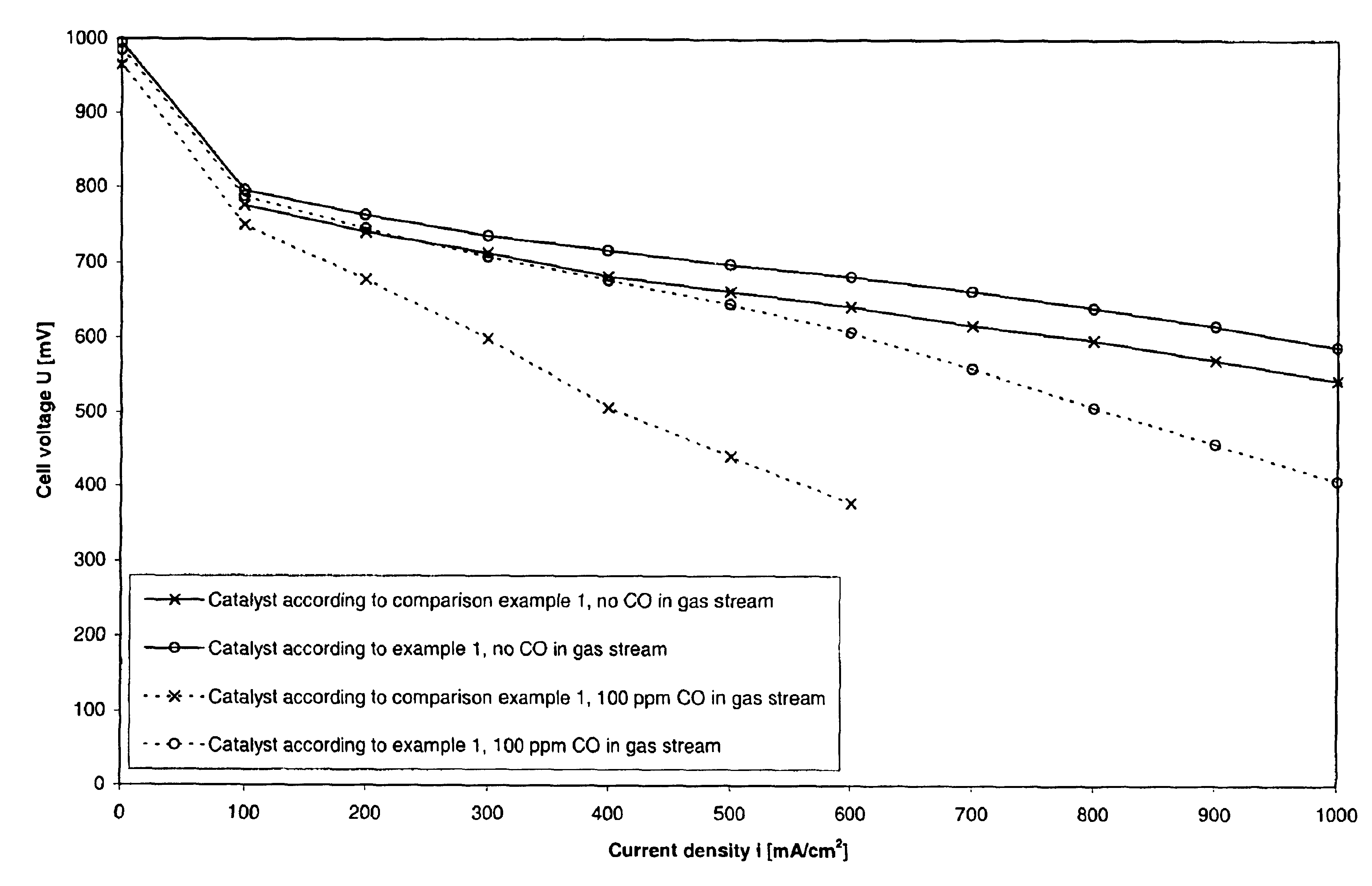

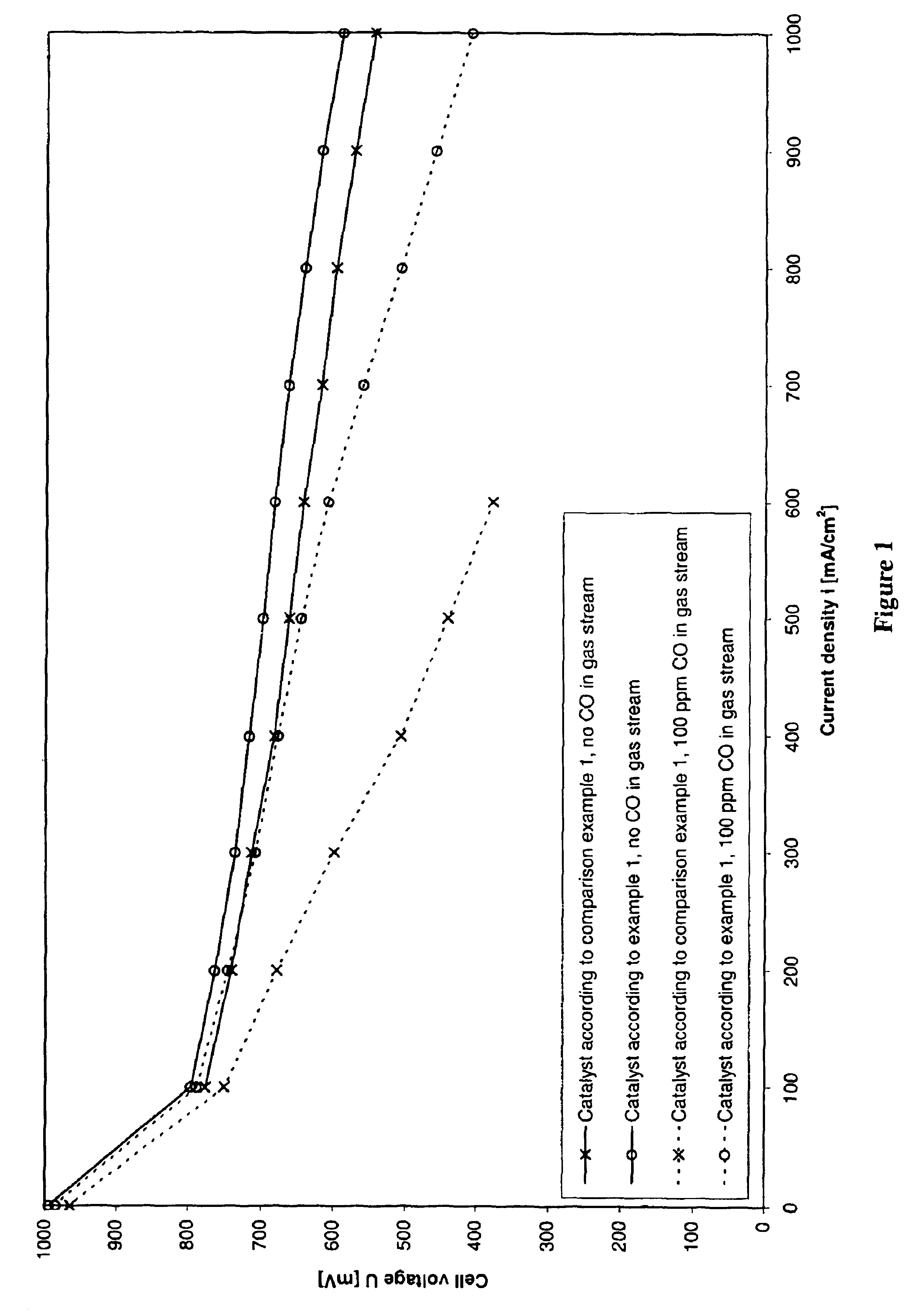

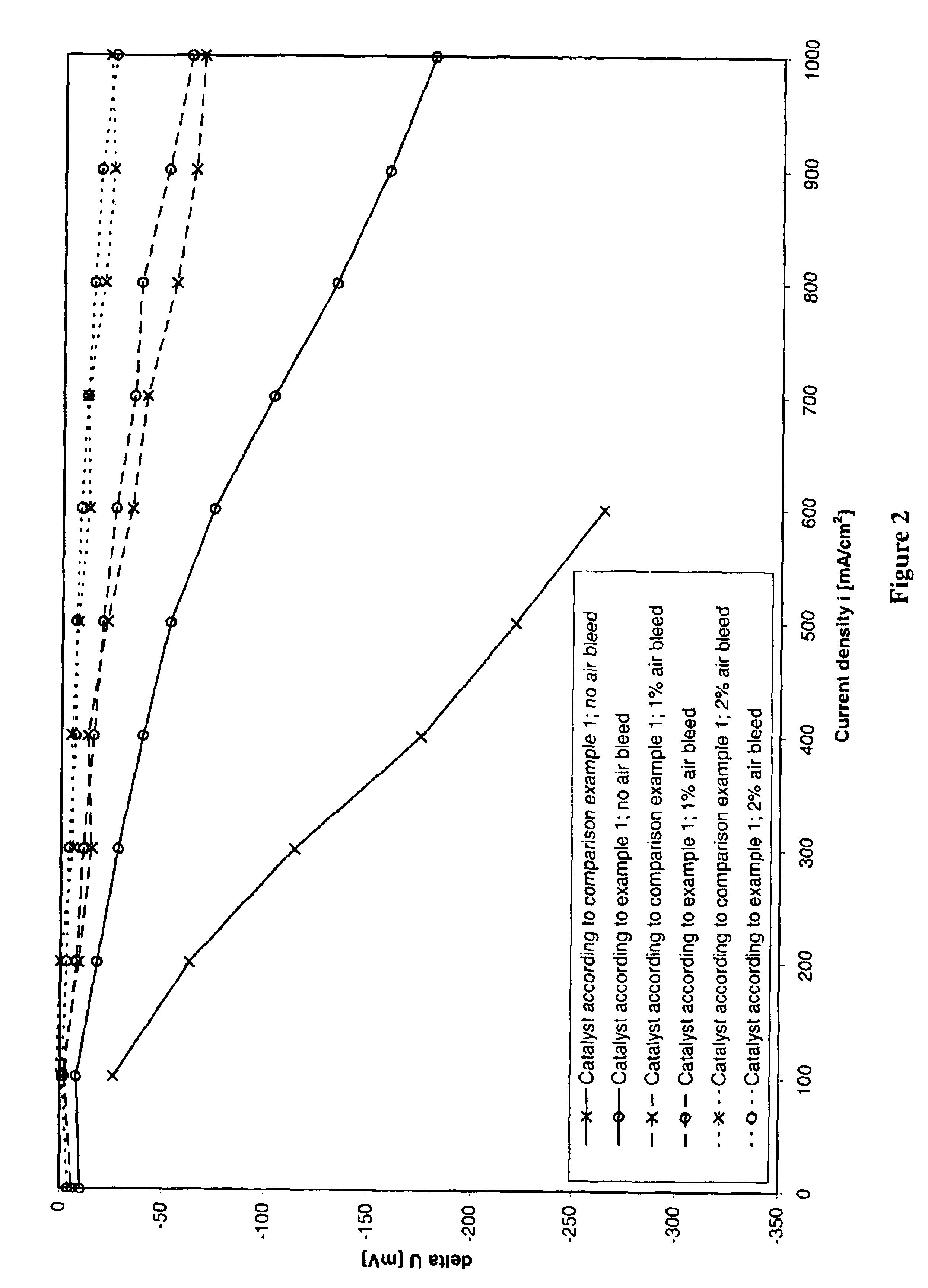

Process for preparing an anode catalyst for fuel cells and the anode catalyst prepared therewith

InactiveUS6797667B2High activityHigh oxidation stateActive material electrodesCatalyst activation/preparationCarboxylic acidRuthenium chloride

The invention provides a process for preparing a platinum-ruthenium catalyst and the catalyst prepared therewith. The catalyst can be supported on a support material in powder form or may also be unsupported. To prepare the supported catalyst, the support material is suspended in water and the suspension is heated to at most the boiling point. While keeping the temperature of the suspension the same, solutions of hexachloroplatinic acid and ruthenium chloride are then added to the suspension, then the pH of the suspension is increased to a value between 6.5 and 10 by adding an alkaline solution and the noble metals are thus precipitated onto the support material. Afterwards, one or more organic carboxylic acids and / or their salts are added to the suspension and the catalyst is chemically reduced, washed, dried and optionally subsequently calcined under an inert or reducing atmosphere at a temperature between 300 und 1000° C. The catalyst is characterised by a high tolerance to carbon monoxide poisoning in the fuel cell.

Owner:UMICORE AG & CO KG

Method for recovering ruthenium catalyst carried by active carbon

InactiveCN1872418AReduce manufacturing costReduce consumptionRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsCatalyst regeneration/reactivationRecovery methodActivated carbon

A recovering process for the activated carbon carried Ru catalyst not containing the compound of alkali metal or alkali-earth metal includes such steps as calcining at 600-1000 deg.C for 2-20 hr to obtain gray mixture, mixing it with KOH and KNO3, holding the temp at 300-950 deg.C for 105 hr, cooling, dissolving in hot water at 50-90 deg.C to obtain K2RuO4 solution, adding sodium hypochlorite and concentrated sulfuric acid, distilling to generate RuO4 gas, absorbing it by strong acid solution, and distilling to obtain Ru salt.

Owner:ZHEJIANG UNIV OF TECH +1

Benzene selective hydrogenation carried ruthenium based catalyst and its preparation

InactiveCN1424293AHigh catalytic efficiencyHigh selectivityHydrocarbon by hydrogenationCatalyst activation/preparationBenzeneHydrogen

A Ru-base catalyst for selective hydrogenation of benzene to prepare cyclohexene is prepared from Ru, carrier (metal oxide), modifier M chosen from Cr, Mo, W, Fe, Co, Cu and La, and salt solution N through introducing hydrogen gas to aqueous solution to reduce Ru(OH)3 and M, and centrifugal washing to remove impurity ions. Its advantages are high activity and selectivity, and easy storage.

Owner:FUDAN UNIV

Method for recovering ruthenium in activated carbon supported ruthenium catalyst

ActiveCN101638727ASafe recyclingHigh recovery rateProcess efficiency improvementActivated carbonAlkaline earth metal

The invention relates to a method for recovering an activated carbon supported ruthenium catalyst, which comprises the steps of: performing high-temperature roasting on an activated carbon supported ruthenium catalyst in which an alkali metal or alkaline-earth metal compound additive is not contained or is removed; performing high-temperature alkaline fusion on a roasted product; dissolving an alkaline fusion product in hot water with a temperature of between 60 and 95 DEG C to obtain a K2RuO4 or Na2RuO4 solution, adding ethanol or an alkaline solution into the K2RuO4 or Na2RuO4 solution to obtain a Ru(OH)4 precipitate; and drying the precipitate, or dissolving the precipitate by using strong acid, or using H2 to reduce the precipitate to obtain different ruthenium products. The method hasthe advantages that precious metal ruthenium can be efficiently recovered, the operation process of the recovery is safe, alkali metal and alkaline-earth metal additives can be synchronously recovered, and the form of the recovered product can be selected. The method has reliable technology, simple operation, low cost and no pollution.

Owner:PETROCHINA CO LTD +1

Supported ruthenium catalyst and preparation method thereof

InactiveCN102476052ALow costEasy to prepareOrganic reductionMolecular sieve catalystsAlkaline earth metalSecondary component

The invention discloses a supported ruthenium catalyst and a preparation method thereof. The preparation method is characterized in that the preparation method comprises the following steps: 1, preprocessing a carrier with a soluble alkaline earth metal salt, wherein the mass of the soluble alkaline earth metal salt accounts for 0.1-20% of the mass of the carrier; and 2, dipping the alkaline earth metal salt processed carrier with a material which comprises a primary active component metallic ruthenium and an assisted catalytic component comprising one or several of Ni, Co, Pd and Pt, wherein the mass of the primary component metallic ruthenium accounts for 0.1-5% of the carrier, and the mass of the secondary component comprising one or several of Ni, Co, Pd and Pt accounts for 0.01-5% of the mass of the carrier. The catalyst of the invention is mainly applied to the selective hydrogenation process of an aromatic ring of an aromatic compound, wherein the aromatic ring of the aromatic compound has at least one alkyl group, one ester group, one hydroxyl group or an amino group and also has at least one C1-8 alkyl group. Compared with catalysts prepared with the prior art, the catalyst of the invention has the advantages of low cost, simple preparation method, high activity, good selectivity, high safety in the operation of the aromatic ring hydrogenation, realization of the operation of the aromatic ring hydrogenation under a low pressure, and good economy.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing chlorine

InactiveUS6852667B2High activityEasy to controlCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive componentOxygen

A process for producing chlorine by oxidizing hydrogen chloride with oxygen. The process uses various supported ruthenium catalysts or a catalyst system containing (A) an active component of a catalyst and (B) a compound having thermal conductivity of a solid phase measured by at least one point within a range from 200 to 500° C. of not less than 4 W / m. ° C.

Owner:SUMITOMO CHEM CO LTD

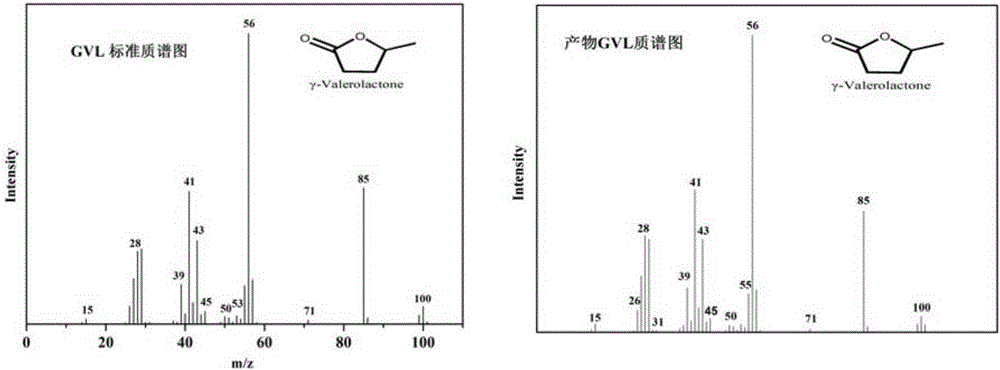

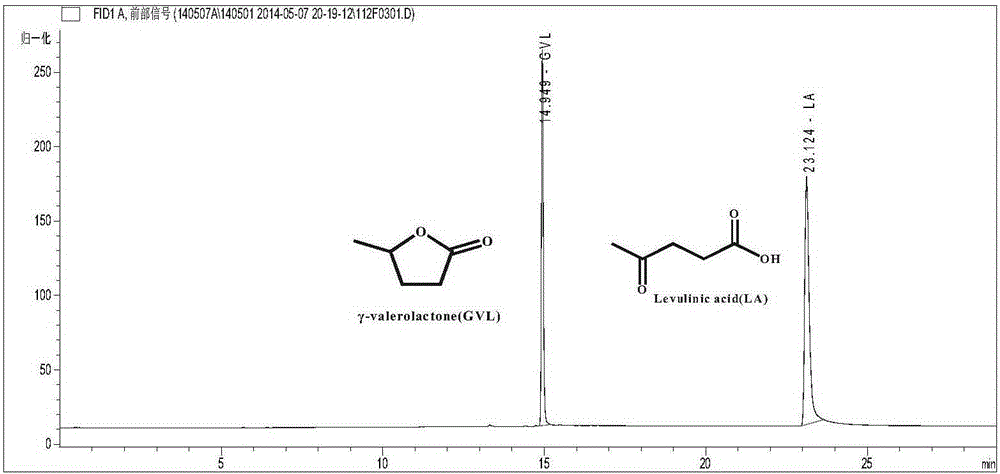

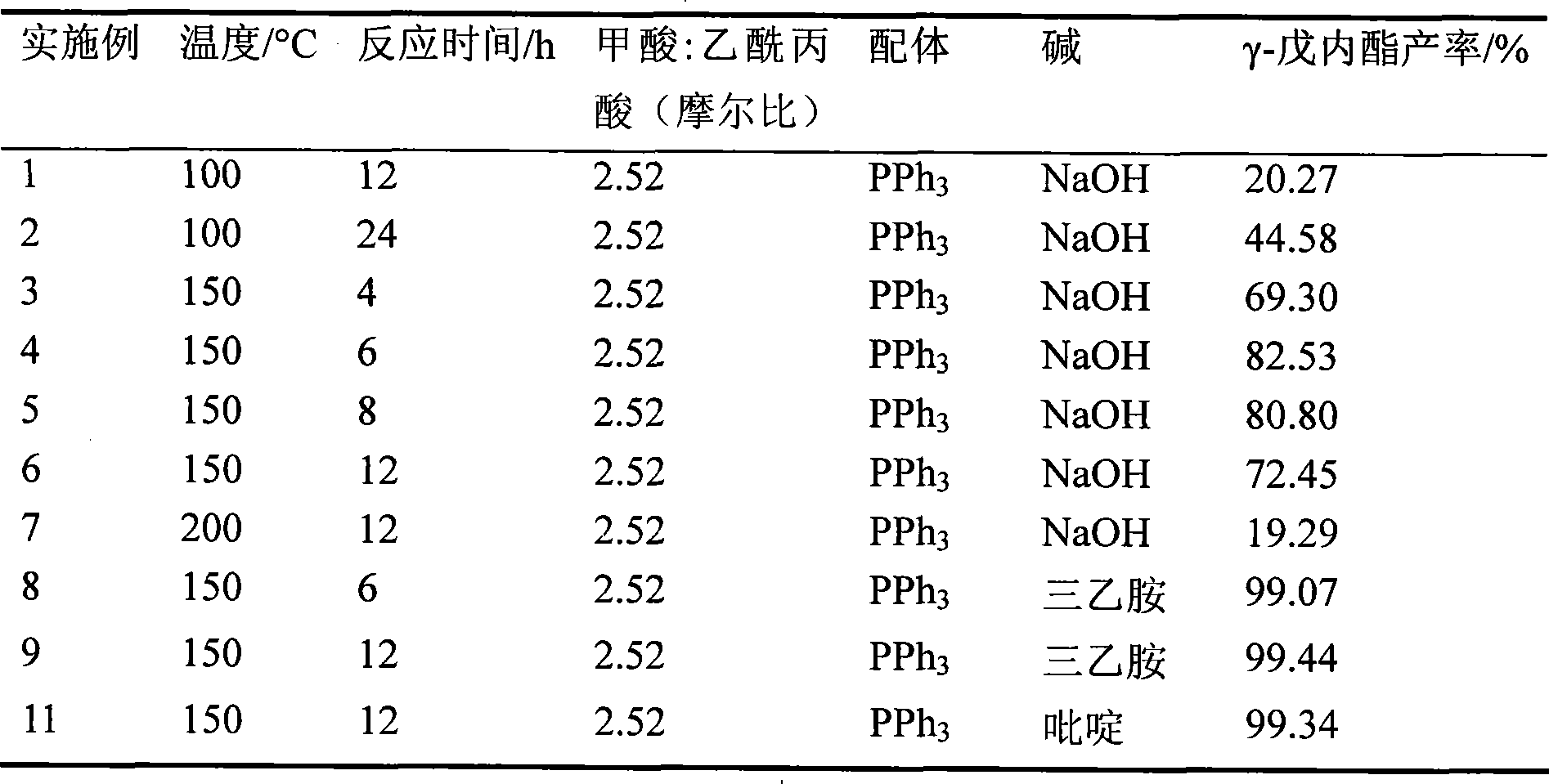

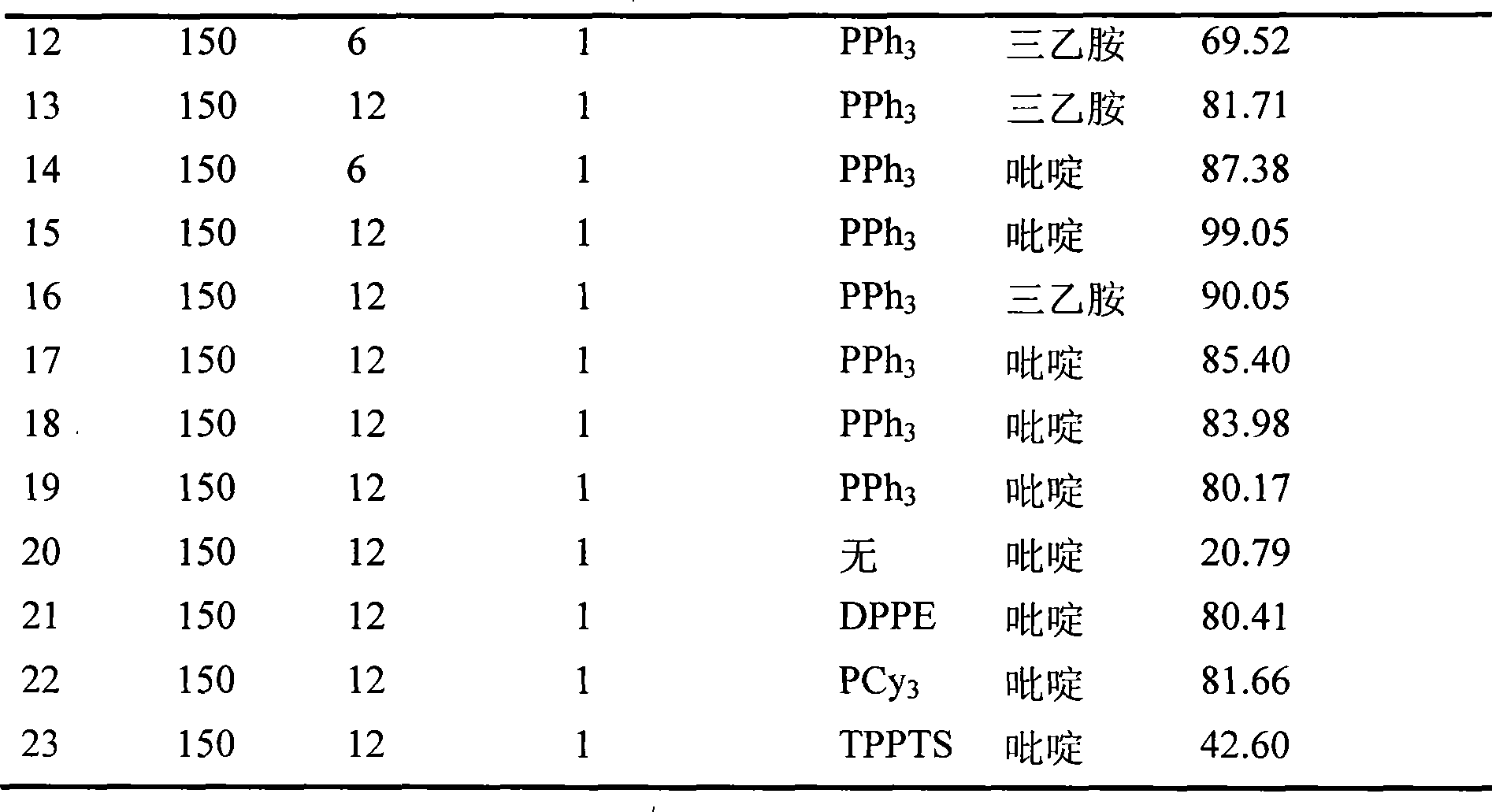

Method for preparing gamma-valerolactone by acetylpropionic acid catalytic hydrogenation

ActiveCN105289592AHigh activityGood reaction selectivityOrganic chemistryMolecular sieve catalystsOrganic acidPtru catalyst

The invention discloses a method for preparing gamma-valerolactone by acetylpropionic acid catalytic hydrogenation. Through high efficiency catalysis of levulinic acid hydrogenation based on a loaded ruthenium catalyst under mild conditions, gamma-valerolactone is prepared. The method has a levulinic acid conversion rate of 100% and gamma-valerolactone selectivity of 99.9%. The loaded ruthenium catalyst has a low active metal load capacity (less than 1.5w.t.%) and high activity (TOF, 7676h<1>), has good water and acid resistance and is suitable for an intermittent reactor and a continuous fixed bed reactor. The method solves the problem that the existing gamma-valerolactone preparation method needs a high temperature and high pressure and utilizes organic acids and bases and an organic solvent, improves preparation method economy and safety, utilizes a small amount of a catalyst, realizes catalyst recycle, has a high product yield and product separation easiness, and has a latent industrial application value.

Owner:SYNFUELS CHINA TECH CO LTD

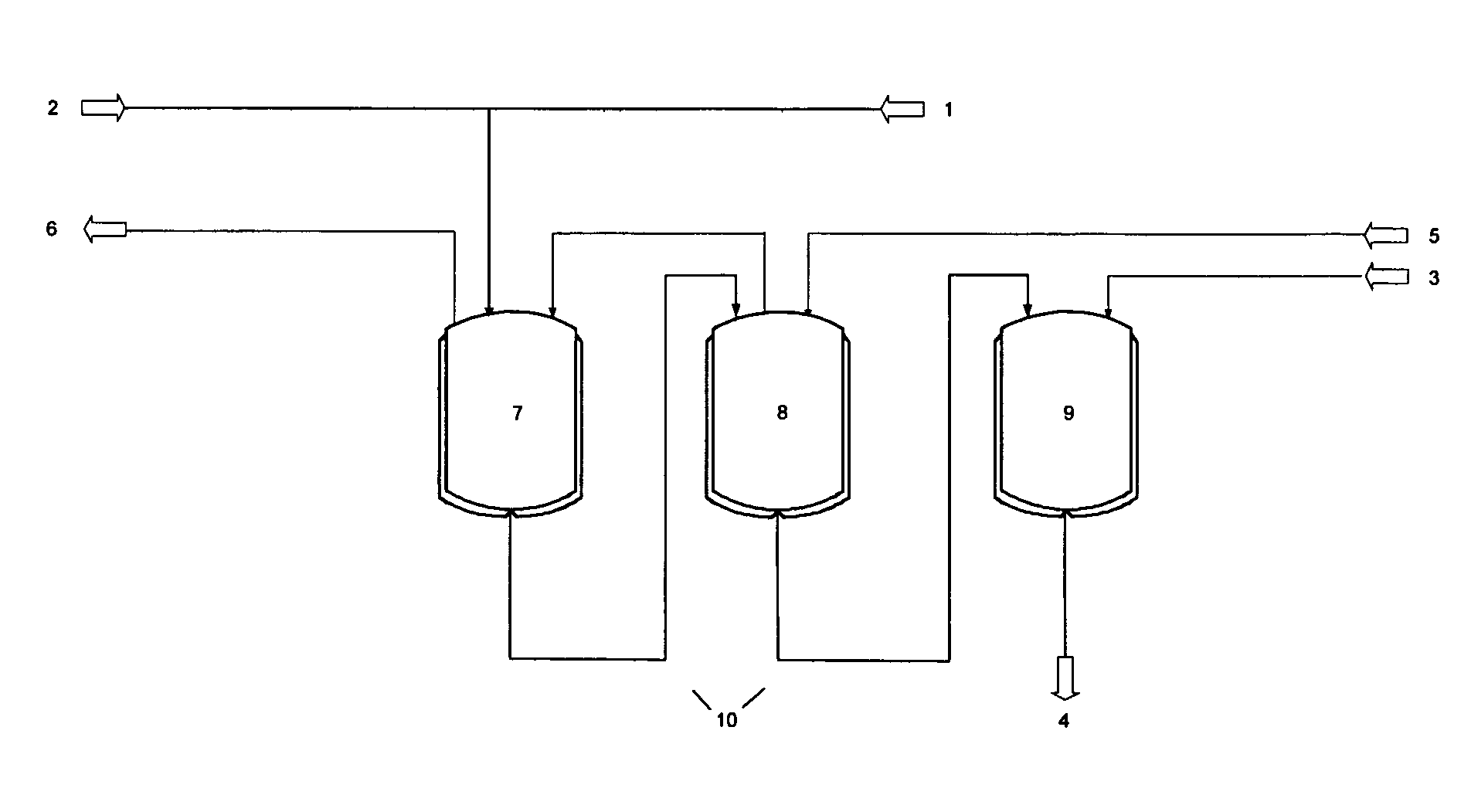

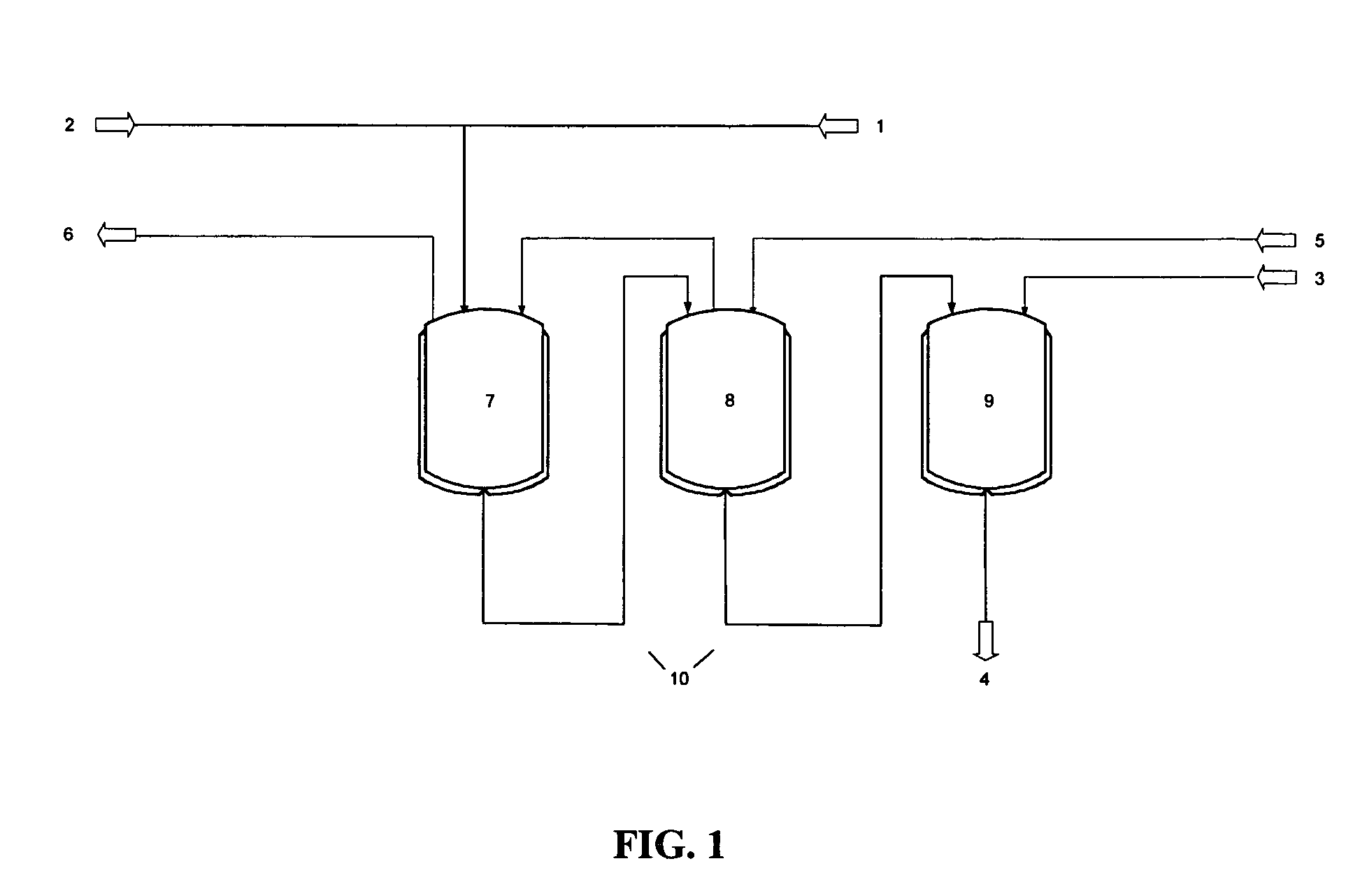

Method for directly preparing gamma-valerolactone from acetylpropionic acid and aminic acid

The invention discloses a method for preparing GAMMA-valerolactone from levulinic acid and formic acid, which is characterized in that the levulinic acid is in situ reduced at 100-200 DEG C in the presence of ruthenium catalyst and formic acid contained in a system as reducer, and distillation is carried out to obtain mixture containing the product GAMMA valerolactone and used catalyst; and mother liquor containing the used catalyst and raw material are mixed to realize circulation of the catalyst, thereby greatly improving environmental friendliness. The method avoids the energy source consumption during valerolactone purification process, avoids hydrogen source acquired from the system exterior, and improves the economy and security of a production system, with the advantages of simple operation process. The formic acid is decomposed to generate large amount of carbon dioxide besides hydrogen, which is convenient for collection and utilization.

Owner:UNIV OF SCI & TECH OF CHINA

Process for continuous ruthenium-catalysed metathesis

InactiveUS7838711B2Less fluctuationReduce riskHydrocarbon by isomerisationOrganic-compounds/hydrides/coordination-complexes catalystsSalt metathesis reactionChemistry

Owner:BOEHRINGER INGELHEIM INT GMBH

Self-humidification membrane electrode for proton exchange membrane fuel cell and preparation method thereof

InactiveCN103078122AImprove hydrophilicityGood moisturizing effectCell electrodesPtru catalystOrganic polymer

The invention discloses a self-humidification membrane electrode for a proton exchange membrane fuel cell and a preparation method thereof. The preparation method comprises the following steps of 1, pre-treating a proton exchange membrane, 2, mixing a carbon-supported platinum or platinum-ruthenium catalyst, a perfluorinated sulfonic acid resin, a hydrophilic organic polymer and an inorganic oxide and in water or a low-boiling point solvent, carrying out ultrasonic treatment to obtain catalyst slurry, and carrying out spray-coating of the catalyst slurry on one side of the proton exchange membrane by an illumination direct-coating technology to obtain an anode catalyst layer, 3, carrying out spray-coating of slurry without the hydrophilic organic polymer and the inorganic oxide on the other side of the proton exchange membrane to obtain a cathode catalyst layer, and 4, carrying out lamination of a gas diffusion layer and the proton exchange membrane of which the two sides are coated with the catalyst layers to obtain the self-humidification membrane electrode. The anode catalyst layer contains the hydrophilic organic polymer and the inorganic oxide so that the self-humidification membrane electrode has excellent self-humidification performances at a high cell temperature and low humidity.

Owner:SOUTH CHINA UNIV OF TECH

Method for synthesizing cyclohexylamine with aniline by means of gas-phase catalytic hydrogenation

ActiveCN102633649AExtended service lifeHigh yieldOrganic compound preparationAmino compound preparationGas phaseFixed bed

The invention discloses a method for synthesizing cyclohexylamine with aniline by means of gas-phase catalytic hydrogenation, which includes the steps: 1) mixing fresh hydrogen with circulating hydrogen; 2) mixing mixed hydrogen with the aniline according to the molar ratio of 15:1-19:1 in an aniline evaporator to enable vaporization of the aniline; 3) carrying out a hydrogenation reaction of vaporized mixed gas in a fixed bed hydrogenation reactor prefilled with cobalt-ruthenium catalyst or nickel-ruthenium catalyst at the reaction temperature of 165-179 DEG C and under the reaction pressureof 0.2-0.3MPa; and 4) materials which are subjected to the hydrogenation reaction enter a separator by means of heat exchange, condensation and cooling, performing gas separation to obtain crude cyclohexylamine, and then rectifying so that a cyclohexylamine product is prepared. By the aid of the method, production cost is effectively reduced, product yield is increased, and the service life of the catalyst is prolonged.

Owner:SHANDONG WEIJIAO GRP

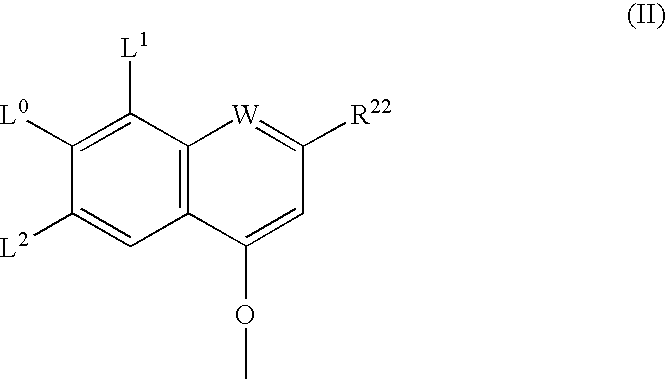

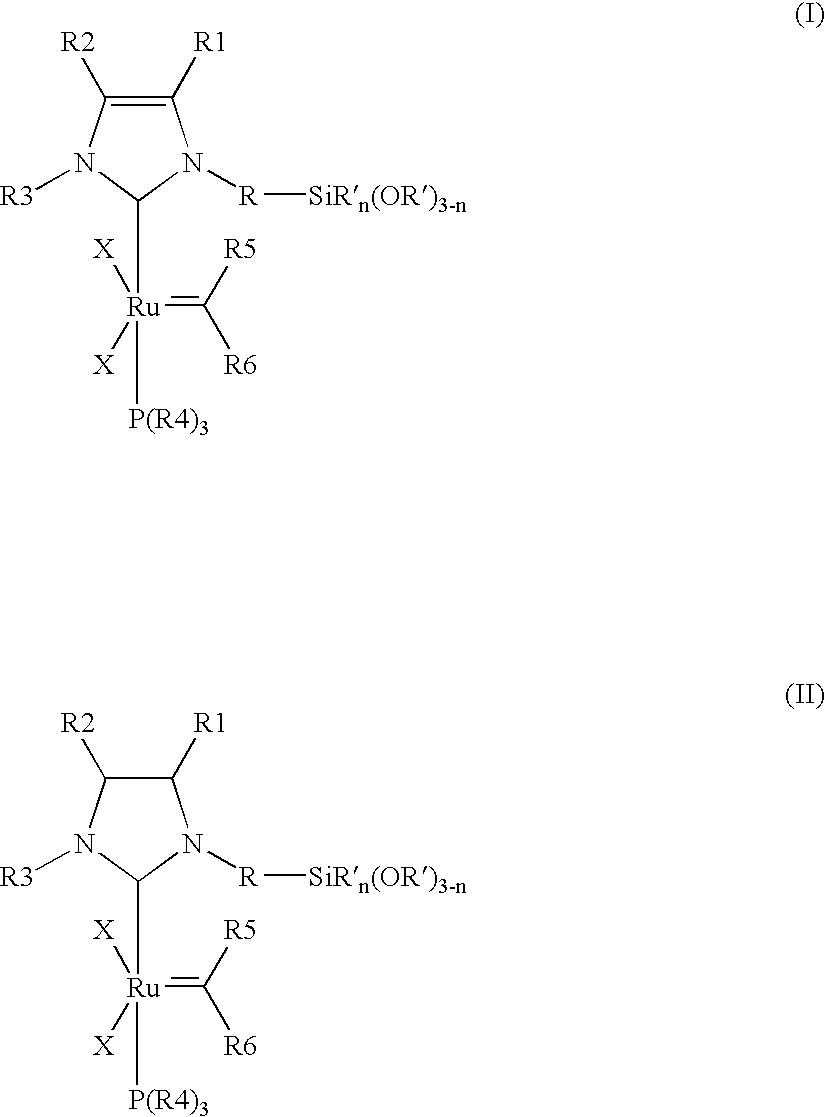

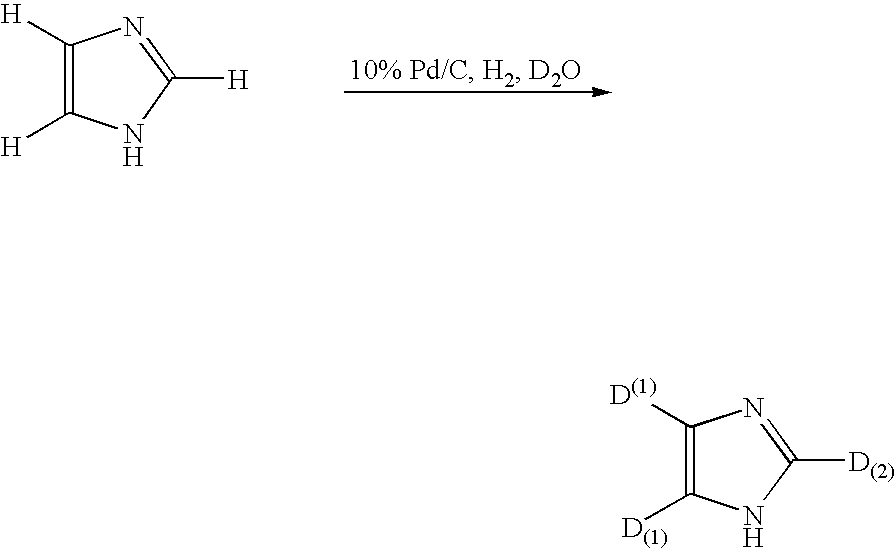

Immobilizable ruthenium catalysts having n-heterocyclic carbene ligands

InactiveUS20060287450A1Ruthenium organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsNitrogenCarbene

The invention relates to immobilisable ruthenium catalysts containing N-heterocyclic carbene ligands of the general formulae (I) and (II) which contain an SiR′n(OR′)3 -carrying group on one of the two nitrogen atoms of the NHC ligand, and to the use thereof as homogeneous catalysts in C-C coupling reactions, in particular olefin metathesis. The invention furthermore relates to the use of the compounds as starting materials for the preparation of analogous immobilised ruthenium catalysts containing N-heterocyclic carbene ligands.

Owner:MERCK PATENT GMBH

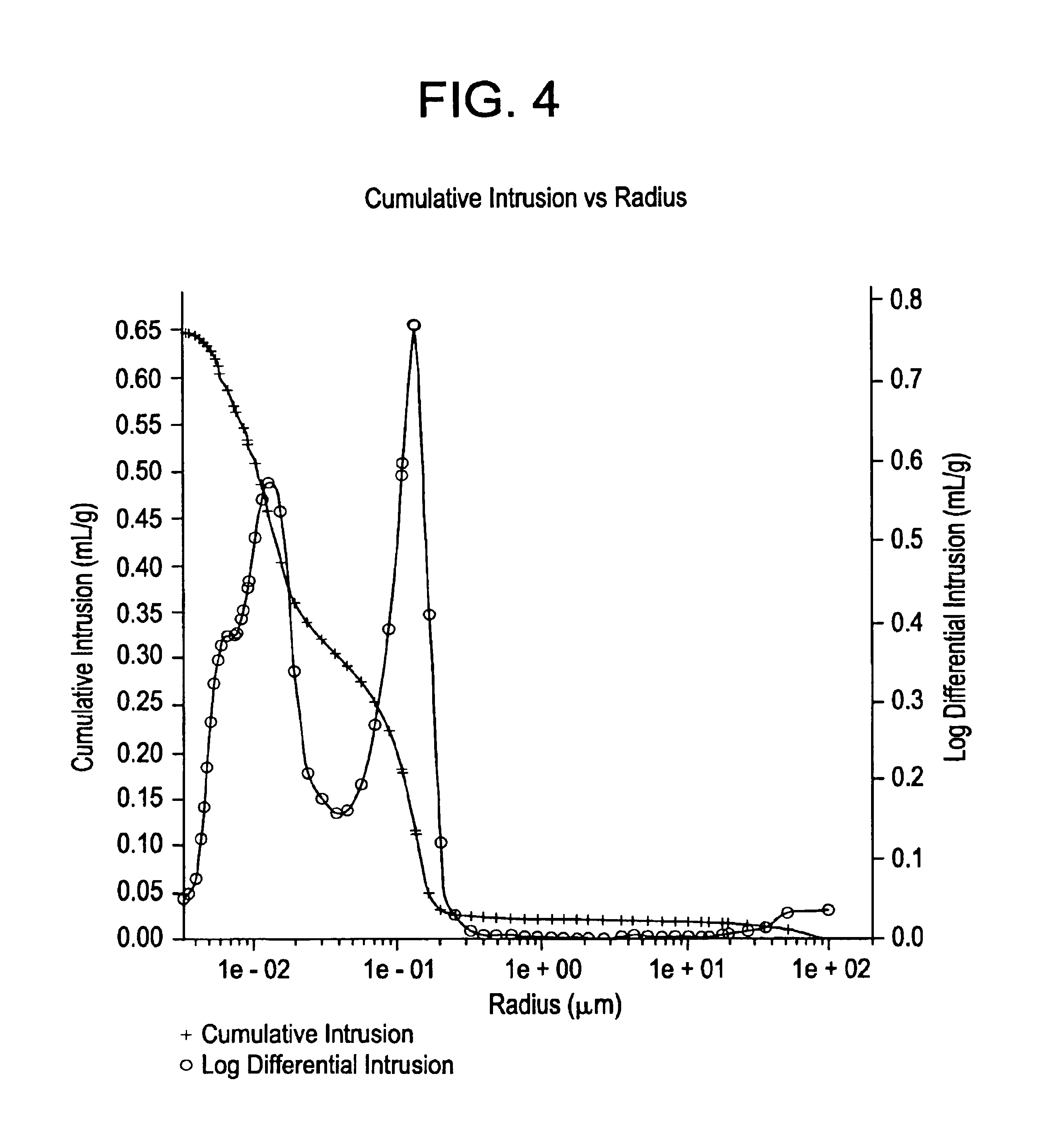

Process for hydrogenating an aromatic amine in the presence of a supported ruthenium catalyst

InactiveUS7030052B2High selectivityExtend working lifeOrganic compound preparationOrganic chemistry methodsHydrogenMetallole

The invention relates to a process for hydrogenating an aromatic amine that has at least one amino group bound to an aromatic nucleus with hydrogen in the presence of a supported catalyst that contains at least ruthenium as active metal. The catalyst support has a BET surface area in the range from greater than 30 m2 / g to less than 70 m2 / g and more than 50% of the pore volume of the catalyst support is formed by macropores having a pore diameter of greater than 50 nm and less than 50% are mesopores having a pore diameter of 2 to 50 nm.

Owner:EVONIK OPERATIONS GMBH

Method for deuteration or tritiation of heterocyclic ring

ActiveUS20060025596A1Isotope introduction to heterocyclic compoundsSugar derivativesDecompositionPalladium catalyst

The present invention relates to a method for deuteration of a heterocyclic ring, which comprises subjecting a compound having a heterocyclic ring to sealed refluxing state in a deuterated solvent in the presence of an activated catalyst selected form a palladium catalyst, a platinum catalyst, a rhodium catalyst, a ruthenium catalyst, a nickel catalyst and a cobalt catalyst. In accordance with a method of the present invention, a hydrogen atom belonging to a heterocyclic ring of a compound having a heterocyclic ring can be very efficiently deuterated because temperature of deuteration reaction can be maintained at higher than boiling point of the solvent. Further, a method for deuteration of the present invention can be applied widely to deuteration of various compounds having a heterocyclic ring which are liable to decomposition under supercritical conditions or acidic conditions, leading to industrial and efficient deuteration of a compound having a heterocyclic ring.

Owner:FUJIFILM WAKO PURE CHEM CORP

Method for preparing halogenated nitrobenzene selective hydrogenation high-activity nano-ruthenium catalyst

InactiveCN101569859AGood dispersionAvoid organic pollutionOrganic compound preparationCatalyst activation/preparationActive agentNitrobenzene

The invention discloses a method for preparing a halogenated nitrobenzene selective hydrogenation high-activity nano-ruthenium catalyst, which comprises the following steps: evenly mixing surfactant aqueous solution with pre-dissolved ruthenium salt solution; adding a reducer to deoxidize the mixture so as to form surfactant stable nano-ruthenium colloidal solution; adding a carrier to the ruthenium colloidal solution for adsorption, and filtering the mixture after the adsorption; and washing the catalyst until the filtrate is neutral to obtain the highly-dispersed supported nano-ruthenium catalyst. The method has the advantages of simplicity, low cost, good repeatability and environmental protection, and the prepared catalyst has high dispersion degree and long service life.

Owner:JIANGSU KANGHENG CHEM

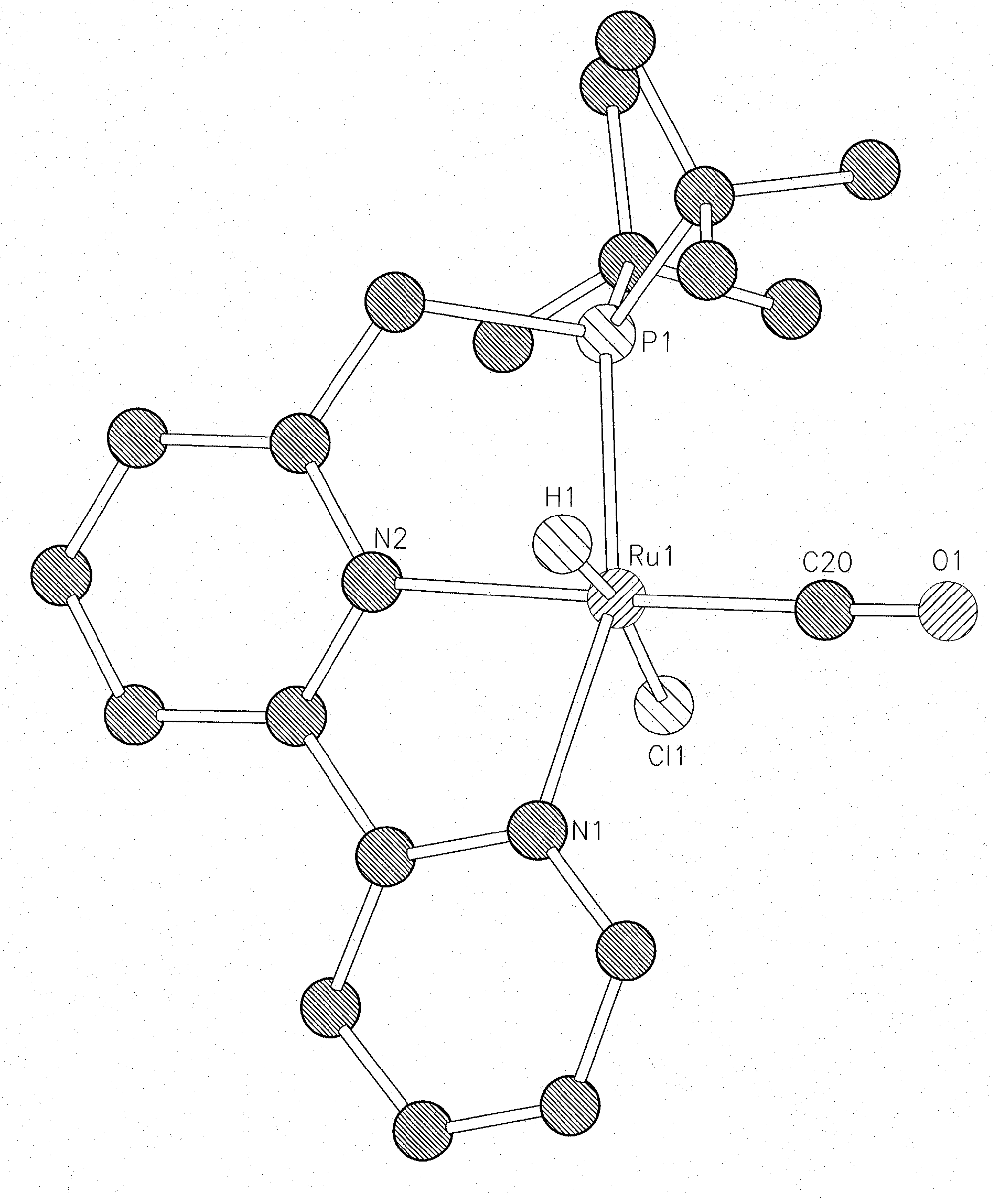

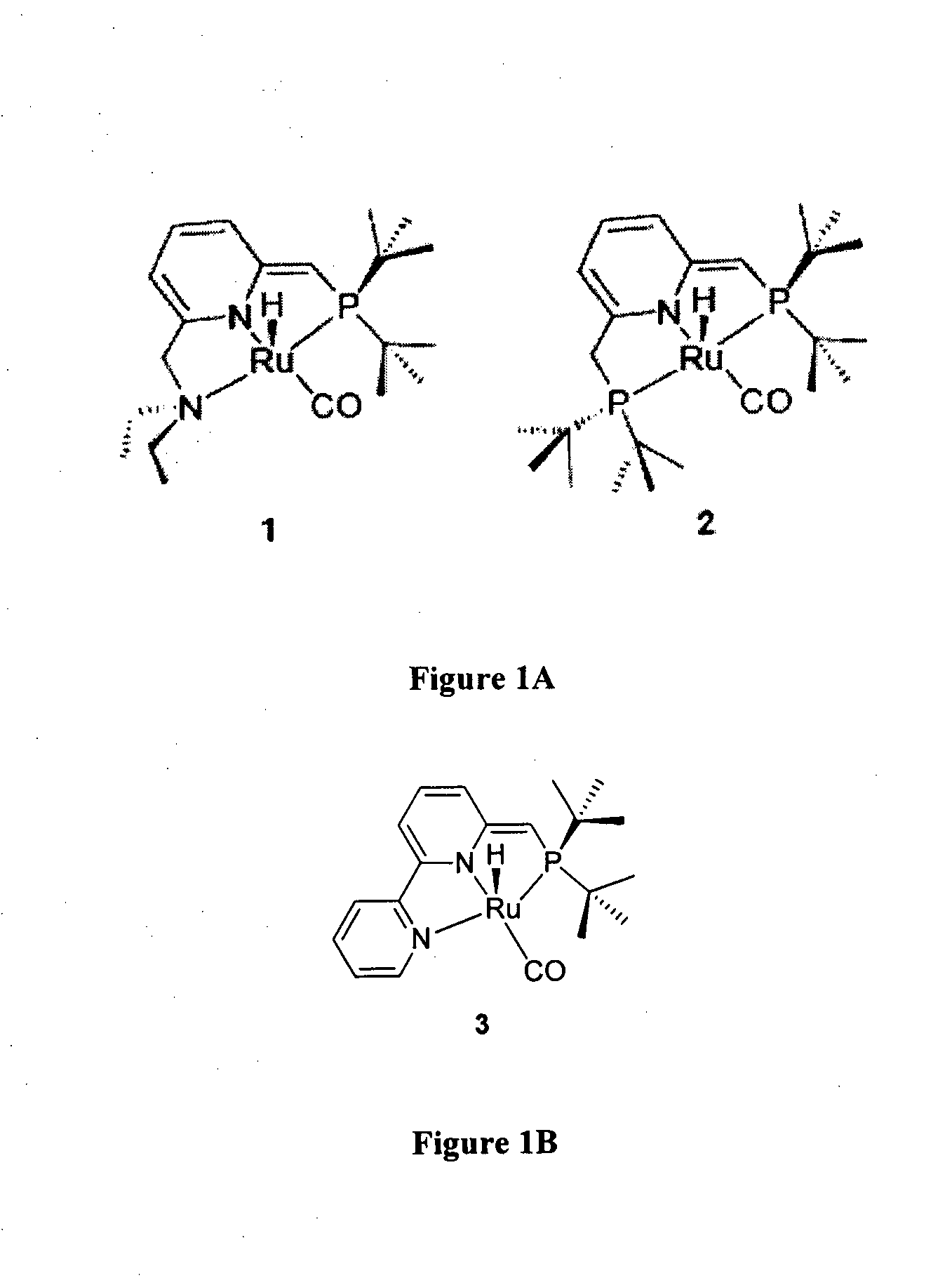

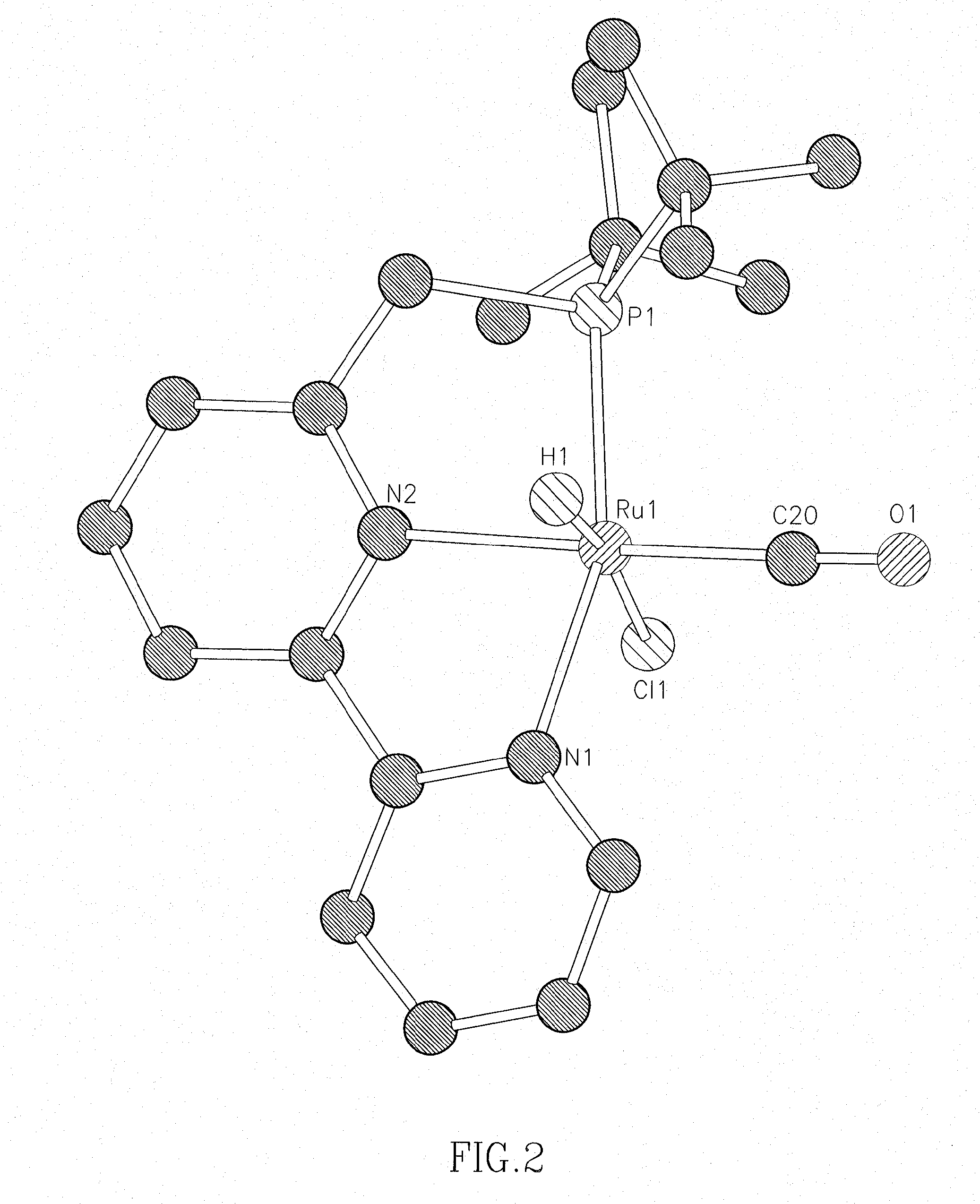

Novel ruthenium complexes and their uses in processes for formation and/or hydrogenation of esters, amides and derivatives thereof

ActiveUS20130281664A1High yieldImprove turnover ratePreparation from carboxylic acid saltsPlatinum group organic compoundsUrea derivativesPolyester

The present invention relates to novel Ruthenium catalysts and related borohydride complexes, and the use of such catalysts, inter alia, for (1) hydrogenation of amides (including polyamides) to alcohols and amines; (2) preparing amides from alcohols with amines (including the preparation of polyamides (e.g., polypeptides) by reacting dialcohols and diamines and / or by polymerization of amino alcohols); (3) hydrogenation of esters to alcohols (including hydrogenation of cyclic esters (lactones) or cyclic di-esters (di-lactones) or polyesters); (4) hydrogenation of organic carbonates (including polycarbonates) to alcohols and hydrogenation of carbamates (including polycarbamates) or urea derivatives to alcohols and amines; (5) dehydrogenative coupling of alcohols to esters; (6) hydrogenation of secondary alcohols to ketones; (7) amidation of esters (i.e., synthesis of amides from esters and amines); (8) acylation of alcohols using esters; (9) coupling of alcohols with water to form carboxylic acids; and (10) dehydrogenation of beta-amino alcohols to form pyrazines. The present invention further relates to the novel uses of certain pyridine Ruthenium catalysts.

Owner:YEDA RES & DEV CO LTD

Ruthenium(II) catalysts for use in stereoselective cyclopropanations

ActiveUS20070270593A1High stereoselectivityHigh yieldRuthenium organic compoundsCobalt organic compoundsProtonationSalen ligand

Chiral ruthenium catalysts comprising salen and alkenyl ligands are provided for stereoselective cyclopropanation, and methods of cyclopropanation are provided. The chiral ruthenium catalyst is prepared in situ by combining an alkenyl ligand, a deprotonated chiral salen ligand, and a ruthenium (II) metal. A preferred catalyst is prepared in situ by combining 2,3-dihydro-4-venylbenzofuran, deprotonated 1,2-cyclohexanediamino-N,N′-bis(3,5-di-t-butyl-salicylidene) and RuCl2(p-cymene)]2.

Owner:VANDA PHARMA INC

A process for removing iron-residues, rhodium- and ruthenium-containing catalyst residues from optionally hydrogenated nitrile rubber

A process is provided for the removal of iron-residues, rhodium- and / or ruthenium-containing catalyst residues from a solution of optionally hydrogenated nitrile rubber containing such iron-residues, rhodium- and / or ruthenium-containing residues by contacting such solution with a specific functionalized ion exchange resin.

Owner:LANXESS DEUTDCHLAND GMBH

Composite oxide supported ruthenium-based ammonia synthesis catalyst and its preparation method

InactiveCN101053835AHigh catalytic activityMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionAlkaline earth metalRare earth

The invention provides a ruthenium catalyst for ammonia synthesis with high activity which has composite oxide as a carrier, and a preparation method thereof. The ruthenium catalysts for ammonia synthesis comprises composite oxide as the carrier, metal Ru as an active component, wherein the capacity is 1-12 wt.% of the active carbon weight calculated based on Ru. The composite oxide is formed by magnesium and one or two or more than two nonferrous metal of: 1) alkaline earth but not magnesium; 2) alkali metals; 3) rare earth metal, wherein the ratio of magnesium and the nonferrous metal based on the amount of substance is 0.2-25:1. The catalyst of the invention has higher catalytic activity and better application prospects compared with the existing ruthenium catalyst for ammonia synthesis which has oxide as a carrier.

Owner:ZHEJIANG UNIV OF TECH

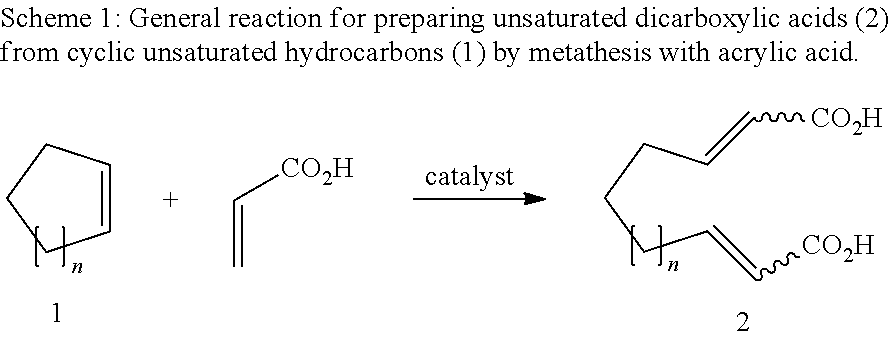

Unsaturated dicarboxylic acids from unsaturated cyclic hydrocarbons and acrylic acid by way of metathesis, the use thereof as monomers for polyamides, polyesters and polyurethanes, and subsequent reaction to diols and diamines

InactiveUS8445720B2Organic compound preparationCarboxylic compound separation/purificationPolyesterPolyamide

The invention relates to a method for producing α,β-unsaturated dicarboxylic acids and the corresponding saturated dicarboxylic acids, whereby the corresponding cycloalkene and acrylic acid are reacted with a ruthenium catalyst by way of a metathesis reaction at high substrate concentrations until the reaction takes place in substance, the resulting dicarboxylic acid being precipitated.

Owner:EVONIK DEGUSSA GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com